Build List

-

Active Filters:

100

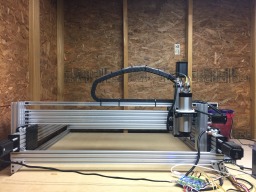

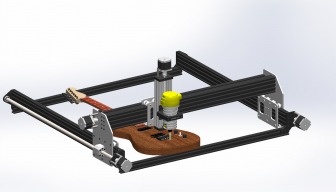

C-Beam XXLarge "Tank"

This is a modified build C-Beam XLarge. 1000mm C-Beam used for X and Y axis, and the Y Axis moves the X bridge, not the material being worked.

Build Author

uGen

Views

18745

Build Author

uGen

Views

18745

Lab Power Supply + Soldering Station

A small 32 V, 96 W lab power supply with voltage/current/power limit, program memory and an outlet to power the popular TS-100 soldering iron

Build Author

Gerald Klein

Views

17625

Build Author

Gerald Klein

Views

17625

300mm Diameter, 1 Meter tall, Delta 3d Printer

I built a custom delta using 3, 1000 mm long C-Beam® Linear Rails and 3 C-Beam Gantry Sets. I had the bottom and top plates water jetted ( for accuracy ) out of 1/2 inch aluminum, from a design that I did in Fusion 360.

Build Author

Kims3DIY

Views

18461

Build Author

Kims3DIY

Views

18461

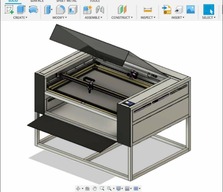

Beamlazer Laser cutter CO2 100W

Hi everyone, im new to the world of lasercutters but i have been granted access for a Trotec laser for a while with old firmware and only compability trought Windows XP. Then i decided to build my own laser, with some easier workflow and support for Windows 10. Since im still a student i have limited resources, so i will try too use scrap parts as much as possible. I will publish photos and updates during my build continously. Gladly taking advices from others.

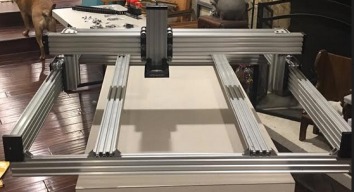

C-Beam 1M

Basing this build on the C-Beam machine XL on the parts store, but added a few things to make it more like the C-Beam XXLarge "Tank" by Dollarz81. Going with the Dewalt 611 instead of a water cooled spindle at first. May change down the road. Using a Panucat Gradus M1 controller with BigFoot drivers.

Build Author

Julius

Views

25697

Build Author

Julius

Views

25697

OX Balls - 1605 Ballscrew Powered 1000mmx1000mmm OX derivative

1000x1000mm Ballscrew driven OX Derivative. Dewalt 611 spindle and TB6600 Drivers.

Build Author

dmasters

Views

8356

Build Author

dmasters

Views

8356

DM C-Beam XXL Tank

1000mm x 1000mm C-Beam XXL CNC with external drivers and high torque Nema 23 motors, 2.2KW Spindle with VFD.

Custom Ox

Custom black and red Big Ox

Build Author

SlyClockWerkz

Views

17032

Build Author

SlyClockWerkz

Views

17032

1000mm X 1500mm OX CNC -- Fiber/Garolite

Building the full size OX.

C-Beam Sphinx Vacuum

A modified 1000x1000 Sphinx, with a built in vaccum table.

1000mm X 1000mm with tinyg

1000mm X 1000mm overhead cnc machine

Build Author

jaron kennell

Views

11356

Build Author

jaron kennell

Views

11356

Rezo 1390 100W CO2 Laser

This laser is a beast. Designed by Jonathan Frost, and built with 45x45mm aluminum for ultimate rigidity. It has a 4'x3' bed with a pass through that can be utilized to cut full 8x4' sheets of plywood, and has a motorized bed. Rēzo is not only faster and more capable than lasers like Thunder Lasers Nova 51 and Aeon Nova 10, but the final build costs are 40-60% less than said commercially available machines. Plans can be found at https://rezo1390.bigcartel.com/product/rezo-1390-plans

Pro Light 1000 CNC Machining Center Rebuild

Replacing the Pro Light control box with a Open Builds BlackBox.

Pure Cbeam 900x1000

This is a pure cbeam build to maximize envelope and rigidity. All the parts used are available from open builds.

C-BEAM 1K

The new C-Beam kit expanded to 1000mm . extra support built in for the extents of the travel.

Build Author

Axnfell

Views

3217

Build Author

Axnfell

Views

3217

WorkBee 1000x2000 ACME Screw Version

Hoping to build a WorkBee 1000 x 1000 (2000) from parts and not a kit, cannot afford the kit in full so going the long way round...

Build Author

spark2

Views

5848

Build Author

spark2

Views

5848

C-Beam - Sphinx 1000x1000mm inspired by Kyo

A stable CNC Router that allows me to cut and carve bigger Parts. The Machine is an original Build from Kyo's Sphinx CNC Machine. Thanks for the great Work and the Effort Kyo. Your Files and Lists helped me a lot to build that Sphinx 1x1m.

Build Author

crnrstndes

Views

4346

Build Author

crnrstndes

Views

4346

C-Beam Upgrade to Larger C-Beam

My goal was to be able to enlarge my C-Beam with as many original parts as possible. I was able to recycle almost all of them with a only the two 500 mm rails left over. I used 1000 mm rails for the X Axis and I added another complete Y Axis assembly. I chose to keep it simple and I am very happy with the result!

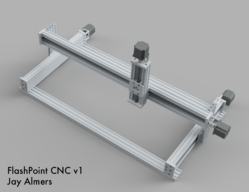

1.3m x 1.3m RF laser cutter

RF 100w laser cutter build, aluminium extrusion

Build Author

Jay Almers

Views

8313

Build Author

Jay Almers

Views

8313

FlashPoint CNC v1: 500mm x 1000mm 3-Axis CNC Router

My build is based on many different builds but pieced together into a unit specifically to suit my needs. The footprint, without motors, is around 500mm x 1000mm with a gantry height of around 250mm. I used a combination of C-Beam, for the linear transmission, and V-Slot for the base and gantry supports. Forged angle connectors were used for attachment and I utilized the C-Beam gantry cart kits with anti-backlash blocks for both Y axes, the X axis, and Z axis.

OX 1000mm Y Axis Upgrade

Expands y-axis to 1000mm. 1/2 day build.

1075 Sphinx

My first attempt at building a CNC. I chose the Sphinx due to ease of build and extensive documentation provided by Kyo.

Build Author

inhan

Views

6330

Build Author

inhan

Views

6330

openbuilds rovo 1000mmx1000mm(rovo x)(korea)

Open build rovo 1000mm * 1000mm. (Rovo x ver) 20.06.2015 now in progress. rovo kit is the 10th product. 8th rovo 750,9 th rovo1000, 10th rovo x ver progress at the same time. 10th item is an aspect of 1000. It changes the size and z-axis has been up.

Build Author

Rick Holder

Views

15577

Build Author

Rick Holder

Views

15577

Gantry Type CNC with Makita Router

The machine has met and exceeded my expectations on repeatability and accuracy. Cost was approx £600 including the Windows tablet.

My Workbee build

Workbee, 1000mmX750mm , from China

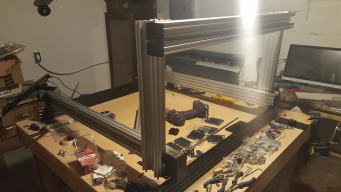

1250x1000 Build

A new design of my based on a couple different machines I have seen both on openbuilds and youtube. In the end will have a and X/Y workspace of 1250mm x 1000mm and a Z axis range of about 200mm.

Little Big OX

A complete CNC newbie is tackling a mighty challenge, Not only is he making a CNC router, He's going to try and upsize it.

Build Author

dcarlisle

Views

10863

Build Author

dcarlisle

Views

10863

pain in my ox

build is in process the machine went together perfectly no issues at all but the software is another issue I have been trying to get the thing dialed in it is driving me nuts I'm still in the process will update if I ever get it figured out

Noob 1000Sphinx

A complete noob stumbling thru his first cnc build in winter.. and trying to find the time with 2 toddlers..

Build Author

JerryD

Views

5426

Build Author

JerryD

Views

5426

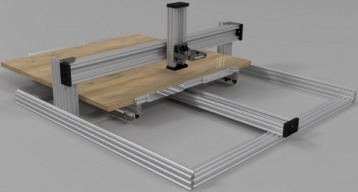

1500x1000mm Adjustable Height

I have the demand to cut/etch tall pieces of material. For this reason, I have designed a machine with 500mm uprights with adjustable gantry height. This way I can raise/lower the sled and z-axis as needed. I've also chosen to use a linear C-channel assembly for the Z axis with the plate mounted to the gantry instead of the other way around. This will allow for maximum range of the z-axis. The parts list/BOM does not include motors/belts/pulleys or electronics.