3D PRINTER BUILDS

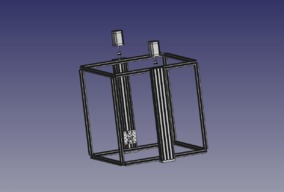

bertha

This build will hopefully be 18x18x24 build space using RAMPS 1.4 with Marlin firmware. Using NEMA 17 motors and belts to drive the X and Y axis, lead screws for the Z axis. The build plate will be heated with a delrin Y carriage for the glass and heatbed. Z axis motors will be top mounted. Possibly and ATX power supply.

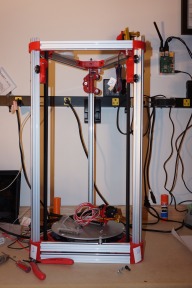

Kossel Mini Delta

This is a Chinese kit I got on ebay from someone in CA.

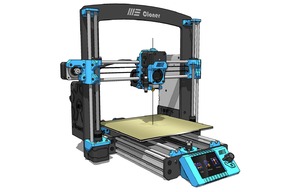

ME - Cloner 3d printer

I decided to start designing this printer, this will be my solution for a more rugged printer that you can use as workhorses...

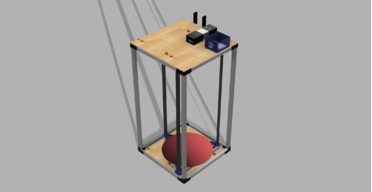

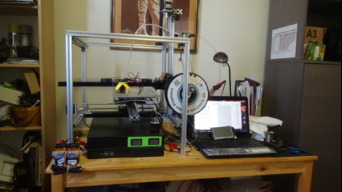

1 Cubic Meter 3D Printer

This is a at home built 1000mm x 1000mm x 1000mm 3d printer. It uses mainly parts from OpenBuild Parts and is very simple to build. The only thing that was custom was the build plate which was designed by myself and tooled at a local machine shop.

Build Author

Darren Dickson

Views

4297

Build Author

Darren Dickson

Views

4297

3D printed CNC Machine

So I thought I would make the Leon van den Beukel version three 3D printed CNC Machine, it is the third incarnation so you would expect a relatively bug-free CNC Machine with a strong foundation.

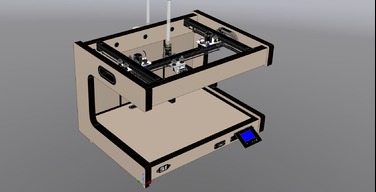

Old Faithful...FDM/CNC machine

I've owned some pretty unreliable printers, and I'll leave it at that... This design comes from the need to have a 3D printer that is reliable, period. I didn't have the money for a several thousand dollar 3d printer with an equivalent build area so that was out of the question. Plus as a fledgling Engineer, I really wanted to blood myself on a project. And that's how Old Faithful came to be. A simple, reliable, rigid, durable machine. Made by me :) Also, it'll be tough enough for light CNC.

Travel Printer

Build using standard parts as much as possible, Open Builds etc. To keep printer usable for more materials will be trying a heated bed with rotary elec union for the thermistor and power.

Build Author

TimVukman

Views

4227

Build Author

TimVukman

Views

4227

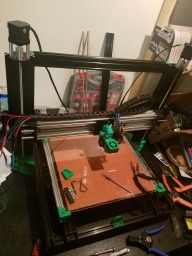

Unique Z

My original Tevo Tarantula kit was ok..... I had issues with the X gantry staying level. I got rid of the wheels and replaced them with linear block bearings. I still had some issues with the X gantry. I swapped out the plastic parts with aluminum which was much better. Still not what I want yet

Infinite Z Delta Printer

Currently completely imaginary

Build Author

Fabio Bertuzz

Views

4170

Build Author

Fabio Bertuzz

Views

4170

DutziDelta RepStrap

Fascinated for some time by 3D Printing. Now, after studying countless forum posts, blogs and similiar stuff, i want to Start with my own build. Maybe a bit much but usually i thrive with the challenge.

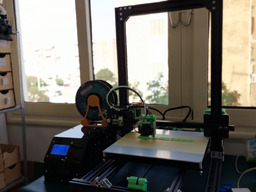

D-Bot Version B

D-Bot with a Replicate controller.

Atlas Delta Bot

The idea here is to build a nice large delta bot from the parts ground on the one builds part store. Other parts that are sources out side of this will be detailed. I have a simple BOM I started that I will upload later.

Build Author

Keith Davis

Views

3973

Build Author

Keith Davis

Views

3973

Vulcan Bot

A 200mm x 300mm x 200mm workhorse that never needs leveling due to Posi-Drive Leveling design.

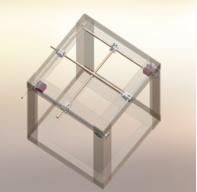

Core XY

Just now in the planning phase of my build. Waiting for some parts to come in to see what I am going to build off of. Print area going to be close to 300x300x350. Trying to decide if I want it enclosed. I do want to print ABS... so probably so.

Cairo 30 3d-printer

We are introducing the Cairo30 3d-printer! It’s our new premium creature with no compromises! The Cairo30 3d-printer is the culmination of our accumulated years of experience designing and producing open-source CNC machines kits.

Build Author

MidnightQuads

Views

3831

Build Author

MidnightQuads

Views

3831

MQTitan printer

Components- RAMPS, running marlin, Nema 17, All metal extruder, 600mm lead screws, 600mm 2020 aluminum extrusions, 12v 30a power supply, 12v LED strip, Typical endstops, 600mm 8mm linear rods, Bearing block for 8mm bearings, Openbuilds plates, wheels, and bearings, 500x500mm borosilicate glass plate

Build Author

George Motichka

Views

3708

Build Author

George Motichka

Views

3708

Transformer

I wanted a machine that could easily switch between 3D Printing and Laser Engraving

Build Author

h3rb

Views

3664

Build Author

h3rb

Views

3664

TEVO Little Monster Marine Vinyl Removable Enclosure

Make a vinyl burrito ENCLOSURE for your TEVO LITTLE MONSTER for < $30 (<$20 if you don't have your vinyl shipped!)

3D Printer 051

Functional real-world 3D printer build with RM2-2RS bearings in routed V grooves on phenolic resin rails (lab countertop scraps) and NSK 25mm linear rails/trucks.

Build Author

Daniel.korneliussen

Views

3420

Build Author

Daniel.korneliussen

Views

3420

Reprap prusa mendel i2 Frankenstein 2018 build

Mad plumbers choice what Else can i say?

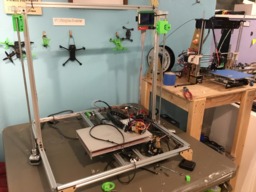

Design and Performance Evaluation of A Large FDM 3D Printer

This build includes the design of a large FDM 3D printer. This machine has a 796mm by 796mm by 900mm (LxWxH) build volume. Motion is controlled by servo motors and the printer runs on python-based marlin firmware.

Build Author

Genetoys

Views

3240

Build Author

Genetoys

Views

3240

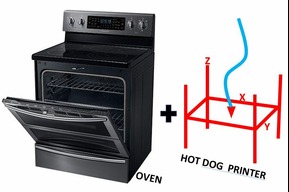

Oven Dog

Building a printer that can fit inside and operate at ~200 C oven temperatures

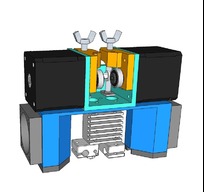

Dual Direct Drive Extruder

a dual extruder build using direct drive for flexible filaments

ivern

Toying around a concept. Inputs are welcome on whether to use lead screw or belt drive. My lead screw will be single start 500 mm lenght, 2 mm pitch and 2 mm lead. Nema 17 motors will be used. All veterans, suggestions please.

Mammoth (Delta printer)

Massive Delta printer with a print area of 25 Inches (634mm).

Build Author

David E. Flores E.

Views

3034

Build Author

David E. Flores E.

Views

3034

F-Ender-Plus 3D Printer

F-Ender-Plus its based on the Ender 3 Pro, but improved: CR-10 hotend, double gear extruder, double z-axis motor, bltouch incorporated, hotbed leveling improved strings kit. Most made using local vendor parts, and still I'm increasing my knowledge of how get better 3D printings by calibrating motors steps, leveling the hotbed and z-axis; using a 3mm thick glass...

Printer number 2

A Large Printer that will hopefully be able to print at least 45cm cubed

THE BIG GREEN MACHINE

1500*1500*1900 (xyz) Biocomposite Pellet 3D printer

26 x 26 x 45 3D Printer/Mill

Super tall 3D printer. All lead screw design.

CupriForge

This build will use 1/2 inch copper water pipe as the primary material for all structural parts. As of now my intent is a cartesian design drawing from a few popular printers. I'm going to use the least amount of printed parts as possible and locally source as much as I can. I have built an EMT-conduit core-xy printer in the past and while it worked out fine, I feel copper is easier to work, manufactured with more precision, still reasonably inexpensive and will look super cool!