CNC ROUTER BUILDS

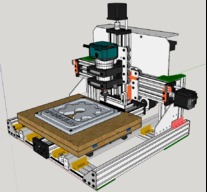

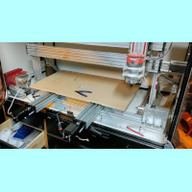

YAWBM - Yet another Workbee Modification

Increase Z axis travel by 20-25mm with minimal modifications

Build Author

GinoTheCop

Views

14515

Build Author

GinoTheCop

Views

14515

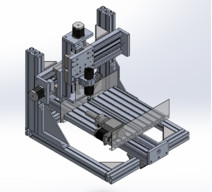

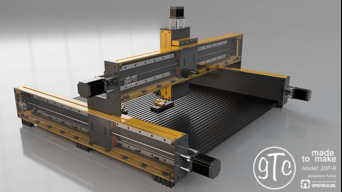

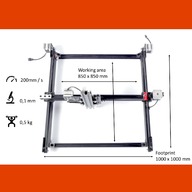

GTC2020

A 1000 by 1000 CNC Router with linear rails and a control box.

Build Author

DaleShaw

Views

4396

Build Author

DaleShaw

Views

4396

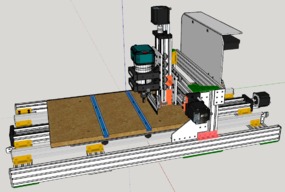

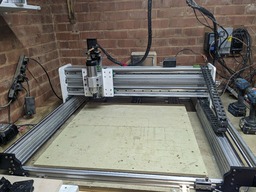

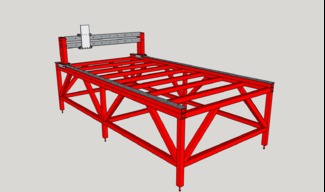

Senior Project CNC table

So for my senior project I decided to build a CNC router. I kind of need to get this done before May so we'll see what all goes down. It's going to be a 3 axis machine (for now) and will be able to handle 4x8 sheets of wood. This is my first build. It's going to be intresting..

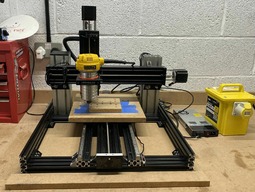

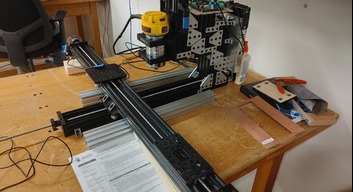

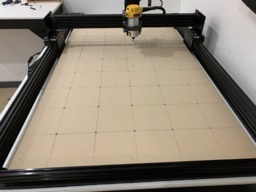

Lead 1010 First time build

First time build of the Lead 1010 CNC with the High Z add on.

Build Author

mathom713

Views

9558

Build Author

mathom713

Views

9558

27" by 40" CNC

DIY design and build of a roughing 2' by 3.5' CNC router

My C-Beam machine...

A C-Beam machine design, strengthened with extra brackets and plates. GRBL controlled, opto-isolated inputs, jogging box.

My C-Beam machine...from 500 to 1000mm base

C-Beam machine - 1000mm base.

Ox cnc improvements chain driven

Just ox cnc experiment

LEAD CNC 1010 Laser Modification

Easy All-in-One Laser and Mounting Kit for your Openbuilds CNC.

Build Author

jeff johnson

Views

5689

Build Author

jeff johnson

Views

5689

workbee 1510

Getting more height out of the !510

Build Author

Forestbird Originals

Views

5365

Build Author

Forestbird Originals

Views

5365

Lead 1010 Build - Anything but stock.

This is a lead 1010 build that I wanted to have a little fun with. I purchased the whole Lead 1010 kit, and felt like studying a few shortcomings of the original to see if I can improve it or just have some fun with it.

Build Author

Corey Corbin

Views

5010

Build Author

Corey Corbin

Views

5010

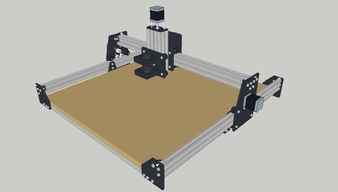

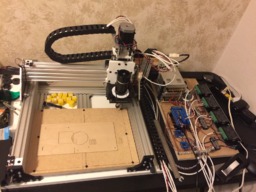

Sphinx Derived Router

I Like the Sphinx design thought I would attempt my first build. I wanted to build this and use Arduino controller with GRBL to be able to learn and understand my machine.

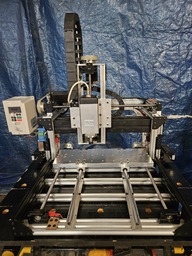

1515 Deluxe

Build features include a double c-beam gantry (bonded & mechanically fastened), linear x rails, custom gantry end plates, a custom linear rail & ballscrew Z axis, and custom lead screw tensioning plates. The primary goal was to remove twist from the 1500mm gantry & stiffen the Z axis.

Build Author

txcomp

Views

6755

Build Author

txcomp

Views

6755

WorkBee 1010 "Get Rid of the Slop" Build

My goals for this build were to eliminate slop and flex while also allowing easy serviceability.

Build Author

SandeepsCNC

Views

12040

Build Author

SandeepsCNC

Views

12040

Raspberry Pi CNC Software

The main objective is to build a software which can completely run on a single board computer, Rasbperry Pi, to reduce the complete cost of building a cnc machine. The software is extensively tested and can be run on any raspberry pi 2/3 boards. With no G-Code dependency, you can do complex 3D relief carving to simple tasks with simple GUI based project development environment. Please go through the YouTube channel for more details https://youtu.be/8KOXqLpvscg

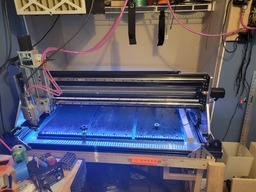

Bored in the garage enclosure build

2 days to build Up and running some EMI issues but I think I have them resolved Big shoutout to the community

WorkBee Saving Lives

Using the WorkBee to protect doctors against Corona virus.

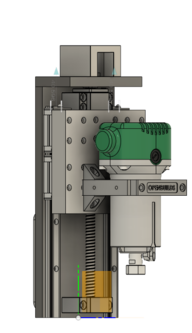

Workbee Z-axis Upgrade

Z-Axis upgrade with linear rails, SFU1204 Ball Screw and full aluminium construction.

Cnc Router 3000 x 1000 mm

In progress

ApiNui - CNC Router ( an oversized workbee )

Based on the WorkBee CNC, this is an oversized router built with a specific use-case in mind, for manufacutring beehives, and beehive components

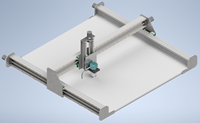

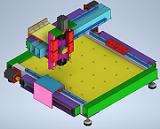

A very affordable CNC routing

In progress CNC, (just design for the momment), I want to get some feedback about the design and the possible flexion of the aluminum profiles chosen

Learning how to build

I made a 5x10 foot cnc out of the parts I bought on this site. It's been upgraded and tinkered with ever since. The end goal is to learn enough to learn to build a large 10x10 foot 3d printer.

Build Author

Yosmany325

Views

2383

Build Author

Yosmany325

Views

2383

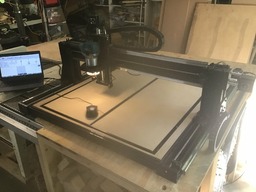

OrionPlus

Cartesian style CNC with a working area of around 360mm x 360mm x 120 mm (X, Y, Z) using Linear rails and ball screws. The linear rails are (Hiwin?) HGR 20mm x 520mm and the ball screws are SFU1204 (12mm lead 4mm) of around +/- 430 mm. The base structure is made from rectangular aluminum profiles of 70mm x 45mm x 3mm (thickness of walls).

Build Author

StrictlyScale

Views

10231

Build Author

StrictlyScale

Views

10231

Lead1010 Build with Enclosure

First time CNC builder puts together a Lead1010 machine.

Build Author

Srđan Marković

Views

3965

Build Author

Srđan Marković

Views

3965

Second machine

Machine with 12,5Nm closed loop steppers or servo steppers

CNC China Router Conversion to Open Builds System

China Router frame with linear bolts, Nema23 and the icing on the cake “open build parts“

Build Author

Yanou Fishel

Views

11200

Build Author

Yanou Fishel

Views

11200

Beefed up Minimill

A beefed up minimill, ready to gnaw on some aluminum! HG15 linear rails, a thick heavy column, bellows and easy fixturing and tramming.

Another C-Beam machine

This is basically a Sphinx variant with few changes of my own...hope it'll work.

Build Author

Colin Russon

Views

3862

Build Author

Colin Russon

Views

3862

TITAN GAMBIT

Anti-Twist Design, larger lead screws, enhanced M8 wheel sets.

Build Author

Jose Alezandre

Views

2154

Build Author

Jose Alezandre

Views

2154

Mighty Chihuahua

The idea was to use materials from previuos failed projects into a succesful one. I have build this tiny but powerfull CNC machine mainly using the universal gantry plates for the X and Y axis. Also another innovative part is the fact that I assembled the Z gantry with 2 aluminum sections of 20X40 and one aluminum seccion of the 20X20. I used NEMA 17 stepper motors with GT2 pulleys. This was designed on Fusion360

AcoustoPlot3D

The Sphinx has all the components I need, except it will need a taller vertical lead screw, the same length as the horizontal ones. It will also need legs. So I need to start with the Sphinx parts list, then make a few changes.

Retractable WorkBee1510 with Marlin+MarlinPanel high level build

WorkBee1510 with retractable space saving stand and customize build Marlin firmware and MarlinPanel (GCode Sender/UI)

Rotary axis for Workbee

Adding a rotary axis to the Workbee 1010. Including height modifications to the Workbee.

The dwarf

This is a build for those of us that want to work fairly large but are in a tight space and budget

Bessy 4x4

I found this to be a very fun exercise in building Bessy and will continue to improve her in the future.

first CNC build

It start out to be an upgrade of a CNC 3018-PRO but ended up being a full build

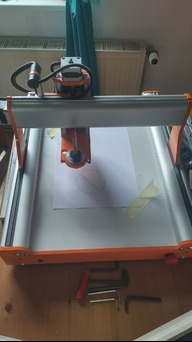

HYDRA multi tool CNC , based on ACRO

modifying ACRO

Build Author

CNCGear

Views

10452

Build Author

CNCGear

Views

10452

The BlackBee CNC

Ball screw drive, linear rail CNC Kit

Workbee with less irritations

My workbee build with some add ons

Pro Light 1000 CNC Machining Center Rebuild

Replacing the Pro Light control box with a Open Builds BlackBox.

Build Author

ckgottabuild

Views

4199

Build Author

ckgottabuild

Views

4199

Lead CNC 1010 Platform and Rotating Laptop Mount

Moveable Lead CNC1010 build with handles on four corners. Everything fits on one sheet of cut out 4x8 plywood

Homemade CNC Router (Under $400)

So Instead of buying a CNC Router which can cost thousands of dollars I ventured on the quest to design and build my own. I have multiple parts to this series. Hopefully all of my information I share helps!

My Openbuilds Journey

I've learned a lot from building this machine, and had and will continue to enjoy using it. Let The CHIPS FLY!

Black gear 1500X3000

My cnc update and rebuild.

Build Author

Quentin Karmark

Views

9184

Build Author

Quentin Karmark

Views

9184

Laguna Swift 4X4 CNC mill retrofitted with OpenBuilds

Used Laguna Swift 4X4 CNC mill with Water-cooled Spindle and RichAuto serial pendant retrofitted with OpenBuilds/Blackbox/Interface

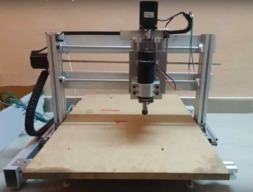

First CNC Router

My very first CNC Router build. It's completely scratch built.

big_recnc v2.0

cnc made with a 6mm metal body .

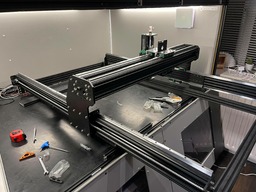

The Beast

1000mm x 1000mm linear rails, double gantry, build in Process... more to come

Gauss Probe Machine

Standard build with high Z using a Gauss probe instead of a router.

An other Ox Metal Build AZ

Had left over parts from cnc plasma build.

Fastmill CNC

Very cheap CNC made from laser fired and bent parts.

LEAD 710 with High Z mod

Overview of a 700mm x 1000mm machine based on the LEAD design and with the High Z mod from the start. Will have a parts list you can use to build yourself if you like the formfactor

Build Author

Steve Hall

Views

4111

Build Author

Steve Hall

Views

4111

Cartesian Style Build UK

Another Cartesian style build with parts from the UK, US & China.

Build Author

Johnny Reich

Views

1973

Build Author

Johnny Reich

Views

1973

ProLight 1000 Mill Retrofit

Update a 20-year old bench top milling machine with OpenBuild Ecosystem electronics.

Lead 1510

Customised Lead 1010 making it a 1510. T-Track work area with dual Y limit switches for auto-squaring. Powered by xPro v5 & CNC.js

GHOST Case by Copper Pour

GHOST Case build for the OpenBuilds Black Box Motion Control System

KillerBee 1515 customized

Killerbee 1515 with modifications.

OB Lead 1515 CNC Router 2021

Building the OB Lead 1515 was straight forward. The on-line OpenBuilds assembly videos were extremely clear and easy to follow. Initial build of this machine is with OpenBuilds BlackBox which simplified getting the electronics to work the first time. OpenBuilds staff are friendly and helpful.

My C-Beam build and modifications

Modified C-Beam which I plan to add a laser module and eventually convert to C-Beam XL size.

New Workbee Z Axis

Hopefully an upgrade of the Z axis of the Workbee.

Build Author

Shaun Weitzel

Views

7245

Build Author

Shaun Weitzel

Views

7245

OpenBuilds Lead 1515

First build of a Lead 1515!

C-beam charmer

Double C-beam Y axis 500mm., Double 2080 X axis 600mm. , C-beam Z axis 250mm, TB-6600 drivers, MKS-DLC32v2 GRBL w/wi-fi and blue tooth

1010 with linear rails

Has a 700 by 700 cutting area and is very stable

Build Author

Jasont

Views

4156

Build Author

Jasont

Views

4156

MY first CNC build

my first cnc build using the lead 1010 to build bigger and better!!

Y table for LEAD Lathe - essentially a High Z Cbeam XL

I built the lathe as a dedicated rotary axis, but I soon realized I could have a back up CNC for very little expense.

Fixed Gantry Easy Assembly

Fixed Gantry CNC with good accuracy and rigidity but for a higher price than the usual CNC's on the site.

Build Author

Ted Moyer

Views

5413

Build Author

Ted Moyer

Views

5413

LEAD 1515 HIGH Z MOD 4KW ER20 7.5 KW VFD

OLD Lead 1010 High Z Mod converted to Newest Lead 1515 with High Z mod, slimmer cbeam motor mounts, thrust bearings etc. Extended by original table out and upgraded my 1.5kw VFD and Spindle to 4kw ER20 Spindle and 7.5kw GT VFD

CNC built, work in progress, fail

2x4 cutting area, enclosed with dust collection mainly built out of wood.

Monster-not-so-mini-mill

My Minimill hit the gym, and isn't so mini anymore

Build Author

Sigifredo Cruz Rojas

Views

4003

Build Author

Sigifredo Cruz Rojas

Views

4003

ALl included interface

I have not too much space and need a portable solution, and tired of cleaning the electronics I decide to put everything inside a box and this is the result.

Sphinx 66

A Sphinx Linear rail build (600mm x 600mm) hence the title Sphinx66. Plates supplied by Chris Laidlaw. Linear rails used MGN15

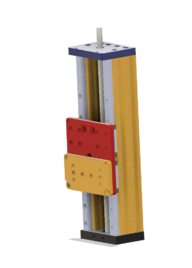

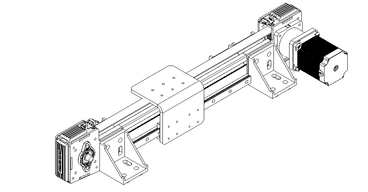

CNC Linear Slide for DIY project

Low cost cnc linear drive for making any xyz cnc structure

Reworked Sepcraft 420 CK

Its alive !

Build Author

Suhmanda

Views

4171

Build Author

Suhmanda

Views

4171

DIY CNC SPINDLE

CNC SPINDLE FOR DIY ROUTERS AND MILLING MACHINES ITSRS-985 MOTOR HAS MUCH BEFINITS THAN ANY OTHER DC MOTOR IN MARKET

Heavy Metal

CNC Mill built for cutting metal.

Techsoft Roland TS-30 rebuild

Replacing the Electronics and Spindle. Intending to rewire all the buttons and make it into a more modern and easy to use CNC.

Build Author

CONUCON

Views

6593

Build Author

CONUCON

Views

6593

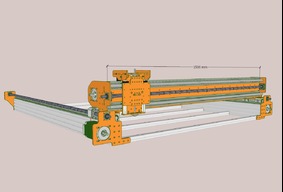

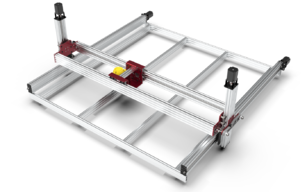

3DTwinX Gantry CNC System

Belt driven 3-axis linear system for high precision and low costs. > Threading and linear real cutting needed

My large machine 48 X 48

This machine is controlled by a Mach3 BOB. I USED Nema 34 stepper motors and a 3kw, water cooled spindle. I’m in the process of adding a vacuum table with 4 zones. I have an X-carve so I use Easel to create G-code for the large machine. I’m currently looking for a way to stabilize the Y-axis. It wiggles a little, so I want to add another linear rail high on both sides.

"Hirata scrap find" CNC

First CNC and first attempt at building one also, so yeah... good luck to me!

Gerber 404 Retrofit

Not sure if the Blackbox X32 is the right option here, just looking for guidance.

zero z mongrel

long overdue overhaul of 1000 x 1000 machine

Small Desktop CNC Router/Mill

I designed and made this from scratch. The frame is welded steel filled with sand, and most of the other parts are aluminium. It's controlled with a DIY ESP32 controller running GRBL_ESP32

5 x 10 CNC - Sub $3000 - Wall Mountable

I wanted a 5 x 10, Wall mounted CNC, that cost less than $3000. I think Im pretty close.

Edge Carve MK1

I have created a video showing the Edger Carve features https://www.youtube.com/watch?v=v5mV_6vyxAA&t=3s

Just Another CNC

I wanted to make my own unit. I enjoy building and was looking for a challenge.