Build List

-

Active Filters:

build

Build Author

Bikes and Beer

Views

4791

Build Author

Bikes and Beer

Views

4791

The Forever Project

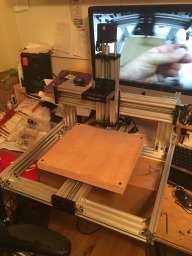

Workbee 1010 Lead Screw with water cooled spindle and enclosure

Build Author

Robert J Rissell

Views

4750

Build Author

Robert J Rissell

Views

4750

Remix of Sage's Delta-Six

I'm looking to build a large build-volume, accurate, steady 3D printer with the eventual aim of swapping in a diode laser to allow for use as a cutter for printing/cutting parts out of balsa sheet for building model aircraft.

Build Author

cory stafford

Views

4725

Build Author

cory stafford

Views

4725

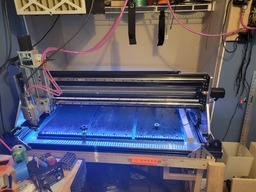

Home built laser cutter

This is a laser cutter built with intent to use arduino as controller for a co2 cutting laser.

My first CNC - The C-Beam Basic

I am a newbie and this is my first build. After hours and hours of research I decided on the C-Beam. I will be changing one or two things but I will basically be building this as per Mark's video.

My Openbuilds Journey

I've learned a lot from building this machine, and had and will continue to enjoy using it. Let The CHIPS FLY!

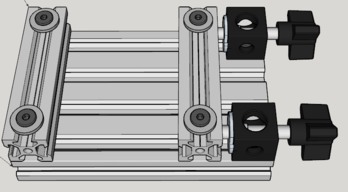

C-Beam on X, Y and Z Attempting to use internal channel first go around

C-Beam build using the small C-Beam gantry plates only.

MY NEW CNC

This build is not based on the ox, but got my ideas and inspiration from my first build,

Sphinx 1000 x 500

Building a Sphinx based CNC based on Kyo's plans. Going with a 1000 x 500 table size.

Build Author

BCulbertson

Views

4522

Build Author

BCulbertson

Views

4522

Lead 1515 with Upgrades

My upgraded OpenBuilds Lead 1515

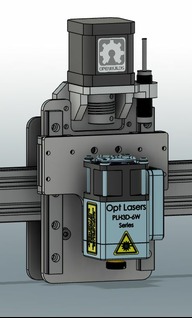

My ACRO Build

An ACRO laser put together with some repurposed and some new parts.

MakerSL style vice - using just off-the-shelf-parts (NB UNTESTED WIP)

An attempt at copying the https://openbuilds.com/builds/makersl-msl-8-ob-vise.4084/ using just off-the-shelf OpenBuilds Parts - no machining

Build Author

ShockingTops

Views

4448

Build Author

ShockingTops

Views

4448

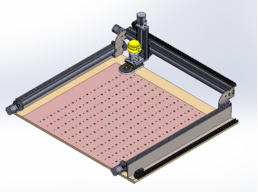

Opening into doors

Construction of a CNC table for a specific project that could cut an area larger than a door (>8'x4'). Much thought went into how to avoid the weight of the gantry bending the (long) Y axis, whilst still keeping down the complexity and cost.

Build Author

DaleShaw

Views

4411

Build Author

DaleShaw

Views

4411

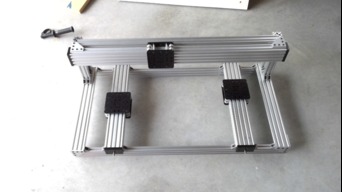

Senior Project CNC table

So for my senior project I decided to build a CNC router. I kind of need to get this done before May so we'll see what all goes down. It's going to be a 3 axis machine (for now) and will be able to handle 4x8 sheets of wood. This is my first build. It's going to be intresting..

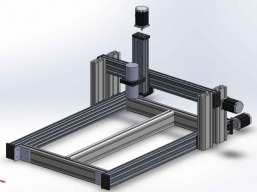

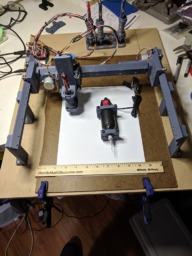

Fully 3D Printed Small CNC Router/Plotter

3D Printed CNC machine. The build is on Thingiverse. https://www.thingiverse.com/thing:3842401 I posted it here to give props to the Openbuilds Control Software!

Brice's CNC Router Build

I'm building a CNC router for a long time. Here's the result on this long journee. I tried to do my best with the basic tools I have. Don't hesitate to ask if you have questions.

Build Author

ckgottabuild

Views

4212

Build Author

ckgottabuild

Views

4212

Lead CNC 1010 Platform and Rotating Laptop Mount

Moveable Lead CNC1010 build with handles on four corners. Everything fits on one sheet of cut out 4x8 plywood

Build Author

Jasont

Views

4188

Build Author

Jasont

Views

4188

MY first CNC build

my first cnc build using the lead 1010 to build bigger and better!!

Build Author

Tristen Poliseno

Views

4187

Build Author

Tristen Poliseno

Views

4187

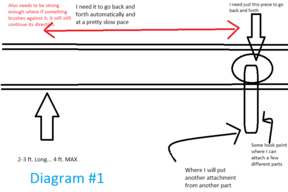

Back and forth rail mechanism

I have the whole description and all the details in the "Body" section!

MiniMill - A must have machine :)

The new MiniMill from Mark and Sonny is a great little machine.

Build Author

Keith Davis

Views

4010

Build Author

Keith Davis

Views

4010

Vulcan Bot

A 200mm x 300mm x 200mm workhorse that never needs leveling due to Posi-Drive Leveling design.

Build Author

cnc-trucker

Views

4007

Build Author

cnc-trucker

Views

4007

Arduino Mega to EMC2 (LinuxCNC) Plasma Table Conversion

This is a story about a guy who started with a $25 set of plans, and through 4 iterations/ rebuilds, ended up with a professional quality CNC plasma table capable of cutting anything steel up to 2 inches thick.

Build Author

theracermark

Views

3963

Build Author

theracermark

Views

3963

Reviving the Origonal PhlatPrinter with BlackBox

Reworked PhlatPrinter Gen1 Adding dual nema 17s to all 3 axis Supprot for carriage to insure even dept cuts Lighting for view of cutting area

CNC China Router Conversion to Open Builds System

China Router frame with linear bolts, Nema23 and the icing on the cake “open build parts“

Build Author

Jones

Views

3931

Build Author

Jones

Views

3931

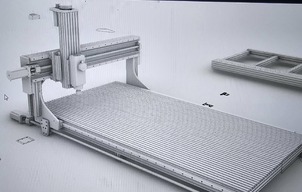

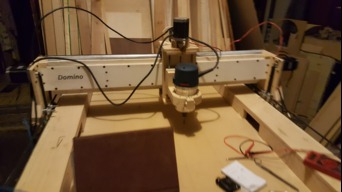

The Domino - 1.5m x 1m

DIY scratch build consisting of gas pipe, skate bearings, 12mm birch, 3/4 maple v-core ply, Nema 23's, and arduino and CNC shield with DRV8825's.

BKE Lead 1010 - First CNC Router

LEAD CNC

Build Author

Rich Bowen

Views

3807

Build Author

Rich Bowen

Views

3807

WannaBe CNC - First time design and build

Design Change - Version 2.0 has a smaller foot print, custom gantry supports, and front and back covers. I will use standard V-Slot for gantry supports leaving me enough travel to manufacture the customer supports with this machine when completed. then update to final build. I also plan to install the controller into the front cover and power supply into the back cover. Should be nice and tidy.

My Ooznest Workbee V2.0 build

I'm new to this whole process, so this is a build by a newbie for newbies.

My 1st C-Beam Router

Pretty happy with the build, had some difficulty with the software loading up the settings due to me using the wrong com.

Desktop CNC

Approximately 910mm x 955mm x 82mm. There is 250mm available in the Z, but the gantry is only 82mm from the bed surface.

Indoor Drumline Props

Triangular Towers

Build Author

Damian V-SLOT Poland

Views

3661

Build Author

Damian V-SLOT Poland

Views

3661

LEGO BOX

Discover our unique DIY project that blends creativity, utility, and sustainability. This guide will take you through the construction of a LEGO display box, ingeniously crafted using offcuts of V-SLOT aluminium profiles and OpenBuilds accessories. Not only is this an eco-friendly approach to reusing surplus materials, but it also results in a stylish, functional display for your prized LEGO models. Whether you're a LEGO enthusiast or have little LEGO fans at home, this innovative project offers

Build Author

Calotype

Views

3551

Build Author

Calotype

Views

3551

My DIY panoramic rolling (&banding) Machine.

DO WHAT YOU IMAGINE !

Cartesian CNC router

This project has been a steep learning curve in an unfamiliar area for me. It has been a very rewarding experience and has opened up so many more possibilities to pursue in the future.

Stock CNC Router

This is my first CNC router, so be kind on the criticism. I'm still learning. Not an engineer, and not a machinist so I am having to research and learn aspect from both of those areas of study!

Plate 'o CBEAM

I'm starting with the c-beam bundle, and I hope to end up with a pretty useful little platemaker/shallow relief carver. I'm hoping to discover how accurate and efficient it can be.

my version of xl

A table top version of the open build xl router kit set build. This use of c - beam and xl kit set was coupled with Mach 3 controller running on Dell opti -plex 755 and win 7 pro licence. A Dell opti-plex 755 empty case was used to house the controls and wiring , including the limit switch and emergency stop safety circuits

Build Author

Neil Scott

Views

3193

Build Author

Neil Scott

Views

3193

Barcelona Build

This will be my second CNC build but this time a proper CNC not a small desktop model that I played with for a while to learn Gcode, It was great but now its time to start playing with the big boys and girls.

Build Author

David E. Flores E.

Views

3155

Build Author

David E. Flores E.

Views

3155

F-Ender-Plus 3D Printer

F-Ender-Plus its based on the Ender 3 Pro, but improved: CR-10 hotend, double gear extruder, double z-axis motor, bltouch incorporated, hotbed leveling improved strings kit. Most made using local vendor parts, and still I'm increasing my knowledge of how get better 3D printings by calibrating motors steps, leveling the hotbed and z-axis; using a 3mm thick glass...

HandCrafted WorkBee - HCWB

This will be a slow build as I collect parts and materials as funds permit for 1000mm x 1000mm Workbee. I call it the "Hand Crafted WorkBee" because I will be hand making the plates and as much of the build as possible using a drill press and hand tools.

Build Author

Linkreincarnate

Views

3094

Build Author

Linkreincarnate

Views

3094

Amazon Special

I have parts that are apparently not suited to a cnc router or a 3d printer. I am still trying to figure out what to make out of what I have,

C-Machine

MY experience as a first time introduction to the CNC world!

Mark 1

My first attempt at building a CNC style machine. Overall my plan is to use the PlanetCNC breakout board and software to run the machine from a dedicated laptop/tablet.

CNC built, work in progress, fail

2x4 cutting area, enclosed with dust collection mainly built out of wood.

Ooznest workbee

This is my first build so I will let you know how I get on

OoozNest WorkBee

A Journey on the WorkBee Build...

C-Beam Machine XL

C-Beam XL upgraded with end-stops, E-stop, and cable chain. Running GRBL on Arduino Mega.

TFE2 CNC Build

My TFE2 CNC Build. The TFE was much smaller and all of the gantry plates were 3D printed. Despite this it will happily machine aluminium without issue. So I decided to use that to make the TFE2 which will be all aluminium plates and much larger (1200x800mm machining area with roughly 140mm in Z so I can later add a rotary axis.)

Lead 1510

Customised Lead 1010 making it a 1510. T-Track work area with dual Y limit switches for auto-squaring. Powered by xPro v5 & CNC.js

Ox cnc improvements chain driven

Just ox cnc experiment