Build List

-

Active Filters:

at

Build Author

Rodrigo Gonzalez

Views

3568

Build Author

Rodrigo Gonzalez

Views

3568

Nightfuel

The user will input a selection from a variety of pre-established drinks. The user will not need a glass, since it will be provided in the automation process. This completely eliminates the need for a bartender if an RFID purchase system is implemented.

Build Author

Calotype

Views

3562

Build Author

Calotype

Views

3562

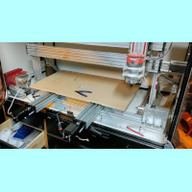

My DIY panoramic rolling (&banding) Machine.

DO WHAT YOU IMAGINE !

Build Author

bpatterson42

Views

3523

Build Author

bpatterson42

Views

3523

Inverted Y C-Beam Machine

Similar to C-Beam Machine build, but with inverted Y-axis assembly to shield drive screw. Integrated XZ gantry can be fixed to any solid surface. Build dimensions are 36" x 36" x 6".

Phlat Printer 3 meets Open Builds

I will go over the attachments for the PP3 Z axis. soon. Before any thing else .You need to know the first PP3 ,used SKP 7 and Mach 3. Later on they used CNC USB.

Design and Performance Evaluation of A Large FDM 3D Printer

This build includes the design of a large FDM 3D printer. This machine has a 796mm by 796mm by 900mm (LxWxH) build volume. Motion is controlled by servo motors and the printer runs on python-based marlin firmware.

Build Author

Stan Howe

Views

3282

Build Author

Stan Howe

Views

3282

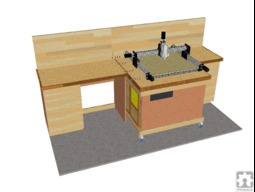

Bee the Boss

The frame of the CNC is going to to Bee a basic Work Bee with maybe 1 modification to the spoil board attachment. This will be located on a custom bench housing the electronics and vacuum. I plan to install Stepper online steppers, drivers, power supplies, and break out board. I will add a 1.5 KW water cooled spindle, with a radiator. The fans from the radiator will pull air from a filtered enclosure for all the electronics.

Build Author

Genetoys

Views

3278

Build Author

Genetoys

Views

3278

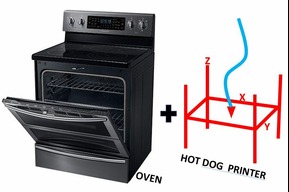

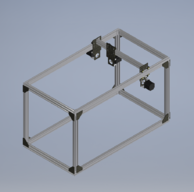

Oven Dog

Building a printer that can fit inside and operate at ~200 C oven temperatures

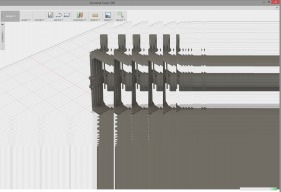

Epoxy dispenser, to apply non-conductive epoxy to electronic board.

Epoxy dispenser, 2nd one, first one works great. Uses HMI to allow for operator to pull up files for different jobs. 9 prox sensors, Eot and home on all 3 axis. High quality nema23 motors with intergrated drives from applied motion. Uses programmable router for drives.

Build Author

Anthony Castelluci

Views

3203

Build Author

Anthony Castelluci

Views

3203

Simple Camera Lofted Camera Slider

Build a manual camera slider.

Build Author

Sir Bagels

Views

3082

Build Author

Sir Bagels

Views

3082

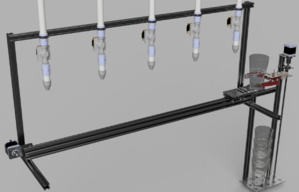

CNC Auto-pipette

Senior Design Project Bennett Robertson, Megan England University of Iowa College of Engineering

THE BIG GREEN MACHINE

1500*1500*1900 (xyz) Biocomposite Pellet 3D printer

2 Axis Lathe cutter

Rubber company use as a lathe cutter for accurate cuts compared to hand cutting.

Y table for LEAD Lathe - essentially a High Z Cbeam XL

I built the lathe as a dedicated rotary axis, but I soon realized I could have a back up CNC for very little expense.

C-Beam Elexa

This build will be based on the C-Beam Plate Maker, with additional changes based on other builds and ideas.

PhlatMDF48

Building a Phlat based CNC for MDF processing. Capacity of 48" x unlimited length.

Gärschrank

A cabinet to keep a constant temperature for pizza or bread mother dough to grow.

NotAnOx

From plywood and linear rail to c-beam. I probably should have bought a kit.

Build Author

Sprags

Views

2704

Build Author

Sprags

Views

2704

C-Beam Kyo Sphinx 10060

More stuff here.

WorkBee Saving Lives

Using the WorkBee to protect doctors against Corona virus.

MIT E-Vent | MIT Emergency Ventilator

Ventilator prototype based of OpenBuilds Stock parts

ApiNui - CNC Router ( an oversized workbee )

Based on the WorkBee CNC, this is an oversized router built with a specific use-case in mind, for manufacutring beehives, and beehive components

Build Author

Jose Alezandre

Views

2173

Build Author

Jose Alezandre

Views

2173

Mighty Chihuahua

The idea was to use materials from previuos failed projects into a succesful one. I have build this tiny but powerfull CNC machine mainly using the universal gantry plates for the X and Y axis. Also another innovative part is the fact that I assembled the Z gantry with 2 aluminum sections of 20X40 and one aluminum seccion of the 20X20. I used NEMA 17 stepper motors with GT2 pulleys. This was designed on Fusion360

My Little Mashup

A mixed drive, PI Controlled machine

Build Author

hbtousa

Views

2131

Build Author

hbtousa

Views

2131

Six_Axis Camera Slider

X is 1000mm, Y is 1500 mm, Z is 1000mm. It Rotates 360 degrees and Tilt also can move 360 degrees. I also have a motor that controls the focus of the camera.

Everything Else

Hi my name is crispin and I'm an aluminum addict.

DRO

Belt drive linear scale for Mill and Lathe

Build Author

Alexander_Bulgaria

Views

1593

Build Author

Alexander_Bulgaria

Views

1593

CNC milling machine,lathe,gantry,fdm,clay 3d printer ALL IN ONE

That is the only cnc you will need for most of your diy projects.

Build Author

robert christensen

Views

1428

Build Author

robert christensen

Views

1428

Tool holder

I saw a video of some one pouring resin in a mold,so i did a little research, i bought some resin,and some molds and magnets all from Amazon, it took me several tries and a big mess but it finally finished. The first pour i poured a small batch to make a templet,i marked all the holes that needed drilling then i marked the underside of the mold where i wanted the magnets, next was making the pcs i needed

Workbee 1010 et laser atomstack M100

Je ne sais pas comment brancher mon laser sur la blackbox?