Build List

-

Active Filters:

wood

Build Author

Mark Carew

Views

84420

Build Author

Mark Carew

Views

84420

OpenBuilds Workbee 1510 (60" x 40")

The OpenBuilds WorkBee 1510 - 1500x1000 Belt Driven CNC Machine

Build Author

Mark Carew

Views

76925

Build Author

Mark Carew

Views

76925

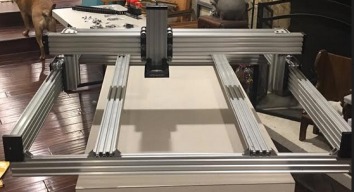

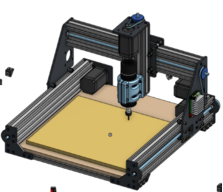

OpenBuilds Workbee 1010 (40" x 40")

The OpenBuilds WorkBee 1010 - 1000x1000 Lead Screw Driven CNC Machine

Build Author

Mark Carew

Views

54254

Build Author

Mark Carew

Views

54254

OpenBuilds Sphinx 55 (20" x 20")

The OpenBuilds Sphinx 55 - 500x500 Lead Screw Machine

Build Author

Mark Carew

Views

33415

Build Author

Mark Carew

Views

33415

OpenBuilds Sphinx 1050 (20" x 40")

The OpenBuilds Sphinx 1050 - 500x1000 Lead Screw Machine

Build Author

Mark Carew

Views

27743

Build Author

Mark Carew

Views

27743

OpenBuilds Workbee 1050 (40" x 20")

The OpenBuilds WorkBee 1050 - 1000x500 Lead Screw Driven CNC Machine

Build Author

viktop

Views

18296

Build Author

viktop

Views

18296

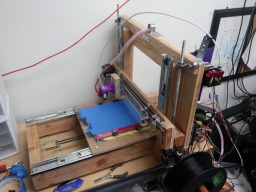

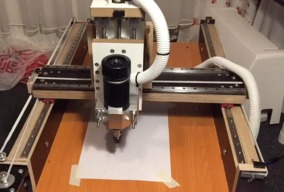

Simple CNC Router (Nema17, V-slot 2040, Arduino, GRBL)

An OX-inspired mini desktop mill.

Build Author

Kims3DIY

Views

18096

Build Author

Kims3DIY

Views

18096

Beamlazer Laser cutter CO2 100W

Hi everyone, im new to the world of lasercutters but i have been granted access for a Trotec laser for a while with old firmware and only compability trought Windows XP. Then i decided to build my own laser, with some easier workflow and support for Windows 10. Since im still a student i have limited resources, so i will try too use scrap parts as much as possible. I will publish photos and updates during my build continously. Gladly taking advices from others.

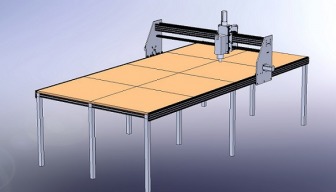

3000x1500 CNC

Here is my Project A CNC 3000 mm by 1500 mm, with a 2.2kW spindle collet ER25 and 4 stepper motor nema 23 425oz-in. The purpose being to have a large work surface for a minimum cost.

Custom 4x4 CNC

I started designing and ordering parts for this build back in Oct 2021. Unfortunately life got in the way and I had to sideline the project to deal with more important projects. I am now back working on this project full time. I originally was building a MPCNC on this torsion box platform I built but quickly realized how difficult it would be to produce anything with good accuracy. So I decided to design my own CNC that would be more robust and accurate.

Build Author

C-CNC

Views

15824

Build Author

C-CNC

Views

15824

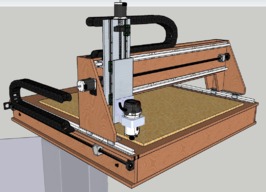

Gantry Style CNC from plywood

I am currently 15 years old, from Germany and trying to build a low budged CNC router. I only designed this CNC based on other CNC routers that I have seen and what I am able of. It consists mostly of 2.3cm plywood to keep costs down. The size of the work area is approx. 40 x 80 cm. I would be really glad if you could give me advice's for improvement on the design and everything else ... ( I could really need your help :) ) enjoy :)

Build Author

Eric Jacobsson

Views

15221

Build Author

Eric Jacobsson

Views

15221

The Floating Dust Shoe

I wanted a dust shoe that have a easy access to tool change and something that kind of float on the surface. And I have seen shoes with long brush that sucked in by the vacuum. I think I have the solution too all that here.

Build Author

Project Hopeless

Views

14298

Build Author

Project Hopeless

Views

14298

Plywood Built CNC Router

This is my first build attempt, a large form (4x4ft.) 3 axis 4-motor CNC router table, . The build components are Baltic birch plywood, stepper motors, SBR linear bearings, and ball screws, LinuxCNC, Mesa controller.

Adjustable Router Guide Template

This project is an adjustable router guide template made with 20x60 V-slot. It was meant as a less expensive and more user friendly alternative to commercially available units.

Build Author

JP Warnke

Views

12715

Build Author

JP Warnke

Views

12715

Warnke CNC Router

A blend of modular aluminum and steel bracketry built to yield fine cuts in hardwood and aluminum. An open table with a shiftable pin-fixture concept will allow the operator to shift longer than Y-travel work-pieces, such as doors, along the Y-axis of the table. This machine has a 44" (X) by 24" (Y) by 8" (Z) travel with water cooled VFD spindle motor, t-slot ext work table, cable carriers, side guards n dual y drives. Total weight (w/base-stand) is about 600lbs.

Roberta Clementine

The Roberta Clementine a proof of concept and progenitor to the series of printers I will be calling the Clementine Sisters. The printer is named after Pittsburgh Pirates baseball player Roberto Clemente. Although it is more accurate to say the printer is named after the school I work for which is named after Clemente the Roberto Clemente Charter School. http://www.myrccs.com Roberta is the first and not really built to last but instead built to test ideas and to produce the parts for successors

Build Author

Mohsen Abbasi

Views

8279

Build Author

Mohsen Abbasi

Views

8279

Portable Foam Cutter

A portable foam cutter to make your forms everyware using a LiPo Battery.

Build Author

Julius

Views

8131

Build Author

Julius

Views

8131

The "Hand" CNC (or OXCarve)

more to come, please follow along the journey!

Build Author

OffAxis

Views

7620

Build Author

OffAxis

Views

7620

OffAxis CNC 1000x1500

Cut Area: 825 x 1340. Max Cutting depth: 2 inches. Arduino based control with Nema 23 and Nema 17 drive. 8mm leadscrew and 2GT belt drive. 400W 48V quite cut spindle.

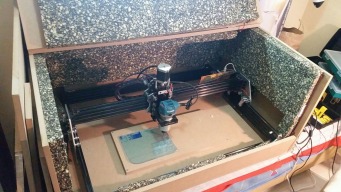

Soundproof case for Ox

Not much to say... Soundproofing box for noisy works... Build in MDF and 20 mm plexiglas. Very effective!!!

Build Author

Fabio Orsi

Views

6879

Build Author

Fabio Orsi

Views

6879

147 RepStrap 002

This project is focused on developing a low-cost, portable and open-source FDM 3D Printer.

Build Author

Stokrotka74

Views

6818

Build Author

Stokrotka74

Views

6818

Racoon CNC

This is a Sphinx variation, aimed to minimize footprint and maximize workarea. Work in progress.

1000mm X 1000mm with tinyg

1000mm X 1000mm overhead cnc machine

Build Author

TurfnSurf

Views

6156

Build Author

TurfnSurf

Views

6156

3-Axis Plywood CNC

Theoretical Working area: 38" x 24" x 6" Actual Working Area: 31" x 23.6" x 4" Positioning Accuracy: about 0.01mm

My 3D Printer

A DIY 3D printer. At beginning made from aluminium profiles, aluminium sheet and wood :)

CNC Lathe Upgrade

So, not much here, as I'm still building, but I'm putting in the work.

EOX

Open builds style wood CNC router. Usable work aria 1000mm x 1250mm x 150MM (X x Y x Z). 80x40 C bleam for the Y axis , two 60x20 beams for X axis and a 60x20 fo Z. Interlocking GT3 belts for X and Y. Looking to change over to a rack and pinion system in the future. 8x8Tr Lead screw for the Z. Leadshine HBS507 close loop drivers and 3-phase servo motor 573HBM20-EC-1000 motors driving the Y and X axis. Would recommend them to anyone looking for servo like performance at a affordable price.

LimpyCNC

Inpired by the OpenBuilds OX and PrintrBot Crawlbot. This is the LimpyCNC. It's still a work-in-progress. But it provides a 120x120cm work space without using up 150x150cm of garage space.

Build Author

Craig Hollabaugh

Views

4791

Build Author

Craig Hollabaugh

Views

4791

Hyatt and My Journey to Tonehenge

I'm conducing guitar loudspeaker cabinet fabrication technique research (material type/thickness, mechanical joints, adhesives, etc) and how these relate to cabinet/speaker coupling and enclosure resonance with respect to psycho-acoustics. Basically, does one speaker cab sound better than another and why?

Build Author

RSch

Views

4730

Build Author

RSch

Views

4730

Scroll-saw Spiral Cutter

Attached to a scroll saw you can cut nested wooden spirals with this jig. Make two, three, four ... interlocking spirals that unwind/unscrew. Fascinating toys or art objects!

Build Author

islahcnc

Views

4400

Build Author

islahcnc

Views

4400

islahcnc&design

I will post soon some more details.

Build Author

Jones

Views

3908

Build Author

Jones

Views

3908

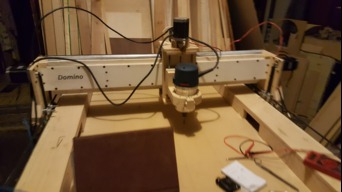

The Domino - 1.5m x 1m

DIY scratch build consisting of gas pipe, skate bearings, 12mm birch, 3/4 maple v-core ply, Nema 23's, and arduino and CNC shield with DRV8825's.

Kruk 0.1

This is a stool, designed in 18mm wood for a cnc router, it's easily scaleable to different wood-thicknesses, in 18mm wood it takes up 1200*1200mm. It can be assembled without screws, nails or glue and can therefore also be easily disassembled.

My new wood mill

First and foremost, I want to create accurate parts for my model aircraft. In second line I am interested in the control and electronics of the milling machine. If you are interested in drawings and the parts list, feel free to contact me.

CNC built, work in progress, fail

2x4 cutting area, enclosed with dust collection mainly built out of wood.

Gluing frame for guitar tops and backs

I have built four of these frames. The first pictured I have been using for maybe a year or two and bought the clamps. The last three I have made I have built my own clamps with openbuild parts. I am still working on the design. At present I use wedges to apply pressure to the side of the wood and block. I am working on a cam system to apply pressure. I just bought 8mm screws with Knobs for quicker adjustment. I will update the build when I make these improvements.

CNC accessory box Made 100 % from recovery materials

Quick construction. A few pieces of wood recovered in the trash can, two hooks one hinge, a few screws and a little glue. [Edit] Added the SVG file for sharing (I forgot it)