Build List

-

Active Filters:

an

Build Author

John J Talavera

Views

8391

Build Author

John J Talavera

Views

8391

CNC FOR EVERYONE, THE DUCK!

www.cncforeveryone.com. the Duck is something that i think would be helpful in my shop since we already do cold casting.

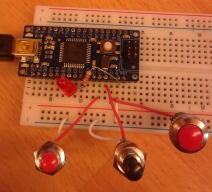

USB Pendant

An USB Pendant for LinuxCNC / Mach3

CraneBot

A minimum parts build with belt driven Z-axis.

Large Manual 3d Printer

This is the largest printer I have found. It is also the cheapest. The reason is that it is run by hand, without computer or motors or electronics. Put an object on one side and move the 3d pen while tracing the object. Move the z dimension by turning the crank on the lab jack to move the printed copy down a notch. Be creative!

Build Author

Mike Andrews

Views

9187

Build Author

Mike Andrews

Views

9187

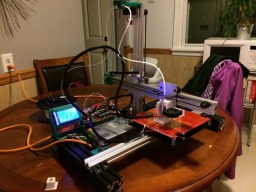

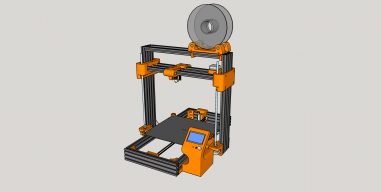

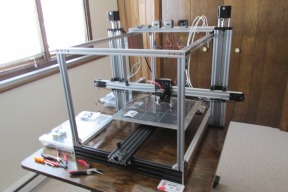

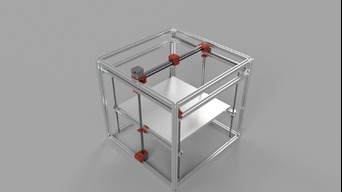

Monster - a multiple material 3D printer with 20"(X) X 14"(Y) X ~20"(Z)

A Laut3k derivative that goes for volume and large number of print materials at the same time. Using OpenBuild linear motion systems to get away from belt drives.

Build Author

Mogens Kusk

Views

5148

Build Author

Mogens Kusk

Views

5148

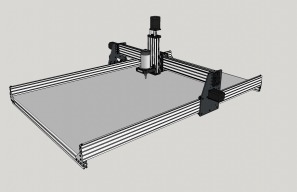

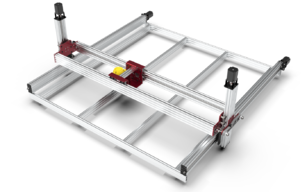

Belt driven 1200mm x 700mm x170mm axis

CNC router

Build Author

William Niedermeyer

Views

19406

Build Author

William Niedermeyer

Views

19406

Structured Light Turntable Scanner

3d Structured Light Scanner with Arduino Controlled Turntable

D-Bot CoreXY printer

A CoreXY D-Bot 3d printer using gantries as wheel-carriages.

BrandoneOuX

I'm Brandoneous; hence, the BrandoneOuX, a cartesian CNC build. Large format (1000mm x 1000mm) but beefed-up to solidly augment the ability to cut Aluminum in addition to wood and other solid materials. As I am currently living in a rented apartment for an out-of-state job, my secondary challenge is to build a sound dampening enclosure that will function as a torsion box base, a sound dampening enclosure, and a dust containment system. Easy, right? Well, we'll see... Join my journey

betterBot

This is going to be a more or less detailed how to build BetterBot. Pictures and more (decent) text are to be added.

Cartesian CNC router

This project has been a steep learning curve in an unfamiliar area for me. It has been a very rewarding experience and has opened up so many more possibilities to pursue in the future.

CBeam OX

i wanted to use both the ox and the C beam C beam for the gantry because its stronger i also made the gantry 20 mm higher so i can cut thinker material i will maybe later go to rack& pinion on the 1500 mm Y axes also instead of the V wheels i will maybe go to hiwin in the furture

Build Author

TouchPadKing

Views

5047

Build Author

TouchPadKing

Views

5047

1500mmx500mm Kossel Delta

Please, look over my build and make any recommendations you can think of! I haven't figured out how long my arms need to be yet. Nor have I done any shopping around to find better prices...

VoS

3D Printer based upon 3d printed parts and open builds componets

Build Author

Rich Bowen

Views

3780

Build Author

Rich Bowen

Views

3780

WannaBe CNC - First time design and build

Design Change - Version 2.0 has a smaller foot print, custom gantry supports, and front and back covers. I will use standard V-Slot for gantry supports leaving me enough travel to manufacture the customer supports with this machine when completed. then update to final build. I also plan to install the controller into the front cover and power supply into the back cover. Should be nice and tidy.

Build Author

Anthony Castelluci

Views

3177

Build Author

Anthony Castelluci

Views

3177

Simple Camera Lofted Camera Slider

Build a manual camera slider.

Build Author

bpatterson42

Views

3485

Build Author

bpatterson42

Views

3485

Inverted Y C-Beam Machine

Similar to C-Beam Machine build, but with inverted Y-axis assembly to shield drive screw. Integrated XZ gantry can be fixed to any solid surface. Build dimensions are 36" x 36" x 6".

32 Button Hand Pendant for the PlanetCNC Control Board

This project is for building a remote hand pendant for the Planet-CNC control board but could be adapted for many other projects. The pendant allows for machine control without being at the computer keyboard and the button functions on the pendant are defined by the user.

Build Author

Mark Carew

Views

27683

Build Author

Mark Carew

Views

27683

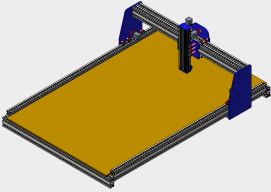

OpenBuilds Workbee 1050 (40" x 20")

The OpenBuilds WorkBee 1050 - 1000x500 Lead Screw Driven CNC Machine

Build Author

Lasersc

Views

5292

Build Author

Lasersc

Views

5292

The D & R TigerPaw Trilogy

Hopefully this will be a quick guide to one way that you can add a laser to an existing CNC router.

Build Author

Neil Scott

Views

3151

Build Author

Neil Scott

Views

3151

Barcelona Build

This will be my second CNC build but this time a proper CNC not a small desktop model that I played with for a while to learn Gcode, It was great but now its time to start playing with the big boys and girls.

Build Author

SandeepsCNC

Views

12019

Build Author

SandeepsCNC

Views

12019

Raspberry Pi CNC Software

The main objective is to build a software which can completely run on a single board computer, Rasbperry Pi, to reduce the complete cost of building a cnc machine. The software is extensively tested and can be run on any raspberry pi 2/3 boards. With no G-Code dependency, you can do complex 3D relief carving to simple tasks with simple GUI based project development environment. Please go through the YouTube channel for more details https://youtu.be/8KOXqLpvscg

Build Author

OpenBuilds

Views

16778

Build Author

OpenBuilds

Views

16778

C-Beam® Tension XL Linear Actuator

Bringing your lead screw precision and accuracy to new lengths using a simplistic tension system!

Build Author

Crazzy French Dude

Views

5253

Build Author

Crazzy French Dude

Views

5253

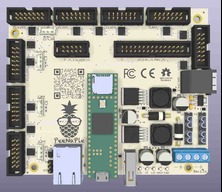

PeeNaPle_V1.4b

PeeNaPle_V1.4b is a BoB controller board for 3D Printers, CnC and cartesian machine, using the latest Teensy_4.1

Build Author

Colin Russon

Views

3848

Build Author

Colin Russon

Views

3848

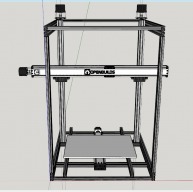

TITAN GAMBIT

Anti-Twist Design, larger lead screws, enhanced M8 wheel sets.

Build Author

OpenBuilds

Views

4632

Build Author

OpenBuilds

Views

4632

Interface magnetic mount

A simple build that helps you to mount the OpenBuilds Interface to the front of your machine.

Build Author

Sergei Starovoitov

Views

5279

Build Author

Sergei Starovoitov

Views

5279

Motorized mic stand

This system allows you to adjust the position of the microphone remotely

Build Author

Steve Hall

Views

4097

Build Author

Steve Hall

Views

4097

Cartesian Style Build UK

Another Cartesian style build with parts from the UK, US & China.

Fixed Gantry Easy Assembly

Fixed Gantry CNC with good accuracy and rigidity but for a higher price than the usual CNC's on the site.

Techsoft Roland TS-30 rebuild

Replacing the Electronics and Spindle. Intending to rewire all the buttons and make it into a more modern and easy to use CNC.

Automated Media Blaster

Automated Media blaster retrofit.

Build Author

robert christensen

Views

1373

Build Author

robert christensen

Views

1373

Tool holder

I saw a video of some one pouring resin in a mold,so i did a little research, i bought some resin,and some molds and magnets all from Amazon, it took me several tries and a big mess but it finally finished. The first pour i poured a small batch to make a templet,i marked all the holes that needed drilling then i marked the underside of the mold where i wanted the magnets, next was making the pcs i needed

Build Author

Leon Style

Views

4621

Build Author

Leon Style

Views

4621

AluVault MINIMAX

Easy build cnc router with t slot profile and nylon machined part

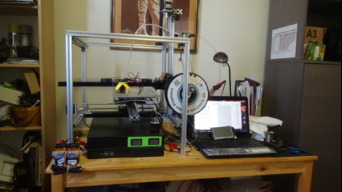

Ez3D - Phoenix 3D Printer Build

This is my 1st submission to openbuilds.com and my 1st venture into building a 3D Printer. The Phoenix 3d Printer is a kit from Ez3D, a company based out of Colorado, started and backed by successful Kick-starter and IndieGogo campaigns. The Phoenix 3d Printer kit is currently backlogged 10 to 12 weeks which means quite a wait. I will be chronicling my experience with this kit as I get it done.

Build Author

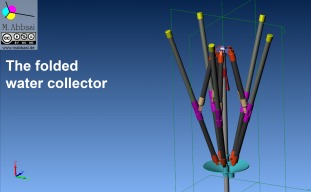

Mohsen Abbasi

Views

8859

Build Author

Mohsen Abbasi

Views

8859

Foldable Rainwater Collector

Realisation of my idea about a foldable collector for rainwater, which is light and easy to make. People around the world need water and can collect rain water with this collector. I made it for syria and all too.

Build Author

Pol Feliu

Views

9205

Build Author

Pol Feliu

Views

9205

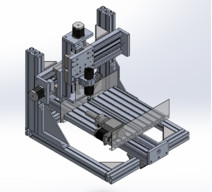

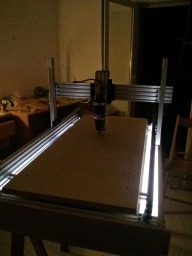

Batxillerat Research Project: Design and construction of a CNC

I'm working on a cartesian cnc router for my school research project

Build Author

CWidt

Views

8607

Build Author

CWidt

Views

8607

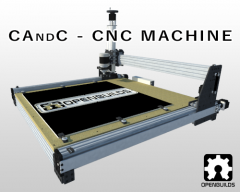

OpenBuilds CAndC - CNC Machine

A new derivative of the famous OX CNC, with increases strength, rigidity, and accuracy.

Bandicoot v1

My first custom build, using vslot rails for Z and Y and 8mm rails for X. Currently printing parts for this using my Prusa I3. The build volume will be roughly 300mm^3, X and Y are belt driven with 8mm acme lead screws for Z. Will be uploading more info shortly as i continue to build the printer.

Build Author

MikieLikesIt

Views

8193

Build Author

MikieLikesIt

Views

8193

Cousin CNC OX Router

A lower profiled machine. Built all out of aluminum. Removable control panel/PC unit. Option for vacuum table and cooling pump for a spindle.

Build Author

DIY3DTech.com

Views

6438

Build Author

DIY3DTech.com

Views

6438

3D Printer Leveler Made with Maker Rail

Leveling Platform / Stand 3D Printers

Wakezor

I'm starting my first own build cnc machine which is inspired by routy and the ox. Were my goal was not to use the ox plates but use the standard plates available in the parts store for the design.

Build Author

zann68

Views

9091

Build Author

zann68

Views

9091

OX CNC 4'x4'

Out with the Old in with the New. Trying to build a nice clean setup that myself and my sons can use and enjoy.

Build Author

Julius

Views

8115

Build Author

Julius

Views

8115

The "Hand" CNC (or OXCarve)

more to come, please follow along the journey!

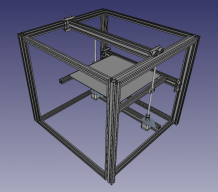

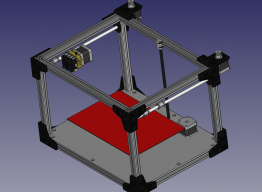

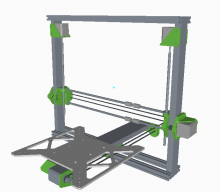

bertha

This build will hopefully be 18x18x24 build space using RAMPS 1.4 with Marlin firmware. Using NEMA 17 motors and belts to drive the X and Y axis, lead screws for the Z axis. The build plate will be heated with a delrin Y carriage for the glass and heatbed. Z axis motors will be top mounted. Possibly and ATX power supply.

Build Author

Ken376

Views

3676

Build Author

Ken376

Views

3676

Welded project cnc first try

Kind of hard to see in this pic now lining up drive s and finishing framework

Large 3D printer 12"x12"x12" with heated bed

I want to have a printer to support senior projects. Also working on supporting 3D printing needs in the local community.

C Beam CNC+Laser

You will be following the assembly of the mechanical kit and how i integrate the electronics into the final build.

Build Author

TimVukman

Views

4246

Build Author

TimVukman

Views

4246

Unique Z

My original Tevo Tarantula kit was ok..... I had issues with the X gantry staying level. I got rid of the wheels and replaced them with linear block bearings. I still had some issues with the X gantry. I swapped out the plastic parts with aluminum which was much better. Still not what I want yet

Build Author

Mark Carew

Views

18117

Build Author

Mark Carew

Views

18117

Nema 23 Belt and Pinion Actuator

This easy to build and effective system can take your builds to the next level! This design is strong and accurate and could be the solution/upgrade that you've been looking for!

Build Author

Darren Dickson

Views

4308

Build Author

Darren Dickson

Views

4308

3D printed CNC Machine

So I thought I would make the Leon van den Beukel version three 3D printed CNC Machine, it is the third incarnation so you would expect a relatively bug-free CNC Machine with a strong foundation.

Angle grinder converted into electric drill

How to convert an angle grinder into an electric drill? Remove the angle grinder, leaving only one main motor, and then find a suitable intermediate roller with a point drill to assemble it.

Build Author

Tristen Poliseno

Views

4129

Build Author

Tristen Poliseno

Views

4129

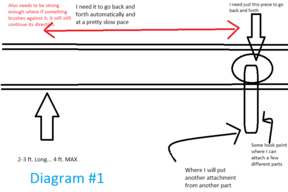

Back and forth rail mechanism

I have the whole description and all the details in the "Body" section!

Build Author

Leboeuf

Views

4872

Build Author

Leboeuf

Views

4872

Cartesian 3d printer

This is the build of a cartesian 3d printer made of an old Anet and Geeeteck, some 2020 alu profil and linear rail. Powered by a Rumba with a Nextion screen. It should be modular and accept dual Extrusion and laser engraving.

Build Author

Jose Alezandre

Views

2143

Build Author

Jose Alezandre

Views

2143

Mighty Chihuahua

The idea was to use materials from previuos failed projects into a succesful one. I have build this tiny but powerfull CNC machine mainly using the universal gantry plates for the X and Y axis. Also another innovative part is the fact that I assembled the Z gantry with 2 aluminum sections of 20X40 and one aluminum seccion of the 20X20. I used NEMA 17 stepper motors with GT2 pulleys. This was designed on Fusion360

CupriForge

This build will use 1/2 inch copper water pipe as the primary material for all structural parts. As of now my intent is a cartesian design drawing from a few popular printers. I'm going to use the least amount of printed parts as possible and locally source as much as I can. I have built an EMT-conduit core-xy printer in the past and while it worked out fine, I feel copper is easier to work, manufactured with more precision, still reasonably inexpensive and will look super cool!

Build Author

Alexander_Bulgaria

Views

1478

Build Author

Alexander_Bulgaria

Views

1478

CNC milling machine,lathe,gantry,fdm,clay 3d printer ALL IN ONE

That is the only cnc you will need for most of your diy projects.

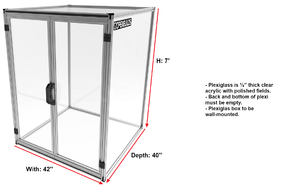

Plexi Panel

Plexi Panel to use for a vfd test enclosure. The box will be wall-mounted on plywood, so the back of the box is not necessary. - The bottom of the box is not necessary because the box will be fixed on concrete on the floor. On the door, I was thinking of putting 4 brackets instead of two. We'll have two 21” doors