Build List

-

Active Filters:

h

Build Author

David Hartkop

Views

2966

Build Author

David Hartkop

Views

2966

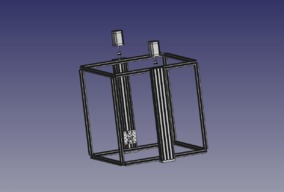

Humanitarian Medical Instrument Sterilizer Made from RepRap Parts

Instructions to build an open-source off-grid medical instrument sterilizer that can be used by aid workers in places without reliable electrical power

SharkBits Holder

Get organized with the SharkBits Holder!

2 Axis Lathe cutter

Rubber company use as a lathe cutter for accurate cuts compared to hand cutting.

Printer number 2

A Large Printer that will hopefully be able to print at least 45cm cubed

Build Author

Gary Caruso

Views

2911

Build Author

Gary Caruso

Views

2911

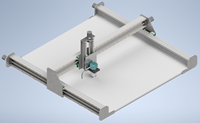

OpenPull From CNC Kitchen.. attempt

This project is a Pull tester for material testing or structural testing with stress (force) data logging, I don't have plans for strain logging but that might be down the road.

Build Author

mjenkins5720

Views

2861

Build Author

mjenkins5720

Views

2861

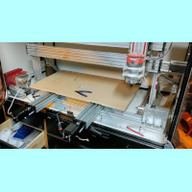

Modified LEAD machine

At the moment this build is in progress, I will be updating the files as I finish the remainder of the machine. This machine is intended to be a multipurpose CNC, but a bit bigger than a desktop unit. The machine is scalable in the X and Y axis.

Y table for LEAD Lathe - essentially a High Z Cbeam XL

I built the lathe as a dedicated rotary axis, but I soon realized I could have a back up CNC for very little expense.

first CNC build

It start out to be an upgrade of a CNC 3018-PRO but ended up being a full build

Build Author

Terone Burgenheim

Views

2742

Build Author

Terone Burgenheim

Views

2742

My CNC

This build is my version of the CBeam machine. I opted to NOT use the Gussets, and instead went for the 40, and 60 mil angle brackets to cut the price back a little further. I started with the smoothieboard but decided it was still "too new" and very much experimental. This build took me a few (2-3) days to complete. The CBeams and Lead-Screws really make building things faster since you don't have to clamor over belts.

Custom push cart for CNC machines

I’m custom building a push table / cart for my cnc machines mostly out things I already had in my garage. Using a gray push utility cart as the main body and building around that.

PhlatMDF48

Building a Phlat based CNC for MDF processing. Capacity of 48" x unlimited length.

Gärschrank

A cabinet to keep a constant temperature for pizza or bread mother dough to grow.

Build Author

Sprags

Views

2654

Build Author

Sprags

Views

2654

C-Beam Kyo Sphinx 10060

More stuff here.

Just Another CNC

I wanted to make my own unit. I enjoy building and was looking for a challenge.

ECNCML (budget mashup)

This build summarizes my CNC milling and laser engraving machine conversion from a dimensional lumber frame and electrical mess to an all aluminum frame with a safe and well constructed (IMHO) control system with the resources I had available.

WorkBee Saving Lives

Using the WorkBee to protect doctors against Corona virus.

Ooznest workbee

This is my first build so I will let you know how I get on

Gluing frame for guitar tops and backs

I have built four of these frames. The first pictured I have been using for maybe a year or two and bought the clamps. The last three I have made I have built my own clamps with openbuild parts. I am still working on the design. At present I use wedges to apply pressure to the side of the wood and block. I am working on a cam system to apply pressure. I just bought 8mm screws with Knobs for quicker adjustment. I will update the build when I make these improvements.

Cnc od grinder and thread grinder

This is a totally original build of an od id grinder and thread grinder, I hope.

CBeam Sphinx Upgrade

Simple upgrade of the Y axis on a Cbeam sphinx from 500mm to 1000mm.

ricks workbee build

i had the ox build and wanted to do a more beeffer style so i went with a workbee style machine ..

ApiNui - CNC Router ( an oversized workbee )

Based on the WorkBee CNC, this is an oversized router built with a specific use-case in mind, for manufacutring beehives, and beehive components

GHOST Case by Copper Pour

GHOST Case build for the OpenBuilds Black Box Motion Control System

Build Author

Jose Alezandre

Views

2136

Build Author

Jose Alezandre

Views

2136

Mighty Chihuahua

The idea was to use materials from previuos failed projects into a succesful one. I have build this tiny but powerfull CNC machine mainly using the universal gantry plates for the X and Y axis. Also another innovative part is the fact that I assembled the Z gantry with 2 aluminum sections of 20X40 and one aluminum seccion of the 20X20. I used NEMA 17 stepper motors with GT2 pulleys. This was designed on Fusion360

My Little Mashup

A mixed drive, PI Controlled machine

Open Builds C-Beam K-cup holder

Making use of c-beam I have had left over from projects.

Ox cnc improvements chain driven

Just ox cnc experiment

Build Author

Daniel Stewart

Views

1977

Build Author

Daniel Stewart

Views

1977

Ultra sun cutter

A sun cutter only using mirror and glass balls with x and y table movement

DRO

Belt drive linear scale for Mill and Lathe

Build Author

Johnny Reich

Views

1942

Build Author

Johnny Reich

Views

1942

ProLight 1000 Mill Retrofit

Update a 20-year old bench top milling machine with OpenBuild Ecosystem electronics.

Build Author

hbtousa

Views

1903

Build Author

hbtousa

Views

1903

Six_Axis Camera Slider

X is 1000mm, Y is 1500 mm, Z is 1000mm. It Rotates 360 degrees and Tilt also can move 360 degrees. I also have a motor that controls the focus of the camera.

Taller couch legs

A simple but elegent couch legs

Build Author

Alexander_Bulgaria

Views

1463

Build Author

Alexander_Bulgaria

Views

1463

CNC milling machine,lathe,gantry,fdm,clay 3d printer ALL IN ONE

That is the only cnc you will need for most of your diy projects.

Build Author

robert christensen

Views

1352

Build Author

robert christensen

Views

1352

Tool holder

I saw a video of some one pouring resin in a mold,so i did a little research, i bought some resin,and some molds and magnets all from Amazon, it took me several tries and a big mess but it finally finished. The first pour i poured a small batch to make a templet,i marked all the holes that needed drilling then i marked the underside of the mold where i wanted the magnets, next was making the pcs i needed

Reducing leadscrew whip

The video demonstrates a practical device to reduce whip