3D PRINTER BUILDS

Build Author

griso

Views

9115

Build Author

griso

Views

9115

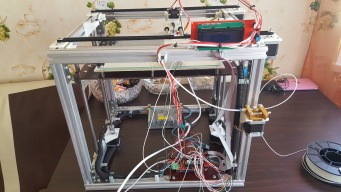

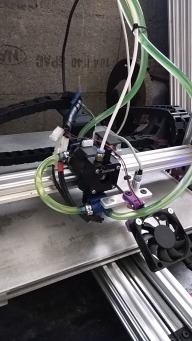

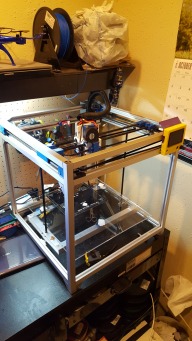

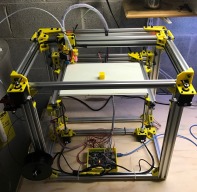

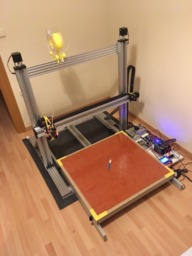

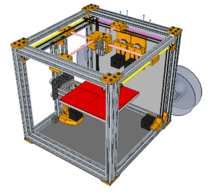

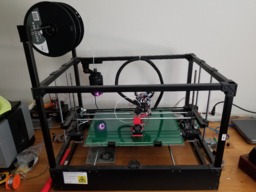

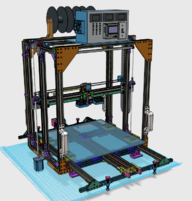

3d nika

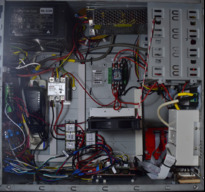

Over 840 parts. Of whom around 450 are screws and nuts, more than 100 parts are printed on a 3D printer, the frame consists of about 60 components. There is nearly 40 electrical components connected with tens of meters of wires, most of them sleeved.

Build Author

boubouexpress

Views

11368

Build Author

boubouexpress

Views

11368

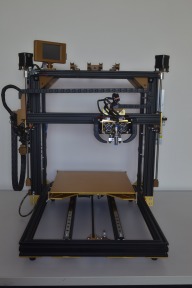

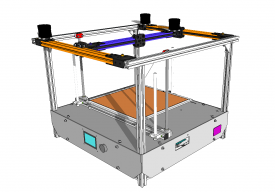

3D Drucker sparkcube V1.1XL V-Slot™ Mini V Linear Actuator Bundle

sparkcube V1.1XL edit V-slot mini v linear

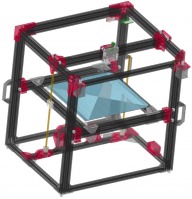

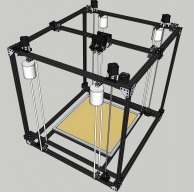

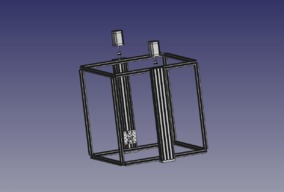

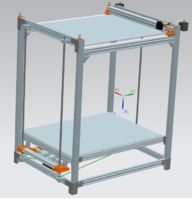

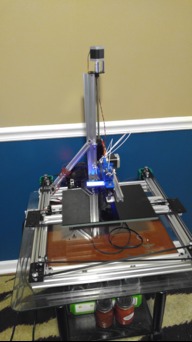

Infinite Z Delta Printer

Currently completely imaginary

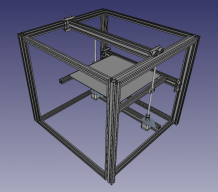

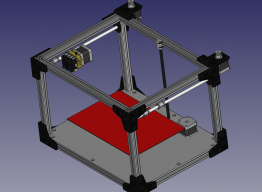

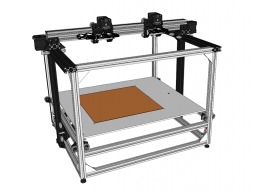

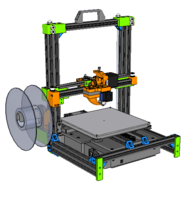

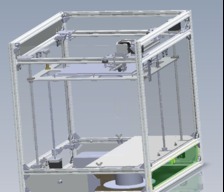

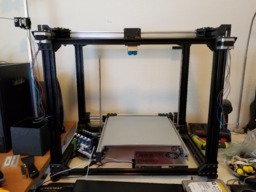

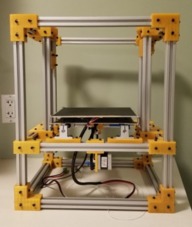

CoreXY Cubish

A dual extrusion CoreXY printer with a 290 X 290mm build volume built entirely out of 2020 aluminum extrusion and using openbuilds mini-carriages for motion.

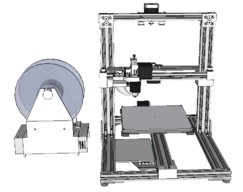

My C-Beam 3D Printer

Larger format FDM printer using C-Beam linear stages

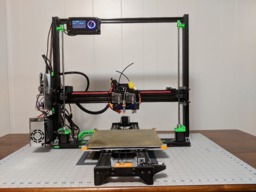

D-Bot CoreXY printer

A CoreXY D-Bot 3d printer using gantries as wheel-carriages.

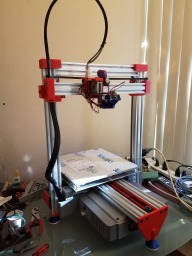

3D printer inspired by the Bukito

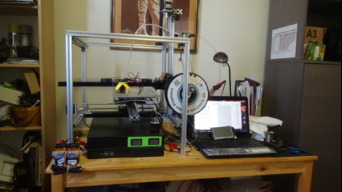

I have been working on this project for something like 3 years on and off, sometimes leaving it for a few months. Now I really want to finish it. For me, the mechanical part was the easy (though long) part because I get to use about 17 CNC machines and MasterCAM and I am a machinist. The hard part is the electronics part. Had a few problems getting Windows to communicate to the X5 Mini via the USB cable but found something on the Smoothie forum and got the machine moving.

Zen3D Atlantis 3D printer, H-Bot mechanics

H-Bot mechanics 3D printer. Build volume - 300x300x300mm dimensions: 560x500x500mm

Watercooled 3D printer : Maximus Evo Rev 2

Watercooled 3D printer

Build Author

Simon Rafferty

Views

7474

Build Author

Simon Rafferty

Views

7474

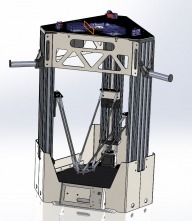

Rigid Delta

A Rigid Delta Printer using C-Beam screw actuators

betterBot

This is going to be a more or less detailed how to build BetterBot. Pictures and more (decent) text are to be added.

Build Author

Jose A. Molina

Views

6832

Build Author

Jose A. Molina

Views

6832

Alice Clementine

Roberta Clementine's first daughter printer Alice Clementine!

MOJO 3D

Fast, Large build area, CoreXY design

Build Author

crystaldragon141

Views

6497

Build Author

crystaldragon141

Views

6497

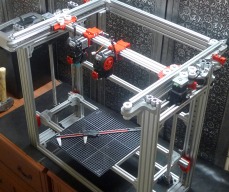

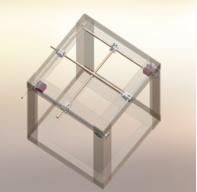

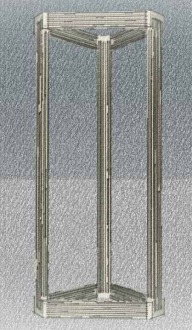

Rostock TETRA V0

This is an experiment to build a Linear Delta Printer using four towers instead of three. Primary reasons: 1. Build area is roughly cubic vs roughly cylindrical 2. Greater speed and precision from additional control provided by fourth tower. 3. Symmetric kinematics from even number of towers.

Build Author

Power Playground

Views

4763

Build Author

Power Playground

Views

4763

PowerBot

This is my own modified version of the D-Bot printer. I wanted to spec this printer to be able to print exotic materials at high accuracy with little to no compromises and maximum reliability.

delta 3d printer kit

HE3D K200 kit build

Another 3D Printer using OpenBuilds Hardware only

A light 3D printer made of OpenBuilds hardware only

Build Author

sgspenceley

Views

8686

Build Author

sgspenceley

Views

8686

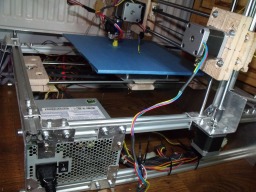

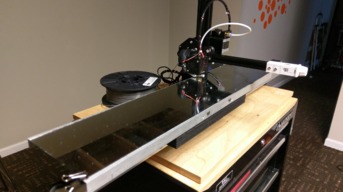

LinearRail - 3D Printer

I have re-purposed many of the parts from my Linear OX build. I'm using MGN 12 linear rails on all three axis, 5 start lead screws on the Z axis and I'm going to experiment with 5 start lead screw on the X axis. The frame plates are made from 1/8" laser cut mild steel, & open builds extrusion.

Hlidskjalf, CoreXYU (dual X-carriage)

Dual X-Carriage CoreXY. Not impossible, but probably the only one. Use the link to Thingiverse "Hlidskjalf" for parts and downloads.

Build Author

dodgenet

Views

6504

Build Author

dodgenet

Views

6504

Budget 1500mm OpenBuilds V-Slot Deltabot Build

This 1500mm tall Delta is a work in progress. The triangle corners are water jetted from 1" 6061 Aluminum, and are welded to 1" square tubing. The 1500mm OpenBuilds 20x20 V-Slot extrusions are held into the corner brackets by two stainless steel set screws per bracket. This printer will need to be reinforced with wall brackets due to the combination of height/materials.

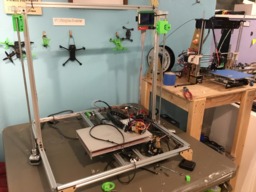

Live D-bot build at MRRF 2017 (Mar 25-26)

I will be attending the 2017 Midwest RepRap Festival (MRRF) with a small team of printer enthusiasts with a goal to fully assemble a Core-XY D-bot onsite during the event. This is our first attempt at building a D-bot and we will be learning things as we go. Our hope is to have the entire machine assembled, wired, and functional (at least to the setup and testing phase) before the end of the show. Please attend and watch us in person or visit our feed channel during/after the event.

Build Author

TouchPadKing

Views

5039

Build Author

TouchPadKing

Views

5039

1500mmx500mm Kossel Delta

Please, look over my build and make any recommendations you can think of! I haven't figured out how long my arms need to be yet. Nor have I done any shopping around to find better prices...

Large Delta Printer made from scrap 80/20

This printer will leverage scrap pieces around the shop to fulfill a single print's needs. It will use a combination of 80/20, OpenBuilds, and 3D printed parts.

Old Faithful...FDM/CNC machine

I've owned some pretty unreliable printers, and I'll leave it at that... This design comes from the need to have a 3D printer that is reliable, period. I didn't have the money for a several thousand dollar 3d printer with an equivalent build area so that was out of the question. Plus as a fledgling Engineer, I really wanted to blood myself on a project. And that's how Old Faithful came to be. A simple, reliable, rigid, durable machine. Made by me :) Also, it'll be tough enough for light CNC.

Large 3D printer 12"x12"x12" with heated bed

I want to have a printer to support senior projects. Also working on supporting 3D printing needs in the local community.

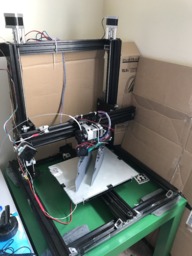

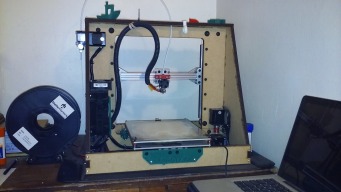

My 3D Printer

A DIY 3D printer. At beginning made from aluminium profiles, aluminium sheet and wood :)

Build Author

Kyo

Views

6445

Build Author

Kyo

Views

6445

C-beam Delta Printer

Large scale delta robot using c-beam as the core frame component.

Build Author

taratata2016

Views

8426

Build Author

taratata2016

Views

8426

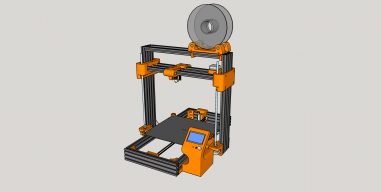

Panther 3D printer

After use of the i3 Prusa 200x200x180, the volume increases to 300x300x450 on the V-Slot and driven by a Megatronics V3

Build Author

Limine3D

Views

8459

Build Author

Limine3D

Views

8459

M3D Squared

A cartesian build with a build dimension of 200x200x750mm. I will be using a dual extruder, heated build plate, and a screw drive for the z axis.

Build Author

Tom Dirriwachter

Views

7254

Build Author

Tom Dirriwachter

Views

7254

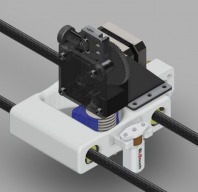

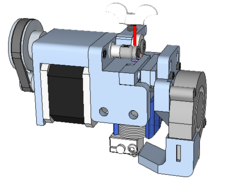

3DS Cube 3 Modular Extruder

How to modularize the 3D Systems Cube 3 extruder nozzle.

Build Author

Dmknerr

Views

5102

Build Author

Dmknerr

Views

5102

Server Rack Printer

My first project build. Concept build to use an existing 7.5 ft tall server rack as the frame. This ptoject may never be completed.

Double trolley X and Z belt training

Total belt drive GT2

VoS

3D Printer based upon 3d printed parts and open builds componets

Build Author

J-Wahl Dezign

Views

9070

Build Author

J-Wahl Dezign

Views

9070

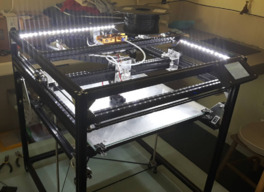

1.4 meter tall build height, 300x410mm build plate cartesian

The original plan was to build a 3d printer with a 1200x1200 build platform with a 600mm build height. I was having issues getting ahold of a large enough borosilicate glass plate for the build so I decided to go for build height. I plan on using a smoothieboard for the controller. The build has currently slowed down. I was removing a broken drillbit from the linear rail mount, and it shattered and took out my eye. I am doing what I can when I can focus my eyes long enough for the build.

The Artist Formerly Known as Prints

Work in progress large volume CoreXY printer

Rob's D-Bot Build

The plan is to make this a fairly stock D-Bot build. We'll see if mods start creeping in.

STEAM Machine

Simple design with a large build volume - 450x450x450

Build Author

Robert E. Nee

Views

17125

Build Author

Robert E. Nee

Views

17125

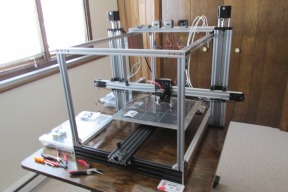

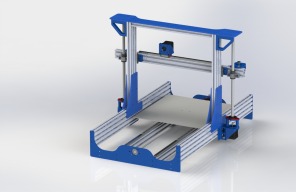

Large cartesian gantry style 3D printer

This will be a fixed bed, v-slot implemented X,Y,Z axis gantry style 3D printer.

CoreXY Cube

CoreXY cube with 600x600x800 volume.

Build Author

recoush

Views

9041

Build Author

recoush

Views

9041

CoreXY 3D build one

an 8020 build with 1010 extrusion (1") Square tubing Rough size is 24x24x36 (600x600x900) The expected usable print area 21.5x21.5X32"roughly (510x510x760) An XY 3D printer with 3 extruders and 3 Z-axis 0.9 degree motors the table (Z-AXIS) will lift up to the XY Carriage on 3 12mm linear rod and 3 8mm Lead screw's Corexy designs complete and Z-axis build is started don’t have a 3D cad system yet so building my prototypes on a pcb layout tool

Build Author

nschreiber0813

Views

5414

Build Author

nschreiber0813

Views

5414

Schreibotics Fabricator MkII

It all started after my prusa i3 build inspired me to experiment with resin 3D printers because I want to learn if they are worth it and if I can design my own printer.

eTrueUp Glide

A TrueUp Glide modified to use 20x40 V-Slot with a 300x300 bed.

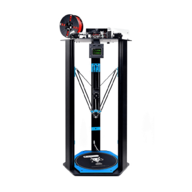

FLSUN Kossel 3D printer

A brief write up of the making of the FLSUN Delta Kit. This kit is based on an open source design. I had a need for a 3D printer without the desire to dive into another project, so a kit was the obvious way to go. I already have a delta printer in the works and so this is more of a stop gap in the interim.

Build Author

THE LINK

Views

5014

Build Author

THE LINK

Views

5014

2020 First build.

Probably cheapest DIY build youl see.

My first printer

My first printer! I went for a simple cartesian design, based on evilc66 one. It uses 1000 mm C-beam linear actuators. The build volume is 700x700x700 mm^3.

Build Author

evgeny156

Views

7248

Build Author

evgeny156

Views

7248

3D Printer on Prusa architecture with best parts available

Wanna quet an nice looking device done by my hands

Build Author

Fabio Orsi

Views

6843

Build Author

Fabio Orsi

Views

6843

147 RepStrap 002

This project is focused on developing a low-cost, portable and open-source FDM 3D Printer.

HUGE 3D printer build

just wanted to share my build of a huge 3d printer. It stands just over 2 meters tall and has a total print area of around 850mm x 850mm.

Codename: Gargoyle

A stout 3D printer build with the hopes of being able to serve as a light mill (PCB) and laser engraver

Skyggen 3D Printer

GT2 belt-driven Cartesian 3D Printer on an OpenBuilds Extrusion gantry, developed through Autodesk Fusion 360.

Norm Inverted - Cartesian

As a tinkerer and hobbyist I need a reliable quality printer on a budget... Meaning I'm not looking to buy a: Prusa, Zortrax or LulzBot because of the added cost their marketing adds. I can definitely build a machine of hopefully equal quality at a lower cost that is not impacted by the marked-up priced from a large reputable manufacturer. I will need to dedicate time and more time for design shakedowns to ensure I produce a quality machine. Bare with me on this build... Thanks!

First CoreXY Build

First CoreXY. Simple Square build, hopes for faster movements.

Build Author

Scotty Orr

Views

11414

Build Author

Scotty Orr

Views

11414

QuorXZ: A String-driven, Core XZ Printer

The QuorXZ doesn't magically appear. It's gestation takes time, careful attention, and requires many parts. However, when it is ready, a magical, mechanical instrument is born....(and when you finally say its name, it sounds a little bit like "corks").

First Ever Build

This is my first attempt at building my own 3d printer.

DIY Ultimaker

This design should give the same performance as the high speed Ultimaker since it uses a similar ultra-light X/Y concept which eliminates any movement of both the X and Y motors to achieve X/Y travel.

Printer number 2

A Large Printer that will hopefully be able to print at least 45cm cubed

TrueUp Bold

A beefed up modification of the TrueUp Kit project

TrueUp LZ

A version of TrueUp using linear bearings/rods for the Z axis. This required enough modification to make a separate OpenBuilds project to avoid confusion for DIYers.

Student OneZ

A simplified version of the TrueUp LZ. Designed for classrooms and students

ivern

Toying around a concept. Inputs are welcome on whether to use lead screw or belt drive. My lead screw will be single start 500 mm lenght, 2 mm pitch and 2 mm lead. Nema 17 motors will be used. All veterans, suggestions please.

Build Author

TimVukman

Views

4227

Build Author

TimVukman

Views

4227

Unique Z

My original Tevo Tarantula kit was ok..... I had issues with the X gantry staying level. I got rid of the wheels and replaced them with linear block bearings. I still had some issues with the X gantry. I swapped out the plastic parts with aluminum which was much better. Still not what I want yet

Core XY

Just now in the planning phase of my build. Waiting for some parts to come in to see what I am going to build off of. Print area going to be close to 300x300x350. Trying to decide if I want it enclosed. I do want to print ABS... so probably so.

Build Author

Terone Burgenheim

Views

6330

Build Author

Terone Burgenheim

Views

6330

CoreXY - Tower Printer

I wanted to try a different way of operating the Z Axis so I setup a tower using 40x40. In the end it worked excellently and can easily print 60mm/s with 150mm/s travels. The coreXY is a very cool kinematic, and you can get some pretty great speed and accuracy. The main issue is the fact your Steps/mm are doubled, so the lower end motors don't like it at high speeds.

Build Author

MidnightQuads

Views

3831

Build Author

MidnightQuads

Views

3831

MQTitan printer

Components- RAMPS, running marlin, Nema 17, All metal extruder, 600mm lead screws, 600mm 2020 aluminum extrusions, 12v 30a power supply, 12v LED strip, Typical endstops, 600mm 8mm linear rods, Bearing block for 8mm bearings, Openbuilds plates, wheels, and bearings, 500x500mm borosilicate glass plate

Build Author

Keith Davis

Views

5343

Build Author

Keith Davis

Views

5343

Torq Xtrdr

Light enough for high speed #3dprinting Strong enough for high speed #3dprinting

Build Author

George Motichka

Views

3708

Build Author

George Motichka

Views

3708

Transformer

I wanted a machine that could easily switch between 3D Printing and Laser Engraving

Build Author

Nicademus

Views

9398

Build Author

Nicademus

Views

9398

CNC/3DPrint/Laser/Mill (formerly CNC-inator3000)

Ultimately - the design is based on the highly successful Ultimaker concept, for which a regular size costs in the thousands, and one of this size would be edging into the 10's of thousands. Expected Build cost - <$800 It is a X/Y Cartesian printer with Raising/Lowering Z axis (Hotbed.) - Overall size is 610mm x 610mm x 750mm - with build volume of around 450mmx450mmx450mm - and will also have the ability to change work tools - such as for CNC Routing, Lazer etching, 3d Scanning, etc.

D-Bot Version B

D-Bot with a Replicate controller.

Build Author

Connor Mckeown

Views

6273

Build Author

Connor Mckeown

Views

6273

My Prusa Build

The process from my bought printer, to a custom home built machine

Build Author

Daniel.korneliussen

Views

3420

Build Author

Daniel.korneliussen

Views

3420

Reprap prusa mendel i2 Frankenstein 2018 build

Mad plumbers choice what Else can i say?

Build Author

Liam Dahler

Views

6422

Build Author

Liam Dahler

Views

6422

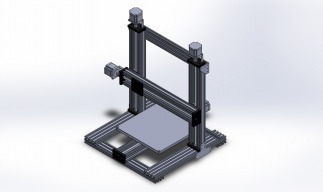

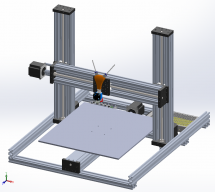

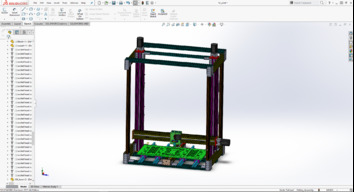

Affordable Cartesian Printer (Initial Design)

This specific build page is a collection of screenshots sampling some of my initial SolidWorks design and pictures showing physical construction of the initial design. I will be creating individual build articles as I redesign, test, and implement new aspects of the printer.

Build Author

BinaryConstruct

Views

10098

Build Author

BinaryConstruct

Views

10098

BinaryConstruct V3

This printer is a design that has evolved over three years. The original goals of this project were to design a rigid printer that had a large print volume, 300mm^3, with easily sources parts and a minimum of complicated printed parts.

Build Author

h3rb

Views

3664

Build Author

h3rb

Views

3664

TEVO Little Monster Marine Vinyl Removable Enclosure

Make a vinyl burrito ENCLOSURE for your TEVO LITTLE MONSTER for < $30 (<$20 if you don't have your vinyl shipped!)

Build Author

h3rb

Views

5570

Build Author

h3rb

Views

5570

TEVO Little Monster Direct Mount Extruder

Cheap, experimental Modification to Tevo Little Monster's bowden system for the extruder

1 Cubic Meter 3D Printer

This is a at home built 1000mm x 1000mm x 1000mm 3d printer. It uses mainly parts from OpenBuild Parts and is very simple to build. The only thing that was custom was the build plate which was designed by myself and tooled at a local machine shop.

Build Author

John Bolduc

Views

5848

Build Author

John Bolduc

Views

5848

SG Duet Delta

This my version of a large no corners cut Delta.

Voxel Evolution

This is a remix of Marshal Peck's Voxel OX, with some design tweaks inspired by Makerparts and jjcolletta. It has a build area of 300mm X 300mm X 480mm, but is easily configured for just about any build area up to 500mm X 500mm X 750mm. I have used some laser cut acrylic plates and a couple of 3D printed parts in its construction, however it can be assembled using nothing but OpenBuilds parts with the exception of the heated bed and the Y axis carrier for the heated bed.

DPR-v2 full metal

pictures and mony doku see later

Delta without vertices

As this is a build in progress, I will update it as I progress.

Build Author

Rat Rig

Views

31189

Build Author

Rat Rig

Views

31189

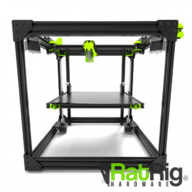

Rat Rig V-Core 3D Printer ( Core XY )

Fully OpenBuilds based Core XY printer design by Rat Rig. CAD files, build manual, build videos available!

V5- 2in1 ( 3dPrint+laser Engraving )

2in1 ( 3dPrint+laser Engraving )

Build Author

JerwanDavis

Views

5997

Build Author

JerwanDavis

Views

5997

Coined by my family as the: Davomatic

Build Notes: Here are all the parts necessary to re-produce this design. Please note, all of the parts are either sourced through openbuilds or have been selected and printed from thingiverse.

Build Author

Mark Rehorst

Views

10066

Build Author

Mark Rehorst

Views

10066

Ultra MegaMax Dominator CoreXY Printer

My self-designed and built, tall-format coreXY printer with 300 x 300 x695 mm print capacity.

Butterfly 3DP V 1.0

tronxy x3 like

My is just the biggest printer. with a printable area - 1760 x 1146 x 1318h

I myself invented this concept printer form

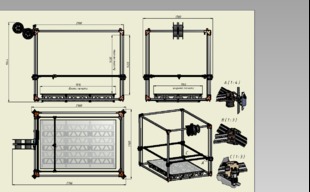

Design and Performance Evaluation of A Large FDM 3D Printer

This build includes the design of a large FDM 3D printer. This machine has a 796mm by 796mm by 900mm (LxWxH) build volume. Motion is controlled by servo motors and the printer runs on python-based marlin firmware.

Build Author

Luke Cunningham

Views

5815

Build Author

Luke Cunningham

Views

5815

Tronxy X1 extension

Video on youtube: https://www.youtube.com/watch?v=vCTbLZ2_m-w&t=36s

26 x 26 x 45 3D Printer/Mill

Super tall 3D printer. All lead screw design.

Build Author

Bob Darrow

Views

9846

Build Author

Bob Darrow

Views

9846

BA3DP

A slightly more than one half cubic meter 3D Printer using V Rails, V Rollers, "C" Rail, mounting plates, and a bunch of 3D printed brackets to provide strength and stability to the frame. Rigidity was the goal and precision and accuracy the result. The software is a whole other topic, many weeks spent dialing that in to make the printer print.

Kraken Core-XY Printer

Core-XY build witha quad nozzle

Build Author

deltajegga

Views

9751

Build Author

deltajegga

Views

9751

THE delta

probably as big as you'd want it...

Build Author

thinman

Views

8652

Build Author

thinman

Views

8652

Delta250

A 250x250 mm Delta Printer utilizing a Duet Wifi controller and a Titan Aero direct drive extruder.

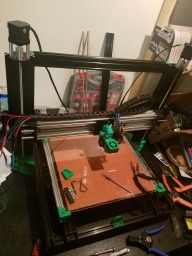

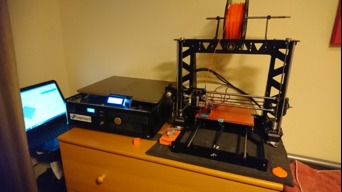

Rigidbot Big with glass bed

Started with a Rigidbot Big Added a single flat glass bed Used a Smoothieboard clone driving DRV8825

Large 3D Printer 5ft by 5ft print bed

New ultra large 3D Printer design. I'm calling it the AutoCrafter

Build Author

CoreCube3D

Views

21538

Build Author

CoreCube3D

Views

21538

CoreCube3D - A CoreXY 3D Printer

Building a CoreXY based 3D printer using primarily parts from China on eBay. Large 500mm frame.

Big a** printer

In-progress 500x500x1800

Build Author

patnap71

Views

6776

Build Author

patnap71

Views

6776

MEGADELTA, TLM CLONE with 500MM bed

All metal frame 500mm bed Delta 3D printer

GhettoPrinter

Dirt cheap build.

Mushu - Large Scale CoreXY

20x26x28 inch Build Volume CoreXY. Unlike many builds, I've decoupled the XY movements from the Z-Axis lead screws to help prevent Wobble, will be using linear guide rails, and mains powered bed heater, and a bed that is Allowed to thermally grow. This build is JUST narrow enough to fit through a standard sized doorway.

Vulcan Pro V1

A posi-drive leveling printer in 300x300x380mm format that easily breaks down for suitcase size shipping.