Build List

-

Active Filters:

cnc

OX

My build of the OX kit from SMW3D.com

My CnC Router, custom DIY not open builds parts

Most of the way through the build, hopefully soon I will have it running

Wakezor

I'm starting my first own build cnc machine which is inspired by routy and the ox. Were my goal was not to use the ox plates but use the standard plates available in the parts store for the design.

Build Author

zann68

Views

8680

Build Author

zann68

Views

8680

OX CNC 4'x4'

Out with the Old in with the New. Trying to build a nice clean setup that myself and my sons can use and enjoy.

Build Author

Gary Bonard

Views

5979

Build Author

Gary Bonard

Views

5979

OxZilla

This is my second Ox with a working area of 14" x 14" x 5" I wanted to build a small sturdy potable CNC router and this OxZilla has the nice upgrades !

Build Author

mirage335

Views

7211

Build Author

mirage335

Views

7211

TazStiff

Portable, high-speed, low-cost advanced multi-tool desktop factory derived from LulzBot Taz and TazMega.

Build Author

Julius

Views

8016

Build Author

Julius

Views

8016

The "Hand" CNC (or OXCarve)

more to come, please follow along the journey!

1500 x 1500 mm OpenBuild CNC

1500 x 1500 mm OpenBuild CNC

Ooznest build - 1500mm x 1000mm

Its the first build for me so its just the story of me attempting to build the kit and hopefully end up with something I can use. Hopefully without destroying anything or anyone.

Build Author

Builder+Bob

Views

3617

Build Author

Builder+Bob

Views

3617

Portable C-Beam

C-Beam Plate maker for My OX!

Ooznest OX CNC for Architecture Modell

While i achieved the desired taler Z axis this was very notable of the cost of the stiffness of the Y axis - the Y axis is now quite wobbly. i do not recommend such a big Z axis on a OX CNC machine where the requirement is a good precision.

Kruk 0.1

This is a stool, designed in 18mm wood for a cnc router, it's easily scaleable to different wood-thicknesses, in 18mm wood it takes up 1200*1200mm. It can be assembled without screws, nails or glue and can therefore also be easily disassembled.

Build Author

Ken376

Views

3580

Build Author

Ken376

Views

3580

Welded project cnc first try

Kind of hard to see in this pic now lining up drive s and finishing framework

Build Author

Linkreincarnate

Views

2978

Build Author

Linkreincarnate

Views

2978

Amazon Special

I have parts that are apparently not suited to a cnc router or a 3d printer. I am still trying to figure out what to make out of what I have,

Gizmo CNC

wanted large work area for laser etch/cuts more than spindle work.

A work in progress

One of my first projects might be cutting proper plates.

CNC PKB2

blueprints here: https://github.com/tomaspavlica/cnc_pkb2

CNC 1000x1000mm C-beam

inspired by http://openbuilds.org/builds/c-beam-sphinx.3605/

Build Author

JerryD

Views

5180

Build Author

JerryD

Views

5180

1500x1000mm Adjustable Height

I have the demand to cut/etch tall pieces of material. For this reason, I have designed a machine with 500mm uprights with adjustable gantry height. This way I can raise/lower the sled and z-axis as needed. I've also chosen to use a linear C-channel assembly for the Z axis with the plate mounted to the gantry instead of the other way around. This will allow for maximum range of the z-axis. The parts list/BOM does not include motors/belts/pulleys or electronics.

Strong? CNC

The goal is to have a relatively strong CNC to be able to cut alu. Working space will be around 800x350x100mm.

C beam Larger and Stronger

My first build based on the original C beam Sphinx. I’m not sure at this point what the final size will be. I have the parts from the c beam Sphinx and extra beams and lead screws to build up to 1000mm x 1000mm.

LaserShark300

300x300 belt drive laser etching/cutting platform. The design was borrowed from another's blog and customized to fit materials on-hand. Was a very fun project to assemble.

Build Author

joetemus

Views

6500

Build Author

joetemus

Views

6500

Shapeoko 2 Z-Axis Upgrade

This is a major redesign to the Z-axis of an otherwise stock Shapeoko 2.

Cnc mill, Plasma cutting and weld table

A functional table for plasma cutting, welding, tooling........

Build Author

Darren Dickson

Views

4125

Build Author

Darren Dickson

Views

4125

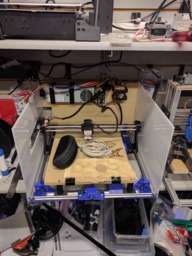

3D printed CNC Machine

So I thought I would make the Leon van den Beukel version three 3D printed CNC Machine, it is the third incarnation so you would expect a relatively bug-free CNC Machine with a strong foundation.

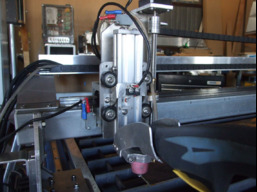

Plasma CNC machine

The plasma CNC that I have built has a water table that measures 1350mm x 650mm. The water is flooded onto the cut area while cutting and recycled around with a pump. This is to reduce smoke, cool the metal being cut to reduce distortion and also to keep sparks to a minimum. Most of the machine has been made from aluminium , the frame and table from steel, the water table, stainless steel.

Build Author

Tristen Poliseno

Views

3861

Build Author

Tristen Poliseno

Views

3861

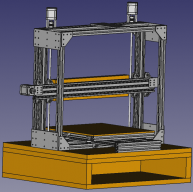

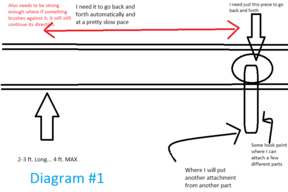

Back and forth rail mechanism

I have the whole description and all the details in the "Body" section!

Build Author

theracermark

Views

3825

Build Author

theracermark

Views

3825

Reviving the Origonal PhlatPrinter with BlackBox

Reworked PhlatPrinter Gen1 Adding dual nema 17s to all 3 axis Supprot for carriage to insure even dept cuts Lighting for view of cutting area

Lead 1510

Customised Lead 1010 making it a 1510. T-Track work area with dual Y limit switches for auto-squaring. Powered by xPro v5 & CNC.js

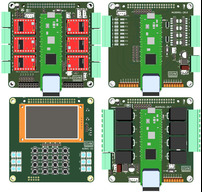

M10CUBE PICO CNC. A Universal Controller

An attempt is to be a Unified Modular Controller based on M10CUBE platform. For GRBLHAL and MARLINHAL applications. HAL porting is under way 1 - WIZnet Pico Clone W5100S-EVB-Pico 2 v- 6 X StepStick. Not sure about the sixth driver, (Pico pins limitation) . External connectors for larger drivers 3 - Opto - isolated spindle PWM. 4 - HMI 5 - I/O on diferent modules and Ethernet 10MBPS communication. Patches will be written to GRBLHAL for Ethernet I/Os (Interrupted).

CNC built, work in progress, fail

2x4 cutting area, enclosed with dust collection mainly built out of wood.

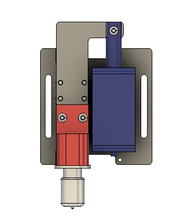

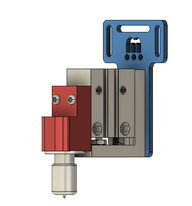

CNC Cutter Knife

CNC knife cutter with loline blades

Pneumatic cnc cutter with festo drive

CNC Glass cutter

Small Desktop CNC Router/Mill

I designed and made this from scratch. The frame is welded steel filled with sand, and most of the other parts are aluminium. It's controlled with a DIY ESP32 controller running GRBL_ESP32

Build Author

Alexander_Bulgaria

Views

1071

Build Author

Alexander_Bulgaria

Views

1071

CNC milling machine,lathe,gantry,fdm,clay 3d printer ALL IN ONE

That is the only cnc you will need for most of your diy projects.