Build List

-

Active Filters:

5

Build Author

ZacharyB

Views

5752

Build Author

ZacharyB

Views

5752

Arizona OpenBuilds MiniMill CNC

I ordered the OpenBuilds MiniMill from the OpenBuilds Parts Store http://openbuildspartstore.com/ They were out of Motors and Electronics when I ordered so I had to source these items elsewhere. But it turned out well doing it this way.

Build Author

jeff johnson

Views

5751

Build Author

jeff johnson

Views

5751

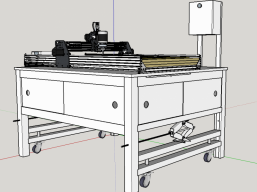

workbee 1510

Getting more height out of the !510

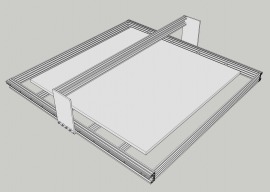

C-Beam Router, 48"x48"

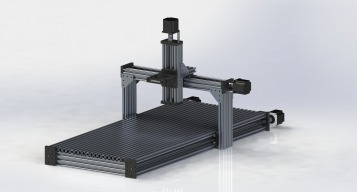

C-Beam Router using 1500mm lengths, 48x48" build area, and rack and pinion movement.

1515 Deluxe

Build features include a double c-beam gantry (bonded & mechanically fastened), linear x rails, custom gantry end plates, a custom linear rail & ballscrew Z axis, and custom lead screw tensioning plates. The primary goal was to remove twist from the 1500mm gantry & stiffen the Z axis.

SUPER OX NEMA 34 1600 OZ Motors!!!

CNC OX 1500X3000

Build Author

Ted Moyer

Views

5519

Build Author

Ted Moyer

Views

5519

LEAD 1515 HIGH Z MOD 4KW ER20 7.5 KW VFD

OLD Lead 1010 High Z Mod converted to Newest Lead 1515 with High Z mod, slimmer cbeam motor mounts, thrust bearings etc. Extended by original table out and upgraded my 1.5kw VFD and Spindle to 4kw ER20 Spindle and 7.5kw GT VFD

Little Big OX

A complete CNC newbie is tackling a mighty challenge, Not only is he making a CNC router, He's going to try and upsize it.

Build Author

JerryD

Views

5329

Build Author

JerryD

Views

5329

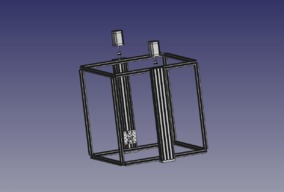

1500x1000mm Adjustable Height

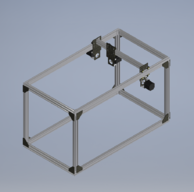

I have the demand to cut/etch tall pieces of material. For this reason, I have designed a machine with 500mm uprights with adjustable gantry height. This way I can raise/lower the sled and z-axis as needed. I've also chosen to use a linear C-channel assembly for the Z axis with the plate mounted to the gantry instead of the other way around. This will allow for maximum range of the z-axis. The parts list/BOM does not include motors/belts/pulleys or electronics.

Phil's Workbee

Wanted a nice project to work and learn on... now have a big CNC to play with A 1500x1000mm Workbee

Build Author

SCYBUCK

Views

5123

Build Author

SCYBUCK

Views

5123

KYO SPHINX a la' SCYBUCK

KYO SPHINX, CENTROID ACORN, GECKO 540, HALL EFFECT LIMIT SWITCHES, 2.2 KW, 24,000 RPM SPINDLE, WATER COOLED, 600 oz-in STEPPERS, INTENDED TO CUT ALUMINUM.

Build Author

TouchPadKing

Views

5096

Build Author

TouchPadKing

Views

5096

1500mmx500mm Kossel Delta

Please, look over my build and make any recommendations you can think of! I haven't figured out how long my arms need to be yet. Nor have I done any shopping around to find better prices...

Build Author

Rob Withoff

Views

5084

Build Author

Rob Withoff

Views

5084

Mini-Mill Enhanced

Some enhancements of the basic mini-mill

Build Author

Corey Corbin

Views

5081

Build Author

Corey Corbin

Views

5081

Sphinx Derived Router

I Like the Sphinx design thought I would attempt my first build. I wanted to build this and use Arduino controller with GRBL to be able to learn and understand my machine.

Build Author

BCulbertson

Views

4966

Build Author

BCulbertson

Views

4966

Lead 1515 with Upgrades

My upgraded OpenBuilds Lead 1515

Build Author

Skoobs

Views

4937

Build Author

Skoobs

Views

4937

Pretty Standard + Slave X Axis

Planning my build, just looking for design input at the moment. I definitely want a slave X axis. I am potentially going to go with one of the 1500W Chinese water cooled spindles.

Build Author

Craig Hollabaugh

Views

4855

Build Author

Craig Hollabaugh

Views

4855

Hyatt and My Journey to Tonehenge

I'm conducing guitar loudspeaker cabinet fabrication technique research (material type/thickness, mechanical joints, adhesives, etc) and how these relate to cabinet/speaker coupling and enclosure resonance with respect to psycho-acoustics. Basically, does one speaker cab sound better than another and why?

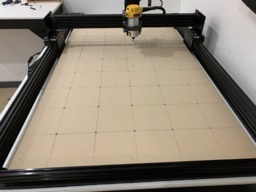

WorkBee 1510 - First CNC Build

This build will go through the construction of a WorkBee 1510 kit from the OpenBuilds Part Store, all mechanical and electrical components were purchased from the store in late October 2018.

1075 Sphinx

My first attempt at building a CNC. I chose the Sphinx due to ease of build and extensive documentation provided by Kyo.

Brice's CNC Router Build

I'm building a CNC router for a long time. Here's the result on this long journee. I tried to do my best with the basic tools I have. Don't hesitate to ask if you have questions.

Build Author

Suhmanda

Views

4263

Build Author

Suhmanda

Views

4263

DIY CNC SPINDLE

CNC SPINDLE FOR DIY ROUTERS AND MILLING MACHINES ITSRS-985 MOTOR HAS MUCH BEFINITS THAN ANY OTHER DC MOTOR IN MARKET

75x75

Simple cnc with 5mm steel plates.

Build Author

crnrstndes

Views

4213

Build Author

crnrstndes

Views

4213

C-Beam Upgrade to Larger C-Beam

My goal was to be able to enlarge my C-Beam with as many original parts as possible. I was able to recycle almost all of them with a only the two 500 mm rails left over. I used 1000 mm rails for the X Axis and I added another complete Y Axis assembly. I chose to keep it simple and I am very happy with the result!

Build Author

rob4cnc

Views

4013

Build Author

rob4cnc

Views

4013

Rock n Roll

The Rock n Roll is built on granite, is solid as a rock, and gathers no moss. This build provides a high degree of accuracy and repeatability. Built to be strong, use redundancy, and use long lever arms to average out imperfections in the equipment. Built to go fast and light. We will use a high speed spindle, large high voltage stepper motors and small cutting heads to overwhelm the forces produced at the cutting head.

Build Author

McAdam

Views

3729

Build Author

McAdam

Views

3729

Need a catchy name - enlarging CNC

The aim of this build is to have a CNC that can cut a FULL sheet of wood when I need it to, but also shrink down and cut smaller sheets the rest of the time. The prototype is based on an OX cnc but soon it will be completely custom using Openbuilds Parts

My 5' by 5'

I have constructed frame out of 1 1/2" square tubing. Have my Y aces mounted. and awaiting parts.

My Workbee build

Workbee, 1000mmX750mm , from China

Lead 1515 tilting table and vertical table accessory

I wanted a CNC machine that was able to do dovetails and other box joints. I also wanted to have it be able to tilt so it would take up less space when I was working on other projects.

Build Author

David E. Flores E.

Views

3330

Build Author

David E. Flores E.

Views

3330

F-Ender-Plus 3D Printer

F-Ender-Plus its based on the Ender 3 Pro, but improved: CR-10 hotend, double gear extruder, double z-axis motor, bltouch incorporated, hotbed leveling improved strings kit. Most made using local vendor parts, and still I'm increasing my knowledge of how get better 3D printings by calibrating motors steps, leveling the hotbed and z-axis; using a 3mm thick glass...

Build Author

Neil Scott

Views

3241

Build Author

Neil Scott

Views

3241

Barcelona Build

This will be my second CNC build but this time a proper CNC not a small desktop model that I played with for a while to learn Gcode, It was great but now its time to start playing with the big boys and girls.

Build Author

Sir Bagels

Views

3110

Build Author

Sir Bagels

Views

3110

CNC Auto-pipette

Senior Design Project Bennett Robertson, Megan England University of Iowa College of Engineering

Printer number 2

A Large Printer that will hopefully be able to print at least 45cm cubed

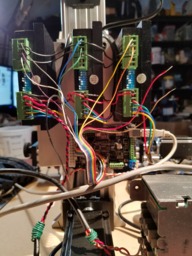

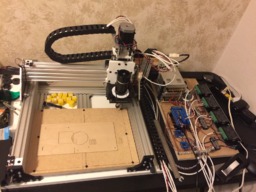

ECNCML (budget mashup)

This build summarizes my CNC milling and laser engraving machine conversion from a dimensional lumber frame and electrical mess to an all aluminum frame with a safe and well constructed (IMHO) control system with the resources I had available.

Lead 1510

Customised Lead 1010 making it a 1510. T-Track work area with dual Y limit switches for auto-squaring. Powered by xPro v5 & CNC.js