CNC ROUTER BUILDS

Build Author

Neil Scott

Views

3278

Build Author

Neil Scott

Views

3278

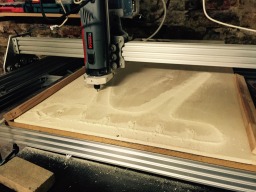

Barcelona Build

This will be my second CNC build but this time a proper CNC not a small desktop model that I played with for a while to learn Gcode, It was great but now its time to start playing with the big boys and girls.

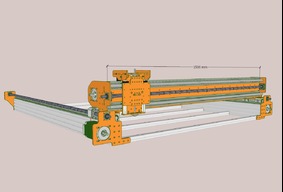

PhlatMDF48

Building a Phlat based CNC for MDF processing. Capacity of 48" x unlimited length.

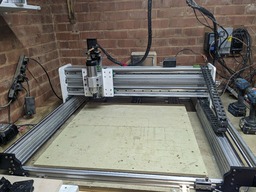

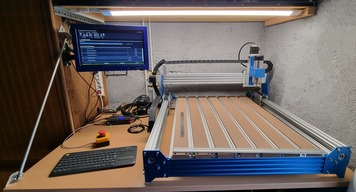

My Ooznest Workbee V2.0 build

I'm new to this whole process, so this is a build by a newbie for newbies.

Build Author

Corey Corbin

Views

5109

Build Author

Corey Corbin

Views

5109

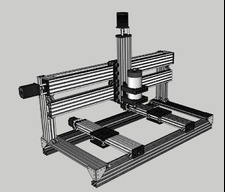

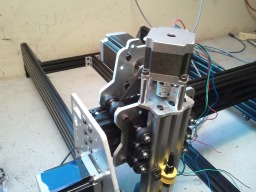

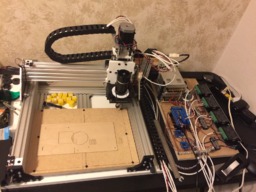

Sphinx Derived Router

I Like the Sphinx design thought I would attempt my first build. I wanted to build this and use Arduino controller with GRBL to be able to learn and understand my machine.

Build Author

SandeepsCNC

Views

12180

Build Author

SandeepsCNC

Views

12180

Raspberry Pi CNC Software

The main objective is to build a software which can completely run on a single board computer, Rasbperry Pi, to reduce the complete cost of building a cnc machine. The software is extensively tested and can be run on any raspberry pi 2/3 boards. With no G-Code dependency, you can do complex 3D relief carving to simple tasks with simple GUI based project development environment. Please go through the YouTube channel for more details https://youtu.be/8KOXqLpvscg

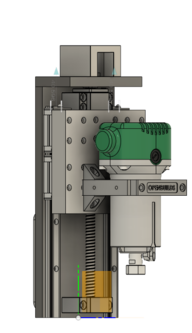

Workbee Z-axis Upgrade

Z-Axis upgrade with linear rails, SFU1204 Ball Screw and full aluminium construction.

Build Author

Colin Russon

Views

3939

Build Author

Colin Russon

Views

3939

TITAN GAMBIT

Anti-Twist Design, larger lead screws, enhanced M8 wheel sets.

AcoustoPlot3D

The Sphinx has all the components I need, except it will need a taller vertical lead screw, the same length as the horizontal ones. It will also need legs. So I need to start with the Sphinx parts list, then make a few changes.

Keeping thing quiet with a custom C Beam XL

A small form factor machine in a soundproof enclosure

The dwarf

This is a build for those of us that want to work fairly large but are in a tight space and budget

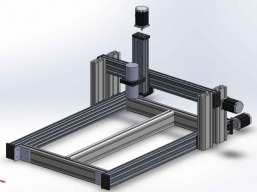

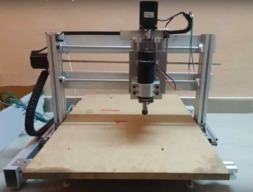

Homemade CNC Router (Under $400)

So Instead of buying a CNC Router which can cost thousands of dollars I ventured on the quest to design and build my own. I have multiple parts to this series. Hopefully all of my information I share helps!

big_recnc v2.0

cnc made with a 6mm metal body .

Build Author

Steve Hall

Views

4185

Build Author

Steve Hall

Views

4185

Cartesian Style Build UK

Another Cartesian style build with parts from the UK, US & China.

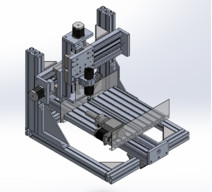

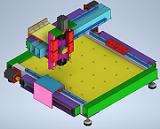

Fixed Gantry Easy Assembly

Fixed Gantry CNC with good accuracy and rigidity but for a higher price than the usual CNC's on the site.

Build Author

Ted Moyer

Views

5548

Build Author

Ted Moyer

Views

5548

LEAD 1515 HIGH Z MOD 4KW ER20 7.5 KW VFD

OLD Lead 1010 High Z Mod converted to Newest Lead 1515 with High Z mod, slimmer cbeam motor mounts, thrust bearings etc. Extended by original table out and upgraded my 1.5kw VFD and Spindle to 4kw ER20 Spindle and 7.5kw GT VFD

Denford CNC Resurrection

Denford CNC Mill Update

Reworked Sepcraft 420 CK

Its alive !

Build Author

Suhmanda

Views

4301

Build Author

Suhmanda

Views

4301

DIY CNC SPINDLE

CNC SPINDLE FOR DIY ROUTERS AND MILLING MACHINES ITSRS-985 MOTOR HAS MUCH BEFINITS THAN ANY OTHER DC MOTOR IN MARKET

Techsoft Roland TS-30 rebuild

Replacing the Electronics and Spindle. Intending to rewire all the buttons and make it into a more modern and easy to use CNC.

Build Author

Alain JBT

Views

691

Build Author

Alain JBT

Views

691

First project Genmitsu ProVerxl 6060 Improved with OpenBuilds System

For a long time I had a project to buy a CNC, in time I have evaluated several possibilities. I chose the option of a pre-constructed and scalable machine according to my needs, with sufficient rigidity features to do work of average importance. The starting investment was important to take into account to allow changes from the open source domain.

"Hirata scrap find" CNC

First CNC and first attempt at building one also, so yeah... good luck to me!

Lead 1515 tilting table and vertical table accessory

I wanted a CNC machine that was able to do dovetails and other box joints. I also wanted to have it be able to tilt so it would take up less space when I was working on other projects.

My Lead 1010

This is a fully loaded Lead 1010 and located in a shed measuring 3 by 2.50 meters. Here i build my guiyats by hand and the help of my Openbuilds friend! Pure for hobby.

Build Author

Leon Style

Views

4680

Build Author

Leon Style

Views

4680

AluVault MINIMAX

Easy build cnc router with t slot profile and nylon machined part

Build Author

Pol Feliu

Views

9277

Build Author

Pol Feliu

Views

9277

Batxillerat Research Project: Design and construction of a CNC

I'm working on a cartesian cnc router for my school research project

Build Author

Zootalaws

Views

6479

Build Author

Zootalaws

Views

6479

OXENlarged

This is a 1500 x 1500 Ox build

HardKnot OX 4x4

I've been working on commercial woodworking CNC's for year's under shop owner's that didn't want me to progress any further at a certain point. This is a project I've wanting to build for about 10 years now. I can't wait for the freedom to build what I know is possible without any negative input.

no xp cnc

This is my first cnc build, never used one before and don't know too much besides what i've read a little bit about them online. It's probably going to be about 31" y axis with hopefully around 4ft x axis, z height is still to be determined.

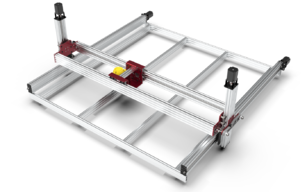

Leveling Gantry

Large leveling platform to hold a 3hp router

Our OX CNC Router Project

Our version of the OX, a Cartesian CNC Router Build. 1,500 mm Y-Axis, 1,000 mm X-Axis, 300 mm Z-Axis - Lots of Fun!

Non OX CNC Router

This CNC Router is to 95% made of standard parts and almost all of them from the http://openbuildspartstore.com/.

ChadRat's ox

This is my first cnc router. I like the open builds concept. I bought parts when I had the money. It seems everytime i think i have all the parts, i find something I am missing. My controller won't be ready until the end of the month so I am in no hurry. I will add things that i find. Eager to make some saw dust.

Build Author

inhan

Views

12603

Build Author

inhan

Views

12603

OPENBUILDS Korea (ROVO 1000)

I am very grateful to Mark Carew with passion and imagination. Therefore, the machine is good, but making the website there too daedanhaeseo The end of the same either way to invisible homework. Thank you for allowing openbuilds team submitted to the challenge once again for those with a passion that I feel like in Korea, I want to be a great help.

Hybrid OX (Ball Screw, Linear Guides, Ect.)

Planning my first build. Hope to achieve a larger format yet rigid design.

KerryH's OX

My adventure in CNC routing.

Meister-CNC

This is a cnc router with 3 axis and a kress 1050 motor. Its 140x120cm and a homebuild with your help!

Build Author

dcarlisle

Views

10769

Build Author

dcarlisle

Views

10769

pain in my ox

build is in process the machine went together perfectly no issues at all but the software is another issue I have been trying to get the thing dialed in it is driving me nuts I'm still in the process will update if I ever get it figured out

Build Author

CWidt

Views

8746

Build Author

CWidt

Views

8746

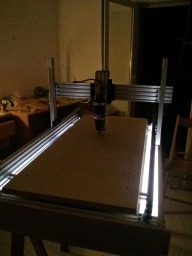

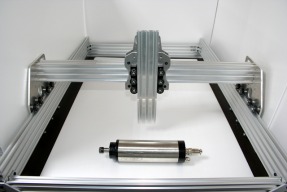

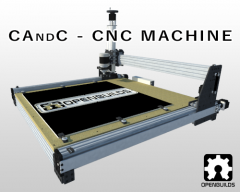

OpenBuilds CAndC - CNC Machine

A new derivative of the famous OX CNC, with increases strength, rigidity, and accuracy.

Ooznest Moded CNC

Modded OX with full nema23 4 point support

McRouter 3 Axis CNC

I wanted to put together a medium size router using PTFE slides from McMaster-Carr. I've had great experience with these slides in long term continuous motion operations in industrial environments.

Build Author

MikieLikesIt

Views

8269

Build Author

MikieLikesIt

Views

8269

Cousin CNC OX Router

A lower profiled machine. Built all out of aluminum. Removable control panel/PC unit. Option for vacuum table and cooling pump for a spindle.

Just Starting

My attempt at planning out my own CNC router

OX

My build of the OX kit from SMW3D.com

C-Beam Router, 48"x48"

C-Beam Router using 1500mm lengths, 48x48" build area, and rack and pinion movement.

My CnC Router, custom DIY not open builds parts

Most of the way through the build, hopefully soon I will have it running

C-Beam on X, Y and Z Attempting to use internal channel first go around

C-Beam build using the small C-Beam gantry plates only.

Wakezor

I'm starting my first own build cnc machine which is inspired by routy and the ox. Were my goal was not to use the ox plates but use the standard plates available in the parts store for the design.

Build Author

zann68

Views

9327

Build Author

zann68

Views

9327

OX CNC 4'x4'

Out with the Old in with the New. Trying to build a nice clean setup that myself and my sons can use and enjoy.

Build Author

Gary Bonard

Views

6189

Build Author

Gary Bonard

Views

6189

OxZilla

This is my second Ox with a working area of 14" x 14" x 5" I wanted to build a small sturdy potable CNC router and this OxZilla has the nice upgrades !

Build Author

Julius

Views

8215

Build Author

Julius

Views

8215

The "Hand" CNC (or OXCarve)

more to come, please follow along the journey!

1500 x 1500 mm OpenBuild CNC

1500 x 1500 mm OpenBuild CNC

Ooznest build - 1500mm x 1000mm

Its the first build for me so its just the story of me attempting to build the kit and hopefully end up with something I can use. Hopefully without destroying anything or anyone.

Build Author

Builder+Bob

Views

3758

Build Author

Builder+Bob

Views

3758

Portable C-Beam

C-Beam Plate maker for My OX!

My 5' by 5'

I have constructed frame out of 1 1/2" square tubing. Have my Y aces mounted. and awaiting parts.

Ooznest OX CNC for Architecture Modell

While i achieved the desired taler Z axis this was very notable of the cost of the stiffness of the Y axis - the Y axis is now quite wobbly. i do not recommend such a big Z axis on a OX CNC machine where the requirement is a good precision.

Build Author

Joe Garritano

Views

11705

Build Author

Joe Garritano

Views

11705

X-carve upgrade

Using criticall OpenBuilds components to upgrade the rigidity and reliability of an X-Carve 1000mm build.

Kruk 0.1

This is a stool, designed in 18mm wood for a cnc router, it's easily scaleable to different wood-thicknesses, in 18mm wood it takes up 1200*1200mm. It can be assembled without screws, nails or glue and can therefore also be easily disassembled.

OnyX-13

This is my OX. There are many like it, but this one is mine. My OX is my best friend. It is my life. I must master it as I must master my life.....

Gizmo CNC

wanted large work area for laser etch/cuts more than spindle work.

A work in progress

One of my first projects might be cutting proper plates.

CNC PKB2

blueprints here: https://github.com/tomaspavlica/cnc_pkb2

CNC 1000x1000mm C-beam

inspired by http://openbuilds.org/builds/c-beam-sphinx.3605/

Build Author

JerryD

Views

5351

Build Author

JerryD

Views

5351

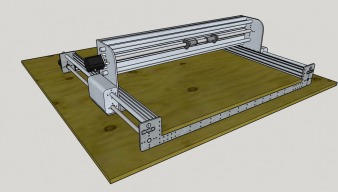

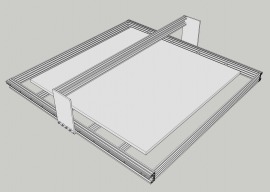

1500x1000mm Adjustable Height

I have the demand to cut/etch tall pieces of material. For this reason, I have designed a machine with 500mm uprights with adjustable gantry height. This way I can raise/lower the sled and z-axis as needed. I've also chosen to use a linear C-channel assembly for the Z axis with the plate mounted to the gantry instead of the other way around. This will allow for maximum range of the z-axis. The parts list/BOM does not include motors/belts/pulleys or electronics.

C Beam CNC+Laser

You will be following the assembly of the mechanical kit and how i integrate the electronics into the final build.

Strong? CNC

The goal is to have a relatively strong CNC to be able to cut alu. Working space will be around 800x350x100mm.

C beam Larger and Stronger

My first build based on the original C beam Sphinx. I’m not sure at this point what the final size will be. I have the parts from the c beam Sphinx and extra beams and lead screws to build up to 1000mm x 1000mm.

C-Beam Elexa

This build will be based on the C-Beam Plate Maker, with additional changes based on other builds and ideas.

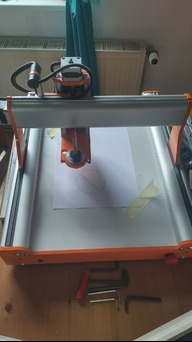

First build - small scale

Using basic standard components, beams, motors, belt drive on x and y, z is a screw. Using Grbl Panel on Windows 10. Really basic router, had trouble getting the controller to turn on the router and set speeds so it is currently wired to a power bar switch so it runs full speed and I just use the switch to turn it on and off. Just getting x, y and z control working properly for now and likely going to switch the router to my dremel 4000 using a 3d printed mounting bracket I got from thingiverse

Noob 1000Sphinx

A complete noob stumbling thru his first cnc build in winter.. and trying to find the time with 2 toddlers..

NotAnOx

From plywood and linear rail to c-beam. I probably should have bought a kit.

Build Author

joetemus

Views

6859

Build Author

joetemus

Views

6859

Shapeoko 2 Z-Axis Upgrade

This is a major redesign to the Z-axis of an otherwise stock Shapeoko 2.

ricks workbee build

i had the ox build and wanted to do a more beeffer style so i went with a workbee style machine ..

Lead 1010 First time build

First time build of the Lead 1010 CNC with the High Z add on.

Build Author

jeff johnson

Views

5770

Build Author

jeff johnson

Views

5770

workbee 1510

Getting more height out of the !510

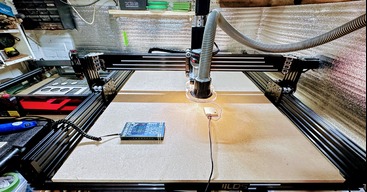

ApiNui - CNC Router ( an oversized workbee )

Based on the WorkBee CNC, this is an oversized router built with a specific use-case in mind, for manufacutring beehives, and beehive components

Build Author

Yosmany325

Views

2440

Build Author

Yosmany325

Views

2440

OrionPlus

Cartesian style CNC with a working area of around 360mm x 360mm x 120 mm (X, Y, Z) using Linear rails and ball screws. The linear rails are (Hiwin?) HGR 20mm x 520mm and the ball screws are SFU1204 (12mm lead 4mm) of around +/- 430 mm. The base structure is made from rectangular aluminum profiles of 70mm x 45mm x 3mm (thickness of walls).

Build Author

Jose Alezandre

Views

2217

Build Author

Jose Alezandre

Views

2217

Mighty Chihuahua

The idea was to use materials from previuos failed projects into a succesful one. I have build this tiny but powerfull CNC machine mainly using the universal gantry plates for the X and Y axis. Also another innovative part is the fact that I assembled the Z gantry with 2 aluminum sections of 20X40 and one aluminum seccion of the 20X20. I used NEMA 17 stepper motors with GT2 pulleys. This was designed on Fusion360

Build Author

theracermark

Views

4034

Build Author

theracermark

Views

4034

Reviving the Origonal PhlatPrinter with BlackBox

Reworked PhlatPrinter Gen1 Adding dual nema 17s to all 3 axis Supprot for carriage to insure even dept cuts Lighting for view of cutting area

First CNC Router

My very first CNC Router build. It's completely scratch built.

Lead 1510

Customised Lead 1010 making it a 1510. T-Track work area with dual Y limit switches for auto-squaring. Powered by xPro v5 & CNC.js

CNC built, work in progress, fail

2x4 cutting area, enclosed with dust collection mainly built out of wood.

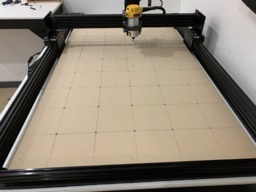

My large machine 48 X 48

This machine is controlled by a Mach3 BOB. I USED Nema 34 stepper motors and a 3kw, water cooled spindle. I’m in the process of adding a vacuum table with 4 zones. I have an X-carve so I use Easel to create G-code for the large machine. I’m currently looking for a way to stabilize the Y-axis. It wiggles a little, so I want to add another linear rail high on both sides.

zero z mongrel

long overdue overhaul of 1000 x 1000 machine

Small Desktop CNC Router/Mill

I designed and made this from scratch. The frame is welded steel filled with sand, and most of the other parts are aluminium. It's controlled with a DIY ESP32 controller running GRBL_ESP32