Build List

-

Active Filters:

route

Kruk 0.1

This is a stool, designed in 18mm wood for a cnc router, it's easily scaleable to different wood-thicknesses, in 18mm wood it takes up 1200*1200mm. It can be assembled without screws, nails or glue and can therefore also be easily disassembled.

Mostly Printed Cartesian CNC

This is a build that is just getting started. Not all of the parts are ordered or printed as of 5/27/2018. Hopefully in the next few weeks all parts will be printed and most parts ordered.

Build Author

Rich Bowen

Views

3814

Build Author

Rich Bowen

Views

3814

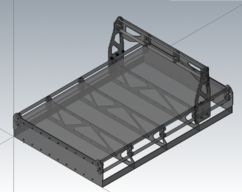

WannaBe CNC - First time design and build

Design Change - Version 2.0 has a smaller foot print, custom gantry supports, and front and back covers. I will use standard V-Slot for gantry supports leaving me enough travel to manufacture the customer supports with this machine when completed. then update to final build. I also plan to install the controller into the front cover and power supply into the back cover. Should be nice and tidy.

Build Author

Builder+Bob

Views

3717

Build Author

Builder+Bob

Views

3717

Portable C-Beam

C-Beam Plate maker for My OX!

Build Author

Ken376

Views

3708

Build Author

Ken376

Views

3708

Welded project cnc first try

Kind of hard to see in this pic now lining up drive s and finishing framework

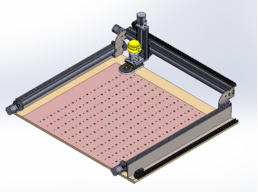

Desktop CNC

Approximately 910mm x 955mm x 82mm. There is 250mm available in the Z, but the gantry is only 82mm from the bed surface.

A work in progress

One of my first projects might be cutting proper plates.

Router for speargun hobby

First router build for speargun fabrication

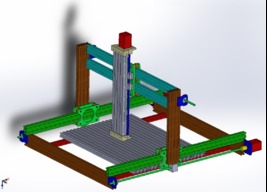

Large C-Beam Sphinx style CNC Build

Started my build of a large Sphinx style cnc Router. I wanted one to handle the Dollar Tree Foam Board (DTFB) so I am making this to handle 2' X 3'. This is my first endeavor for a CNC so I am learning as I go but there is one thing for sure.

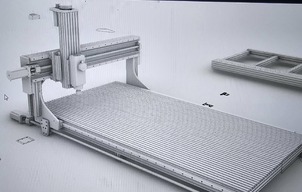

Cartesian CNC router

This project has been a steep learning curve in an unfamiliar area for me. It has been a very rewarding experience and has opened up so many more possibilities to pursue in the future.

my version of xl

A table top version of the open build xl router kit set build. This use of c - beam and xl kit set was coupled with Mach 3 controller running on Dell opti -plex 755 and win 7 pro licence. A Dell opti-plex 755 empty case was used to house the controls and wiring , including the limit switch and emergency stop safety circuits

Just Starting

My attempt at planning out my own CNC router

Dust Shoe for Kyo's Sphinx

Dust Shoe design for a CNC router. Attaches to Chris Laidlaw's Mount design, with the DeWalt D26200 (which I think is the DWP 611 in the US).

Cnc Router 3000 x 1000 mm

In progress

Homemade CNC Router (Under $400)

So Instead of buying a CNC Router which can cost thousands of dollars I ventured on the quest to design and build my own. I have multiple parts to this series. Hopefully all of my information I share helps!

Build Author

Linkreincarnate

Views

3103

Build Author

Linkreincarnate

Views

3103

Amazon Special

I have parts that are apparently not suited to a cnc router or a 3d printer. I am still trying to figure out what to make out of what I have,

Router Box

This box is made from tough aluminum with plastic boards, helps hold WiFi Routers, Modems, or/ Ethernet Switches! The aluminum can resist the heat produced by these electronics, and the weight of the electronics, also being light itself. This box is the thing you need to hold your electronic devices!

C-Machine

MY experience as a first time introduction to the CNC world!

Repurposed Steel Table 4 x 8 Build

Repurposed Steel Table for CNC Router Build.

Something a Tad different

Future CNC router kit design

PhlatMDF48

Building a Phlat based CNC for MDF processing. Capacity of 48" x unlimited length.

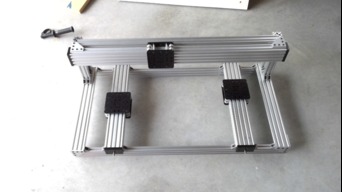

First build - small scale

Using basic standard components, beams, motors, belt drive on x and y, z is a screw. Using Grbl Panel on Windows 10. Really basic router, had trouble getting the controller to turn on the router and set speeds so it is currently wired to a power bar switch so it runs full speed and I just use the switch to turn it on and off. Just getting x, y and z control working properly for now and likely going to switch the router to my dremel 4000 using a 3d printed mounting bracket I got from thingiverse

Gizmo CNC

wanted large work area for laser etch/cuts more than spindle work.

CNC Router Machine

CNC Router with working area 550*550*200

CNC built, work in progress, fail

2x4 cutting area, enclosed with dust collection mainly built out of wood.

TFE2 CNC Build

My TFE2 CNC Build. The TFE was much smaller and all of the gantry plates were 3D printed. Despite this it will happily machine aluminium without issue. So I decided to use that to make the TFE2 which will be all aluminium plates and much larger (1200x800mm machining area with roughly 140mm in Z so I can later add a rotary axis.)

C-Beam Machine XL

C-Beam XL upgraded with end-stops, E-stop, and cable chain. Running GRBL on Arduino Mega.

Build Author

robert christensen

Views

1428

Build Author

robert christensen

Views

1428

Tool holder

I saw a video of some one pouring resin in a mold,so i did a little research, i bought some resin,and some molds and magnets all from Amazon, it took me several tries and a big mess but it finally finished. The first pour i poured a small batch to make a templet,i marked all the holes that needed drilling then i marked the underside of the mold where i wanted the magnets, next was making the pcs i needed