Build List

-

Active Filters:

as

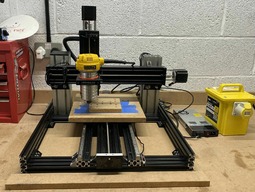

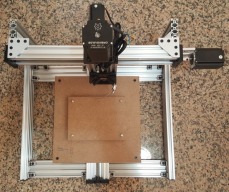

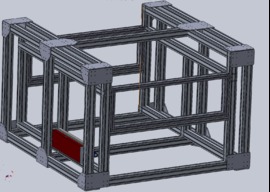

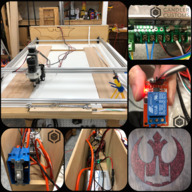

Router / Plasma Prototype Build

this is my first attempt at a CNC Table

ORCA Laser Build

This is my take on the Acro Laser system made from mostly salvaged, scrap, or leftover parts. I modified the plates in an attempt to maximize the cutting area and I wanted a lightweight adjustable Z axis.

![Acros with customizations [WIP]](https://builds.openbuilds.com/data/article_images/l/6/6329.jpg?t=1517104699)

Build Author

Sam Price

Views

5753

Build Author

Sam Price

Views

5753

Acros with customizations [WIP]

This is a work in progress ACROS build with new legs and wire tracks.

Build Author

Anthony Bolgar

Views

5700

Build Author

Anthony Bolgar

Views

5700

Air assist/fume collector for Diode Laser Engraver

This is a work in progress

PCBman CNC

This is a design for a desktop CNC machine. It may be a router or laser. I am undecided as to the final design.

Build Author

Todd Brous

Views

5561

Build Author

Todd Brous

Views

5561

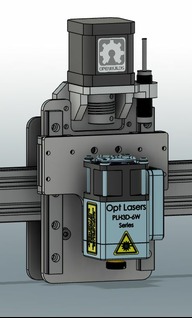

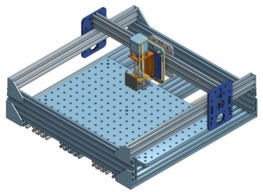

Modified Acro with build plate, Z-axis and OPT Laser

Modified Acro for laser engraving. Extra height and and a sturdy build surface for part fixtures, custom mount plates, OPT Laser, and a Z-Axis.

Build Author

CandlerCustoms

Views

5459

Build Author

CandlerCustoms

Views

5459

Candler Customs - Custom CNC Machine

Inexpensive Custom CNC Machine or swappable Laser Engraver utilizing OpenBuilds ACRO System

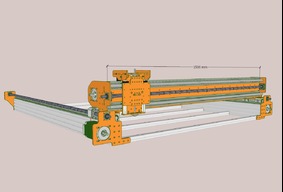

x_y_module laser engraver

low cost 2 axis cnc laser, really portable and easily expandable

Build Author

Lasersc

Views

5345

Build Author

Lasersc

Views

5345

The D & R TigerPaw Trilogy

Hopefully this will be a quick guide to one way that you can add a laser to an existing CNC router.

Build Author

Tomas F Uribe

Views

5305

Build Author

Tomas F Uribe

Views

5305

Atucnc

2 1/2 axis CNC chassis. Convertible to plasma, 3D printer and welder. Currently used as router. Plotting table dim: X axis 620 mm, Y 650 mm, Z 100 mm. Created for teaching purposes, open source license, currently used for engraving ukiyo-e wood plates and printmaking

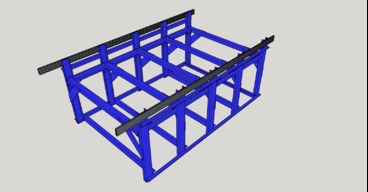

Cnc mill, Plasma cutting and weld table

A functional table for plasma cutting, welding, tooling........

My C-Beam build and modifications

Modified C-Beam which I plan to add a laser module and eventually convert to C-Beam XL size.

McRouter 3 Axis CNC

I wanted to put together a medium size router using PTFE slides from McMaster-Carr. I've had great experience with these slides in long term continuous motion operations in industrial environments.

Laser cutter

Full aluminium profiles construction. Synrad 50w CO2 laser. Ruida controller. Yaskawa servo motors

Learning how to build

I made a 5x10 foot cnc out of the parts I bought on this site. It's been upgraded and tinkered with ever since. The end goal is to learn enough to learn to build a large 10x10 foot 3d printer.

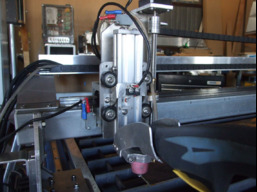

Plasma CNC machine

The plasma CNC that I have built has a water table that measures 1350mm x 650mm. The water is flooded onto the cut area while cutting and recycled around with a pump. This is to reduce smoke, cool the metal being cut to reduce distortion and also to keep sparks to a minimum. Most of the machine has been made from aluminium , the frame and table from steel, the water table, stainless steel.

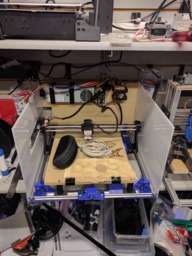

C-Beam CNC (1st cnc build!)

1st build CBeam Machine w/ raspberry pi-protoneer hat controller

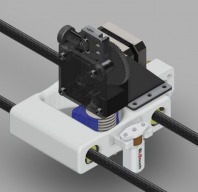

V5- 2in1 ( 3dPrint+laser Engraving )

2in1 ( 3dPrint+laser Engraving )

Piggy back engraver for ShopBot

Built from leftover T-Slot extrusions plates and hardware from other defunct projects.

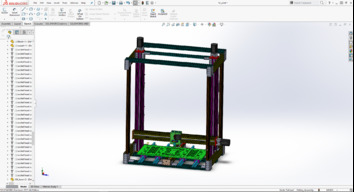

Norm Inverted - Cartesian

As a tinkerer and hobbyist I need a reliable quality printer on a budget... Meaning I'm not looking to buy a: Prusa, Zortrax or LulzBot because of the added cost their marketing adds. I can definitely build a machine of hopefully equal quality at a lower cost that is not impacted by the marked-up priced from a large reputable manufacturer. I will need to dedicate time and more time for design shakedowns to ensure I produce a quality machine. Bare with me on this build... Thanks!

Build Author

Hisha

Views

4965

Build Author

Hisha

Views

4965

Routy based build

Routy based build using 1000mm Y axis beams and 500mm X axis beams. Using a 20x80 Z axis to use the OpenBuilds router mount.

First CNC Build

Building my First CNC for PCB milling. Some modification done to the original build from OpenBuild Bundle.

4' by 2' Lasercutter

4foot by 2 foot, 10W El-Cheapo blue laser

Starting my build 2.8mx1.4m

Starting my cnc router, laser and plasma using aluminium 80x80

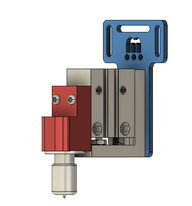

Z Floating Head

It's a Z floating head idea. Works well. Recommend cleaning the inside of your holes well with Q tips, and polishing the 1/4-20 bolts with car wax and you won't need oil as it slides perfectly. Hope this helps

Build Author

cory stafford

Views

4732

Build Author

cory stafford

Views

4732

Home built laser cutter

This is a laser cutter built with intent to use arduino as controller for a co2 cutting laser.

My 80w Laser build (1000x1000 cutting area)

This is a 80w laser which I am building (picture of the case) the frame is constructed with normal square tubing with plastic corners. this laser needs to live outside

1.3m x 1.3m RF laser cutter

RF 100w laser cutter build, aluminium extrusion

My ACRO Build

An ACRO laser put together with some repurposed and some new parts.

Build Author

Denis Lapratte

Views

4511

Build Author

Denis Lapratte

Views

4511

All metal Ox hybrid CNC Router Table

This is my second CNC build, but the first one that I design from the ground up. The base is all metal because I want to add Plasma facility later on. I used the Ox model for the gantry plates and made a few changes to adapt to my design. Since I wanted to use parts from my first CNC to save as much as possible, I kept the 5/8 Hi-Lead Screw I had from Roton for the Y and Z axis. I will also add a downdraft table to keep all parts tight on the table for cutting.

Absolute positioning hardware and software

Absolute linear positioning using deBruijn sequences.

Build Author

Doug Rowley

Views

4303

Build Author

Doug Rowley

Views

4303

My Workbee 1010

This is a workbee 1010 build using the mechanical parts from Open Builds. The electrical and electronic parts were from a prior build of a Root 3 CNC by Sailor Pete.

big_recnc v2.0

cnc made with a 6mm metal body .

Dedicated Rotary Laser Made from Scrap and Spares

A clone of https://openbuilds.com/builds/dedicated-compact-rotary-axis-laser-engraver.10204/

Fastmill CNC

Very cheap CNC made from laser fired and bent parts.

Build Author

cnc-trucker

Views

4054

Build Author

cnc-trucker

Views

4054

Arduino Mega to EMC2 (LinuxCNC) Plasma Table Conversion

This is a story about a guy who started with a $25 set of plans, and through 4 iterations/ rebuilds, ended up with a professional quality CNC plasma table capable of cutting anything steel up to 2 inches thick.

GIGAWATT 2.1 LASER CUTTER

Progetto di un laser CO2 da 50w Autocostruito, con scheda di controllo MKS Sbase v.1.3 Firmware Smoothieware versione CNC Struttura realizzata con profili T-slot 20x20 e 20x40

Build Author

Quinnthouzand

Views

3984

Build Author

Quinnthouzand

Views

3984

Mustardo - The Mustard Bot

The goal for this bot is to lay down mustard on sausages and burger patties in a smooth and sexy way that looks good for the camera.

Build Author

theracermark

Views

3970

Build Author

theracermark

Views

3970

Reviving the Origonal PhlatPrinter with BlackBox

Reworked PhlatPrinter Gen1 Adding dual nema 17s to all 3 axis Supprot for carriage to insure even dept cuts Lighting for view of cutting area

Budget friendly starter build

DIY CO2 laser build. Budget friendly, 2020 T/V-slot profiles and scalability.

Kruk 0.1

This is a stool, designed in 18mm wood for a cnc router, it's easily scaleable to different wood-thicknesses, in 18mm wood it takes up 1200*1200mm. It can be assembled without screws, nails or glue and can therefore also be easily disassembled.

Build Author

George Motichka

Views

3746

Build Author

George Motichka

Views

3746

Transformer

I wanted a machine that could easily switch between 3D Printing and Laser Engraving

Build Author

h3rb

Views

3711

Build Author

h3rb

Views

3711

TEVO Little Monster Marine Vinyl Removable Enclosure

Make a vinyl burrito ENCLOSURE for your TEVO LITTLE MONSTER for < $30 (<$20 if you don't have your vinyl shipped!)

Build Author

Ken376

Views

3708

Build Author

Ken376

Views

3708

Welded project cnc first try

Kind of hard to see in this pic now lining up drive s and finishing framework

Build Author

McAdam

Views

3707

Build Author

McAdam

Views

3707

Need a catchy name - enlarging CNC

The aim of this build is to have a CNC that can cut a FULL sheet of wood when I need it to, but also shrink down and cut smaller sheets the rest of the time. The prototype is based on an OX cnc but soon it will be completely custom using Openbuilds Parts

c-beam XLarge with ZLarge

XLarge with ZLarge

LaserShark300

300x300 belt drive laser etching/cutting platform. The design was borrowed from another's blog and customized to fit materials on-hand. Was a very fun project to assemble.

Build Author

Genetoys

Views

3278

Build Author

Genetoys

Views

3278

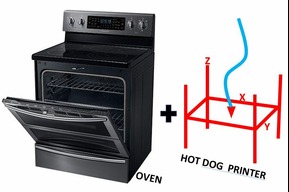

Oven Dog

Building a printer that can fit inside and operate at ~200 C oven temperatures

Build Author

Neil Scott

Views

3203

Build Author

Neil Scott

Views

3203

Barcelona Build

This will be my second CNC build but this time a proper CNC not a small desktop model that I played with for a while to learn Gcode, It was great but now its time to start playing with the big boys and girls.

Project Infinity co2 laser

1m x 1.8m 60w co2 laser build.

Build Author

mjenkins5720

Views

2900

Build Author

mjenkins5720

Views

2900

Modified LEAD machine

At the moment this build is in progress, I will be updating the files as I finish the remainder of the machine. This machine is intended to be a multipurpose CNC, but a bit bigger than a desktop unit. The machine is scalable in the X and Y axis.

Hevavy duty 1300mm x 1300mm laser cutter Ceramic tube Servo motors

Starting the next Laser build, Plan to complete within 60 days.

Large format laser

Large format laser build for Student use at my school as well as some personal use.

Build Author

Terone Burgenheim

Views

2801

Build Author

Terone Burgenheim

Views

2801

My CNC

This build is my version of the CBeam machine. I opted to NOT use the Gussets, and instead went for the 40, and 60 mil angle brackets to cut the price back a little further. I started with the smoothieboard but decided it was still "too new" and very much experimental. This build took me a few (2-3) days to complete. The CBeams and Lead-Screws really make building things faster since you don't have to clamor over belts.

Gizmo CNC

wanted large work area for laser etch/cuts more than spindle work.

ECNCML (budget mashup)

This build summarizes my CNC milling and laser engraving machine conversion from a dimensional lumber frame and electrical mess to an all aluminum frame with a safe and well constructed (IMHO) control system with the resources I had available.

Galvos

3d printable galvos

Pneumatic cnc cutter with festo drive

CNC Glass cutter

Acro 1010 with 10 watt Laser

Built a 32"x40" ACRO Kit for my 10watt Endurance Laser. Put it in a stand alone clamshell cabinet, added a 340cfm 6" fan and variable speed switch for the fan. Using LIght Burn for my primary software. It seems to be work well.

Automated Media Blaster

Automated Media blaster retrofit.

GHOST Case by Copper Pour

GHOST Case build for the OpenBuilds Black Box Motion Control System

My Little Mashup

A mixed drive, PI Controlled machine

AcoustoPlot3D

The Sphinx has all the components I need, except it will need a taller vertical lead screw, the same length as the horizontal ones. It will also need legs. So I need to start with the Sphinx parts list, then make a few changes.

Build Author

Daniel Stewart

Views

2009

Build Author

Daniel Stewart

Views

2009

Ultra sun cutter

A sun cutter only using mirror and glass balls with x and y table movement

Build Author

robert christensen

Views

1428

Build Author

robert christensen

Views

1428

Tool holder

I saw a video of some one pouring resin in a mold,so i did a little research, i bought some resin,and some molds and magnets all from Amazon, it took me several tries and a big mess but it finally finished. The first pour i poured a small batch to make a templet,i marked all the holes that needed drilling then i marked the underside of the mold where i wanted the magnets, next was making the pcs i needed

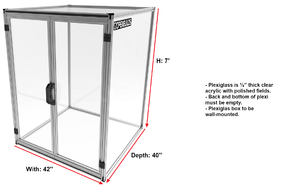

Plexi Panel

Plexi Panel to use for a vfd test enclosure. The box will be wall-mounted on plywood, so the back of the box is not necessary. - The bottom of the box is not necessary because the box will be fixed on concrete on the floor. On the door, I was thinking of putting 4 brackets instead of two. We'll have two 21” doors