Build List

-

Active Filters:

3

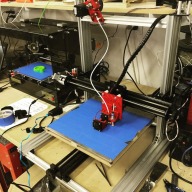

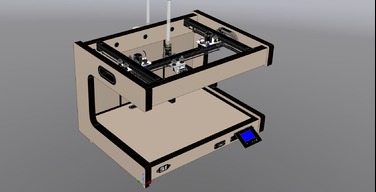

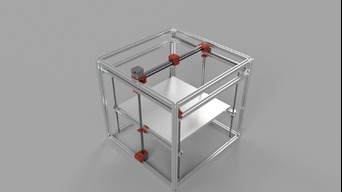

First CoreXY Build

First CoreXY. Simple Square build, hopes for faster movements.

Build Author

Tomas F Uribe

Views

5298

Build Author

Tomas F Uribe

Views

5298

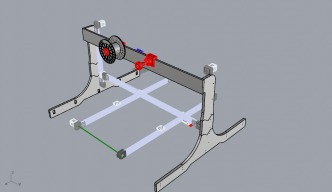

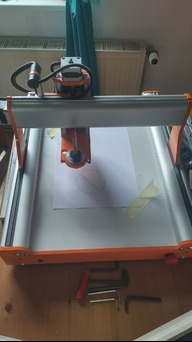

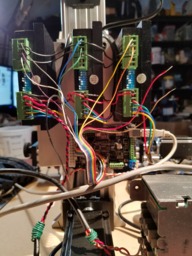

Atucnc

2 1/2 axis CNC chassis. Convertible to plasma, 3D printer and welder. Currently used as router. Plotting table dim: X axis 620 mm, Y 650 mm, Z 100 mm. Created for teaching purposes, open source license, currently used for engraving ukiyo-e wood plates and printmaking

Build Author

Crazzy French Dude

Views

5296

Build Author

Crazzy French Dude

Views

5296

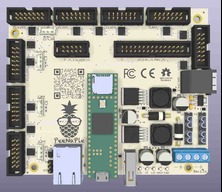

PeeNaPle_V1.4b

PeeNaPle_V1.4b is a BoB controller board for 3D Printers, CnC and cartesian machine, using the latest Teensy_4.1

dave's RepStrap

PVC foam Core frame made from a Delta facet display. a curb find while walking home.

delta 3d printer kit

HE3D K200 kit build

Lead screw printer

High quality e3d parts with a minimalist design

V5- 2in1 ( 3dPrint+laser Engraving )

2in1 ( 3dPrint+laser Engraving )

Build Author

TouchPadKing

Views

5068

Build Author

TouchPadKing

Views

5068

1500mmx500mm Kossel Delta

Please, look over my build and make any recommendations you can think of! I haven't figured out how long my arms need to be yet. Nor have I done any shopping around to find better prices...

Build Author

patdee

Views

5051

Build Author

patdee

Views

5051

777 CNC Build

To begin the "Build" I have ordered a few parts from OpenBuilds to get started. They are arriving today; according to "tracking". I cant wait! Praise Jesus! This 85 yr old man is getting a "New " life. Hallelujah and amen. Because I am building this on an existing machine, I have to be careful; so I will order some parts then see what I don't need (such as a base); along with parts that I may need to adapt it to the machine. It should be fun! "Caint wait!"

Build Author

Rob Withoff

Views

5008

Build Author

Rob Withoff

Views

5008

Mini-Mill Enhanced

Some enhancements of the basic mini-mill

VoS

3D Printer based upon 3d printed parts and open builds componets

Norm Inverted - Cartesian

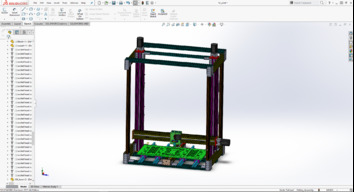

As a tinkerer and hobbyist I need a reliable quality printer on a budget... Meaning I'm not looking to buy a: Prusa, Zortrax or LulzBot because of the added cost their marketing adds. I can definitely build a machine of hopefully equal quality at a lower cost that is not impacted by the marked-up priced from a large reputable manufacturer. I will need to dedicate time and more time for design shakedowns to ensure I produce a quality machine. Bare with me on this build... Thanks!

Build Author

Leboeuf

Views

4915

Build Author

Leboeuf

Views

4915

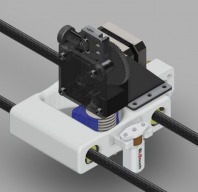

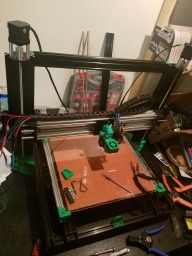

Cartesian 3d printer

This is the build of a cartesian 3d printer made of an old Anet and Geeeteck, some 2020 alu profil and linear rail. Powered by a Rumba with a Nextion screen. It should be modular and accept dual Extrusion and laser engraving.

large format printer

I am hoping to post a detailed build of my printer it is a large format using the RepRap RAMPS 1.4 & Mega 2560 & DRV8825 Driver + optical end stop +LCD 12864 -C 0.4mm Far-end Distal Dual-Head Nozzle Extruder Double Nozzle

Build Author

Power Playground

Views

4799

Build Author

Power Playground

Views

4799

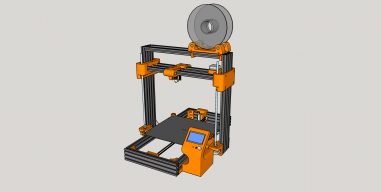

PowerBot

This is my own modified version of the D-Bot printer. I wanted to spec this printer to be able to print exotic materials at high accuracy with little to no compromises and maximum reliability.

Voxel Evolution

This is a remix of Marshal Peck's Voxel OX, with some design tweaks inspired by Makerparts and jjcolletta. It has a build area of 300mm X 300mm X 480mm, but is easily configured for just about any build area up to 500mm X 500mm X 750mm. I have used some laser cut acrylic plates and a couple of 3D printed parts in its construction, however it can be assembled using nothing but OpenBuilds parts with the exception of the heated bed and the Y axis carrier for the heated bed.

GhettoPrinter

Dirt cheap build.

Techsoft Roland TS-30 rebuild

Replacing the Electronics and Spindle. Intending to rewire all the buttons and make it into a more modern and easy to use CNC.

bertha

This build will hopefully be 18x18x24 build space using RAMPS 1.4 with Marlin firmware. Using NEMA 17 motors and belts to drive the X and Y axis, lead screws for the Z axis. The build plate will be heated with a delrin Y carriage for the glass and heatbed. Z axis motors will be top mounted. Possibly and ATX power supply.

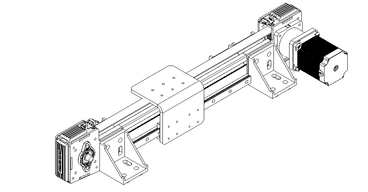

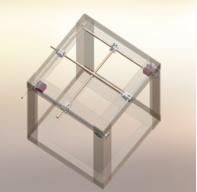

CNC Linear Slide for DIY project

Low cost cnc linear drive for making any xyz cnc structure

Build Author

islahcnc

Views

4415

Build Author

islahcnc

Views

4415

islahcnc&design

I will post soon some more details.

Build Author

Darren Dickson

Views

4351

Build Author

Darren Dickson

Views

4351

3D printed CNC Machine

So I thought I would make the Leon van den Beukel version three 3D printed CNC Machine, it is the third incarnation so you would expect a relatively bug-free CNC Machine with a strong foundation.

Build Author

Doug Rowley

Views

4291

Build Author

Doug Rowley

Views

4291

My Workbee 1010

This is a workbee 1010 build using the mechanical parts from Open Builds. The electrical and electronic parts were from a prior build of a Root 3 CNC by Sailor Pete.

Old Faithful...FDM/CNC machine

I've owned some pretty unreliable printers, and I'll leave it at that... This design comes from the need to have a 3D printer that is reliable, period. I didn't have the money for a several thousand dollar 3d printer with an equivalent build area so that was out of the question. Plus as a fledgling Engineer, I really wanted to blood myself on a project. And that's how Old Faithful came to be. A simple, reliable, rigid, durable machine. Made by me :) Also, it'll be tough enough for light CNC.

Brice's CNC Router Build

I'm building a CNC router for a long time. Here's the result on this long journee. I tried to do my best with the basic tools I have. Don't hesitate to ask if you have questions.

Build Author

Fabio Bertuzz

Views

4188

Build Author

Fabio Bertuzz

Views

4188

DutziDelta RepStrap

Fascinated for some time by 3D Printing. Now, after studying countless forum posts, blogs and similiar stuff, i want to Start with my own build. Maybe a bit much but usually i thrive with the challenge.

Build Author

Edgar Robles

Views

4065

Build Author

Edgar Robles

Views

4065

Sheethexapod

Sheethexapod works with basic mechanims as direct metal-metal links and joints, all movements can be done by a rc servomotor in this case towerpro model.

Build Author

Keith Davis

Views

4010

Build Author

Keith Davis

Views

4010

Vulcan Bot

A 200mm x 300mm x 200mm workhorse that never needs leveling due to Posi-Drive Leveling design.

Core XY

Just now in the planning phase of my build. Waiting for some parts to come in to see what I am going to build off of. Print area going to be close to 300x300x350. Trying to decide if I want it enclosed. I do want to print ABS... so probably so.

Cairo 30 3d-printer

We are introducing the Cairo30 3d-printer! It’s our new premium creature with no compromises! The Cairo30 3d-printer is the culmination of our accumulated years of experience designing and producing open-source CNC machines kits.

Ancient Roland Table top Mill

The parts are now very reasonable.

Reworked Sepcraft 420 CK

Its alive !

Build Author

Ken376

Views

3705

Build Author

Ken376

Views

3705

Welded project cnc first try

Kind of hard to see in this pic now lining up drive s and finishing framework

Build Author

McAdam

Views

3704

Build Author

McAdam

Views

3704

Need a catchy name - enlarging CNC

The aim of this build is to have a CNC that can cut a FULL sheet of wood when I need it to, but also shrink down and cut smaller sheets the rest of the time. The prototype is based on an OX cnc but soon it will be completely custom using Openbuilds Parts

Build Author

h3rb

Views

3699

Build Author

h3rb

Views

3699

TEVO Little Monster Marine Vinyl Removable Enclosure

Make a vinyl burrito ENCLOSURE for your TEVO LITTLE MONSTER for < $30 (<$20 if you don't have your vinyl shipped!)

3D Printer 051

Functional real-world 3D printer build with RM2-2RS bearings in routed V grooves on phenolic resin rails (lab countertop scraps) and NSK 25mm linear rails/trucks.

Design and Performance Evaluation of A Large FDM 3D Printer

This build includes the design of a large FDM 3D printer. This machine has a 796mm by 796mm by 900mm (LxWxH) build volume. Motion is controlled by servo motors and the printer runs on python-based marlin firmware.

Pen Plotter

All metal A3 CoreXY pen plotter

Bedroom Builds (BrB) DIY CNC

So I am employed in the automotive industry and I walk by thousands of dollars of CNC products daily that are no use to me due to being a Technologist and not a machinist. So therefore with some research I found openbuilds and their great selection of products to build my own CNC. This CNC will consist of 4 axis one removable 360 degree axis for turning alongside a x axis table Y axis stationary gantry and a Z axis attracted to the Y axis linear actuator.

Build Author

Genetoys

Views

3269

Build Author

Genetoys

Views

3269

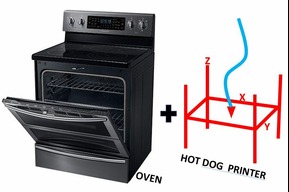

Oven Dog

Building a printer that can fit inside and operate at ~200 C oven temperatures

ivern

Toying around a concept. Inputs are welcome on whether to use lead screw or belt drive. My lead screw will be single start 500 mm lenght, 2 mm pitch and 2 mm lead. Nema 17 motors will be used. All veterans, suggestions please.

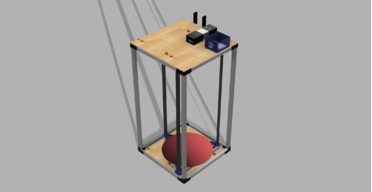

Mammoth (Delta printer)

Massive Delta printer with a print area of 25 Inches (634mm).

Build Author

David E. Flores E.

Views

3155

Build Author

David E. Flores E.

Views

3155

F-Ender-Plus 3D Printer

F-Ender-Plus its based on the Ender 3 Pro, but improved: CR-10 hotend, double gear extruder, double z-axis motor, bltouch incorporated, hotbed leveling improved strings kit. Most made using local vendor parts, and still I'm increasing my knowledge of how get better 3D printings by calibrating motors steps, leveling the hotbed and z-axis; using a 3mm thick glass...

Build Author

Linkreincarnate

Views

3095

Build Author

Linkreincarnate

Views

3095

Amazon Special

I have parts that are apparently not suited to a cnc router or a 3d printer. I am still trying to figure out what to make out of what I have,

THE BIG GREEN MACHINE

1500*1500*1900 (xyz) Biocomposite Pellet 3D printer

Build Author

Terone Burgenheim

Views

2790

Build Author

Terone Burgenheim

Views

2790

My CNC

This build is my version of the CBeam machine. I opted to NOT use the Gussets, and instead went for the 40, and 60 mil angle brackets to cut the price back a little further. I started with the smoothieboard but decided it was still "too new" and very much experimental. This build took me a few (2-3) days to complete. The CBeams and Lead-Screws really make building things faster since you don't have to clamor over belts.

Galvos

3d printable galvos

Build Author

Bill325

Views

2306

Build Author

Bill325

Views

2306

One more life for a cube

Modify a Gen1 Cube printer into a small cnc router to cut pcbs and light (VERY light) milling work. Also easy to swap out the rotary head and mount a laser head for engraving.

26 x 26 x 45 3D Printer/Mill

Super tall 3D printer. All lead screw design.