Build List

-

Active Filters:

c-beam

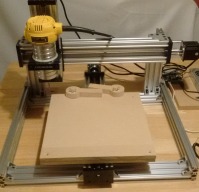

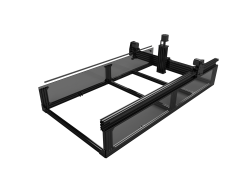

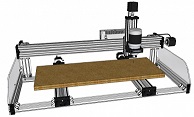

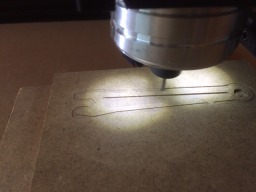

Jim's C-Beam Machine Build

This machine is fantastic. Teamed up with Fusion 360, Inkscape, and GrblPanel, I'm well on my way towards making at least one Christmas gift this year. I had some frustrating times during the build, mainly with getting everything to go together square, but overall it was fun. I can see that I'm going to need to be a bit creative in order to max out the work area for this machine so that I can produce the product I bought it for, but it will be able to do so much more for me as well.

Build Author

Maxime Favre

Views

9625

Build Author

Maxime Favre

Views

9625

SmoothiebrainZ CBeam Machine

Modded Plate maker with: Smoothiebrainz board and DQ542MA SN04 Endstops Modded Z axis Aluminium build plate and renforced Y axis Dust shoe

CNC Glass Grinder

This is a 1-Axis CNC Glass Grinder. It uses a hobby grinder to miter a precise angle on the edge of a piece of glass.

My first CNC - The C-Beam Basic

I am a newbie and this is my first build. After hours and hours of research I decided on the C-Beam. I will be changing one or two things but I will basically be building this as per Mark's video.

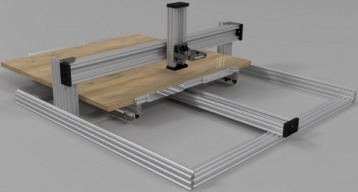

Nox 1500mm x 1500mm C-Beam

C-Beam build using a double C-Beam for the X axis. 1500mm x 1500mm

Build Author

Bridge Port

Views

9527

Build Author

Bridge Port

Views

9527

CNC Line Boring Machine

This is a CNC Line Boring Machine for our cabinet shop. It drills the holes every 32 mm for the adjustable shelf pins in the cabinet side pieces. I chose this option over purchasing a multi-head boring machine that requires 11 drill bits - Left & Right hand twist - that also requires a lot of strength to plunge that many drill bits into the wood to be drilled.

Cbeam Digital Mitre Saw Fence

Work in progress.. but nearing completion :)

Moag's CNC Mill

A design in progress, to 3D carve two-part Aluminium injection moulds for Soft Plastic Lures and Lead Jigs, so I can prototype some of the concepts rattling around in my head. All Openbuilds parts where possible, 1000x500mm footprint, 0.8kw Water-cooled Spindle?, High Torque Stepper?,Smoothieboard?, I still have no idea. As a newbie to the CNC world, any wisdom would be welcome to take this from just a idea into reality so I can start playing with all this awesome stuff. Thanks in advance

C-Beam Big Mouth

My first build was with the basic C-Beam Build. I soon found the z clearance a little constricting So I added 2 500 mm actuators to support the x axis rail . I also left off the front and back y axis support rails for easy cleaning. I mounted the base of the machine to 1/2" mdf with 10/32 screws and blind nuts.

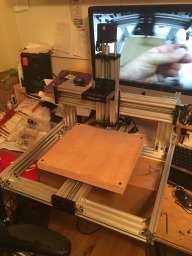

My 1st C-Beam Router

Pretty happy with the build, had some difficulty with the software loading up the settings due to me using the wrong com.

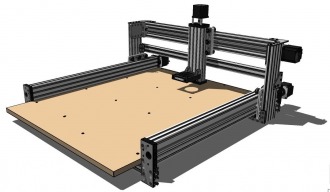

Metalguru's C-Beam 750

This is a C-Beam build, fairly heavy duty, and 750mm x 750mm. Should be a good, sturdy machine that's relatively easy to assemble.

Build Author

UltiBots

Views

10676

Build Author

UltiBots

Views

10676

Machined Aluminum MagBall Carriages

Machined Aluminum MagBall Carriages

Build Author

Rwetzler

Views

9602

Build Author

Rwetzler

Views

9602

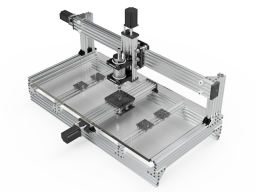

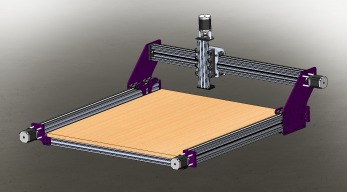

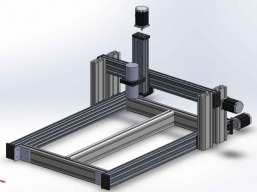

C-Beam Prototype

This is a variant of a typical OX (Mark Carew inspiration) router using C-Beams/8mm Acme rods to drive all three axis. I went with a 1000mm x 1000mm frame size. Useable space is 28" (711mm) X 26" (660mm) with a Z axis work travel of approx. 3.25" (82.5mm). A TinyG is used as a controller along with Fusion 360/Chilipper as the software for generating and running gcode files.

TAZ C-Beam CnC Router by RC-CnC

C-Beam inspired CnC Router (1000x750) Approx 90mm of Z travel

laser add-on for C-Beam machine

3.8 W laser add-on for C-Beam machine. Can easily be swapped with the router.

Gargoile reproduction C-Beam™ Machine - Plate Maker

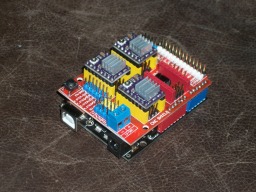

A stock C-Beam with a CNC shield with DRV8825's

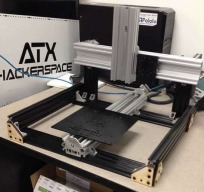

C-Beam Machine Bundle

Short description of my assembly and use of the C-Beam bundle from the Open Builds Part Store.

Build Author

Laurence Carroll

Views

11060

Build Author

Laurence Carroll

Views

11060

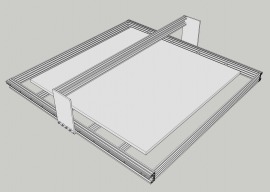

C-Beam Double X

Per the special notes its a variant of the C-Beam, Machine.... I have noticed that alot of people build a CNC router to cut parts for other larger CNC machines.. eg Delta Printers etc....plus this will enable me to cut parts for model RC plans UAV's etc...

Build Author

Charles Roseberry

Views

5167

Build Author

Charles Roseberry

Views

5167

C-Beam 1000mmx1000mm

C-Beam basic package doubled in size.

Murphy OX-CNC Dreamin

I am in the design phase of my CNC. I would like to thank everyone who has placed resources on the site. I am using it to the up most! I will update as I continue the design and share my progress.

Builder Bob's CNC

Here is the consolidation of my woodworking shop, a CNC Router!

C-Beam Plate Machine

My first openbuilds submission, plain old c-beam machine. Seems like I've spent more time fighting the forum here redirecting in circles than actually building the machine. I'll try to add more pics if I ever find a path out of this corn maze...

C-Beam for lithophanes

First venture into cnc machining I decided on the C-Beam .

The MULE (an OX inspired 3-axis CNC)

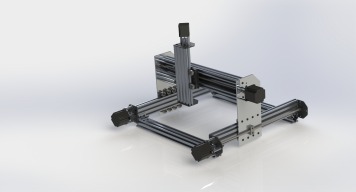

The Mule is a 3-axis CNC inspired by the OX CNC by Mark Carew. This machine borrows the OX's sturdy frame and upgrades the X and Y linear actuators through the use of three 500mm lead screws (as opposed to the belt system of the OX). The result is an inexpensive, sturdy, and powerful design built for cutting tough materials such as aluminum.

Build Author

evildean

Views

9019

Build Author

evildean

Views

9019

OX-SUMO, SUMO-OX, OXSUMO?

One meter square. Short and stout.... reminds me of a Sumo Wrestler. A temporary and adjustable configuration I have devised to cut my own plates. I have kicked around ideas for about a year and the C-Beam extrusion has made this attempt to realize my ideas irresistible. This is just one step towards bigger and better things!

C-beam Router rack and pinion

I want build a frame that is as sturdy as possibility while at the same time keeping it as compact as possible. working area will be approx 1200mm x 600mm

C-beam Camera slider

feel kind of bad calling this a build because of pretty much everything is off the shelf parts. I'm writing my own sketch right now for the motion but there is a version or 2 floating around on the net based of this design. I will post my code once it's done.

Build Author

motopreserve

Views

9195

Build Author

motopreserve

Views

9195

Persnickety Plate Maker

My very first attempt at a CNC build. Based on the OpenBuilds C-Beam Machine, small tweaks will be made to tailor it for my goals: machining G10, aluminum & some carbon fiber for use with multirotor and motorcycle parts. I am looking forward to the day when I am comfortable enough to bring the ideas in my head to the tip of the end mill in a smooth fashion...

C-Beam on X, Y and Z Attempting to use internal channel first go around

C-Beam build using the small C-Beam gantry plates only.

C-Beam Router, 48"x48"

C-Beam Router using 1500mm lengths, 48x48" build area, and rack and pinion movement.

STEAM crane printer

The STEAM Crane 3d printer uses the new C-Beam linear rail. It is being developed for an after school / summer camp program for kids. All of the electronics are housed in the base and the wiring is routed down the channels of the c-beam. This is done to contain as much of the loose wiring as possible, hopefully keeping it safer for kids.

C-BEAM 1K

The new C-Beam kit expanded to 1000mm . extra support built in for the extents of the travel.