Build List

-

Active Filters:

plate

Build Author

Mark Carew

Views

272102

Build Author

Mark Carew

Views

272102

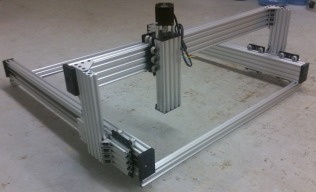

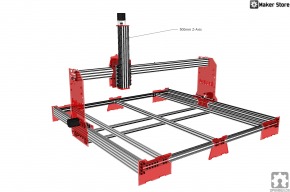

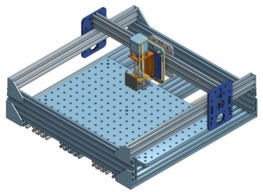

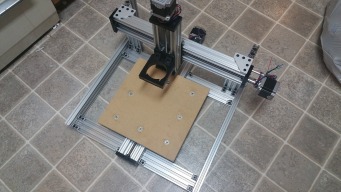

C-Beam® Machine - Plate Maker

This C-beam Machine is an in affordable CNC plate maker and 3D carving machine!

Sphinx 55 on MGN12 linear rails

My machine is a combination of the Openbuilds Sphinx 55, MGN12 linear rails knockoffs and custom made plates made by Chris Laidlaw

Build Author

Teflon4

Views

16075

Build Author

Teflon4

Views

16075

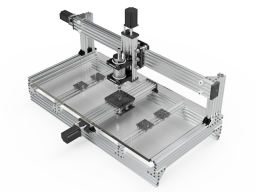

TZ C-Beam Machine Plate Maker

A Modified and augmented Ooznest C-Beam Machine Plate Maker.

Build Author

Savvas

Views

19854

Build Author

Savvas

Views

19854

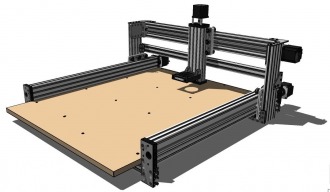

C-Beam Lead Screw CNC Mountain

I’m making a desktop CNC machine based on the C-Beam platform. It will be driven by Tr8 Lead Screws, and initially made from 12mm birch ply plates.

Build Author

Savvas

Views

14544

Build Author

Savvas

Views

14544

Halloumi CNC Machine - Acetal Plates

I built the original machine using plywood plates, and always intended to upgrade those parts to more durable ones. I decided to go with acetal as it's a lot easier to cut than aluminium. I used fusion 360 to model and rebuild the original machine. Once I have assembled everything and feel confident it all works I will release the plate designs here.

Adjustable Router Guide Template

This project is an adjustable router guide template made with 20x60 V-slot. It was meant as a less expensive and more user friendly alternative to commercially available units.

Build Author

Maxime Favre

Views

9613

Build Author

Maxime Favre

Views

9613

SmoothiebrainZ CBeam Machine

Modded Plate maker with: Smoothiebrainz board and DQ542MA SN04 Endstops Modded Z axis Aluminium build plate and renforced Y axis Dust shoe

Build Author

Corey Corbin

Views

8001

Build Author

Corey Corbin

Views

8001

Ball Screw Carrier.

Create a ball screw carrier with out BF BK bearing blocks.

Build Author

SlyClockWerkz

Views

17041

Build Author

SlyClockWerkz

Views

17041

1000mm X 1500mm OX CNC -- Fiber/Garolite

Building the full size OX.

Build Author

Joe Garritano

Views

11881

Build Author

Joe Garritano

Views

11881

X-carve upgrade

Using criticall OpenBuilds components to upgrade the rigidity and reliability of an X-Carve 1000mm build.

Build Author

Keith Davis

Views

31817

Build Author

Keith Davis

Views

31817

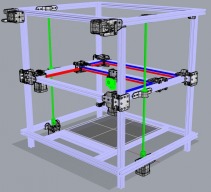

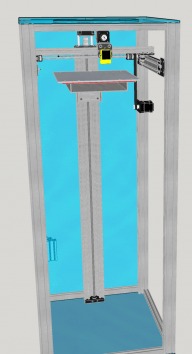

OpenXY

Combines the layout factor of a CoreXY while using Cartesian logic. The design has a fixed build plate - moving an X/Y frame on the Z axis enclosed by an outer main frame.

Build Author

JCPhlux

Views

26778

Build Author

JCPhlux

Views

26778

Tesseract

Large Core XY 3d Printer W/fixed build plate

DTG OX

From where Mark left off from the Ox build I am going to film the whole process of customizing the Ox.

The Hoss

The purpose of this build is to create a simple, strong modular build that is rugged enough to cut out some of the softer metals along with wood and plastics. Using basic parts like the universal plates, t-nuts and v- wheels coupled with the strength of C-Beam I am sure this will deliever the desired results!!

Build Author

TomH

Views

16507

Build Author

TomH

Views

16507

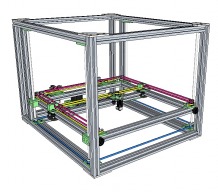

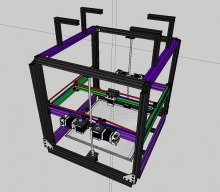

H-Bot CoreXY Cube with Fixed Build Plate

Use of V-Slot for frame and rails with option to use identical 500mm uncut lengths: 8 * 20x60 x 500mm 8 * 20x40 x 500mm 7 * 20x20 x 500mm (2 cut into four identical 125mm pieces for filament holders) Use of uncut 500mm rails obtained through use of 12 joining plates for use as spacers. Alternate approach is to trim two 20x40 and 1 20x20 rail by 6-8mm each. Build volume ~400mm cubed (with dual extruders). Use of only openbuilds components! Currently in design phase...

Moag's CNC Mill

A design in progress, to 3D carve two-part Aluminium injection moulds for Soft Plastic Lures and Lead Jigs, so I can prototype some of the concepts rattling around in my head. All Openbuilds parts where possible, 1000x500mm footprint, 0.8kw Water-cooled Spindle?, High Torque Stepper?,Smoothieboard?, I still have no idea. As a newbie to the CNC world, any wisdom would be welcome to take this from just a idea into reality so I can start playing with all this awesome stuff. Thanks in advance

Build Author

jamesdjadams

Views

12388

Build Author

jamesdjadams

Views

12388

C-Beam XL - TinyG - Aluminium Plate - Dewalt 611

C-Beam XL build using TinyG V8.

Build Author

Ronald van Arkel

Views

16806

Build Author

Ronald van Arkel

Views

16806

Upgrading the C-Beam machine

So we have new plates, stronger motors, belt drive reduction, but what should we do with them? In this article you might find the answer you were looking for as we took an “old” C-Beam machine and started to upgrade the X/Z body and added more torque and precision to the Z-axis.

Build Author

Jason @ MCC

Views

13508

Build Author

Jason @ MCC

Views

13508

QueenBee Pro CNC Router and Lathe

A 1000x1500mm QueenBee Pro with a 4th Axis Rotary attachment/Lathe Bed.

Build Author

Mark Carew

Views

17380

Build Author

Mark Carew

Views

17380

C-Beam XLarge X/Y Table

This OpenBuilds C-Beam XLarge X/Y Table is a great display of how easy it is to modify and create awesome configurations with the OpenBuilds system!

C-Beam Elexa

This build will be based on the C-Beam Plate Maker, with additional changes based on other builds and ideas.

Build Author

Mark Carew

Views

18802

Build Author

Mark Carew

Views

18802

NEMA 17 Belt and Pinion Actuator

This Belt and Pinion actuator is a great example of how easy it is to convert your machine into a belt drive system.

Build Author

Mark Rehorst

Views

10328

Build Author

Mark Rehorst

Views

10328

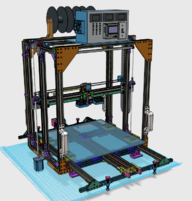

Ultra MegaMax Dominator CoreXY Printer

My self-designed and built, tall-format coreXY printer with 300 x 300 x695 mm print capacity.

Build Author

Mark Carew

Views

18780

Build Author

Mark Carew

Views

18780

Nema 23 Belt and Pinion Actuator

This easy to build and effective system can take your builds to the next level! This design is strong and accurate and could be the solution/upgrade that you've been looking for!

Build Author

Bob Darrow

Views

10415

Build Author

Bob Darrow

Views

10415

BA3DP

A slightly more than one half cubic meter 3D Printer using V Rails, V Rollers, "C" Rail, mounting plates, and a bunch of 3D printed brackets to provide strength and stability to the frame. Rigidity was the goal and precision and accuracy the result. The software is a whole other topic, many weeks spent dialing that in to make the printer print.

Build Author

Christian James

Views

10340

Build Author

Christian James

Views

10340

Workbee "style" 1010 cnc

This build is based on the Workbee 1010 CNC. It is not a kit build and is much the same as the original but with some significant changes made here and there as the build progresses.

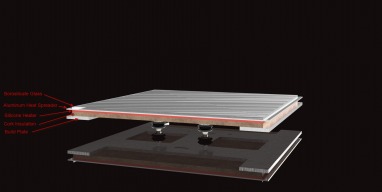

12.5" x 12" Assembled Heated Build Plate

Custom build plate for 300mm x 300mm (12"x12"). The hole pattern is for the 20x60 V Slot

Build Author

OpenBuilds

Views

17889

Build Author

OpenBuilds

Views

17889

C-Beam® Tension XL Linear Actuator

Bringing your lead screw precision and accuracy to new lengths using a simplistic tension system!

Build Author

Jose Alezandre

Views

2315

Build Author

Jose Alezandre

Views

2315

Mighty Chihuahua

The idea was to use materials from previuos failed projects into a succesful one. I have build this tiny but powerfull CNC machine mainly using the universal gantry plates for the X and Y axis. Also another innovative part is the fact that I assembled the Z gantry with 2 aluminum sections of 20X40 and one aluminum seccion of the 20X20. I used NEMA 17 stepper motors with GT2 pulleys. This was designed on Fusion360

Aluminium OX - Canada

Document my OX build process. I will also be sharing SolidWorks parts files & assemblies.

Build Author

Todd Brous

Views

5867

Build Author

Todd Brous

Views

5867

Modified Acro with build plate, Z-axis and OPT Laser

Modified Acro for laser engraving. Extra height and and a sturdy build surface for part fixtures, custom mount plates, OPT Laser, and a Z-Axis.

Build Author

Carl van Heezik

Views

8642

Build Author

Carl van Heezik

Views

8642

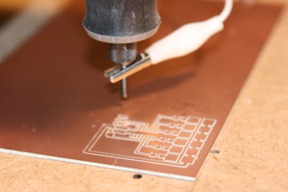

C-Beam™ Machine for PCB milling

C-Beam Machine for PCB milling

Build Author

Kyo

Views

10355

Build Author

Kyo

Views

10355

Plate Maker V-slot Table

C-beam Plate Maker V-slot Table System to aid in clamping and setup of jobs.

Build Author

Anthony Castelluci

Views

3307

Build Author

Anthony Castelluci

Views

3307

Simple Camera Lofted Camera Slider

Build a manual camera slider.

Build Author

Builder+Bob

Views

3875

Build Author

Builder+Bob

Views

3875

Portable C-Beam

C-Beam Plate maker for My OX!

Build Author

Huub65

Views

9503

Build Author

Huub65

Views

9503

My C Beam - NEMA 17 - GRBL- Arduino project

Cbeam machine. Using small stepper motors (NEMA 17) and Arduino controller. Try to get this working in de upcoming month.

Build Author

Greg Lampman

Views

9350

Build Author

Greg Lampman

Views

9350

C-Beam Intro to CNC

Build log for my first CNC machine, a C-Beam Plate Maker

Build Author

Limine3D

Views

8720

Build Author

Limine3D

Views

8720

M3D Squared

A cartesian build with a build dimension of 200x200x750mm. I will be using a dual extruder, heated build plate, and a screw drive for the z axis.

C-Beam Machine XL

Overview of my experience building the C-Beam Machine XL from OpenBuilds, along with updates as I move along and get it going. My application is for creating plates needed for lab functions, 19 rack bay covers, and whatever else arises.

Metalguru's C-Beam 750

This is a C-Beam build, fairly heavy duty, and 750mm x 750mm. Should be a good, sturdy machine that's relatively easy to assemble.

Build Author

Matt Nelson

Views

12474

Build Author

Matt Nelson

Views

12474

Matt's Ox

I'm building an OX CNC router. It will be the larger size of 750x 1000mm. This should give me a working area of about 22"x30".

New Custom CNC with C-Beam Rails

Hello all, wanted to share my custom build that I planed to do. My idea was to drill foam blocks to make molds for my projects. The CNC will be 1500-1500mm with a higher Z-Axis. So I redesigned the Gantry Plates that will be cut out at some other place. I hope you can share your opinion on my project.