Build List

-

Active Filters:

ballscrew

zero z mongrel

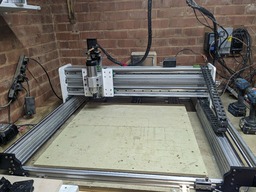

long overdue overhaul of 1000 x 1000 machine

Build Author

EvanH

Views

5336

Build Author

EvanH

Views

5336

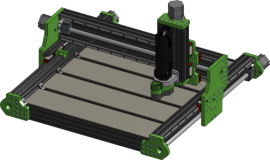

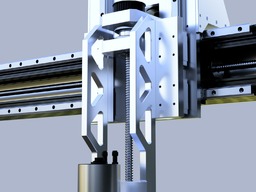

"Hawk" Heavy-duty dual-Z pseudo C-Beam

A compact, strong machine with very high Z clearance, yet can still mill aluminium easily.

Build Author

Troy Proffitt

Views

29443

Build Author

Troy Proffitt

Views

29443

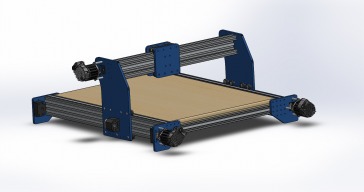

Sphinx Upgraded plates / ballscrews and linear rail

Upgraded Sphinx Cbeam using 3/8 aluminum plates and linear rails / ballscrews

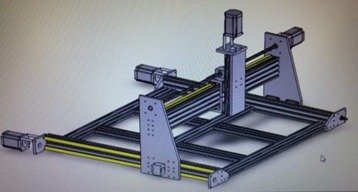

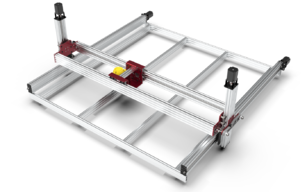

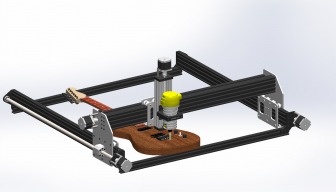

LR/BS CNC Router

An easy to source/easy to build, yet quite robust CNC router. This design has not yet be implemented.

Build Author

Rob Taylor

Views

19343

Build Author

Rob Taylor

Views

19343

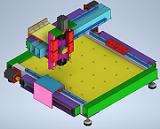

M4: 1510SS Heavy Mk.I

A 1500x1200mm, 20mm rail and 1610 ballscrew, heavy-duty, four-axis gantry machine. As high speed as spindle power MRR will allow for. Approx 4 x 3 x 1ft travels, intermediate size between benchtop and floor-scale units. Aiming at $10-15k machine in the $3k region.

Build Author

Scott Martinez

Views

12421

Build Author

Scott Martinez

Views

12421

The Growler

This machine is a heavy duty, moving gantry style CNC router. It uses Teknic ClearPath servo motors driving ballscrews and linear rails. The machine has 36" x 48" x 19" of travel with about 7" of clearance below the gantry.

Build Author

BeTrue3D

Views

22749

Build Author

BeTrue3D

Views

22749

BeTrue3D Printer

High Quality CoreXY with focus on quality and optimized printarea versus physical size of the printer.

Build Author

evil2002usna

Views

11695

Build Author

evil2002usna

Views

11695

Evil Ox

Cheap Ballscrew Ox CNC Router.

HD CNC

Heavy Duty build with 1605 Ballscrew and Linear Rail

Build Author

C-CNC

Views

16761

Build Author

C-CNC

Views

16761

Gantry Style CNC from plywood

I am currently 15 years old, from Germany and trying to build a low budged CNC router. I only designed this CNC based on other CNC routers that I have seen and what I am able of. It consists mostly of 2.3cm plywood to keep costs down. The size of the work area is approx. 40 x 80 cm. I would be really glad if you could give me advice's for improvement on the design and everything else ... ( I could really need your help :) ) enjoy :)

Build Author

mathom713

Views

9783

Build Author

mathom713

Views

9783

27" by 40" CNC

DIY design and build of a roughing 2' by 3.5' CNC router

Build Author

Colin Russon

Views

4038

Build Author

Colin Russon

Views

4038

TITAN GAMBIT

Anti-Twist Design, larger lead screws, enhanced M8 wheel sets.

Build Author

Yosmany325

Views

2525

Build Author

Yosmany325

Views

2525

OrionPlus

Cartesian style CNC with a working area of around 360mm x 360mm x 120 mm (X, Y, Z) using Linear rails and ball screws. The linear rails are (Hiwin?) HGR 20mm x 520mm and the ball screws are SFU1204 (12mm lead 4mm) of around +/- 430 mm. The base structure is made from rectangular aluminum profiles of 70mm x 45mm x 3mm (thickness of walls).

1515 Deluxe

Build features include a double c-beam gantry (bonded & mechanically fastened), linear x rails, custom gantry end plates, a custom linear rail & ballscrew Z axis, and custom lead screw tensioning plates. The primary goal was to remove twist from the 1500mm gantry & stiffen the Z axis.

Build Author

HuguesP

Views

9410

Build Author

HuguesP

Views

9410

YACLR CNC

Yet Another Chinese Linear Rail CNC, my first one, doing this mainly for the fun of building it more than using it.

Build Author

Vunnie

Views

6938

Build Author

Vunnie

Views

6938

Workbee CNC on steroids

My First major improvement was changing the controller to a Acorn board. I loved the way a dedicated userinterface was speeding up my workflow. Next project my Y Axis. On Aliexpress I ordered a couple of 16mm ballscrews and some lineair rail. Before I took my gantry off I quickly made some aluminium profiles to fit my carriages. Withouth any doubt these improvements where worth it

ricks workbee build

i had the ox build and wanted to do a more beeffer style so i went with a workbee style machine ..

Build Author

TurfnSurf

Views

7307

Build Author

TurfnSurf

Views

7307

DIY C-Beam CNC

Theoretical Working Area: 360x360x75mm Actual Working Area: 300x300x75mm Will Update Later

Brice's CNC Router Build

I'm building a CNC router for a long time. Here's the result on this long journee. I tried to do my best with the basic tools I have. Don't hesitate to ask if you have questions.

Build Author

Michael.M

Views

9859

Build Author

Michael.M

Views

9859

Sphinx Evolution

Let me explain: About a year ago I was planning to build a CNC router of my own design. I started gathering components including the THK linear rails. I soon found out you pretty much need a CNC to build a CNC and this is when I decided to build my Sphinx machine. I've had these rails and some other parts sitting around so it's time I used them! I'm planning to incorporate linear rails and 1605 ballscrews into the Sphinx design. I really like the overall appearance of the Sphinx.

Build Author

Colin Russon

Views

9603

Build Author

Colin Russon

Views

9603

OX / X3 CNC / Similar Z axis / 1605 Linear Actuator

Z axes 1605 ballscrew, a comparative design proposal.

Build Author

Julius

Views

25746

Build Author

Julius

Views

25746

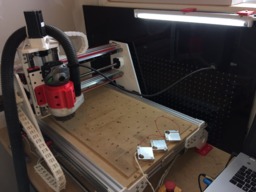

OX Balls - 1605 Ballscrew Powered 1000mmx1000mmm OX derivative

1000x1000mm Ballscrew driven OX Derivative. Dewalt 611 spindle and TB6600 Drivers.

Build Author

TurfnSurf

Views

6334

Build Author

TurfnSurf

Views

6334

3-Axis Plywood CNC

Theoretical Working area: 38" x 24" x 6" Actual Working Area: 31" x 23.6" x 4" Positioning Accuracy: about 0.01mm

Ox Stainless with ballscrews

Ox Stainless with ballscrews for motion, nema 23 steppers, LInuxcnc for control software. Using basic parts for frame from Makersupplies, and the rest sourced from ebay. Building a small router hoping it will be able to cut aluminum with decent results.

Linear Rail derivative with ball screw

basic start to design of cnc machine

Build Author

evgeny156

Views

7453

Build Author

evgeny156

Views

7453

3D Printer on Prusa architecture with best parts available

Wanna quet an nice looking device done by my hands

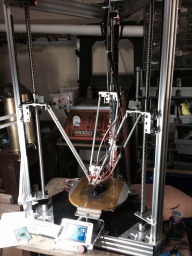

Delta 3D Printer

This is a Delta build using 1610 ballscrews from China