Cartesian Style Bots

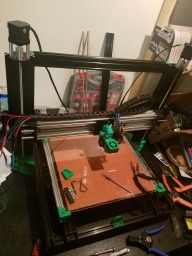

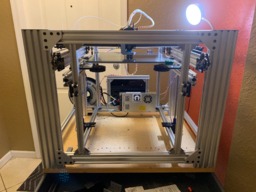

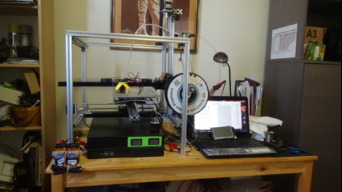

Old Faithful...FDM/CNC machine

I've owned some pretty unreliable printers, and I'll leave it at that... This design comes from the need to have a 3D printer that is reliable, period. I didn't have the money for a several thousand dollar 3d printer with an equivalent build area so that was out of the question. Plus as a fledgling Engineer, I really wanted to blood myself on a project. And that's how Old Faithful came to be. A simple, reliable, rigid, durable machine. Made by me :) Also, it'll be tough enough for light CNC.

Build Author

taratata2016

Views

8491

Build Author

taratata2016

Views

8491

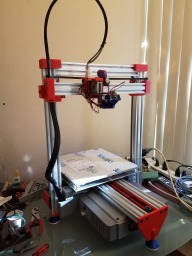

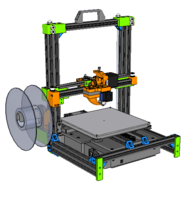

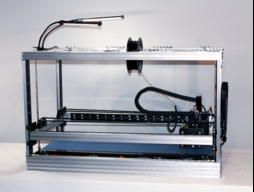

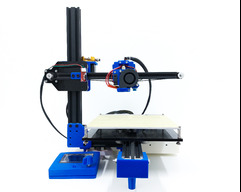

Panther 3D printer

After use of the i3 Prusa 200x200x180, the volume increases to 300x300x450 on the V-Slot and driven by a Megatronics V3

Build Author

Limine3D

Views

8512

Build Author

Limine3D

Views

8512

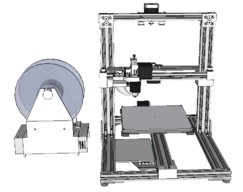

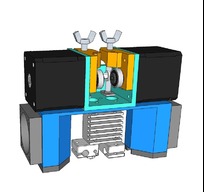

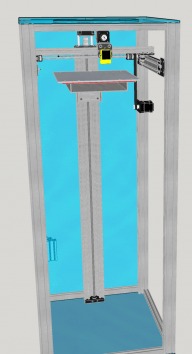

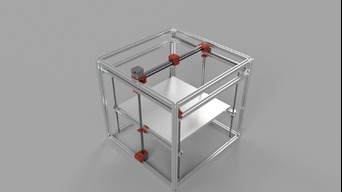

M3D Squared

A cartesian build with a build dimension of 200x200x750mm. I will be using a dual extruder, heated build plate, and a screw drive for the z axis.

Build Author

J-Wahl Dezign

Views

9107

Build Author

J-Wahl Dezign

Views

9107

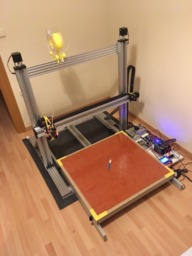

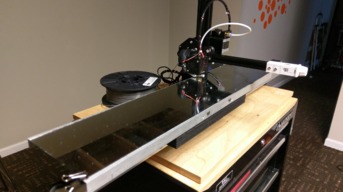

1.4 meter tall build height, 300x410mm build plate cartesian

The original plan was to build a 3d printer with a 1200x1200 build platform with a 600mm build height. I was having issues getting ahold of a large enough borosilicate glass plate for the build so I decided to go for build height. I plan on using a smoothieboard for the controller. The build has currently slowed down. I was removing a broken drillbit from the linear rail mount, and it shattered and took out my eye. I am doing what I can when I can focus my eyes long enough for the build.

STEAM Machine

Simple design with a large build volume - 450x450x450

eTrueUp Glide

A TrueUp Glide modified to use 20x40 V-Slot with a 300x300 bed.

My first printer

My first printer! I went for a simple cartesian design, based on evilc66 one. It uses 1000 mm C-beam linear actuators. The build volume is 700x700x700 mm^3.

Build Author

evgeny156

Views

7289

Build Author

evgeny156

Views

7289

3D Printer on Prusa architecture with best parts available

Wanna quet an nice looking device done by my hands

Build Author

Fabio Orsi

Views

6904

Build Author

Fabio Orsi

Views

6904

147 RepStrap 002

This project is focused on developing a low-cost, portable and open-source FDM 3D Printer.

Codename: Gargoyle

A stout 3D printer build with the hopes of being able to serve as a light mill (PCB) and laser engraver

Skyggen 3D Printer

GT2 belt-driven Cartesian 3D Printer on an OpenBuilds Extrusion gantry, developed through Autodesk Fusion 360.

Norm Inverted - Cartesian

As a tinkerer and hobbyist I need a reliable quality printer on a budget... Meaning I'm not looking to buy a: Prusa, Zortrax or LulzBot because of the added cost their marketing adds. I can definitely build a machine of hopefully equal quality at a lower cost that is not impacted by the marked-up priced from a large reputable manufacturer. I will need to dedicate time and more time for design shakedowns to ensure I produce a quality machine. Bare with me on this build... Thanks!

TrueUp Bold

A beefed up modification of the TrueUp Kit project

TrueUp LZ

A version of TrueUp using linear bearings/rods for the Z axis. This required enough modification to make a separate OpenBuilds project to avoid confusion for DIYers.

Student OneZ

A simplified version of the TrueUp LZ. Designed for classrooms and students

ivern

Toying around a concept. Inputs are welcome on whether to use lead screw or belt drive. My lead screw will be single start 500 mm lenght, 2 mm pitch and 2 mm lead. Nema 17 motors will be used. All veterans, suggestions please.

Build Author

TimVukman

Views

4265

Build Author

TimVukman

Views

4265

Unique Z

My original Tevo Tarantula kit was ok..... I had issues with the X gantry staying level. I got rid of the wheels and replaced them with linear block bearings. I still had some issues with the X gantry. I swapped out the plastic parts with aluminum which was much better. Still not what I want yet

Build Author

MidnightQuads

Views

3870

Build Author

MidnightQuads

Views

3870

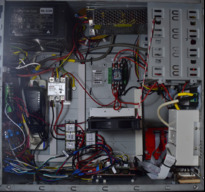

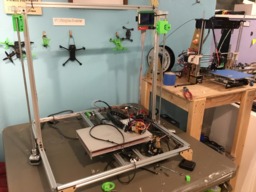

MQTitan printer

Components- RAMPS, running marlin, Nema 17, All metal extruder, 600mm lead screws, 600mm 2020 aluminum extrusions, 12v 30a power supply, 12v LED strip, Typical endstops, 600mm 8mm linear rods, Bearing block for 8mm bearings, Openbuilds plates, wheels, and bearings, 500x500mm borosilicate glass plate

Build Author

George Motichka

Views

3746

Build Author

George Motichka

Views

3746

Transformer

I wanted a machine that could easily switch between 3D Printing and Laser Engraving

Build Author

Nicademus

Views

9483

Build Author

Nicademus

Views

9483

CNC/3DPrint/Laser/Mill (formerly CNC-inator3000)

Ultimately - the design is based on the highly successful Ultimaker concept, for which a regular size costs in the thousands, and one of this size would be edging into the 10's of thousands. Expected Build cost - <$800 It is a X/Y Cartesian printer with Raising/Lowering Z axis (Hotbed.) - Overall size is 610mm x 610mm x 750mm - with build volume of around 450mmx450mmx450mm - and will also have the ability to change work tools - such as for CNC Routing, Lazer etching, 3d Scanning, etc.

Build Author

Connor Mckeown

Views

6343

Build Author

Connor Mckeown

Views

6343

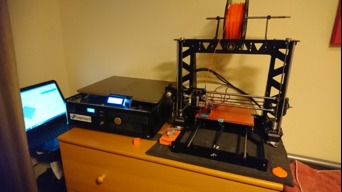

My Prusa Build

The process from my bought printer, to a custom home built machine

Build Author

Daniel.korneliussen

Views

3459

Build Author

Daniel.korneliussen

Views

3459

Reprap prusa mendel i2 Frankenstein 2018 build

Mad plumbers choice what Else can i say?

Build Author

Liam Dahler

Views

6466

Build Author

Liam Dahler

Views

6466

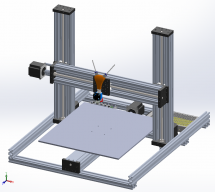

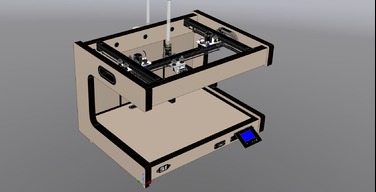

Affordable Cartesian Printer (Initial Design)

This specific build page is a collection of screenshots sampling some of my initial SolidWorks design and pictures showing physical construction of the initial design. I will be creating individual build articles as I redesign, test, and implement new aspects of the printer.

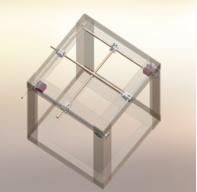

1 Cubic Meter 3D Printer

This is a at home built 1000mm x 1000mm x 1000mm 3d printer. It uses mainly parts from OpenBuild Parts and is very simple to build. The only thing that was custom was the build plate which was designed by myself and tooled at a local machine shop.

Voxel Evolution

This is a remix of Marshal Peck's Voxel OX, with some design tweaks inspired by Makerparts and jjcolletta. It has a build area of 300mm X 300mm X 480mm, but is easily configured for just about any build area up to 500mm X 500mm X 750mm. I have used some laser cut acrylic plates and a couple of 3D printed parts in its construction, however it can be assembled using nothing but OpenBuilds parts with the exception of the heated bed and the Y axis carrier for the heated bed.

Build Author

JerwanDavis

Views

6037

Build Author

JerwanDavis

Views

6037

Coined by my family as the: Davomatic

Build Notes: Here are all the parts necessary to re-produce this design. Please note, all of the parts are either sourced through openbuilds or have been selected and printed from thingiverse.

Butterfly 3DP V 1.0

tronxy x3 like

Design and Performance Evaluation of A Large FDM 3D Printer

This build includes the design of a large FDM 3D printer. This machine has a 796mm by 796mm by 900mm (LxWxH) build volume. Motion is controlled by servo motors and the printer runs on python-based marlin firmware.

Build Author

Luke Cunningham

Views

5863

Build Author

Luke Cunningham

Views

5863

Tronxy X1 extension

Video on youtube: https://www.youtube.com/watch?v=vCTbLZ2_m-w&t=36s

26 x 26 x 45 3D Printer/Mill

Super tall 3D printer. All lead screw design.

Big a** printer

In-progress 500x500x1800

GhettoPrinter

Dirt cheap build.

Vulcan Pro V1

A posi-drive leveling printer in 300x300x380mm format that easily breaks down for suitcase size shipping.

Build Author

Keith Davis

Views

4017

Build Author

Keith Davis

Views

4017

Vulcan Bot

A 200mm x 300mm x 200mm workhorse that never needs leveling due to Posi-Drive Leveling design.

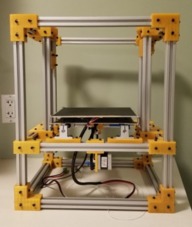

Openbuilds CubeBot 3D Printer

Cartesian type 3d printer build

Build Author

David Florian

Views

11473

Build Author

David Florian

Views

11473

Dual Extruders 3D Printer - Zidex Upgraded

How to build an Independent Dual EXtruder (IDEX) 3D printer from OpenBuilds parts.

18x36x16 Inch 3D Printer - Work in progress

Tough 3D Printer using OpenBuilds Parts!

Mini Additive Manufacturing Printer by Chris Scholl

Mini Additive Manufacturing Printer by Chris Scholl

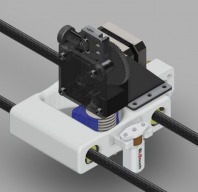

Dual Direct Drive Extruder

a dual extruder build using direct drive for flexible filaments

Build Author

Leboeuf

Views

4919

Build Author

Leboeuf

Views

4919

Cartesian 3d printer

This is the build of a cartesian 3d printer made of an old Anet and Geeeteck, some 2020 alu profil and linear rail. Powered by a Rumba with a Nextion screen. It should be modular and accept dual Extrusion and laser engraving.

Stabilus 3d Large Format Printer Kit

Stabilus 3d Large Format Printer Kit

3D Printer 051

Functional real-world 3D printer build with RM2-2RS bearings in routed V grooves on phenolic resin rails (lab countertop scraps) and NSK 25mm linear rails/trucks.

CupriForge

This build will use 1/2 inch copper water pipe as the primary material for all structural parts. As of now my intent is a cartesian design drawing from a few popular printers. I'm going to use the least amount of printed parts as possible and locally source as much as I can. I have built an EMT-conduit core-xy printer in the past and while it worked out fine, I feel copper is easier to work, manufactured with more precision, still reasonably inexpensive and will look super cool!

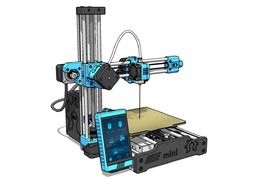

ME-Mini 3D Printer

Prusa mini inspired 3d printer

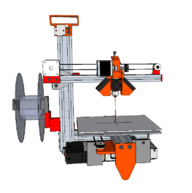

Simpl3rBot

A framing design for cantilever style printers

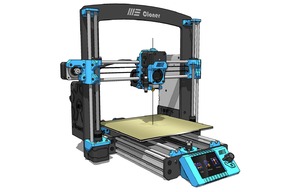

ME - Cloner 3d printer

I decided to start designing this printer, this will be my solution for a more rugged printer that you can use as workhorses...

Build Author

Ahmed Ibrahim

Views

9750

Build Author

Ahmed Ibrahim

Views

9750

Cairo Mini 3d-Printer

We are introducing the Cairo Mini 3d-printer! It’s a DIY fully Open-source Reproducible 20x20cm 3d-printer. The original goal of the Cairo Mini 3d-printer is to create a low-cost 3d-printer below 220$(3500 LE). That anyone can build with ease.

Build Author

David E. Flores E.

Views

3201

Build Author

David E. Flores E.

Views

3201

F-Ender-Plus 3D Printer

F-Ender-Plus its based on the Ender 3 Pro, but improved: CR-10 hotend, double gear extruder, double z-axis motor, bltouch incorporated, hotbed leveling improved strings kit. Most made using local vendor parts, and still I'm increasing my knowledge of how get better 3D printings by calibrating motors steps, leveling the hotbed and z-axis; using a 3mm thick glass...