Build List

Galvos

3d printable galvos

Ooznest workbee

This is my first build so I will let you know how I get on

Cnc od grinder and thread grinder

This is a totally original build of an od id grinder and thread grinder, I hope.

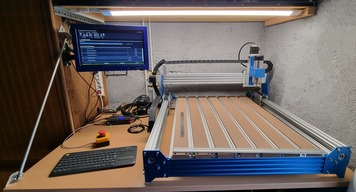

OoozNest WorkBee

A Journey on the WorkBee Build...

Gluing frame for guitar tops and backs

I have built four of these frames. The first pictured I have been using for maybe a year or two and bought the clamps. The last three I have made I have built my own clamps with openbuild parts. I am still working on the design. At present I use wedges to apply pressure to the side of the wood and block. I am working on a cam system to apply pressure. I just bought 8mm screws with Knobs for quicker adjustment. I will update the build when I make these improvements.

C-Beam Machine XL

C-Beam XL upgraded with end-stops, E-stop, and cable chain. Running GRBL on Arduino Mega.

CBeam Sphinx Upgrade

Simple upgrade of the Y axis on a Cbeam sphinx from 500mm to 1000mm.

MIT E-Vent | MIT Emergency Ventilator

Ventilator prototype based of OpenBuilds Stock parts

Build Author

Yosmany325

Views

2440

Build Author

Yosmany325

Views

2440

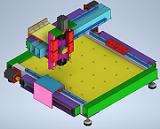

OrionPlus

Cartesian style CNC with a working area of around 360mm x 360mm x 120 mm (X, Y, Z) using Linear rails and ball screws. The linear rails are (Hiwin?) HGR 20mm x 520mm and the ball screws are SFU1204 (12mm lead 4mm) of around +/- 430 mm. The base structure is made from rectangular aluminum profiles of 70mm x 45mm x 3mm (thickness of walls).

frugal-ist workbee

a 1000x1000 acme screw workbee built as frugally as possible. thanks so much to ooznest and openbuilds :)

ricks workbee build

i had the ox build and wanted to do a more beeffer style so i went with a workbee style machine ..

Build Author

Bill325

Views

2357

Build Author

Bill325

Views

2357

One more life for a cube

Modify a Gen1 Cube printer into a small cnc router to cut pcbs and light (VERY light) milling work. Also easy to swap out the rotary head and mount a laser head for engraving.

ApiNui - CNC Router ( an oversized workbee )

Based on the WorkBee CNC, this is an oversized router built with a specific use-case in mind, for manufacutring beehives, and beehive components

C beam Larger and Stronger

My first build based on the original C beam Sphinx. I’m not sure at this point what the final size will be. I have the parts from the c beam Sphinx and extra beams and lead screws to build up to 1000mm x 1000mm.

Weeding Delta

A Delta robot for weeding crops using AI and ROS2

26 x 26 x 45 3D Printer/Mill

Super tall 3D printer. All lead screw design.

Lead 1510

Customised Lead 1010 making it a 1510. T-Track work area with dual Y limit switches for auto-squaring. Powered by xPro v5 & CNC.js

My Little Mashup

A mixed drive, PI Controlled machine

AcoustoPlot3D

The Sphinx has all the components I need, except it will need a taller vertical lead screw, the same length as the horizontal ones. It will also need legs. So I need to start with the Sphinx parts list, then make a few changes.

cnc vreesbank 2500x30000

This cnc milling machine is 3 meters by 30 meters,

Open Builds C-Beam K-cup holder

Making use of c-beam I have had left over from projects.

Everything Else

Hi my name is crispin and I'm an aluminum addict.

Ox cnc improvements chain driven

Just ox cnc experiment

Build Author

Johnny Reich

Views

2075

Build Author

Johnny Reich

Views

2075

ProLight 1000 Mill Retrofit

Update a 20-year old bench top milling machine with OpenBuild Ecosystem electronics.

Build Author

Daniel Stewart

Views

2049

Build Author

Daniel Stewart

Views

2049

Ultra sun cutter

A sun cutter only using mirror and glass balls with x and y table movement

Mortiser

A work-in-progress build using OpenBuilds parts to create a mortising jig.

The dwarf

This is a build for those of us that want to work fairly large but are in a tight space and budget

Build Author

Alexander_Bulgaria

Views

1698

Build Author

Alexander_Bulgaria

Views

1698

CNC milling machine,lathe,gantry,fdm,clay 3d printer ALL IN ONE

That is the only cnc you will need for most of your diy projects.

CupriForge

This build will use 1/2 inch copper water pipe as the primary material for all structural parts. As of now my intent is a cartesian design drawing from a few popular printers. I'm going to use the least amount of printed parts as possible and locally source as much as I can. I have built an EMT-conduit core-xy printer in the past and while it worked out fine, I feel copper is easier to work, manufactured with more precision, still reasonably inexpensive and will look super cool!

Build Author

robert christensen

Views

1519

Build Author

robert christensen

Views

1519

Tool holder

I saw a video of some one pouring resin in a mold,so i did a little research, i bought some resin,and some molds and magnets all from Amazon, it took me several tries and a big mess but it finally finished. The first pour i poured a small batch to make a templet,i marked all the holes that needed drilling then i marked the underside of the mold where i wanted the magnets, next was making the pcs i needed

Workbee 1010 et laser atomstack M100

Je ne sais pas comment brancher mon laser sur la blackbox?

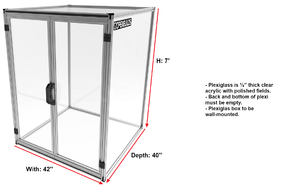

Plexi Panel

Plexi Panel to use for a vfd test enclosure. The box will be wall-mounted on plywood, so the back of the box is not necessary. - The bottom of the box is not necessary because the box will be fixed on concrete on the floor. On the door, I was thinking of putting 4 brackets instead of two. We'll have two 21” doors

Build Author

Alain JBT

Views

706

Build Author

Alain JBT

Views

706

First project Genmitsu ProVerxl 6060 Improved with OpenBuilds System

For a long time I had a project to buy a CNC, in time I have evaluated several possibilities. I chose the option of a pre-constructed and scalable machine according to my needs, with sufficient rigidity features to do work of average importance. The starting investment was important to take into account to allow changes from the open source domain.

Reducing leadscrew whip

The video demonstrates a practical device to reduce whip