Build List

-

Active Filters:

beam

Build Author

Teflon4

Views

16108

Build Author

Teflon4

Views

16108

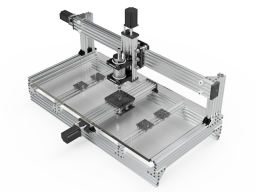

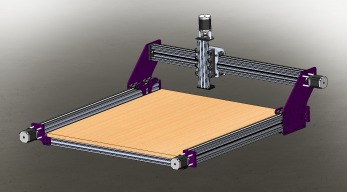

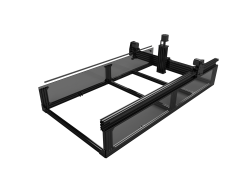

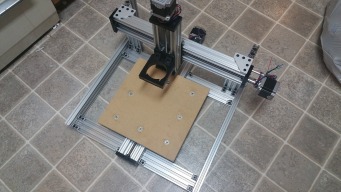

TZ C-Beam Machine Plate Maker

A Modified and augmented Ooznest C-Beam Machine Plate Maker.

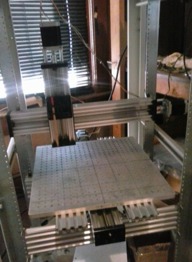

RSW's C-Beam Build

I built a CNC Router using 3/4 MDF, 1/8 aluminum angle for bearing races and various other odds and ends. I learned a lot about how not to build a CNC router. I found Openbuilds.com and decided to build a C-Beam for my first build. The long term idea is to use this machine to build custom plates for and OX type machine and a 3d printer.

C Beam Served

C Beam Machine built in a server cab. Hopefully this keeps every thing enclosed , clean and quite ?

Build Author

Ronald van Arkel

Views

16855

Build Author

Ronald van Arkel

Views

16855

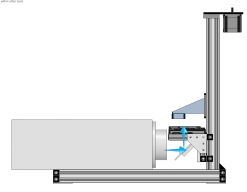

Upgrading the C-Beam machine

So we have new plates, stronger motors, belt drive reduction, but what should we do with them? In this article you might find the answer you were looking for as we took an “old” C-Beam machine and started to upgrade the X/Z body and added more torque and precision to the Z-axis.

C-Beam Elexa

This build will be based on the C-Beam Plate Maker, with additional changes based on other builds and ideas.

SkyKae sphinx - c beam xl hybrid

I took what I thought were the best parts of the sphinx and the c beam xl to build a bigger and faster machine.

Build Author

Terone Burgenheim

Views

2908

Build Author

Terone Burgenheim

Views

2908

My CNC

This build is my version of the CBeam machine. I opted to NOT use the Gussets, and instead went for the 40, and 60 mil angle brackets to cut the price back a little further. I started with the smoothieboard but decided it was still "too new" and very much experimental. This build took me a few (2-3) days to complete. The CBeams and Lead-Screws really make building things faster since you don't have to clamor over belts.

Build Author

jamesdjadams

Views

12427

Build Author

jamesdjadams

Views

12427

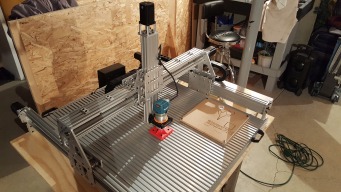

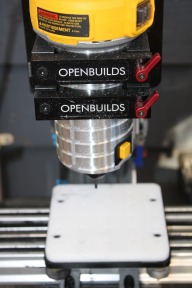

C-Beam XL - TinyG - Aluminium Plate - Dewalt 611

C-Beam XL build using TinyG V8.

Another Sphinx - 1000mm x 750mm

The reason for building this CNC is to help me in my guitar building hobby. (telecasters)

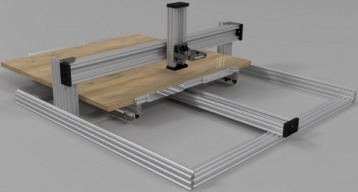

C beam machine (with larger T-slot platform)

Larger, more rigid build plate C beam machine

ZANTRY CNC

CNC Based on CBeam, with No custom Plates, and Z GANTRY

My 2nd cnc build

My new build to upgrade from my worn out shapeoko

Build Author

Kyo

Views

10455

Build Author

Kyo

Views

10455

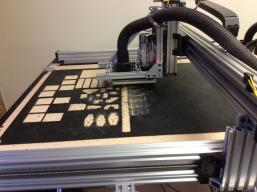

Plate Maker V-slot Table

C-beam Plate Maker V-slot Table System to aid in clamping and setup of jobs.

C-Beam XL ( 1 meter²)

A modified C-Beam Build with a few Addons

Build Author

Anthony Castelluci

Views

3335

Build Author

Anthony Castelluci

Views

3335

Simple Camera Lofted Camera Slider

Build a manual camera slider.

C-Beam XXLarge "Laser "Tank""

A re-imagining of Dollarz81's XXL Tank in Laser form

Heavy duty C Beam

a 1000mm x 1500mm CBeam build with hgr20 hiwin rails 600w er16 spindle

C beam Larger and Stronger

My first build based on the original C beam Sphinx. I’m not sure at this point what the final size will be. I have the parts from the c beam Sphinx and extra beams and lead screws to build up to 1000mm x 1000mm.

Build Author

Greg Lampman

Views

9393

Build Author

Greg Lampman

Views

9393

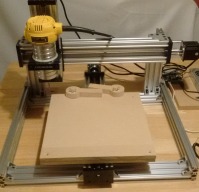

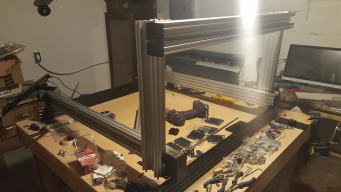

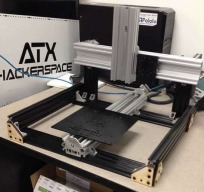

C-Beam Intro to CNC

Build log for my first CNC machine, a C-Beam Plate Maker

C Beam CNC+Laser

You will be following the assembly of the mechanical kit and how i integrate the electronics into the final build.

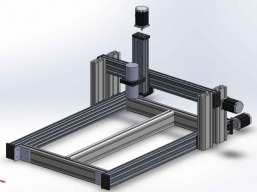

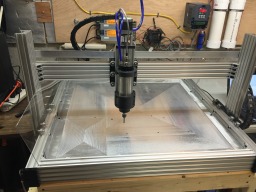

C-Beam Machine XL

Overview of my experience building the C-Beam Machine XL from OpenBuilds, along with updates as I move along and get it going. My application is for creating plates needed for lab functions, 19 rack bay covers, and whatever else arises.

C beam xl

I would recommend this challenge to any woodworker looking for something new.

Vertek CNC - 1000mm x 750mm Linear Rail on C Beam

C beam gantry with steel guide rails!

BD's C-Beam Machine CNC Router (WIP)

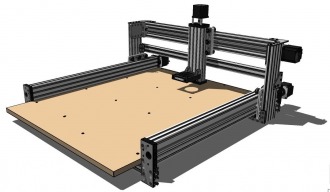

CNC router table based on OpenBuilds C-Beam Machine bundle.

C-Beam Machine upgrade to 1000mm x 1000mm

This built is to convert an existing 500x500 C-Beam Machine into 1000x1000. Inspired by several builds including C-Beam Machine : (http://www.openbuilds.com/builds/c-beam%E2%84%A2-machine-plate-maker.2020/) and Gino's build : (http://www.openbuilds.com/builds/c-beam-gtc.3250/)

The Hoss

The purpose of this build is to create a simple, strong modular build that is rugged enough to cut out some of the softer metals along with wood and plastics. Using basic parts like the universal plates, t-nuts and v- wheels coupled with the strength of C-Beam I am sure this will deliever the desired results!!

Build Author

Robert Bailey

Views

29615

Build Author

Robert Bailey

Views

29615

FRANKINATOR -- My CNC Router Built Around The C-Beam Rail

I started this build about 2 weeks after the c-beam hit the store. I purchased a single bundle and ordered a TinyG to run it. where I work I have Hardware, Software and Mechanical engineers and they all got sucked into my project. they want one to do prototyping at the office, once they see mine...

Build Author

Sonny Lowe

Views

7167

Build Author

Sonny Lowe

Views

7167

The MakerSL Customized OB Minimill

This is my interpretation of the OB Minimill, what I've changed so far, and what may continue to change as my requirements change.

CNC Planning

Reusing parts to build a CNC - planning stage

Dixie C-Beam XL

Build log of the Dixie C-Beam XL CNC Router.

C-Beam based modular Resin Printer

The build is based on a 500mm C-Beam and the SeeMeCNC FlexVat. The C-Beam is both the linear motion and a structural element of the design. The frame that holds the 45 degree first surface mirror and the build vat can slide up and down the C-Beam to accommodate projectors with lenses at different elevations.

Build Author

mikev

Views

8768

Build Author

mikev

Views

8768

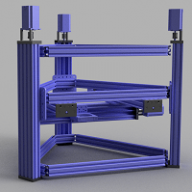

C-Beam Evolution MkII

The C-Beam Evolution is an evolving machine. The MkII is inspired by Kyo's C-Beam Spinx but currently uses my own design of plates made of 8mm acrylic (X-axis ends) and 6mm polycarbonate (Y axis ends). The plates were made on the MkI but I hope to be able to make 6mm aluminium plates on the MkII for the MkIII.

Triangular CNC Milling Machine

A wonky build to eliminate slop on a long Z axis

Contrariwise -- A C-Beam Router

A C-Beam router made almost entirely of standard parts. Electronics include an xPro v2 board and NEMA 23 motors. Cuts are made with a small 300W DC spindle. A pressure foot is used to minimize the need for workholding.

C-Beam XL build

So for a summary its a great kit that was easy to build, could not be more happy.

Makerparts.ca Prusa i3Pro 300

Concept for a Prusa i3 made from Cbeam Extrusion. X & Y using GT2 Belts, Z using Acme Screws Goal is to build a simple. and very Solid Printer Single Z Motor to keep the Z Screws in Sync. (Might require Geared Nema 17) 12" x 12" x 12" Build volume Nema 17's

OX Super "C" - Cpmpleted 11/02/16

This CNC utilizes the C-BEAM extruded aluminum for the "X", "Y", and "Z" axis. The gantry will move similar to the OX along with the "Z" except I am incorporating the C-BEAM instead of the 20x60 V-RAIL. To make the system as strong as possible I am using two C-BEAM rails back to back. The "Y" axis will encompass two sets of roller on both side of the C-BEAM extruded rails for added strength. All of the plates for this were created using the C-BEAM machine I completed several month ago.

Rex

This build is inspired by the Lulzbot Taz printers and makes use of the new OpenBuilds C-Beam

Build Author

chenderson

Views

13044

Build Author

chenderson

Views

13044

CRH C-BEAM Router, steel capable

C-beam based CNC router using mostly openbuilds parts.

c-beam hello world

My first ever build. Straight C-beam with tinyg controller a few do-dads and some make do choices. Non-metric length lead screws to save long lead time. Jog knobs to cover the extra length and also practical. My old Bosch Colt never had it so good. Build out work remains, wire dressing, drag chain, vacuum, permanent base, etc.

Slightly larger sphinx

Another C-Beam Sphinx but a little larger,

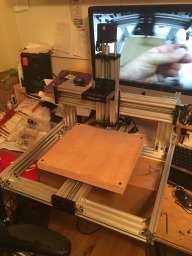

Jim's C-Beam Machine Build

This machine is fantastic. Teamed up with Fusion 360, Inkscape, and GrblPanel, I'm well on my way towards making at least one Christmas gift this year. I had some frustrating times during the build, mainly with getting everything to go together square, but overall it was fun. I can see that I'm going to need to be a bit creative in order to max out the work area for this machine so that I can produce the product I bought it for, but it will be able to do so much more for me as well.

CBeam OX

i wanted to use both the ox and the C beam C beam for the gantry because its stronger i also made the gantry 20 mm higher so i can cut thinker material i will maybe later go to rack& pinion on the 1500 mm Y axes also instead of the V wheels i will maybe go to hiwin in the furture

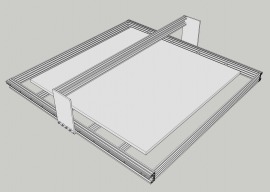

Pure Cbeam 900x1000

This is a pure cbeam build to maximize envelope and rigidity. All the parts used are available from open builds.

Build Author

Maxime Favre

Views

9640

Build Author

Maxime Favre

Views

9640

SmoothiebrainZ CBeam Machine

Modded Plate maker with: Smoothiebrainz board and DQ542MA SN04 Endstops Modded Z axis Aluminium build plate and renforced Y axis Dust shoe

CNC Glass Grinder

This is a 1-Axis CNC Glass Grinder. It uses a hobby grinder to miter a precise angle on the edge of a piece of glass.

My first CNC - The C-Beam Basic

I am a newbie and this is my first build. After hours and hours of research I decided on the C-Beam. I will be changing one or two things but I will basically be building this as per Mark's video.

Nox 1500mm x 1500mm C-Beam

C-Beam build using a double C-Beam for the X axis. 1500mm x 1500mm

Build Author

Bridge Port

Views

9559

Build Author

Bridge Port

Views

9559

CNC Line Boring Machine

This is a CNC Line Boring Machine for our cabinet shop. It drills the holes every 32 mm for the adjustable shelf pins in the cabinet side pieces. I chose this option over purchasing a multi-head boring machine that requires 11 drill bits - Left & Right hand twist - that also requires a lot of strength to plunge that many drill bits into the wood to be drilled.

Cbeam Digital Mitre Saw Fence

Work in progress.. but nearing completion :)

Moag's CNC Mill

A design in progress, to 3D carve two-part Aluminium injection moulds for Soft Plastic Lures and Lead Jigs, so I can prototype some of the concepts rattling around in my head. All Openbuilds parts where possible, 1000x500mm footprint, 0.8kw Water-cooled Spindle?, High Torque Stepper?,Smoothieboard?, I still have no idea. As a newbie to the CNC world, any wisdom would be welcome to take this from just a idea into reality so I can start playing with all this awesome stuff. Thanks in advance

C-Beam Big Mouth

My first build was with the basic C-Beam Build. I soon found the z clearance a little constricting So I added 2 500 mm actuators to support the x axis rail . I also left off the front and back y axis support rails for easy cleaning. I mounted the base of the machine to 1/2" mdf with 10/32 screws and blind nuts.

My 1st C-Beam Router

Pretty happy with the build, had some difficulty with the software loading up the settings due to me using the wrong com.

Metalguru's C-Beam 750

This is a C-Beam build, fairly heavy duty, and 750mm x 750mm. Should be a good, sturdy machine that's relatively easy to assemble.

Build Author

UltiBots

Views

10688

Build Author

UltiBots

Views

10688

Machined Aluminum MagBall Carriages

Machined Aluminum MagBall Carriages

Build Author

Rwetzler

Views

9628

Build Author

Rwetzler

Views

9628

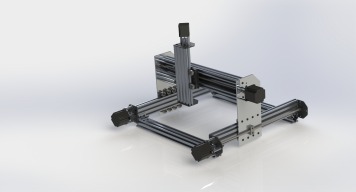

C-Beam Prototype

This is a variant of a typical OX (Mark Carew inspiration) router using C-Beams/8mm Acme rods to drive all three axis. I went with a 1000mm x 1000mm frame size. Useable space is 28" (711mm) X 26" (660mm) with a Z axis work travel of approx. 3.25" (82.5mm). A TinyG is used as a controller along with Fusion 360/Chilipper as the software for generating and running gcode files.

TAZ C-Beam CnC Router by RC-CnC

C-Beam inspired CnC Router (1000x750) Approx 90mm of Z travel

C-Beam CNC (1st cnc build!)

1st build CBeam Machine w/ raspberry pi-protoneer hat controller

laser add-on for C-Beam machine

3.8 W laser add-on for C-Beam machine. Can easily be swapped with the router.

XDrive 3d Printer

XDrive 3d printer, high quality large build volume.

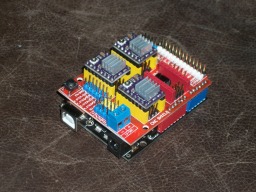

Gargoile reproduction C-Beam™ Machine - Plate Maker

A stock C-Beam with a CNC shield with DRV8825's

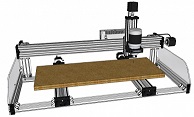

C-Beam Machine Bundle

Short description of my assembly and use of the C-Beam bundle from the Open Builds Part Store.

Build Author

Laurence Carroll

Views

11074

Build Author

Laurence Carroll

Views

11074

C-Beam Double X

Per the special notes its a variant of the C-Beam, Machine.... I have noticed that alot of people build a CNC router to cut parts for other larger CNC machines.. eg Delta Printers etc....plus this will enable me to cut parts for model RC plans UAV's etc...

Plate 'o CBEAM

I'm starting with the c-beam bundle, and I hope to end up with a pretty useful little platemaker/shallow relief carver. I'm hoping to discover how accurate and efficient it can be.

Build Author

Charles Roseberry

Views

5179

Build Author

Charles Roseberry

Views

5179

C-Beam 1000mmx1000mm

C-Beam basic package doubled in size.

Build Author

Builder+Bob

Views

3906

Build Author

Builder+Bob

Views

3906

Portable C-Beam

C-Beam Plate maker for My OX!

Murphy OX-CNC Dreamin

I am in the design phase of my CNC. I would like to thank everyone who has placed resources on the site. I am using it to the up most! I will update as I continue the design and share my progress.

C beam cnc modified

C beam cnc modified

Builder Bob's CNC

Here is the consolidation of my woodworking shop, a CNC Router!

C-Beam Plate Machine

My first openbuilds submission, plain old c-beam machine. Seems like I've spent more time fighting the forum here redirecting in circles than actually building the machine. I'll try to add more pics if I ever find a path out of this corn maze...

C-Beam for lithophanes

First venture into cnc machining I decided on the C-Beam .

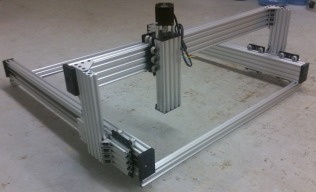

The MULE (an OX inspired 3-axis CNC)

The Mule is a 3-axis CNC inspired by the OX CNC by Mark Carew. This machine borrows the OX's sturdy frame and upgrades the X and Y linear actuators through the use of three 500mm lead screws (as opposed to the belt system of the OX). The result is an inexpensive, sturdy, and powerful design built for cutting tough materials such as aluminum.

Build Author

evildean

Views

9027

Build Author

evildean

Views

9027

OX-SUMO, SUMO-OX, OXSUMO?

One meter square. Short and stout.... reminds me of a Sumo Wrestler. A temporary and adjustable configuration I have devised to cut my own plates. I have kicked around ideas for about a year and the C-Beam extrusion has made this attempt to realize my ideas irresistible. This is just one step towards bigger and better things!

C-beam Router rack and pinion

I want build a frame that is as sturdy as possibility while at the same time keeping it as compact as possible. working area will be approx 1200mm x 600mm

C-beam Camera slider

feel kind of bad calling this a build because of pretty much everything is off the shelf parts. I'm writing my own sketch right now for the motion but there is a version or 2 floating around on the net based of this design. I will post my code once it's done.

Build Author

motopreserve

Views

9207

Build Author

motopreserve

Views

9207

Persnickety Plate Maker

My very first attempt at a CNC build. Based on the OpenBuilds C-Beam Machine, small tweaks will be made to tailor it for my goals: machining G10, aluminum & some carbon fiber for use with multirotor and motorcycle parts. I am looking forward to the day when I am comfortable enough to bring the ideas in my head to the tip of the end mill in a smooth fashion...

C-Beam on X, Y and Z Attempting to use internal channel first go around

C-Beam build using the small C-Beam gantry plates only.

C-Beam Router, 48"x48"

C-Beam Router using 1500mm lengths, 48x48" build area, and rack and pinion movement.

STEAM crane printer

The STEAM Crane 3d printer uses the new C-Beam linear rail. It is being developed for an after school / summer camp program for kids. All of the electronics are housed in the base and the wiring is routed down the channels of the c-beam. This is done to contain as much of the loose wiring as possible, hopefully keeping it safer for kids.

C-BEAM 1K

The new C-Beam kit expanded to 1000mm . extra support built in for the extents of the travel.