Build List

-

Active Filters:

d

Build Author

Gary Caruso

Views

2727

Build Author

Gary Caruso

Views

2727

OpenPull From CNC Kitchen.. attempt

This project is a Pull tester for material testing or structural testing with stress (force) data logging, I don't have plans for strain logging but that might be down the road.

Hevavy duty 1300mm x 1300mm laser cutter Ceramic tube Servo motors

Starting the next Laser build, Plan to complete within 60 days.

Mark 1

My first attempt at building a CNC style machine. Overall my plan is to use the PlanetCNC breakout board and software to run the machine from a dedicated laptop/tablet.

Build Author

Terone Burgenheim

Views

2654

Build Author

Terone Burgenheim

Views

2654

My CNC

This build is my version of the CBeam machine. I opted to NOT use the Gussets, and instead went for the 40, and 60 mil angle brackets to cut the price back a little further. I started with the smoothieboard but decided it was still "too new" and very much experimental. This build took me a few (2-3) days to complete. The CBeams and Lead-Screws really make building things faster since you don't have to clamor over belts.

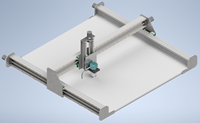

First build - small scale

Using basic standard components, beams, motors, belt drive on x and y, z is a screw. Using Grbl Panel on Windows 10. Really basic router, had trouble getting the controller to turn on the router and set speeds so it is currently wired to a power bar switch so it runs full speed and I just use the switch to turn it on and off. Just getting x, y and z control working properly for now and likely going to switch the router to my dremel 4000 using a 3d printed mounting bracket I got from thingiverse

Build Author

Sprags

Views

2525

Build Author

Sprags

Views

2525

C-Beam Kyo Sphinx 10060

More stuff here.

Gärschrank

A cabinet to keep a constant temperature for pizza or bread mother dough to grow.

Build Author

David E. Flores E.

Views

2515

Build Author

David E. Flores E.

Views

2515

F-Ender-Plus 3D Printer

F-Ender-Plus its based on the Ender 3 Pro, but improved: CR-10 hotend, double gear extruder, double z-axis motor, bltouch incorporated, hotbed leveling improved strings kit. Most made using local vendor parts, and still I'm increasing my knowledge of how get better 3D printings by calibrating motors steps, leveling the hotbed and z-axis; using a 3mm thick glass...

ECNCML (budget mashup)

This build summarizes my CNC milling and laser engraving machine conversion from a dimensional lumber frame and electrical mess to an all aluminum frame with a safe and well constructed (IMHO) control system with the resources I had available.

Ooznest workbee

This is my first build so I will let you know how I get on

Galvos

3d printable galvos

CNC built, work in progress, fail

2x4 cutting area, enclosed with dust collection mainly built out of wood.

WorkBee Saving Lives

Using the WorkBee to protect doctors against Corona virus.

Gluing frame for guitar tops and backs

I have built four of these frames. The first pictured I have been using for maybe a year or two and bought the clamps. The last three I have made I have built my own clamps with openbuild parts. I am still working on the design. At present I use wedges to apply pressure to the side of the wood and block. I am working on a cam system to apply pressure. I just bought 8mm screws with Knobs for quicker adjustment. I will update the build when I make these improvements.

OoozNest WorkBee

A Journey on the WorkBee Build...

Cnc od grinder and thread grinder

This is a totally original build of an od id grinder and thread grinder, I hope.

CBeam Sphinx Upgrade

Simple upgrade of the Y axis on a Cbeam sphinx from 500mm to 1000mm.

C-Beam Machine XL

C-Beam XL upgraded with end-stops, E-stop, and cable chain. Running GRBL on Arduino Mega.

MIT E-Vent | MIT Emergency Ventilator

Ventilator prototype based of OpenBuilds Stock parts

ricks workbee build

i had the ox build and wanted to do a more beeffer style so i went with a workbee style machine ..

Build Author

Bill325

Views

2186

Build Author

Bill325

Views

2186

One more life for a cube

Modify a Gen1 Cube printer into a small cnc router to cut pcbs and light (VERY light) milling work. Also easy to swap out the rotary head and mount a laser head for engraving.

Needle cutter for foamplates

Cutting Depron foam panels by an oscillating needle

ApiNui - CNC Router ( an oversized workbee )

Based on the WorkBee CNC, this is an oversized router built with a specific use-case in mind, for manufacutring beehives, and beehive components

Stinger-Panting Images in the Air

Stinger displays images in the air by using a single column of LEDs. Special computer code converts graphics to pixels; then, the pixels are send to the strings of LEDs, which with the help of of the motor's fast movement the most colorful are displayed on thin air.

Build Author

Jose Alezandre

Views

2053

Build Author

Jose Alezandre

Views

2053

Mighty Chihuahua

The idea was to use materials from previuos failed projects into a succesful one. I have build this tiny but powerfull CNC machine mainly using the universal gantry plates for the X and Y axis. Also another innovative part is the fact that I assembled the Z gantry with 2 aluminum sections of 20X40 and one aluminum seccion of the 20X20. I used NEMA 17 stepper motors with GT2 pulleys. This was designed on Fusion360

26 x 26 x 45 3D Printer/Mill

Super tall 3D printer. All lead screw design.

Open Builds C-Beam K-cup holder

Making use of c-beam I have had left over from projects.

Just Another CNC

I wanted to make my own unit. I enjoy building and was looking for a challenge.

Lead 1510

Customised Lead 1010 making it a 1510. T-Track work area with dual Y limit switches for auto-squaring. Powered by xPro v5 & CNC.js

Ox cnc improvements chain driven

Just ox cnc experiment

Build Author

Daniel Stewart

Views

1891

Build Author

Daniel Stewart

Views

1891

Ultra sun cutter

A sun cutter only using mirror and glass balls with x and y table movement

DRO

Belt drive linear scale for Mill and Lathe

Weeding Delta

A Delta robot for weeding crops using AI and ROS2

Automated Media Blaster

Automated Media blaster retrofit.

Build Author

hbtousa

Views

1426

Build Author

hbtousa

Views

1426

Six_Axis Camera Slider

X is 1000mm, Y is 1500 mm, Z is 1000mm. It Rotates 360 degrees and Tilt also can move 360 degrees. I also have a motor that controls the focus of the camera.

CNC accessory box Made 100 % from recovery materials

Quick construction. A few pieces of wood recovered in the trash can, two hooks one hinge, a few screws and a little glue. [Edit] Added the SVG file for sharing (I forgot it)

Build Author

Alexander_Bulgaria

Views

1075

Build Author

Alexander_Bulgaria

Views

1075

CNC milling machine,lathe,gantry,fdm,clay 3d printer ALL IN ONE

That is the only cnc you will need for most of your diy projects.

Build Author

robert christensen

Views

984

Build Author

robert christensen

Views

984

Tool holder

I saw a video of some one pouring resin in a mold,so i did a little research, i bought some resin,and some molds and magnets all from Amazon, it took me several tries and a big mess but it finally finished. The first pour i poured a small batch to make a templet,i marked all the holes that needed drilling then i marked the underside of the mold where i wanted the magnets, next was making the pcs i needed

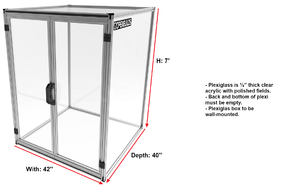

Plexi Panel

Plexi Panel to use for a vfd test enclosure. The box will be wall-mounted on plywood, so the back of the box is not necessary. - The bottom of the box is not necessary because the box will be fixed on concrete on the floor. On the door, I was thinking of putting 4 brackets instead of two. We'll have two 21” doors

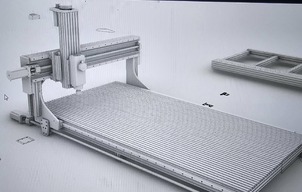

TFE2 CNC Build

My TFE2 CNC Build. The TFE was much smaller and all of the gantry plates were 3D printed. Despite this it will happily machine aluminium without issue. So I decided to use that to make the TFE2 which will be all aluminium plates and much larger (1200x800mm machining area with roughly 140mm in Z so I can later add a rotary axis.)