Build List

-

Active Filters:

dust

Build Author

Eric Jacobsson

Views

15483

Build Author

Eric Jacobsson

Views

15483

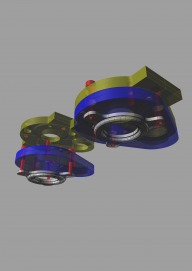

The Floating Dust Shoe

I wanted a dust shoe that have a easy access to tool change and something that kind of float on the surface. And I have seen shoes with long brush that sucked in by the vacuum. I think I have the solution too all that here.

Dust Boot and Holddown in one

only 2 screws to hold down even bent sheet material and vaccum dust removal in one

OX Fixed Dust Shoe

A simple fixed dust shoe for your OX.

Build Author

Maxime Favre

Views

9547

Build Author

Maxime Favre

Views

9547

SmoothiebrainZ CBeam Machine

Modded Plate maker with: Smoothiebrainz board and DQ542MA SN04 Endstops Modded Z axis Aluminium build plate and renforced Y axis Dust shoe

Magnetic CNC Dust Shoe with LED lights and Camera*

Making my own magnetic dust shoe with led lights and a camera. Showing my progress from beginning to now.

Build Author

BCulbertson

Views

5308

Build Author

BCulbertson

Views

5308

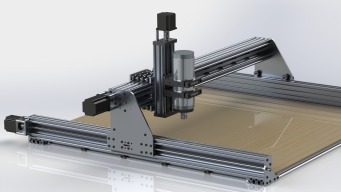

Lead 1515 with Upgrades

My upgraded OpenBuilds Lead 1515

Build Author

Joe Young

Views

5955

Build Author

Joe Young

Views

5955

Goliath - CNC + 3D printer Hybrid

Mostly for Mill work, and FDM 3D printing (mostly Nylonx). I'm currently in the process of adding some hardware for a project requiring lathe work. I've included a solidworks 2014 pack and go for those of you interested in the build. if you need another file type, just let me know and i can try to accommodate. This is a scratch build (electronics and hardware)... see photos. Everything is pretty close to industrial quality... Electronics too. I got sick of other COTS designs breaking down

C-Beam Dust Shoe

A short description of the dust shoe I made for my machine.

Build Author

Apothus

Views

22543

Build Author

Apothus

Views

22543

Sphinx rigid XL

Rigid variant of the C-Beam sphinx platform

Build Author

Steve Marsh

Views

5786

Build Author

Steve Marsh

Views

5786

Dust Shoe for Colt router and OxCarve

A simple 3D printed dust shoe for the cnc router. 2 parts held together with magnets for easy bit changes.

Dust Shoe for Kyo's Sphinx

Dust Shoe design for a CNC router. Attaches to Chris Laidlaw's Mount design, with the DeWalt D26200 (which I think is the DWP 611 in the US).

Build Author

Stan Howe

Views

3375

Build Author

Stan Howe

Views

3375

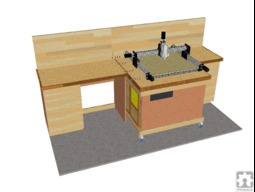

Bee the Boss

The frame of the CNC is going to to Bee a basic Work Bee with maybe 1 modification to the spoil board attachment. This will be located on a custom bench housing the electronics and vacuum. I plan to install Stepper online steppers, drivers, power supplies, and break out board. I will add a 1.5 KW water cooled spindle, with a radiator. The fans from the radiator will pull air from a filtered enclosure for all the electronics.

Build Author

StrictlyScale

Views

10550

Build Author

StrictlyScale

Views

10550

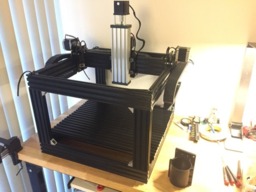

Lead1010 Build with Enclosure

First time CNC builder puts together a Lead1010 machine.

Build Author

OpenBuilds

Views

34307

Build Author

OpenBuilds

Views

34307

OpenBuilds Enclosure Series

Easy to build series of enclosures for all your CNC needs!