Build List

-

Active Filters:

nt

Build Author

MrMojoRisin

Views

7558

Build Author

MrMojoRisin

Views

7558

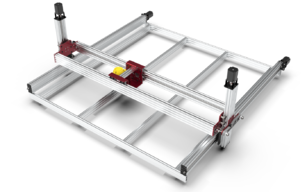

IIOT WiFi Portable CNC Plasma Cutter

IIOT WiFi Plasma CNC.

Build Author

Cortellini

Views

5577

Build Author

Cortellini

Views

5577

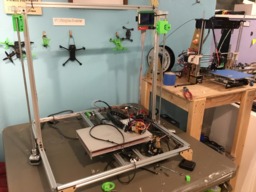

the Feedback Fractal project

The Story of the Scecina Memorial High School 1510 BUILD will unfold through a series of 10 minute Episodes. Each episode will consist of video showing how to assemble some aspect of the 1510 overlaid with a discussion about Technology, Art, Philosophy... and Life the Universe and Everything. Episode two is soon to follow. If sufficient interest ensues, the episodes may continue beyond the building of the 1510 to relate its use in the making of the Art.

Build Author

Keith Davis

Views

4050

Build Author

Keith Davis

Views

4050

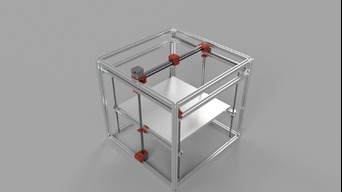

Vulcan Bot

A 200mm x 300mm x 200mm workhorse that never needs leveling due to Posi-Drive Leveling design.

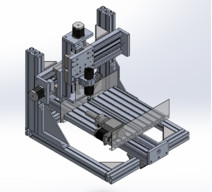

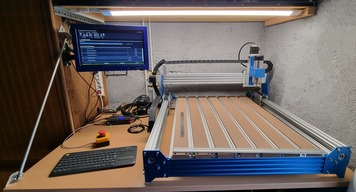

PhlatMDF48

Building a Phlat based CNC for MDF processing. Capacity of 48" x unlimited length.

Build Author

OpenBuilds

Views

17156

Build Author

OpenBuilds

Views

17156

C-Beam® Tension XL Linear Actuator

Bringing your lead screw precision and accuracy to new lengths using a simplistic tension system!

Build Author

Crazzy French Dude

Views

5368

Build Author

Crazzy French Dude

Views

5368

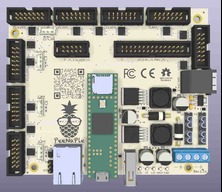

PeeNaPle_V1.4b

PeeNaPle_V1.4b is a BoB controller board for 3D Printers, CnC and cartesian machine, using the latest Teensy_4.1

Build Author

Colin Russon

Views

3916

Build Author

Colin Russon

Views

3916

TITAN GAMBIT

Anti-Twist Design, larger lead screws, enhanced M8 wheel sets.

AcoustoPlot3D

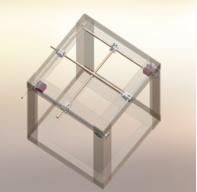

The Sphinx has all the components I need, except it will need a taller vertical lead screw, the same length as the horizontal ones. It will also need legs. So I need to start with the Sphinx parts list, then make a few changes.

Build Author

OpenBuilds

Views

4716

Build Author

OpenBuilds

Views

4716

Interface magnetic mount

A simple build that helps you to mount the OpenBuilds Interface to the front of your machine.

Fixed Gantry Easy Assembly

Fixed Gantry CNC with good accuracy and rigidity but for a higher price than the usual CNC's on the site.

Automated Media Blaster

Automated Media blaster retrofit.

Build Author

robert christensen

Views

1478

Build Author

robert christensen

Views

1478

Tool holder

I saw a video of some one pouring resin in a mold,so i did a little research, i bought some resin,and some molds and magnets all from Amazon, it took me several tries and a big mess but it finally finished. The first pour i poured a small batch to make a templet,i marked all the holes that needed drilling then i marked the underside of the mold where i wanted the magnets, next was making the pcs i needed

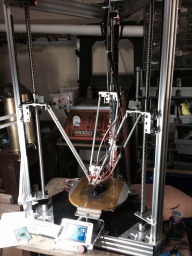

Monster Delta

As a 3rd year mechatronic engineer with a plan to print my 4th year thesis project and with no elegant backup plan, I ran into a problem, I'm gonna need a bigger printer. Loving the DeltaPrintr kickstarter, but needing it before the end of next year I have resolved to make my own.

Build Author

Josh Mascote

Views

7393

Build Author

Josh Mascote

Views

7393

Z3D Delta Printer

Berrybot inspired delta 3d printer with a few other tweaks and modifications.

Ez3D - Phoenix 3D Printer Build

This is my 1st submission to openbuilds.com and my 1st venture into building a 3D Printer. The Phoenix 3d Printer is a kit from Ez3D, a company based out of Colorado, started and backed by successful Kick-starter and IndieGogo campaigns. The Phoenix 3d Printer kit is currently backlogged 10 to 12 weeks which means quite a wait. I will be chronicling my experience with this kit as I get it done.

Build Author

Mohsen Abbasi

Views

8944

Build Author

Mohsen Abbasi

Views

8944

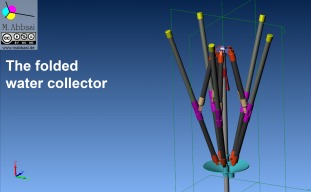

Foldable Rainwater Collector

Realisation of my idea about a foldable collector for rainwater, which is light and easy to make. People around the world need water and can collect rain water with this collector. I made it for syria and all too.

Build Author

Zootalaws

Views

6462

Build Author

Zootalaws

Views

6462

OXENlarged

This is a 1500 x 1500 Ox build

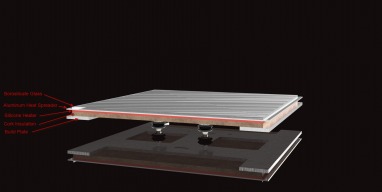

12.5" x 12" Assembled Heated Build Plate

Custom build plate for 300mm x 300mm (12"x12"). The hole pattern is for the 20x60 V Slot

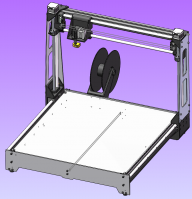

large format printer

I am hoping to post a detailed build of my printer it is a large format using the RepRap RAMPS 1.4 & Mega 2560 & DRV8825 Driver + optical end stop +LCD 12864 -C 0.4mm Far-end Distal Dual-Head Nozzle Extruder Double Nozzle

Bandicoot v1

My first custom build, using vslot rails for Z and Y and 8mm rails for X. Currently printing parts for this using my Prusa I3. The build volume will be roughly 300mm^3, X and Y are belt driven with 8mm acme lead screws for Z. Will be uploading more info shortly as i continue to build the printer.

Build Author

MikieLikesIt

Views

8242

Build Author

MikieLikesIt

Views

8242

Cousin CNC OX Router

A lower profiled machine. Built all out of aluminum. Removable control panel/PC unit. Option for vacuum table and cooling pump for a spindle.

Build Author

DIY3DTech.com

Views

6503

Build Author

DIY3DTech.com

Views

6503

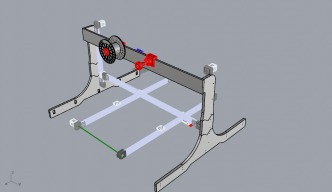

3D Printer Leveler Made with Maker Rail

Leveling Platform / Stand 3D Printers

Build Author

Fabio Bertuzz

Views

4235

Build Author

Fabio Bertuzz

Views

4235

DutziDelta RepStrap

Fascinated for some time by 3D Printing. Now, after studying countless forum posts, blogs and similiar stuff, i want to Start with my own build. Maybe a bit much but usually i thrive with the challenge.

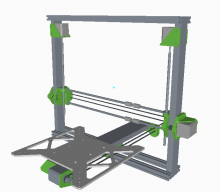

HAPP Printer

This 3D Printer is made to provide the most accurate results with the least amount of investment. This Printer is being designed to allow the common user to own a very accurate piece of machinery.

3D Printed Solid - Large Format Printer

I need a large build plate without spending 10-20k for a "store" built printer.

Delta 3D Printer

This is a Delta build using 1610 ballscrews from China

Build Author

Gary Bonard

Views

6164

Build Author

Gary Bonard

Views

6164

OxZilla

This is my second Ox with a working area of 14" x 14" x 5" I wanted to build a small sturdy potable CNC router and this OxZilla has the nice upgrades !

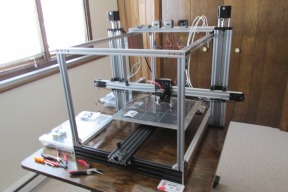

bertha

This build will hopefully be 18x18x24 build space using RAMPS 1.4 with Marlin firmware. Using NEMA 17 motors and belts to drive the X and Y axis, lead screws for the Z axis. The build plate will be heated with a delrin Y carriage for the glass and heatbed. Z axis motors will be top mounted. Possibly and ATX power supply.

Build Author

Cbrown330

Views

5373

Build Author

Cbrown330

Views

5373

Big 3d Printer, Big Brown

This is a big 609 x 609 x 914 3d pritner with exchangable hot ends and extruders.

Infinite Z Delta Printer

Currently completely imaginary

Build Author

Joe Garritano

Views

11636

Build Author

Joe Garritano

Views

11636

X-carve upgrade

Using criticall OpenBuilds components to upgrade the rigidity and reliability of an X-Carve 1000mm build.

Build Author

Jose A. Molina

Views

6990

Build Author

Jose A. Molina

Views

6990

Remote Controlled Robot Spider(Teaching Tool)

This Project is meant to teach introductory robotics and arduino styled micro-controllers to HS and MS students.

Build Author

Power Playground

Views

4836

Build Author

Power Playground

Views

4836

PowerBot

This is my own modified version of the D-Bot printer. I wanted to spec this printer to be able to print exotic materials at high accuracy with little to no compromises and maximum reliability.

delta 3d printer kit

HE3D K200 kit build

Build Author

Ken376

Views

3733

Build Author

Ken376

Views

3733

Welded project cnc first try

Kind of hard to see in this pic now lining up drive s and finishing framework

Build Author

Linkreincarnate

Views

3122

Build Author

Linkreincarnate

Views

3122

Amazon Special

I have parts that are apparently not suited to a cnc router or a 3d printer. I am still trying to figure out what to make out of what I have,

Large 3D printer 12"x12"x12" with heated bed

I want to have a printer to support senior projects. Also working on supporting 3D printing needs in the local community.

My 3D Printer

A DIY 3D printer. At beginning made from aluminium profiles, aluminium sheet and wood :)

Everything Else

Hi my name is crispin and I'm an aluminum addict.

Build Author

THE LINK

Views

5072

Build Author

THE LINK

Views

5072

2020 First build.

Probably cheapest DIY build youl see.

ivern

Toying around a concept. Inputs are welcome on whether to use lead screw or belt drive. My lead screw will be single start 500 mm lenght, 2 mm pitch and 2 mm lead. Nema 17 motors will be used. All veterans, suggestions please.

Build Author

TimVukman

Views

4290

Build Author

TimVukman

Views

4290

Unique Z

My original Tevo Tarantula kit was ok..... I had issues with the X gantry staying level. I got rid of the wheels and replaced them with linear block bearings. I still had some issues with the X gantry. I swapped out the plastic parts with aluminum which was much better. Still not what I want yet

Core XY

Just now in the planning phase of my build. Waiting for some parts to come in to see what I am going to build off of. Print area going to be close to 300x300x350. Trying to decide if I want it enclosed. I do want to print ABS... so probably so.

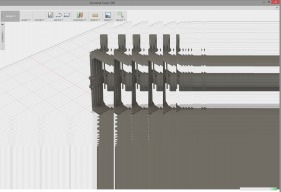

First build - small scale

Using basic standard components, beams, motors, belt drive on x and y, z is a screw. Using Grbl Panel on Windows 10. Really basic router, had trouble getting the controller to turn on the router and set speeds so it is currently wired to a power bar switch so it runs full speed and I just use the switch to turn it on and off. Just getting x, y and z control working properly for now and likely going to switch the router to my dremel 4000 using a 3d printed mounting bracket I got from thingiverse

Build Author

MidnightQuads

Views

3895

Build Author

MidnightQuads

Views

3895

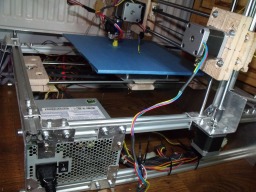

MQTitan printer

Components- RAMPS, running marlin, Nema 17, All metal extruder, 600mm lead screws, 600mm 2020 aluminum extrusions, 12v 30a power supply, 12v LED strip, Typical endstops, 600mm 8mm linear rods, Bearing block for 8mm bearings, Openbuilds plates, wheels, and bearings, 500x500mm borosilicate glass plate

Noob 1000Sphinx

A complete noob stumbling thru his first cnc build in winter.. and trying to find the time with 2 toddlers..

Build Author

Blyn3D

Views

6372

Build Author

Blyn3D

Views

6372

Fourth Axis Mill Prototype

I really like the 4th axis I purchased a few years back, but when I went looking for it again the suppliers who once carried it no longer do. Anyone know who makes it? Center hole receives collets. I own a ShopSmith so I am using a 5/8th rod and can mount it's chucks onto this machine. Also I like the use of the skateboard wheels, they are adjustable and one could use more sets over a longer axis. The Sherline z-axis is not my first choice, I just had a spare.

Build Author

h3rb

Views

3732

Build Author

h3rb

Views

3732

TEVO Little Monster Marine Vinyl Removable Enclosure

Make a vinyl burrito ENCLOSURE for your TEVO LITTLE MONSTER for < $30 (<$20 if you don't have your vinyl shipped!)

Build Author

h3rb

Views

5701

Build Author

h3rb

Views

5701

TEVO Little Monster Direct Mount Extruder

Cheap, experimental Modification to Tevo Little Monster's bowden system for the extruder

Build Author

Mark Carew

Views

18333

Build Author

Mark Carew

Views

18333

Nema 23 Belt and Pinion Actuator

This easy to build and effective system can take your builds to the next level! This design is strong and accurate and could be the solution/upgrade that you've been looking for!

26 x 26 x 45 3D Printer/Mill

Super tall 3D printer. All lead screw design.

Build Author

Darren Dickson

Views

4420

Build Author

Darren Dickson

Views

4420

3D printed CNC Machine

So I thought I would make the Leon van den Beukel version three 3D printed CNC Machine, it is the third incarnation so you would expect a relatively bug-free CNC Machine with a strong foundation.

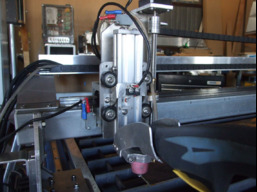

Plasma CNC machine

The plasma CNC that I have built has a water table that measures 1350mm x 650mm. The water is flooded onto the cut area while cutting and recycled around with a pump. This is to reduce smoke, cool the metal being cut to reduce distortion and also to keep sparks to a minimum. Most of the machine has been made from aluminium , the frame and table from steel, the water table, stainless steel.

Build Author

Leboeuf

Views

4973

Build Author

Leboeuf

Views

4973

Cartesian 3d printer

This is the build of a cartesian 3d printer made of an old Anet and Geeeteck, some 2020 alu profil and linear rail. Powered by a Rumba with a Nextion screen. It should be modular and accept dual Extrusion and laser engraving.

Build Author

Jose Alezandre

Views

2198

Build Author

Jose Alezandre

Views

2198

Mighty Chihuahua

The idea was to use materials from previuos failed projects into a succesful one. I have build this tiny but powerfull CNC machine mainly using the universal gantry plates for the X and Y axis. Also another innovative part is the fact that I assembled the Z gantry with 2 aluminum sections of 20X40 and one aluminum seccion of the 20X20. I used NEMA 17 stepper motors with GT2 pulleys. This was designed on Fusion360

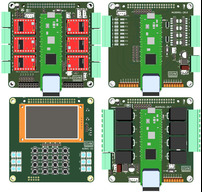

M10CUBE PICO CNC. A Universal Controller

An attempt is to be a Unified Modular Controller based on M10CUBE platform. For GRBLHAL and MARLINHAL applications. HAL porting is under way 1 - WIZnet Pico Clone W5100S-EVB-Pico 2 v- 6 X StepStick. Not sure about the sixth driver, (Pico pins limitation) . External connectors for larger drivers 3 - Opto - isolated spindle PWM. 4 - HMI 5 - I/O on diferent modules and Ethernet 10MBPS communication. Patches will be written to GRBLHAL for Ethernet I/Os (Interrupted).

Build Author

Alain JBT

Views

315

Build Author

Alain JBT

Views

315

First project Genmitsu ProVerxl 6060 Improved with OpenBuilds System

For a long time I had a project to buy a CNC, in time I have evaluated several possibilities. I chose the option of a pre-constructed and scalable machine according to my needs, with sufficient rigidity features to do work of average importance. The starting investment was important to take into account to allow changes from the open source domain.

Build Author

Alexander_Bulgaria

Views

1653

Build Author

Alexander_Bulgaria

Views

1653

CNC milling machine,lathe,gantry,fdm,clay 3d printer ALL IN ONE

That is the only cnc you will need for most of your diy projects.