Build List

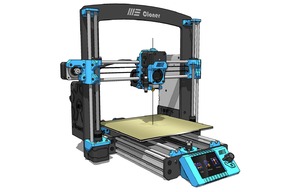

ME - Cloner 3d printer

I decided to start designing this printer, this will be my solution for a more rugged printer that you can use as workhorses...

Build Author

Gary Caruso

Views

3094

Build Author

Gary Caruso

Views

3094

OpenPull From CNC Kitchen.. attempt

This project is a Pull tester for material testing or structural testing with stress (force) data logging, I don't have plans for strain logging but that might be down the road.

7 Axis Camera Slider with Telescoping Vertical Lift

A six axis camera slider with a 7th LIFT axis added!

New Workbee Z Axis

Hopefully an upgrade of the Z axis of the Workbee.

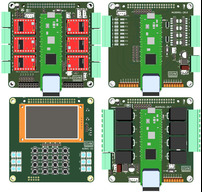

M10CUBE PICO CNC. A Universal Controller

An attempt is to be a Unified Modular Controller based on M10CUBE platform. For GRBLHAL and MARLINHAL applications. HAL porting is under way 1 - WIZnet Pico Clone W5100S-EVB-Pico 2 v- 6 X StepStick. Not sure about the sixth driver, (Pico pins limitation) . External connectors for larger drivers 3 - Opto - isolated spindle PWM. 4 - HMI 5 - I/O on diferent modules and Ethernet 10MBPS communication. Patches will be written to GRBLHAL for Ethernet I/Os (Interrupted).

C-beam charmer

Double C-beam Y axis 500mm., Double 2080 X axis 600mm. , C-beam Z axis 250mm, TB-6600 drivers, MKS-DLC32v2 GRBL w/wi-fi and blue tooth

Travel Printer

Build using standard parts as much as possible, Open Builds etc. To keep printer usable for more materials will be trying a heated bed with rotary elec union for the thermistor and power.

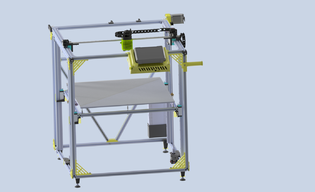

3D printer for printing Clay/Paste

I designed this 3D printer from scratch for my mechanical engineering capstone project. It's made for printing clay but should be able to print any paste material. The clay extruder system could be easily modified to work with almost any 3D printer. The printer is approximately the same size as an Ender 3.

2 Axis Lathe cutter

Rubber company use as a lathe cutter for accurate cuts compared to hand cutting.

THE BIG GREEN MACHINE

1500*1500*1900 (xyz) Biocomposite Pellet 3D printer

Build Author

Jasont

Views

4321

Build Author

Jasont

Views

4321

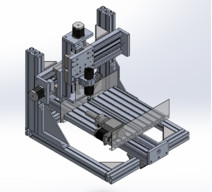

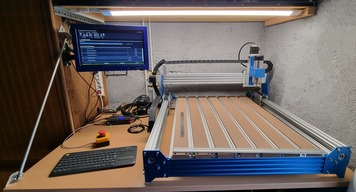

MY first CNC build

my first cnc build using the lead 1010 to build bigger and better!!

Dedicated Rotary Laser Made from Scrap and Spares

A clone of https://openbuilds.com/builds/dedicated-compact-rotary-axis-laser-engraver.10204/

Budget friendly starter build

DIY CO2 laser build. Budget friendly, 2020 T/V-slot profiles and scalability.

Fixed Gantry Easy Assembly

Fixed Gantry CNC with good accuracy and rigidity but for a higher price than the usual CNC's on the site.

CNC built, work in progress, fail

2x4 cutting area, enclosed with dust collection mainly built out of wood.

Build Author

OpenBuilds

Views

5930

Build Author

OpenBuilds

Views

5930

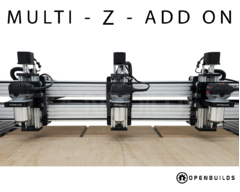

Multi Z LEAD Machine Addon

The Multi Z adds multiple Z axis to a LEAD CNC Machine allowing it to cut and carve 2 to 3 times the amount of projects in the tame it takes to make just one

Build Author

Cam Garrett

Views

4086

Build Author

Cam Garrett

Views

4086

Sturdy Motorized Photographic Copy Stand

i would like to build a sturdy motorized photographic copy stand. i have hobbled together a hand crank version using a used umbrella pole but it is not suitable as it is awkward and wobbly.

My ACRO Build

An ACRO laser put together with some repurposed and some new parts.

Techsoft Roland TS-30 rebuild

Replacing the Electronics and Spindle. Intending to rewire all the buttons and make it into a more modern and easy to use CNC.

My large machine 48 X 48

This machine is controlled by a Mach3 BOB. I USED Nema 34 stepper motors and a 3kw, water cooled spindle. I’m in the process of adding a vacuum table with 4 zones. I have an X-carve so I use Easel to create G-code for the large machine. I’m currently looking for a way to stabilize the Y-axis. It wiggles a little, so I want to add another linear rail high on both sides.

Build Author

Alain JBT

Views

706

Build Author

Alain JBT

Views

706

First project Genmitsu ProVerxl 6060 Improved with OpenBuilds System

For a long time I had a project to buy a CNC, in time I have evaluated several possibilities. I chose the option of a pre-constructed and scalable machine according to my needs, with sufficient rigidity features to do work of average importance. The starting investment was important to take into account to allow changes from the open source domain.

"Hirata scrap find" CNC

First CNC and first attempt at building one also, so yeah... good luck to me!

Build Author

Elias Ramburger

Views

6136

Build Author

Elias Ramburger

Views

6136

600 volume 3D-Printer "ABEA"

Hello. I build this 600 by 600 printer and hope to share it. I plan to sell custom builds with my website in the middle of this yeahr while making all parts accesibble online for replacements and own builds. My plan was to build a better and more accessible big volume 3d-printer as cheap as possible. I got some inspiration of the ender creality 3, the crazy-Print xyz 300 and the veho 600 tronxy which was simply not relaible and satisfying overal.

Gerber 404 Retrofit

Not sure if the Blackbox X32 is the right option here, just looking for guidance.

Build Author

David E. Flores E.

Views

7861

Build Author

David E. Flores E.

Views

7861

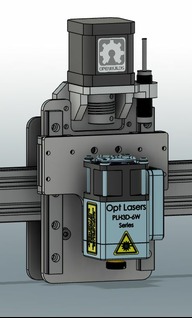

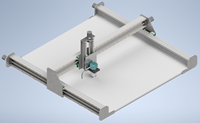

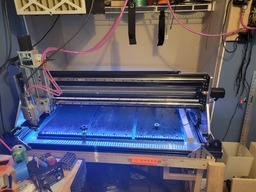

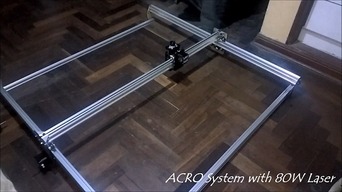

ACRO System w/Laser 80W

This is my version of the OpenBuilds ACRO System CNC, a 1010 version (1000mm x 1000mm). I need this machine to build PCB prototypes within 2-days at maximum. I will try to build PCBs using drill and laser methods...

Build Author

David E. Flores E.

Views

3398

Build Author

David E. Flores E.

Views

3398

F-Ender-Plus 3D Printer

F-Ender-Plus its based on the Ender 3 Pro, but improved: CR-10 hotend, double gear extruder, double z-axis motor, bltouch incorporated, hotbed leveling improved strings kit. Most made using local vendor parts, and still I'm increasing my knowledge of how get better 3D printings by calibrating motors steps, leveling the hotbed and z-axis; using a 3mm thick glass...

Build Author

David E. Flores E.

Views

5950

Build Author

David E. Flores E.

Views

5950

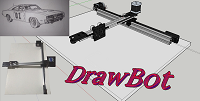

DaveWare DrawBot

Turning my prototypes into real objects, it will be required a great amount of drawings, A LOT. Therefore, against the ink costs raise price push me to think in a way to draw models, blueprints, etc. at very, VERY low cost. This is where my DrawBot was born

Build Author

Alexander_Bulgaria

Views

1698

Build Author

Alexander_Bulgaria

Views

1698

CNC milling machine,lathe,gantry,fdm,clay 3d printer ALL IN ONE

That is the only cnc you will need for most of your diy projects.

5 x 10 CNC - Sub $3000 - Wall Mountable

I wanted a 5 x 10, Wall mounted CNC, that cost less than $3000. I think Im pretty close.

Pen Plotter

All metal A3 CoreXY pen plotter

Needle cutter for foamplates

Cutting Depron foam panels by an oscillating needle

Workbee 1010 et laser atomstack M100

Je ne sais pas comment brancher mon laser sur la blackbox?

Just Another CNC

I wanted to make my own unit. I enjoy building and was looking for a challenge.

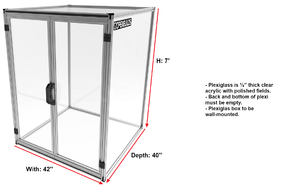

Plexi Panel

Plexi Panel to use for a vfd test enclosure. The box will be wall-mounted on plywood, so the back of the box is not necessary. - The bottom of the box is not necessary because the box will be fixed on concrete on the floor. On the door, I was thinking of putting 4 brackets instead of two. We'll have two 21” doors

Build Author

robert christensen

Views

1519

Build Author

robert christensen

Views

1519

Tool holder

I saw a video of some one pouring resin in a mold,so i did a little research, i bought some resin,and some molds and magnets all from Amazon, it took me several tries and a big mess but it finally finished. The first pour i poured a small batch to make a templet,i marked all the holes that needed drilling then i marked the underside of the mold where i wanted the magnets, next was making the pcs i needed