Build List

-

Active Filters:

to

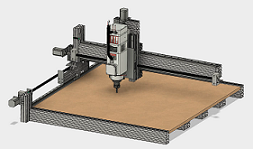

Epoxy dispenser, to apply non-conductive epoxy to electronic board.

Epoxy dispenser, 2nd one, first one works great. Uses HMI to allow for operator to pull up files for different jobs. 9 prox sensors, Eot and home on all 3 axis. High quality nema23 motors with intergrated drives from applied motion. Uses programmable router for drives.

Build Author

Anthony Castelluci

Views

3203

Build Author

Anthony Castelluci

Views

3203

Simple Camera Lofted Camera Slider

Build a manual camera slider.

Build Author

Sir Bagels

Views

3082

Build Author

Sir Bagels

Views

3082

CNC Auto-pipette

Senior Design Project Bennett Robertson, Megan England University of Iowa College of Engineering

Build Author

David Hartkop

Views

2998

Build Author

David Hartkop

Views

2998

Humanitarian Medical Instrument Sterilizer Made from RepRap Parts

Instructions to build an open-source off-grid medical instrument sterilizer that can be used by aid workers in places without reliable electrical power

Build Author

Bucky Wootmaster

Views

2950

Build Author

Bucky Wootmaster

Views

2950

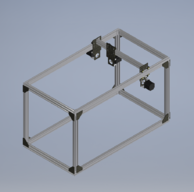

Bucky CNC

CNC machine using extrusions with linear rails and ball screws on all axes - no plates

MIT E-Vent | MIT Emergency Ventilator

Ventilator prototype based of OpenBuilds Stock parts

Stinger-Panting Images in the Air

Stinger displays images in the air by using a single column of LEDs. Special computer code converts graphics to pixels; then, the pixels are send to the strings of LEDs, which with the help of of the motor's fast movement the most colorful are displayed on thin air.

Lead 1510

Customised Lead 1010 making it a 1510. T-Track work area with dual Y limit switches for auto-squaring. Powered by xPro v5 & CNC.js

Build Author

hbtousa

Views

2131

Build Author

hbtousa

Views

2131

Six_Axis Camera Slider

X is 1000mm, Y is 1500 mm, Z is 1000mm. It Rotates 360 degrees and Tilt also can move 360 degrees. I also have a motor that controls the focus of the camera.

Build Author

Johnny Reich

Views

1991

Build Author

Johnny Reich

Views

1991

ProLight 1000 Mill Retrofit

Update a 20-year old bench top milling machine with OpenBuild Ecosystem electronics.

CNC accessory box Made 100 % from recovery materials

Quick construction. A few pieces of wood recovered in the trash can, two hooks one hinge, a few screws and a little glue. [Edit] Added the SVG file for sharing (I forgot it)

Build Author

robert christensen

Views

1428

Build Author

robert christensen

Views

1428

Tool holder

I saw a video of some one pouring resin in a mold,so i did a little research, i bought some resin,and some molds and magnets all from Amazon, it took me several tries and a big mess but it finally finished. The first pour i poured a small batch to make a templet,i marked all the holes that needed drilling then i marked the underside of the mold where i wanted the magnets, next was making the pcs i needed

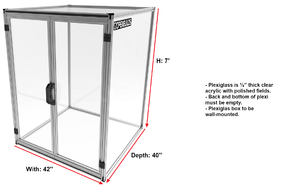

Plexi Panel

Plexi Panel to use for a vfd test enclosure. The box will be wall-mounted on plywood, so the back of the box is not necessary. - The bottom of the box is not necessary because the box will be fixed on concrete on the floor. On the door, I was thinking of putting 4 brackets instead of two. We'll have two 21” doors

Workbee 1010 et laser atomstack M100

Je ne sais pas comment brancher mon laser sur la blackbox?