Build List

-

Active Filters:

upgrade

Build Author

pek

Views

85242

Build Author

pek

Views

85242

Prusa i3 Bear Upgrade V2

Stronger frame for Prusa i3 MK2(s), MK2.5 and MK3 3D printer

Build Author

Ronald van Arkel

Views

16826

Build Author

Ronald van Arkel

Views

16826

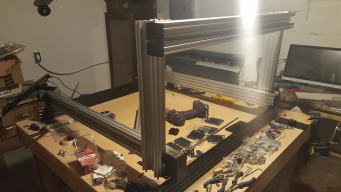

Upgrading the C-Beam machine

So we have new plates, stronger motors, belt drive reduction, but what should we do with them? In this article you might find the answer you were looking for as we took an “old” C-Beam machine and started to upgrade the X/Z body and added more torque and precision to the Z-axis.

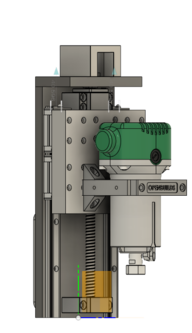

MiniMill Z Axis Upgrade with Offset Motor

Upgrade your Minimill with an off-set Z Axis Motor

C-Beam to C-Beam XL Upgrade

This is my first public build. Please be kind. We upgraded our C-Beam to the C-Cbeam X-Large. I want to give special thanks to Moag and the OpenBuilds team for making this happen.

Build Author

Savvas

Views

14554

Build Author

Savvas

Views

14554

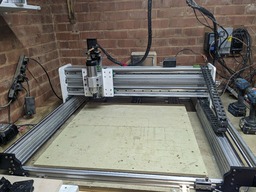

Halloumi CNC Machine - Acetal Plates

I built the original machine using plywood plates, and always intended to upgrade those parts to more durable ones. I decided to go with acetal as it's a lot easier to cut than aluminium. I used fusion 360 to model and rebuild the original machine. Once I have assembled everything and feel confident it all works I will release the plate designs here.

![(R)OX CNC [FR/EN]](https://builds.openbuilds.com/data/article_images/l/1/1584.jpg?t=1423259127)

Build Author

AndersFaust

Views

12733

Build Author

AndersFaust

Views

12733

(R)OX CNC [FR/EN]

Another (R)OX CNC something like build, in French please ! Pics Heavy !

Build Author

Andreas Bockert

Views

12221

Build Author

Andreas Bockert

Views

12221

Sphinx Z-axis upgrade

Upgraded Z-axis for Sphinx-style CNC using ball screws and linear rails.

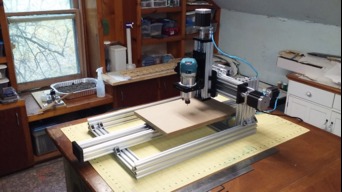

Somewhat Simple Lead screw conversion for an OX CNC

Somewhat Simple Lead screw conversion for an OX CNC.

Build Author

Joe Garritano

Views

11918

Build Author

Joe Garritano

Views

11918

X-carve upgrade

Using criticall OpenBuilds components to upgrade the rigidity and reliability of an X-Carve 1000mm build.

Build Author

CNCGear

Views

10987

Build Author

CNCGear

Views

10987

The BlackBee CNC

Ball screw drive, linear rail CNC Kit

K40 upgrades

Cheap chinese K40 laser upgrades, including 60x30cm working area, MKS or SKR controllerboard (smoothieware or marlin, not yet decided.) Light, psu and a bit more :)

MMXL - A MiniMill Conversion

Using most of the parts of the MiniMill, and adding a few other parts (cost < $200), transforms the MiniMill into a very capable machine. Final build area as shown is 10.25" x 16". With a custom Y-plate, I will take it to 10.25" x 20-24".

Build Author

joetemus

Views

7096

Build Author

joetemus

Views

7096

Shapeoko 2 Z-Axis Upgrade

This is a major redesign to the Z-axis of an otherwise stock Shapeoko 2.

Build Author

txcomp

Views

7083

Build Author

txcomp

Views

7083

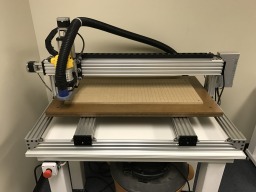

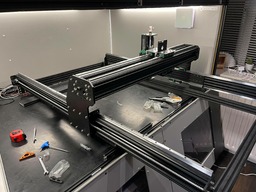

WorkBee 1010 "Get Rid of the Slop" Build

My goals for this build were to eliminate slop and flex while also allowing easy serviceability.

Build Author

Vunnie

Views

6941

Build Author

Vunnie

Views

6941

Workbee CNC on steroids

My First major improvement was changing the controller to a Acorn board. I loved the way a dedicated userinterface was speeding up my workflow. Next project my Y Axis. On Aliexpress I ordered a couple of 16mm ballscrews and some lineair rail. Before I took my gantry off I quickly made some aluminium profiles to fit my carriages. Withouth any doubt these improvements where worth it

Workbee Z-axis Upgrade

Z-Axis upgrade with linear rails, SFU1204 Ball Screw and full aluminium construction.

zero z mongrel

long overdue overhaul of 1000 x 1000 machine

Build Author

Forestbird Originals

Views

5725

Build Author

Forestbird Originals

Views

5725

Lead 1010 Build - Anything but stock.

This is a lead 1010 build that I wanted to have a little fun with. I purchased the whole Lead 1010 kit, and felt like studying a few shortcomings of the original to see if I can improve it or just have some fun with it.

Pure Cbeam 900x1000

This is a pure cbeam build to maximize envelope and rigidity. All the parts used are available from open builds.

Build Author

Limine3D

Views

4782

Build Author

Limine3D

Views

4782

Shapeoko 1 upgrades

Replaced the original Z-axis for a shapeoko with a c-beam upgrade. This upgrade required a nema 17 mount and a quiet spindle mount I printed with a 3D printer.

Infinite Z Delta Printer

Currently completely imaginary

Build Author

David E. Flores E.

Views

3843

Build Author

David E. Flores E.

Views

3843

F-Ender-Plus 3D Printer

F-Ender-Plus its based on the Ender 3 Pro, but improved: CR-10 hotend, double gear extruder, double z-axis motor, bltouch incorporated, hotbed leveling improved strings kit. Most made using local vendor parts, and still I'm increasing my knowledge of how get better 3D printings by calibrating motors steps, leveling the hotbed and z-axis; using a 3mm thick glass...

CBeam Sphinx Upgrade

Simple upgrade of the Y axis on a Cbeam sphinx from 500mm to 1000mm.

Build Author

Alain JBT

Views

1809

Build Author

Alain JBT

Views

1809

First project Genmitsu ProVerxl 6060 Improved with OpenBuilds System Management

For a long time I had a project to buy a CNC, in time I have evaluated several possibilities. I chose the option of a pre-constructed and scalable machine according to my needs, with sufficient rigidity features to do work of average importance. The starting investment was important to take into account to allow changes from the open source domain.