Build List

-

Active Filters:

din

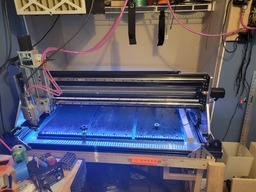

My Lead 1010

This is a fully loaded Lead 1010 and located in a shed measuring 3 by 2.50 meters. Here i build my guiyats by hand and the help of my Openbuilds friend! Pure for hobby.

Build Author

Jasont

Views

4594

Build Author

Jasont

Views

4594

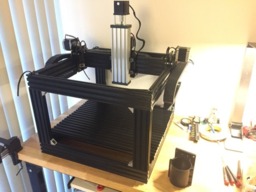

MY first CNC build

my first cnc build using the lead 1010 to build bigger and better!!

Build Author

Glenn Weston

Views

11712

Build Author

Glenn Weston

Views

11712

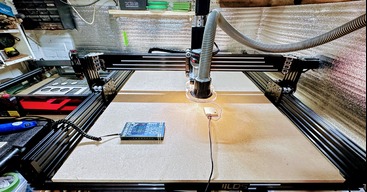

"AcroCadabra" My Acro Laser built with my C-Beam XL

Well I built a C-Beam XL around a year ago, I am still learning things as I make stuff with it, it has been quite a wonderful learning experience. Now I have gained enough confidence and knowhow to Mill the required Plates to build an Acro Laser System using the Acro Laser Sketchup Model. I have pulled the Model apart in Sketchup, isolated the Plates and generated the G-Code to cut/Mill the plates. I have used Sketchucam to generate the G-Code. I Use Mach3 on my C-Beam XL to Mill.

Build Author

Cosmosteel

Views

4732

Build Author

Cosmosteel

Views

4732

Clear Acrylic Dust Shoe

Attaches router with screw clamping. Clear Skirt is 2" long or can be made longer if requested. Works well keeping dust within the chamber. It can be made to fit shapeoko, ox cnc, workbee, xcarve, 6040, laguna,piranha, millright etc. with similar setup including Bosh, Makita , dewalt 611 routers or spindles.

Build Author

Joe Young

Views

6099

Build Author

Joe Young

Views

6099

Goliath - CNC + 3D printer Hybrid

Mostly for Mill work, and FDM 3D printing (mostly Nylonx). I'm currently in the process of adding some hardware for a project requiring lathe work. I've included a solidworks 2014 pack and go for those of you interested in the build. if you need another file type, just let me know and i can try to accommodate. This is a scratch build (electronics and hardware)... see photos. Everything is pretty close to industrial quality... Electronics too. I got sick of other COTS designs breaking down

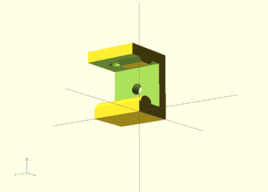

DIN 35mm -like quick clip for 20mm extrusion

A half baked idea for mounting electrics and electronics using a 35mm-DIN-rail-like mounting.

Build Author

Beam

Views

11905

Build Author

Beam

Views

11905

DIY Flywheel Camera Slider

My take on a non affordable slider.

80watt Lasercutter, workingarea 105x52[cm], steel frame

I will write a short buildlog here with mostly pictures. I designed this lasercutter in solidworks(not totally finished) for a good overview and such that the steel tubes could be lasercut by a company, the metal frame is based on the lasercutter the KÄSER, which you can find on cnczone.nl. The mechical parts are designed by myself because I had no mill to my use, so the mechnical parts are lasercut(same company as tube) steelplates welded together.

Build Author

JerryD

Views

5445

Build Author

JerryD

Views

5445

1500x1000mm Adjustable Height

I have the demand to cut/etch tall pieces of material. For this reason, I have designed a machine with 500mm uprights with adjustable gantry height. This way I can raise/lower the sled and z-axis as needed. I've also chosen to use a linear C-channel assembly for the Z axis with the plate mounted to the gantry instead of the other way around. This will allow for maximum range of the z-axis. The parts list/BOM does not include motors/belts/pulleys or electronics.

Build Author

dodgenet

Views

6745

Build Author

dodgenet

Views

6745

Budget 1500mm OpenBuilds V-Slot Deltabot Build

This 1500mm tall Delta is a work in progress. The triangle corners are water jetted from 1" 6061 Aluminum, and are welded to 1" square tubing. The 1500mm OpenBuilds 20x20 V-Slot extrusions are held into the corner brackets by two stainless steel set screws per bracket. This printer will need to be reinforced with wall brackets due to the combination of height/materials.

My first OX build

This is the story of my experience building a 1000 x 750mm OOZNest OX CNC router

![80watt Lasercutter, workingarea 105x52[cm], steel frame](https://builds.openbuilds.com/data/article_images/l/6/6014.jpg?t=1513166610)