Build List

-

Active Filters:

b

Y table for LEAD Lathe - essentially a High Z Cbeam XL

I built the lathe as a dedicated rotary axis, but I soon realized I could have a back up CNC for very little expense.

Something a Tad different

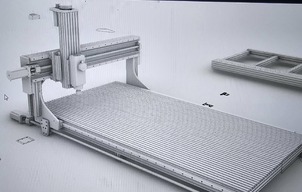

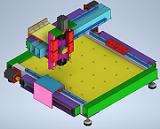

Future CNC router kit design

C-Beam Elexa

This build will be based on the C-Beam Plate Maker, with additional changes based on other builds and ideas.

Black Box/ Power supply brackets

This items are so cool that they need to be together, so I decided to create brackets that connect both pieces together

Build Author

Terone Burgenheim

Views

2801

Build Author

Terone Burgenheim

Views

2801

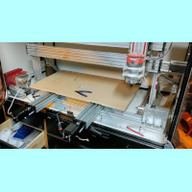

My CNC

This build is my version of the CBeam machine. I opted to NOT use the Gussets, and instead went for the 40, and 60 mil angle brackets to cut the price back a little further. I started with the smoothieboard but decided it was still "too new" and very much experimental. This build took me a few (2-3) days to complete. The CBeams and Lead-Screws really make building things faster since you don't have to clamor over belts.

Mark 1

My first attempt at building a CNC style machine. Overall my plan is to use the PlanetCNC breakout board and software to run the machine from a dedicated laptop/tablet.

Custom push cart for CNC machines

I’m custom building a push table / cart for my cnc machines mostly out things I already had in my garage. Using a gray push utility cart as the main body and building around that.

Gärschrank

A cabinet to keep a constant temperature for pizza or bread mother dough to grow.

First build - small scale

Using basic standard components, beams, motors, belt drive on x and y, z is a screw. Using Grbl Panel on Windows 10. Really basic router, had trouble getting the controller to turn on the router and set speeds so it is currently wired to a power bar switch so it runs full speed and I just use the switch to turn it on and off. Just getting x, y and z control working properly for now and likely going to switch the router to my dremel 4000 using a 3d printed mounting bracket I got from thingiverse

NotAnOx

From plywood and linear rail to c-beam. I probably should have bought a kit.

Build Author

Sprags

Views

2704

Build Author

Sprags

Views

2704

C-Beam Kyo Sphinx 10060

More stuff here.

C-beam charmer

Double C-beam Y axis 500mm., Double 2080 X axis 600mm. , C-beam Z axis 250mm, TB-6600 drivers, MKS-DLC32v2 GRBL w/wi-fi and blue tooth

ECNCML (budget mashup)

This build summarizes my CNC milling and laser engraving machine conversion from a dimensional lumber frame and electrical mess to an all aluminum frame with a safe and well constructed (IMHO) control system with the resources I had available.

CNC built, work in progress, fail

2x4 cutting area, enclosed with dust collection mainly built out of wood.

WorkBee Saving Lives

Using the WorkBee to protect doctors against Corona virus.

TFE2 CNC Build

My TFE2 CNC Build. The TFE was much smaller and all of the gantry plates were 3D printed. Despite this it will happily machine aluminium without issue. So I decided to use that to make the TFE2 which will be all aluminium plates and much larger (1200x800mm machining area with roughly 140mm in Z so I can later add a rotary axis.)

Ooznest workbee

This is my first build so I will let you know how I get on

OoozNest WorkBee

A Journey on the WorkBee Build...

C-Beam Machine XL

C-Beam XL upgraded with end-stops, E-stop, and cable chain. Running GRBL on Arduino Mega.

CBeam Sphinx Upgrade

Simple upgrade of the Y axis on a Cbeam sphinx from 500mm to 1000mm.

Acro 1010 with 10 watt Laser

Built a 32"x40" ACRO Kit for my 10watt Endurance Laser. Put it in a stand alone clamshell cabinet, added a 340cfm 6" fan and variable speed switch for the fan. Using LIght Burn for my primary software. It seems to be work well.

Build Author

Yosmany325

Views

2396

Build Author

Yosmany325

Views

2396

OrionPlus

Cartesian style CNC with a working area of around 360mm x 360mm x 120 mm (X, Y, Z) using Linear rails and ball screws. The linear rails are (Hiwin?) HGR 20mm x 520mm and the ball screws are SFU1204 (12mm lead 4mm) of around +/- 430 mm. The base structure is made from rectangular aluminum profiles of 70mm x 45mm x 3mm (thickness of walls).

frugal-ist workbee

a 1000x1000 acme screw workbee built as frugally as possible. thanks so much to ooznest and openbuilds :)

ricks workbee build

i had the ox build and wanted to do a more beeffer style so i went with a workbee style machine ..

Build Author

Bill325

Views

2311

Build Author

Bill325

Views

2311

One more life for a cube

Modify a Gen1 Cube printer into a small cnc router to cut pcbs and light (VERY light) milling work. Also easy to swap out the rotary head and mount a laser head for engraving.

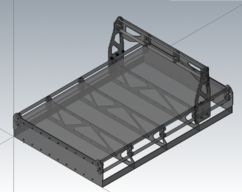

ApiNui - CNC Router ( an oversized workbee )

Based on the WorkBee CNC, this is an oversized router built with a specific use-case in mind, for manufacutring beehives, and beehive components

C beam Larger and Stronger

My first build based on the original C beam Sphinx. I’m not sure at this point what the final size will be. I have the parts from the c beam Sphinx and extra beams and lead screws to build up to 1000mm x 1000mm.

Automated Media Blaster

Automated Media blaster retrofit.

Weeding Delta

A Delta robot for weeding crops using AI and ROS2

Lead 1510

Customised Lead 1010 making it a 1510. T-Track work area with dual Y limit switches for auto-squaring. Powered by xPro v5 & CNC.js

Everything Else

Hi my name is crispin and I'm an aluminum addict.

Ox cnc improvements chain driven

Just ox cnc experiment

Build Author

Johnny Reich

Views

1993

Build Author

Johnny Reich

Views

1993

ProLight 1000 Mill Retrofit

Update a 20-year old bench top milling machine with OpenBuild Ecosystem electronics.

CNC accessory box Made 100 % from recovery materials

Quick construction. A few pieces of wood recovered in the trash can, two hooks one hinge, a few screws and a little glue. [Edit] Added the SVG file for sharing (I forgot it)

Build Author

Alexander_Bulgaria

Views

1595

Build Author

Alexander_Bulgaria

Views

1595

CNC milling machine,lathe,gantry,fdm,clay 3d printer ALL IN ONE

That is the only cnc you will need for most of your diy projects.

Build Author

robert christensen

Views

1428

Build Author

robert christensen

Views

1428

Tool holder

I saw a video of some one pouring resin in a mold,so i did a little research, i bought some resin,and some molds and magnets all from Amazon, it took me several tries and a big mess but it finally finished. The first pour i poured a small batch to make a templet,i marked all the holes that needed drilling then i marked the underside of the mold where i wanted the magnets, next was making the pcs i needed

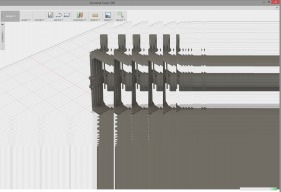

Reducing leadscrew whip

The video demonstrates a practical device to reduce whip