Build List

-

Active Filters:

d

CNC PKB2

blueprints here: https://github.com/tomaspavlica/cnc_pkb2

CNC 1000x1000mm C-beam

inspired by http://openbuilds.org/builds/c-beam-sphinx.3605/

Build Author

JerryD

Views

5180

Build Author

JerryD

Views

5180

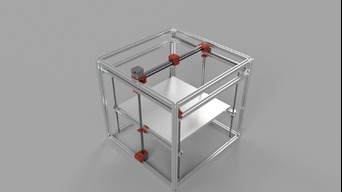

1500x1000mm Adjustable Height

I have the demand to cut/etch tall pieces of material. For this reason, I have designed a machine with 500mm uprights with adjustable gantry height. This way I can raise/lower the sled and z-axis as needed. I've also chosen to use a linear C-channel assembly for the Z axis with the plate mounted to the gantry instead of the other way around. This will allow for maximum range of the z-axis. The parts list/BOM does not include motors/belts/pulleys or electronics.

ivern

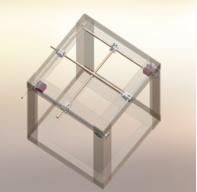

Toying around a concept. Inputs are welcome on whether to use lead screw or belt drive. My lead screw will be single start 500 mm lenght, 2 mm pitch and 2 mm lead. Nema 17 motors will be used. All veterans, suggestions please.

Build Author

TimVukman

Views

4115

Build Author

TimVukman

Views

4115

Unique Z

My original Tevo Tarantula kit was ok..... I had issues with the X gantry staying level. I got rid of the wheels and replaced them with linear block bearings. I still had some issues with the X gantry. I swapped out the plastic parts with aluminum which was much better. Still not what I want yet

Core XY

Just now in the planning phase of my build. Waiting for some parts to come in to see what I am going to build off of. Print area going to be close to 300x300x350. Trying to decide if I want it enclosed. I do want to print ABS... so probably so.

First build - small scale

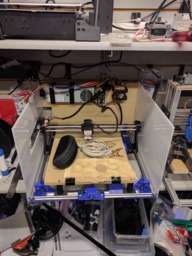

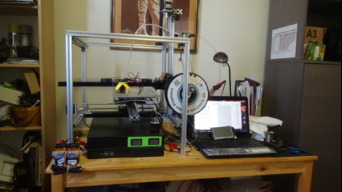

Using basic standard components, beams, motors, belt drive on x and y, z is a screw. Using Grbl Panel on Windows 10. Really basic router, had trouble getting the controller to turn on the router and set speeds so it is currently wired to a power bar switch so it runs full speed and I just use the switch to turn it on and off. Just getting x, y and z control working properly for now and likely going to switch the router to my dremel 4000 using a 3d printed mounting bracket I got from thingiverse

Build Author

h3rb

Views

3540

Build Author

h3rb

Views

3540

TEVO Little Monster Marine Vinyl Removable Enclosure

Make a vinyl burrito ENCLOSURE for your TEVO LITTLE MONSTER for < $30 (<$20 if you don't have your vinyl shipped!)

Build Author

h3rb

Views

5415

Build Author

h3rb

Views

5415

TEVO Little Monster Direct Mount Extruder

Cheap, experimental Modification to Tevo Little Monster's bowden system for the extruder

Build Author

Mark Carew

Views

17618

Build Author

Mark Carew

Views

17618

Nema 23 Belt and Pinion Actuator

This easy to build and effective system can take your builds to the next level! This design is strong and accurate and could be the solution/upgrade that you've been looking for!

Build Author

Mark Carew

Views

12695

Build Author

Mark Carew

Views

12695

C-Beam® Double Wide Gantry Actuator

This easy to build actuator is configured to have not only strength, but accuracy! This low profile option offers endless possibilities, and we cant wait to see how this actuator is implemented in your build ideas!

26 x 26 x 45 3D Printer/Mill

Super tall 3D printer. All lead screw design.

LaserShark300

300x300 belt drive laser etching/cutting platform. The design was borrowed from another's blog and customized to fit materials on-hand. Was a very fun project to assemble.

Build Author

joetemus

Views

6500

Build Author

joetemus

Views

6500

Shapeoko 2 Z-Axis Upgrade

This is a major redesign to the Z-axis of an otherwise stock Shapeoko 2.

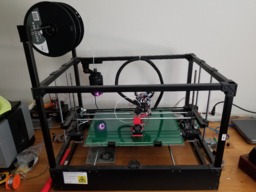

Rigidbot Big with glass bed

Started with a Rigidbot Big Added a single flat glass bed Used a Smoothieboard clone driving DRV8825

Cnc mill, Plasma cutting and weld table

A functional table for plasma cutting, welding, tooling........

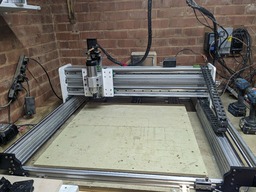

ricks workbee build

i had the ox build and wanted to do a more beeffer style so i went with a workbee style machine ..

Build Author

Darren Dickson

Views

4125

Build Author

Darren Dickson

Views

4125

3D printed CNC Machine

So I thought I would make the Leon van den Beukel version three 3D printed CNC Machine, it is the third incarnation so you would expect a relatively bug-free CNC Machine with a strong foundation.

Lead 1010 First time build

First time build of the Lead 1010 CNC with the High Z add on.

Angle grinder converted into electric drill

How to convert an angle grinder into an electric drill? Remove the angle grinder, leaving only one main motor, and then find a suitable intermediate roller with a point drill to assemble it.

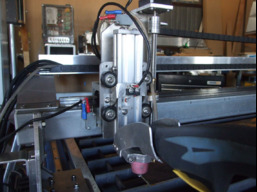

Plasma CNC machine

The plasma CNC that I have built has a water table that measures 1350mm x 650mm. The water is flooded onto the cut area while cutting and recycled around with a pump. This is to reduce smoke, cool the metal being cut to reduce distortion and also to keep sparks to a minimum. Most of the machine has been made from aluminium , the frame and table from steel, the water table, stainless steel.

Build Author

Tristen Poliseno

Views

3858

Build Author

Tristen Poliseno

Views

3858

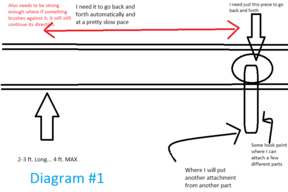

Back and forth rail mechanism

I have the whole description and all the details in the "Body" section!

ApiNui - CNC Router ( an oversized workbee )

Based on the WorkBee CNC, this is an oversized router built with a specific use-case in mind, for manufacutring beehives, and beehive components

Build Author

Leboeuf

Views

4741

Build Author

Leboeuf

Views

4741

Cartesian 3d printer

This is the build of a cartesian 3d printer made of an old Anet and Geeeteck, some 2020 alu profil and linear rail. Powered by a Rumba with a Nextion screen. It should be modular and accept dual Extrusion and laser engraving.

Build Author

Jose Alezandre

Views

2053

Build Author

Jose Alezandre

Views

2053

Mighty Chihuahua

The idea was to use materials from previuos failed projects into a succesful one. I have build this tiny but powerfull CNC machine mainly using the universal gantry plates for the X and Y axis. Also another innovative part is the fact that I assembled the Z gantry with 2 aluminum sections of 20X40 and one aluminum seccion of the 20X20. I used NEMA 17 stepper motors with GT2 pulleys. This was designed on Fusion360

750x750 Plasma cutter table

It startet in May with some leftovers from a cnc router build. Now in the middle of December its 99% finish. Everything is lowcost, spend about 1600$ so far.

DRO

Belt drive linear scale for Mill and Lathe

Build Author

theracermark

Views

3824

Build Author

theracermark

Views

3824

Reviving the Origonal PhlatPrinter with BlackBox

Reworked PhlatPrinter Gen1 Adding dual nema 17s to all 3 axis Supprot for carriage to insure even dept cuts Lighting for view of cutting area

First CNC Router

My very first CNC Router build. It's completely scratch built.

Lead 1510

Customised Lead 1010 making it a 1510. T-Track work area with dual Y limit switches for auto-squaring. Powered by xPro v5 & CNC.js

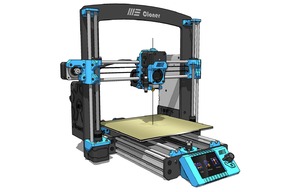

ME - Cloner 3d printer

I decided to start designing this printer, this will be my solution for a more rugged printer that you can use as workhorses...

Budget friendly starter build

DIY CO2 laser build. Budget friendly, 2020 T/V-slot profiles and scalability.

CNC built, work in progress, fail

2x4 cutting area, enclosed with dust collection mainly built out of wood.

CNC Cutter Knife

CNC knife cutter with loline blades

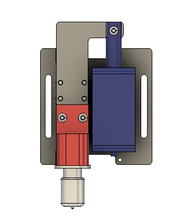

Z Floating Head

It's a Z floating head idea. Works well. Recommend cleaning the inside of your holes well with Q tips, and polishing the 1/4-20 bolts with car wax and you won't need oil as it slides perfectly. Hope this helps

zero z mongrel

long overdue overhaul of 1000 x 1000 machine

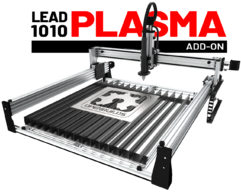

LEAD 1010 PLASMA Add-On

LEAD 1010 PLASMA Add-On is a great modification you can do for your LEAD 1010 to convert it into a metal cutting monster machine!

Small Desktop CNC Router/Mill

I designed and made this from scratch. The frame is welded steel filled with sand, and most of the other parts are aluminium. It's controlled with a DIY ESP32 controller running GRBL_ESP32

Build Author

Alexander_Bulgaria

Views

1069

Build Author

Alexander_Bulgaria

Views

1069

CNC milling machine,lathe,gantry,fdm,clay 3d printer ALL IN ONE

That is the only cnc you will need for most of your diy projects.

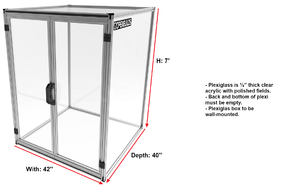

Plexi Panel

Plexi Panel to use for a vfd test enclosure. The box will be wall-mounted on plywood, so the back of the box is not necessary. - The bottom of the box is not necessary because the box will be fixed on concrete on the floor. On the door, I was thinking of putting 4 brackets instead of two. We'll have two 21” doors