CNC ROUTER BUILDS

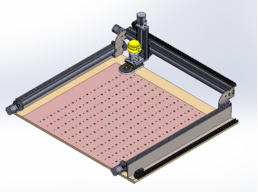

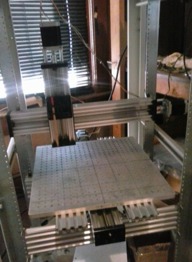

Desktop CNC

Approximately 910mm x 955mm x 82mm. There is 250mm available in the Z, but the gantry is only 82mm from the bed surface.

Build Author

McAdam

Views

3750

Build Author

McAdam

Views

3750

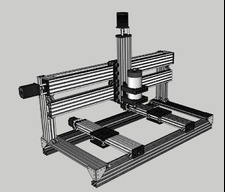

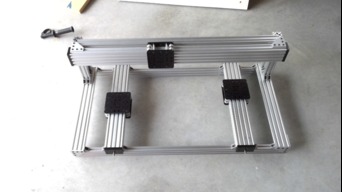

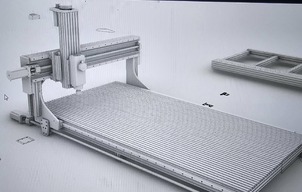

Need a catchy name - enlarging CNC

The aim of this build is to have a CNC that can cut a FULL sheet of wood when I need it to, but also shrink down and cut smaller sheets the rest of the time. The prototype is based on an OX cnc but soon it will be completely custom using Openbuilds Parts

Denford CNC Resurrection

Denford CNC Mill Update

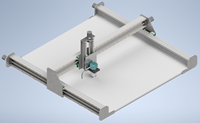

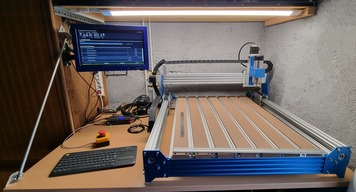

Retractable WorkBee1510 with Marlin+MarlinPanel high level build

WorkBee1510 with retractable space saving stand and customize build Marlin firmware and MarlinPanel (GCode Sender/UI)

Gerber 404 Retrofit

Not sure if the Blackbox X32 is the right option here, just looking for guidance.

rectangles

https://www.youtube.com/watch?v=NT0N1rt3F7c it's alive

A work in progress

One of my first projects might be cutting proper plates.

Rotary axis for Workbee

Adding a rotary axis to the Workbee 1010. Including height modifications to the Workbee.

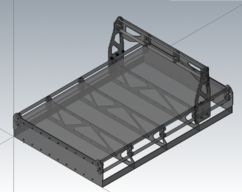

My 5' by 5'

I have constructed frame out of 1 1/2" square tubing. Have my Y aces mounted. and awaiting parts.

c-beam XLarge with ZLarge

XLarge with ZLarge

Build Author

bpatterson42

Views

3583

Build Author

bpatterson42

Views

3583

Inverted Y C-Beam Machine

Similar to C-Beam Machine build, but with inverted Y-axis assembly to shield drive screw. Integrated XZ gantry can be fixed to any solid surface. Build dimensions are 36" x 36" x 6".

Router for speargun hobby

First router build for speargun fabrication

My Workbee build

Workbee, 1000mmX750mm , from China

C-Beam unit with 400W Spindle

Standard (If there is one) C-Beam with plnth

Phil's MiniMill

A quick little mini mill build

Large C-Beam Sphinx style CNC Build

Started my build of a large Sphinx style cnc Router. I wanted one to handle the Dollar Tree Foam Board (DTFB) so I am making this to handle 2' X 3'. This is my first endeavor for a CNC so I am learning as I go but there is one thing for sure.

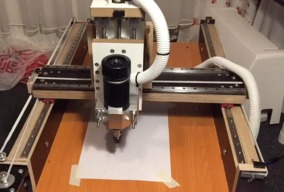

Stock CNC Router

This is my first CNC router, so be kind on the criticism. I'm still learning. Not an engineer, and not a machinist so I am having to research and learn aspect from both of those areas of study!

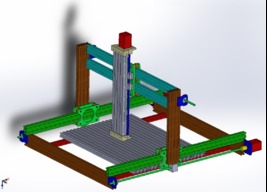

Cartesian CNC router

This project has been a steep learning curve in an unfamiliar area for me. It has been a very rewarding experience and has opened up so many more possibilities to pursue in the future.

Keeping thing quiet with a custom C Beam XL

A small form factor machine in a soundproof enclosure

CNC machine 700x1200mm

I love to build things. I want a large cnc machine can do with little money. use Aduino .

Plate 'o CBEAM

I'm starting with the c-beam bundle, and I hope to end up with a pretty useful little platemaker/shallow relief carver. I'm hoping to discover how accurate and efficient it can be.

Lead 1515 tilting table and vertical table accessory

I wanted a CNC machine that was able to do dovetails and other box joints. I also wanted to have it be able to tilt so it would take up less space when I was working on other projects.

C Beam CNC+Laser

You will be following the assembly of the mechanical kit and how i integrate the electronics into the final build.

my version of xl

A table top version of the open build xl router kit set build. This use of c - beam and xl kit set was coupled with Mach 3 controller running on Dell opti -plex 755 and win 7 pro licence. A Dell opti-plex 755 empty case was used to house the controls and wiring , including the limit switch and emergency stop safety circuits

Build Author

Stan Howe

Views

3356

Build Author

Stan Howe

Views

3356

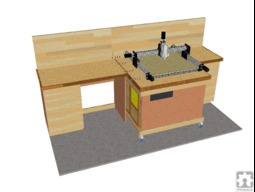

Bee the Boss

The frame of the CNC is going to to Bee a basic Work Bee with maybe 1 modification to the spoil board attachment. This will be located on a custom bench housing the electronics and vacuum. I plan to install Stepper online steppers, drivers, power supplies, and break out board. I will add a 1.5 KW water cooled spindle, with a radiator. The fans from the radiator will pull air from a filtered enclosure for all the electronics.

Bedroom Builds (BrB) DIY CNC

So I am employed in the automotive industry and I walk by thousands of dollars of CNC products daily that are no use to me due to being a Technologist and not a machinist. So therefore with some research I found openbuilds and their great selection of products to build my own CNC. This CNC will consist of 4 axis one removable 360 degree axis for turning alongside a x axis table Y axis stationary gantry and a Z axis attracted to the Y axis linear actuator.

Just Starting

My attempt at planning out my own CNC router

Dust Shoe for Kyo's Sphinx

Dust Shoe design for a CNC router. Attaches to Chris Laidlaw's Mount design, with the DeWalt D26200 (which I think is the DWP 611 in the US).

Gauss Probe Machine

Standard build with high Z using a Gauss probe instead of a router.

BrandoneOuX

I'm Brandoneous; hence, the BrandoneOuX, a cartesian CNC build. Large format (1000mm x 1000mm) but beefed-up to solidly augment the ability to cut Aluminum in addition to wood and other solid materials. As I am currently living in a rented apartment for an out-of-state job, my secondary challenge is to build a sound dampening enclosure that will function as a torsion box base, a sound dampening enclosure, and a dust containment system. Easy, right? Well, we'll see... Join my journey

Build Author

Neil Scott

Views

3278

Build Author

Neil Scott

Views

3278

Barcelona Build

This will be my second CNC build but this time a proper CNC not a small desktop model that I played with for a while to learn Gcode, It was great but now its time to start playing with the big boys and girls.

Another Kyo inspired Sphinx

A 1000mm x 1000mm copy of Kyo's Sphinx

HandCrafted WorkBee - HCWB

This will be a slow build as I collect parts and materials as funds permit for 1000mm x 1000mm Workbee. I call it the "Hand Crafted WorkBee" because I will be hand making the plates and as much of the build as possible using a drill press and hand tools.

Noob 1000Sphinx

A complete noob stumbling thru his first cnc build in winter.. and trying to find the time with 2 toddlers..

Cnc Router 3000 x 1000 mm

In progress

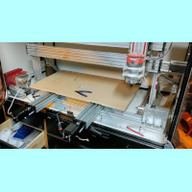

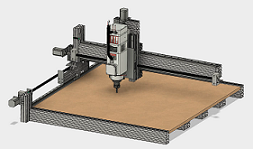

Homemade CNC Router (Under $400)

So Instead of buying a CNC Router which can cost thousands of dollars I ventured on the quest to design and build my own. I have multiple parts to this series. Hopefully all of my information I share helps!

Just Another CNC

I wanted to make my own unit. I enjoy building and was looking for a challenge.

Build Author

Axnfell

Views

3110

Build Author

Axnfell

Views

3110

WorkBee 1000x2000 ACME Screw Version

Hoping to build a WorkBee 1000 x 1000 (2000) from parts and not a kit, cannot afford the kit in full so going the long way round...

C Beam Served

C Beam Machine built in a server cab. Hopefully this keeps every thing enclosed , clean and quite ?

TFE2 CNC Build

My TFE2 CNC Build. The TFE was much smaller and all of the gantry plates were 3D printed. Despite this it will happily machine aluminium without issue. So I decided to use that to make the TFE2 which will be all aluminium plates and much larger (1200x800mm machining area with roughly 140mm in Z so I can later add a rotary axis.)

Workbee with less irritations

My workbee build with some add ons

C-Machine

MY experience as a first time introduction to the CNC world!

Repurposed Steel Table 4 x 8 Build

Repurposed Steel Table for CNC Router Build.

Build Author

Bucky Wootmaster

Views

3005

Build Author

Bucky Wootmaster

Views

3005

Bucky CNC

CNC machine using extrusions with linear rails and ball screws on all axes - no plates

Y table for LEAD Lathe - essentially a High Z Cbeam XL

I built the lathe as a dedicated rotary axis, but I soon realized I could have a back up CNC for very little expense.

My new wood mill

First and foremost, I want to create accurate parts for my model aircraft. In second line I am interested in the control and electronics of the milling machine. If you are interested in drawings and the parts list, feel free to contact me.

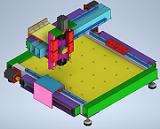

Something a Tad different

Future CNC router kit design

first CNC build

It start out to be an upgrade of a CNC 3018-PRO but ended up being a full build

C-Beam Elexa

This build will be based on the C-Beam Plate Maker, with additional changes based on other builds and ideas.

Build Author

Terone Burgenheim

Views

2836

Build Author

Terone Burgenheim

Views

2836

My CNC

This build is my version of the CBeam machine. I opted to NOT use the Gussets, and instead went for the 40, and 60 mil angle brackets to cut the price back a little further. I started with the smoothieboard but decided it was still "too new" and very much experimental. This build took me a few (2-3) days to complete. The CBeams and Lead-Screws really make building things faster since you don't have to clamor over belts.

Mark 1

My first attempt at building a CNC style machine. Overall my plan is to use the PlanetCNC breakout board and software to run the machine from a dedicated laptop/tablet.

PhlatMDF48

Building a Phlat based CNC for MDF processing. Capacity of 48" x unlimited length.

NotAnOx

From plywood and linear rail to c-beam. I probably should have bought a kit.

First build - small scale

Using basic standard components, beams, motors, belt drive on x and y, z is a screw. Using Grbl Panel on Windows 10. Really basic router, had trouble getting the controller to turn on the router and set speeds so it is currently wired to a power bar switch so it runs full speed and I just use the switch to turn it on and off. Just getting x, y and z control working properly for now and likely going to switch the router to my dremel 4000 using a 3d printed mounting bracket I got from thingiverse

Build Author

Sprags

Views

2749

Build Author

Sprags

Views

2749

C-Beam Kyo Sphinx 10060

More stuff here.

C-beam charmer

Double C-beam Y axis 500mm., Double 2080 X axis 600mm. , C-beam Z axis 250mm, TB-6600 drivers, MKS-DLC32v2 GRBL w/wi-fi and blue tooth

Gizmo CNC

wanted large work area for laser etch/cuts more than spindle work.

CNC Router Machine

CNC Router with working area 550*550*200

ECNCML (budget mashup)

This build summarizes my CNC milling and laser engraving machine conversion from a dimensional lumber frame and electrical mess to an all aluminum frame with a safe and well constructed (IMHO) control system with the resources I had available.

CNC built, work in progress, fail

2x4 cutting area, enclosed with dust collection mainly built out of wood.

WorkBee Saving Lives

Using the WorkBee to protect doctors against Corona virus.

An other Ox Metal Build AZ

Had left over parts from cnc plasma build.

Ooznest workbee

This is my first build so I will let you know how I get on

OoozNest WorkBee

A Journey on the WorkBee Build...

C-Beam Machine XL

C-Beam XL upgraded with end-stops, E-stop, and cable chain. Running GRBL on Arduino Mega.

CBeam Sphinx Upgrade

Simple upgrade of the Y axis on a Cbeam sphinx from 500mm to 1000mm.

Build Author

Yosmany325

Views

2440

Build Author

Yosmany325

Views

2440

OrionPlus

Cartesian style CNC with a working area of around 360mm x 360mm x 120 mm (X, Y, Z) using Linear rails and ball screws. The linear rails are (Hiwin?) HGR 20mm x 520mm and the ball screws are SFU1204 (12mm lead 4mm) of around +/- 430 mm. The base structure is made from rectangular aluminum profiles of 70mm x 45mm x 3mm (thickness of walls).

frugal-ist workbee

a 1000x1000 acme screw workbee built as frugally as possible. thanks so much to ooznest and openbuilds :)

ricks workbee build

i had the ox build and wanted to do a more beeffer style so i went with a workbee style machine ..

Build Author

Bill325

Views

2354

Build Author

Bill325

Views

2354

One more life for a cube

Modify a Gen1 Cube printer into a small cnc router to cut pcbs and light (VERY light) milling work. Also easy to swap out the rotary head and mount a laser head for engraving.

ApiNui - CNC Router ( an oversized workbee )

Based on the WorkBee CNC, this is an oversized router built with a specific use-case in mind, for manufacutring beehives, and beehive components

C beam Larger and Stronger

My first build based on the original C beam Sphinx. I’m not sure at this point what the final size will be. I have the parts from the c beam Sphinx and extra beams and lead screws to build up to 1000mm x 1000mm.

GHOST Case by Copper Pour

GHOST Case build for the OpenBuilds Black Box Motion Control System

Build Author

Jose Alezandre

Views

2217

Build Author

Jose Alezandre

Views

2217

Mighty Chihuahua

The idea was to use materials from previuos failed projects into a succesful one. I have build this tiny but powerfull CNC machine mainly using the universal gantry plates for the X and Y axis. Also another innovative part is the fact that I assembled the Z gantry with 2 aluminum sections of 20X40 and one aluminum seccion of the 20X20. I used NEMA 17 stepper motors with GT2 pulleys. This was designed on Fusion360

Lead 1510

Customised Lead 1010 making it a 1510. T-Track work area with dual Y limit switches for auto-squaring. Powered by xPro v5 & CNC.js

My Little Mashup

A mixed drive, PI Controlled machine

AcoustoPlot3D

The Sphinx has all the components I need, except it will need a taller vertical lead screw, the same length as the horizontal ones. It will also need legs. So I need to start with the Sphinx parts list, then make a few changes.

cnc vreesbank 2500x30000

This cnc milling machine is 3 meters by 30 meters,

Ox cnc improvements chain driven

Just ox cnc experiment

Build Author

Johnny Reich

Views

2069

Build Author

Johnny Reich

Views

2069

ProLight 1000 Mill Retrofit

Update a 20-year old bench top milling machine with OpenBuild Ecosystem electronics.

CNC accessory box Made 100 % from recovery materials

Quick construction. A few pieces of wood recovered in the trash can, two hooks one hinge, a few screws and a little glue. [Edit] Added the SVG file for sharing (I forgot it)

The dwarf

This is a build for those of us that want to work fairly large but are in a tight space and budget

Build Author

Alain JBT

Views

691

Build Author

Alain JBT

Views

691

First project Genmitsu ProVerxl 6060 Improved with OpenBuilds System

For a long time I had a project to buy a CNC, in time I have evaluated several possibilities. I chose the option of a pre-constructed and scalable machine according to my needs, with sufficient rigidity features to do work of average importance. The starting investment was important to take into account to allow changes from the open source domain.