LASER - PLASMA BUILDS

Build Author

Hilleke

Views

7880

Build Author

Hilleke

Views

7880

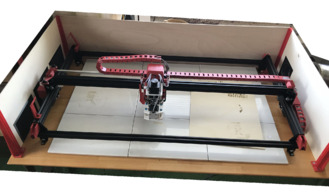

Acro System cable management and enclosure

wooden parts of the enclosure can be removed easily used the existing extraction of my glass bead burners

Build Author

David E. Flores E.

Views

7866

Build Author

David E. Flores E.

Views

7866

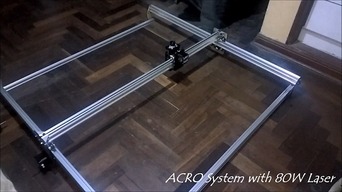

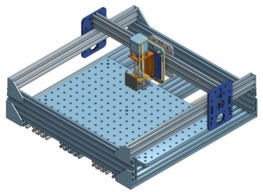

ACRO System w/Laser 80W

This is my version of the OpenBuilds ACRO System CNC, a 1010 version (1000mm x 1000mm). I need this machine to build PCB prototypes within 2-days at maximum. I will try to build PCBs using drill and laser methods...

laser gantry use mini v end block my own design

i always make laser cutting machine, but when i see openbuilds, this can make more cheap gantry for make laser cutting.

Custom 40W Laser Cutter

So this is my custom 40W build. I wanted to make another laser similar to the one I built but a lot smaller and an all in one system so that if I ever decide to do a farmers market or something similar, I wanted to be able to put the laser on the back of the car and drive to whatever location. I think it's going to work. It will be see-through with lights and screens eveywhere. The lights alone should attract people like flies. That's the plan anyway.

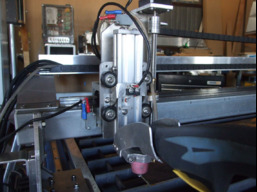

Plasma CNC, 4'6" × 8'8" v0318

A plasma table able to cut 4'6" x 8'8" sheet. Low cost as possible.

Build Author

MrMojoRisin

Views

7617

Build Author

MrMojoRisin

Views

7617

IIOT WiFi Portable CNC Plasma Cutter

IIOT WiFi Plasma CNC.

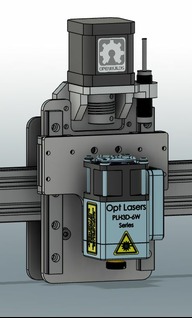

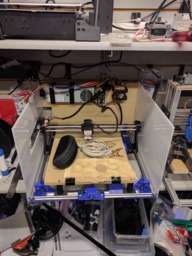

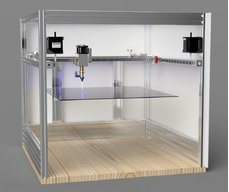

Corexy laser

I have tested my Opt Lasers laser module on a "open" frame for some time. Decided that I want to test a corexy setup and combine it with a boxed/enclosed design - my goal is to get high precision + a safe setup with protection from the laser light + a fan to extract the smoke/exhaust..

Based on 608 tube Plasma Cutter

Simple steel tube design Plasma water table

Build Author

Jacob Christiansen

Views

7300

Build Author

Jacob Christiansen

Views

7300

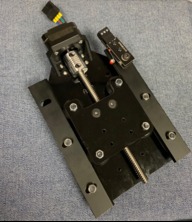

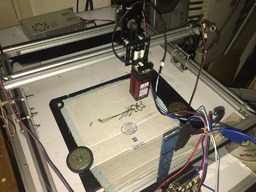

ACRO 1010 with custom Z axis

This is my build for an ACRO system with a custom z-axis for changing z height for focusing or for adjusting depth when making multiple passes when cutting.

5'x10' CNC Plasma/Mill Table

Plasma Mill CNC

Build Author

Bruce Walker

Views

7132

Build Author

Bruce Walker

Views

7132

BD's Burn Box - ACRO Laser Engraver System

Two plus years in the making, I finally have a working ACRO 510 laser engraver system complete with enclosure and air filtration.

Home made CNC Plasma Cutter

Not completed yet but it does work, I will be changing small things as I finish the build and I have learned a lot from this build I am looking forward to finishing this one and Building another maybe larger table.

80watt Lasercutter, workingarea 105x52[cm], steel frame

I will write a short buildlog here with mostly pictures. I designed this lasercutter in solidworks(not totally finished) for a good overview and such that the steel tubes could be lasercut by a company, the metal frame is based on the lasercutter the KÄSER, which you can find on cnczone.nl. The mechical parts are designed by myself because I had no mill to my use, so the mechnical parts are lasercut(same company as tube) steelplates welded together.

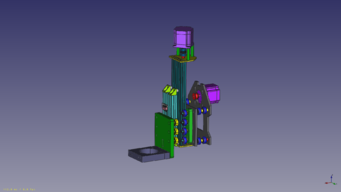

Z Axis for ACRO

Created a small Z axis for the ACRO motion system. I wanted to more easily adjust the height of the laser to accommodate various thicknesses of material, without having to manually loosen screws to adjust. Also wanted to be able to vary the height for multiple cutting passes on some materials. Try to stick to a similar aesthetic as the original ACRO system and plates.

750x750 Plasma cutter table

It startet in May with some leftovers from a cnc router build. Now in the middle of December its 99% finish. Everything is lowcost, spend about 1600$ so far.

Vacuum laser table

Large 10’x6’ vacuum table made from steel tubing and 1/4 inch steel plate

1250x1000 Build

A new design of my based on a couple different machines I have seen both on openbuilds and youtube. In the end will have a and X/Y workspace of 1250mm x 1000mm and a Z axis range of about 200mm.

Silverchris's Laser Cutter

Work in Progress of a laser cutter design. Based on the CoreXY build from https://makerstore.com.au

Update for my 3D Printer - Big Size

I like combo machines, so I upgrade my 3D Printer with a Laser. It is a double head combination. The Laser is easy removable.

DIY LED acrylic lamp

This is a simple lamp using only 2 LEDs & 2 AAA batteries.

ORCA Laser Build

This is my take on the Acro Laser system made from mostly salvaged, scrap, or leftover parts. I modified the plates in an attempt to maximize the cutting area and I wanted a lightweight adjustable Z axis.

![Acros with customizations [WIP]](https://builds.openbuilds.com/data/article_images/l/6/6329.jpg?t=1517104699)

Build Author

Sam Price

Views

5817

Build Author

Sam Price

Views

5817

Acros with customizations [WIP]

This is a work in progress ACROS build with new legs and wire tracks.

Build Author

Todd Brous

Views

5682

Build Author

Todd Brous

Views

5682

Modified Acro with build plate, Z-axis and OPT Laser

Modified Acro for laser engraving. Extra height and and a sturdy build surface for part fixtures, custom mount plates, OPT Laser, and a Z-Axis.

Build Author

Lasersc

Views

5463

Build Author

Lasersc

Views

5463

The D & R TigerPaw Trilogy

Hopefully this will be a quick guide to one way that you can add a laser to an existing CNC router.

x_y_module laser engraver

low cost 2 axis cnc laser, really portable and easily expandable

Build Author

tarekhassan2030

Views

5399

Build Author

tarekhassan2030

Views

5399

Home build from A to Z

I made this from A to Z at home by myself with reading and watching tones of videos. 50 cm X 50 cm but I get 40cm x 35 cm as a real workread

Laser cutter

Full aluminium profiles construction. Synrad 50w CO2 laser. Ruida controller. Yaskawa servo motors

Plasma CNC machine

The plasma CNC that I have built has a water table that measures 1350mm x 650mm. The water is flooded onto the cut area while cutting and recycled around with a pump. This is to reduce smoke, cool the metal being cut to reduce distortion and also to keep sparks to a minimum. Most of the machine has been made from aluminium , the frame and table from steel, the water table, stainless steel.

Piggy back engraver for ShopBot

Built from leftover T-Slot extrusions plates and hardware from other defunct projects.

Z Floating Head

It's a Z floating head idea. Works well. Recommend cleaning the inside of your holes well with Q tips, and polishing the 1/4-20 bolts with car wax and you won't need oil as it slides perfectly. Hope this helps

4' by 2' Lasercutter

4foot by 2 foot, 10W El-Cheapo blue laser

Build Author

cory stafford

Views

4790

Build Author

cory stafford

Views

4790

Home built laser cutter

This is a laser cutter built with intent to use arduino as controller for a co2 cutting laser.

My 80w Laser build (1000x1000 cutting area)

This is a 80w laser which I am building (picture of the case) the frame is constructed with normal square tubing with plastic corners. this laser needs to live outside

My ACRO Build

An ACRO laser put together with some repurposed and some new parts.

1.3m x 1.3m RF laser cutter

RF 100w laser cutter build, aluminium extrusion

Build Author

cnc-trucker

Views

4420

Build Author

cnc-trucker

Views

4420

Arduino Mega to EMC2 (LinuxCNC) Plasma Table Conversion

This is a story about a guy who started with a $25 set of plans, and through 4 iterations/ rebuilds, ended up with a professional quality CNC plasma table capable of cutting anything steel up to 2 inches thick.

Dedicated Rotary Laser Made from Scrap and Spares

A clone of https://openbuilds.com/builds/dedicated-compact-rotary-axis-laser-engraver.10204/

GIGAWATT 2.1 LASER CUTTER

Progetto di un laser CO2 da 50w Autocostruito, con scheda di controllo MKS Sbase v.1.3 Firmware Smoothieware versione CNC Struttura realizzata con profili T-slot 20x20 e 20x40

Budget friendly starter build

DIY CO2 laser build. Budget friendly, 2020 T/V-slot profiles and scalability.

Needle cutter for foamplates

Cutting Depron foam panels by an oscillating needle

LaserShark300

300x300 belt drive laser etching/cutting platform. The design was borrowed from another's blog and customized to fit materials on-hand. Was a very fun project to assemble.

Project Infinity co2 laser

1m x 1.8m 60w co2 laser build.

Hevavy duty 1300mm x 1300mm laser cutter Ceramic tube Servo motors

Starting the next Laser build, Plan to complete within 60 days.

Large format laser

Large format laser build for Student use at my school as well as some personal use.

Acro 1010 with 10 watt Laser

Built a 32"x40" ACRO Kit for my 10watt Endurance Laser. Put it in a stand alone clamshell cabinet, added a 340cfm 6" fan and variable speed switch for the fan. Using LIght Burn for my primary software. It seems to be work well.

Build Author

robert christensen

Views

1521

Build Author

robert christensen

Views

1521

Tool holder

I saw a video of some one pouring resin in a mold,so i did a little research, i bought some resin,and some molds and magnets all from Amazon, it took me several tries and a big mess but it finally finished. The first pour i poured a small batch to make a templet,i marked all the holes that needed drilling then i marked the underside of the mold where i wanted the magnets, next was making the pcs i needed

Workbee 1010 et laser atomstack M100

Je ne sais pas comment brancher mon laser sur la blackbox?

![80watt Lasercutter, workingarea 105x52[cm], steel frame](https://builds.openbuilds.com/data/article_images/l/6/6014.jpg?t=1513166610)