Cartesian Style CNC

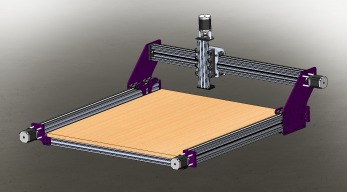

The Nguni - an OX variant

A modified OX with more X clearance, MDF plates, vacuum table

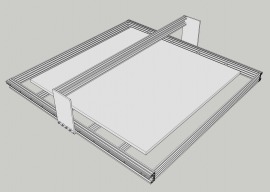

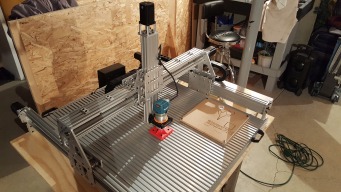

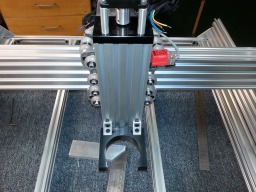

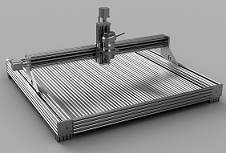

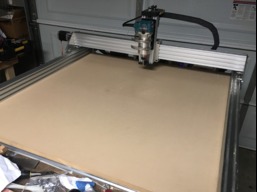

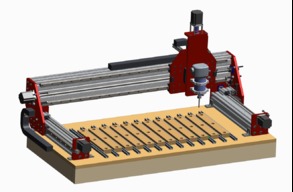

C-Beam Router, 48"x48"

C-Beam Router using 1500mm lengths, 48x48" build area, and rack and pinion movement.

Build Author

evildean

Views

8916

Build Author

evildean

Views

8916

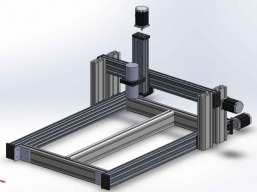

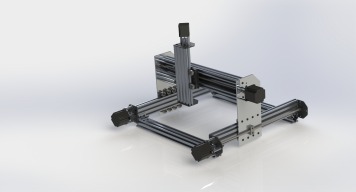

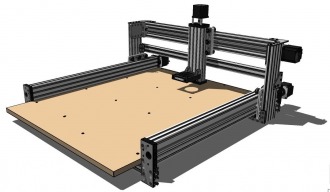

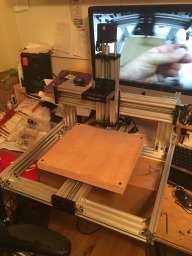

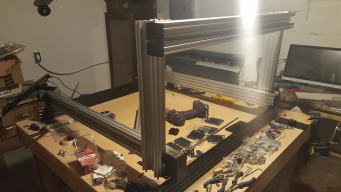

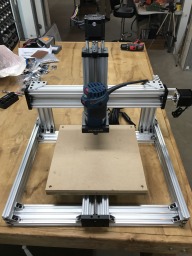

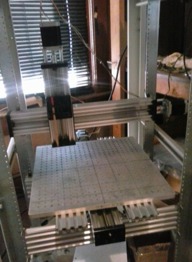

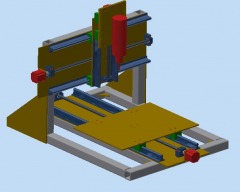

OX-SUMO, SUMO-OX, OXSUMO?

One meter square. Short and stout.... reminds me of a Sumo Wrestler. A temporary and adjustable configuration I have devised to cut my own plates. I have kicked around ideas for about a year and the C-Beam extrusion has made this attempt to realize my ideas irresistible. This is just one step towards bigger and better things!

Build Author

Peter Oakes

Views

44324

Build Author

Peter Oakes

Views

44324

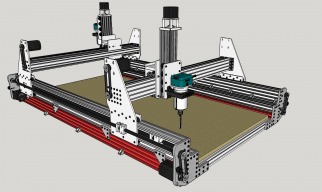

The Bull Dog, A RoverCNC OX based 1500mm x 1500mm CNC - Tutorial build

I have based this build on the OX build so I will not be going into too much detail of specefic assembly modules as they asre so well covered by Mark Carew already, but will go through the complete build on video. I will be addig additional tutorials on steppers and the other electronic parts as needed though as this project is sponsored by RS Components in the form of most of the Electronics and this is also the key focus of my YouTube channel www.youtube.com/c/thebreadboardca.

C-Beam on X, Y and Z Attempting to use internal channel first go around

C-Beam build using the small C-Beam gantry plates only.

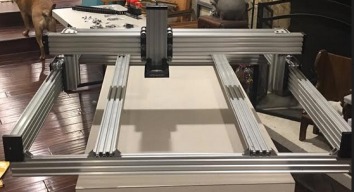

Square OX

Square shaped OX for doing general purpose engraving and cutting into wood, acrylic, and aluminum.

The Ox That Wood

This is my story about my need for a CNC router on a budget that wound up in the $5K range !!! but I have a good belt drive Ox

Wakezor

I'm starting my first own build cnc machine which is inspired by routy and the ox. Were my goal was not to use the ox plates but use the standard plates available in the parts store for the design.

Build Author

zann68

Views

9334

Build Author

zann68

Views

9334

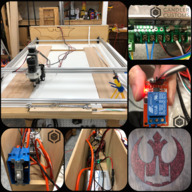

OX CNC 4'x4'

Out with the Old in with the New. Trying to build a nice clean setup that myself and my sons can use and enjoy.

Build Author

Gary Bonard

Views

6190

Build Author

Gary Bonard

Views

6190

OxZilla

This is my second Ox with a working area of 14" x 14" x 5" I wanted to build a small sturdy potable CNC router and this OxZilla has the nice upgrades !

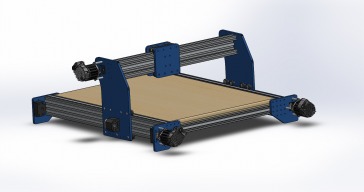

The MULE (an OX inspired 3-axis CNC)

The Mule is a 3-axis CNC inspired by the OX CNC by Mark Carew. This machine borrows the OX's sturdy frame and upgrades the X and Y linear actuators through the use of three 500mm lead screws (as opposed to the belt system of the OX). The result is an inexpensive, sturdy, and powerful design built for cutting tough materials such as aluminum.

Ooznest OX CNC Build

Ooznest OX CNC build

Build Author

Julius

Views

8216

Build Author

Julius

Views

8216

The "Hand" CNC (or OXCarve)

more to come, please follow along the journey!

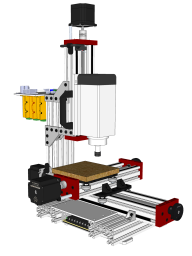

Desktop CNC

This unit is made with openbuild v-rail and c-beam. using direct drive with lead screws. Nema23 motors

C-Beam for lithophanes

First venture into cnc machining I decided on the C-Beam .

Murphy OX-CNC Dreamin

I am in the design phase of my CNC. I would like to thank everyone who has placed resources on the site. I am using it to the up most! I will update as I continue the design and share my progress.

Build Author

evil2002usna

Views

11580

Build Author

evil2002usna

Views

11580

Evil Ox

Cheap Ballscrew Ox CNC Router.

1500 x 1500 mm OpenBuild CNC

1500 x 1500 mm OpenBuild CNC

Ooznest build - 1500mm x 1000mm

Its the first build for me so its just the story of me attempting to build the kit and hopefully end up with something I can use. Hopefully without destroying anything or anyone.

OX Super "C" - Cpmpleted 11/02/16

This CNC utilizes the C-BEAM extruded aluminum for the "X", "Y", and "Z" axis. The gantry will move similar to the OX along with the "Z" except I am incorporating the C-BEAM instead of the 20x60 V-RAIL. To make the system as strong as possible I am using two C-BEAM rails back to back. The "Y" axis will encompass two sets of roller on both side of the C-BEAM extruded rails for added strength. All of the plates for this were created using the C-BEAM machine I completed several month ago.

Plate 'o CBEAM

I'm starting with the c-beam bundle, and I hope to end up with a pretty useful little platemaker/shallow relief carver. I'm hoping to discover how accurate and efficient it can be.

Build Author

Matt Nelson

Views

12334

Build Author

Matt Nelson

Views

12334

Matt's Ox

I'm building an OX CNC router. It will be the larger size of 750x 1000mm. This should give me a working area of about 22"x30".

TAZ C-Beam CnC Router by RC-CnC

C-Beam inspired CnC Router (1000x750) Approx 90mm of Z travel

My first build: a other OX CNC

I love to build things. I decided to build a CNC machine to help me build more things! I had a lot of fun and I learn a lot of thing in the process of building this machine. p.s. my primary language is french not english. Forgive me if I made some mistake.

Build Author

eddyg

Views

5006

Build Author

eddyg

Views

5006

OX with a Custom Electronics Case

Embarking on my first build and trying to start with a clean setup by creating an enclosure box for my controllers and power supply.

1x1m Ooznest Ox

Building my first router and I choose the ooznest Ox since it looks to be the latest and greatest among routers.

C-Beam CNC (1st cnc build!)

1st build CBeam Machine w/ raspberry pi-protoneer hat controller

Build Author

Rwetzler

Views

9400

Build Author

Rwetzler

Views

9400

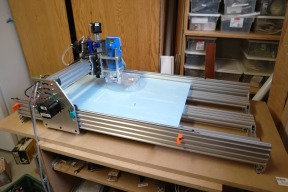

C-Beam Prototype

This is a variant of a typical OX (Mark Carew inspiration) router using C-Beams/8mm Acme rods to drive all three axis. I went with a 1000mm x 1000mm frame size. Useable space is 28" (711mm) X 26" (660mm) with a Z axis work travel of approx. 3.25" (82.5mm). A TinyG is used as a controller along with Fusion 360/Chilipper as the software for generating and running gcode files.

Promoveo Study Builds

Promoteo Build

Metalguru's C-Beam 750

This is a C-Beam build, fairly heavy duty, and 750mm x 750mm. Should be a good, sturdy machine that's relatively easy to assemble.

Dream to practical

This is my journey from a dream machine to a practical (for me) machine. This is a Cartesian style frame that can change tool heads quickly. The first version will have milling and 3D printing tool heads. Later on I'll add a drag knife tool head.

My 1st C-Beam Router

Pretty happy with the build, had some difficulty with the software loading up the settings due to me using the wrong com.

CNC machine 700x1200mm

I love to build things. I want a large cnc machine can do with little money. use Aduino .

CrOX Carbon Reinforced OX

Modified OX with carbon fiber reinforced X and Z axes. 1500mm Y, 1000mm X and 120mm Z clearence

OX based lead screw Machine

Initial design for my CNC mill\router based around C beams

Custom Ox

Custom black and red Big Ox

Cheap linear rail set up for z-axis

A easy to do cheap upgrade for the z axis

Schematix OX metal build

OX metal build from an noob

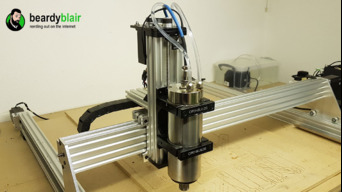

Big Ox Heavy Duty

A Heavy Duty version of the standard Big Ox build.

Build Author

beardyblair

Views

25316

Build Author

beardyblair

Views

25316

Sphinx XL

My build log of an adapted Sphinx design with additional height and a larger X and Y axis.

C-Beam Machine XL

Overview of my experience building the C-Beam Machine XL from OpenBuilds, along with updates as I move along and get it going. My application is for creating plates needed for lab functions, 19 rack bay covers, and whatever else arises.

Kruk 0.1

This is a stool, designed in 18mm wood for a cnc router, it's easily scaleable to different wood-thicknesses, in 18mm wood it takes up 1200*1200mm. It can be assembled without screws, nails or glue and can therefore also be easily disassembled.

Pure Cbeam 900x1000

This is a pure cbeam build to maximize envelope and rigidity. All the parts used are available from open builds.

Ooznest OX, Workbench, & Folding Table

An OX based unit with innovation surrounding it -- 9 drawers, workbench, folding CNC table, & portability.

Stainless OX kit

This is a 1500 X 1500 Stainless OX kit build, by a cnc novice. It is the first cnc machine i have ovned and build I got this kit from http://makersupplies.dk/20-ox-cnc-kits

Schematix Ox-Metal Build

A build of Schematix's Ox-Metal design, with a 0.8kw watercooled spindle.

Large C-Beam Sphinx style CNC Build

Started my build of a large Sphinx style cnc Router. I wanted one to handle the Dollar Tree Foam Board (DTFB) so I am making this to handle 2' X 3'. This is my first endeavor for a CNC so I am learning as I go but there is one thing for sure.

Build Author

JP Warnke

Views

12839

Build Author

JP Warnke

Views

12839

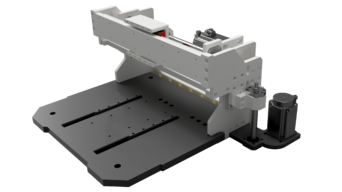

Warnke CNC Router

A blend of modular aluminum and steel bracketry built to yield fine cuts in hardwood and aluminum. An open table with a shiftable pin-fixture concept will allow the operator to shift longer than Y-travel work-pieces, such as doors, along the Y-axis of the table. This machine has a 44" (X) by 24" (Y) by 8" (Z) travel with water cooled VFD spindle motor, t-slot ext work table, cable carriers, side guards n dual y drives. Total weight (w/base-stand) is about 600lbs.

Build Author

mikev

Views

8603

Build Author

mikev

Views

8603

C-Beam Evolution MkII

The C-Beam Evolution is an evolving machine. The MkII is inspired by Kyo's C-Beam Spinx but currently uses my own design of plates made of 8mm acrylic (X-axis ends) and 6mm polycarbonate (Y axis ends). The plates were made on the MkI but I hope to be able to make 6mm aluminium plates on the MkII for the MkIII.

OX CNC Build

OX CNC built using the kit from SMW3D with a Smoothieboard 5 and external motor drivers.

Yet another Sphinx

Here's my Sphinx with a few slight modifications.

My 2nd cnc build

My new build to upgrade from my worn out shapeoko

Vertical Drill Mill

Mill drill using a dremel and some 3d printed parts

1000mm X 1000mm with tinyg

1000mm X 1000mm overhead cnc machine

Ox Stainless with ballscrews

Ox Stainless with ballscrews for motion, nema 23 steppers, LInuxcnc for control software. Using basic parts for frame from Makersupplies, and the rest sourced from ebay. Building a small router hoping it will be able to cut aluminum with decent results.

Build Author

Chetan PM

Views

3828

Build Author

Chetan PM

Views

3828

Composer

Gantry style rigid build

Build Author

McAdam

Views

3752

Build Author

McAdam

Views

3752

Need a catchy name - enlarging CNC

The aim of this build is to have a CNC that can cut a FULL sheet of wood when I need it to, but also shrink down and cut smaller sheets the rest of the time. The prototype is based on an OX cnc but soon it will be completely custom using Openbuilds Parts

Build Author

Matt Barile

Views

7538

Build Author

Matt Barile

Views

7538

Fixed Gantry Welded Steel Router

Fully welded, fixed gantry CNC router, with chinese linear motion parts, in progress

C-Beam Machine upgrade to 1000mm x 1000mm

This built is to convert an existing 500x500 C-Beam Machine into 1000x1000. Inspired by several builds including C-Beam Machine : (http://www.openbuilds.com/builds/c-beam%E2%84%A2-machine-plate-maker.2020/) and Gino's build : (http://www.openbuilds.com/builds/c-beam-gtc.3250/)

CNC PKB2

blueprints here: https://github.com/tomaspavlica/cnc_pkb2

C-Beam Desktop On Rails

My attempt at a Desktop CNC using C-Beam and Open-Rail with Steel Wheel bearings and LeadScrew Drive.

Build Author

Hisha

Views

5068

Build Author

Hisha

Views

5068

Routy based build

Routy based build using 1000mm Y axis beams and 500mm X axis beams. Using a 20x80 Z axis to use the OpenBuilds router mount.

Build Author

Huub65

Views

9322

Build Author

Huub65

Views

9322

My C Beam - NEMA 17 - GRBL- Arduino project

Cbeam machine. Using small stepper motors (NEMA 17) and Arduino controller. Try to get this working in de upcoming month.

Arctic_Stingray CNC

This build is based on the C-Beam build by Mark Carew. I have added axis limit switches and a remote mounted control cabinet. This build also uses a custom moveable table.

Project There is No Kill Like Overkill

Very stout 2'x4' machine with a deep Z axis

Build Author

JerryD

Views

5353

Build Author

JerryD

Views

5353

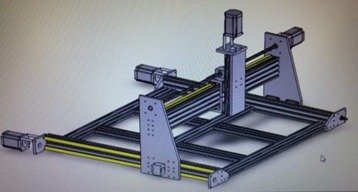

1500x1000mm Adjustable Height

I have the demand to cut/etch tall pieces of material. For this reason, I have designed a machine with 500mm uprights with adjustable gantry height. This way I can raise/lower the sled and z-axis as needed. I've also chosen to use a linear C-channel assembly for the Z axis with the plate mounted to the gantry instead of the other way around. This will allow for maximum range of the z-axis. The parts list/BOM does not include motors/belts/pulleys or electronics.

BD's C-Beam Machine CNC Router (WIP)

CNC router table based on OpenBuilds C-Beam Machine bundle.

Mark 1

My first attempt at building a CNC style machine. Overall my plan is to use the PlanetCNC breakout board and software to run the machine from a dedicated laptop/tablet.

Sphinx 1000 x 500

Building a Sphinx based CNC based on Kyo's plans. Going with a 1000 x 500 table size.

Stock CNC Router

This is my first CNC router, so be kind on the criticism. I'm still learning. Not an engineer, and not a machinist so I am having to research and learn aspect from both of those areas of study!

C Beam CNC+Laser

You will be following the assembly of the mechanical kit and how i integrate the electronics into the final build.

OX, of the house Steel

OOZNEST Style OX machine with 3D printed panels

Strong? CNC

The goal is to have a relatively strong CNC to be able to cut alu. Working space will be around 800x350x100mm.

C beam Larger and Stronger

My first build based on the original C beam Sphinx. I’m not sure at this point what the final size will be. I have the parts from the c beam Sphinx and extra beams and lead screws to build up to 1000mm x 1000mm.

Linear Rail derivative with ball screw

basic start to design of cnc machine

Heavy duty C Beam

a 1000mm x 1500mm CBeam build with hgr20 hiwin rails 600w er16 spindle

OB Minimill with bottom frame PSU+Drivers

All-in-one OB Minimill

C beam machine (with larger T-slot platform)

Larger, more rigid build plate C beam machine

Brokkr CNC 2.0

1M C-beam xy variant

Build Author

SecretSpy711

Views

22614

Build Author

SecretSpy711

Views

22614

RigidOko

Heavily upgrading my 1200x500 Shapeoko 2... ...er, wait, scratch that... Building an all new machine, roughly the same size, that should be more rigid than a Shapeoko 3!

Build Author

Tucstrlly

Views

9098

Build Author

Tucstrlly

Views

9098

Stainless OX Kit Build "Diamondback CNC"

A copy of the Stainless Ox by Martin Barfoed. Similar design, construction and control.

Yet another 1x1 Sphinx

Build a 1x1 Sphinx/Sphinx XL style CNC.

1200X600 SPHINX

Need cnc to make alumunium sign, brass stamp, etc

C Beam Served

C Beam Machine built in a server cab. Hopefully this keeps every thing enclosed , clean and quite ?

Dust Shoe for Kyo's Sphinx

Dust Shoe design for a CNC router. Attaches to Chris Laidlaw's Mount design, with the DeWalt D26200 (which I think is the DWP 611 in the US).

Build Author

pedrofernandez

Views

12193

Build Author

pedrofernandez

Views

12193

Another Sphinx 7550 Made by an Openbuilds Cbeam

feel free to ask anything about this builds, but im a airline pilot and sometimes responding maybe will take me. while!!

Build Author

Dave Pyatt

Views

4525

Build Author

Dave Pyatt

Views

4525

DaveP's Homemade CNC Project

Somewhere along the line sometime around February 2017 I got the bug in my head that I needed to build a CNC router. This is where I am today...

Build Author

Terone Burgenheim

Views

2836

Build Author

Terone Burgenheim

Views

2836

My CNC

This build is my version of the CBeam machine. I opted to NOT use the Gussets, and instead went for the 40, and 60 mil angle brackets to cut the price back a little further. I started with the smoothieboard but decided it was still "too new" and very much experimental. This build took me a few (2-3) days to complete. The CBeams and Lead-Screws really make building things faster since you don't have to clamor over belts.

Build Author

GDanger117

Views

12379

Build Author

GDanger117

Views

12379

Gantry CNC - Decisions made only to change over and over.

This is my first CNC build. As per the norm, I went in with months of research, planning, and resource gathering tied neatly together with a solid plan. As the path went on, the plan continued to change to accommodate issues I hadn't counted on. But, at the end of the road, the project reached completion, and I learned a ton along the way!

Build Author

CandlerCustoms

Views

5579

Build Author

CandlerCustoms

Views

5579

Candler Customs - Custom CNC Machine

Inexpensive Custom CNC Machine or swappable Laser Engraver utilizing OpenBuilds ACRO System

Somewhat Simple Lead screw conversion for an OX CNC

Somewhat Simple Lead screw conversion for an OX CNC.

Build Author

Camvec

Views

6288

Build Author

Camvec

Views

6288

WorkBee CNC full kit 1500mm x 1500mm

This will be my first build ever! Looking forward to it , just gotta finish the new workshop first then I'm on it!

Build Author

OffAxis

Views

7759

Build Author

OffAxis

Views

7759

OffAxis CNC 1000x1500

Cut Area: 825 x 1340. Max Cutting depth: 2 inches. Arduino based control with Nema 23 and Nema 17 drive. 8mm leadscrew and 2GT belt drive. 400W 48V quite cut spindle.

Build Author

TurfnSurf

Views

6227

Build Author

TurfnSurf

Views

6227

3-Axis Plywood CNC

Theoretical Working area: 38" x 24" x 6" Actual Working Area: 31" x 23.6" x 4" Positioning Accuracy: about 0.01mm

Build Author

TurfnSurf

Views

7157

Build Author

TurfnSurf

Views

7157

DIY C-Beam CNC

Theoretical Working Area: 360x360x75mm Actual Working Area: 300x300x75mm Will Update Later

Build Author

spark2

Views

5707

Build Author

spark2

Views

5707

C-Beam - Sphinx 1000x1000mm inspired by Kyo

A stable CNC Router that allows me to cut and carve bigger Parts. The Machine is an original Build from Kyo's Sphinx CNC Machine. Thanks for the great Work and the Effort Kyo. Your Files and Lists helped me a lot to build that Sphinx 1x1m.

Another Kyo inspired Sphinx

A 1000mm x 1000mm copy of Kyo's Sphinx

Build Author

Sprags

Views

2752

Build Author

Sprags

Views

2752

C-Beam Kyo Sphinx 10060

More stuff here.

Build Author

jz321

Views

4577

Build Author

jz321

Views

4577

OTiS 500mm

OTiS (Off The Shelf) is 500mm cartesian CNC that can be built with all off the shelf parts from OpenBuildsStore. It features C-Beam actuators and a V-Slot frame.

Build Author

crnrstndes

Views

4253

Build Author

crnrstndes

Views

4253

C-Beam Upgrade to Larger C-Beam

My goal was to be able to enlarge my C-Beam with as many original parts as possible. I was able to recycle almost all of them with a only the two 500 mm rails left over. I used 1000 mm rails for the X Axis and I added another complete Y Axis assembly. I chose to keep it simple and I am very happy with the result!