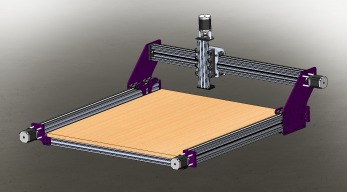

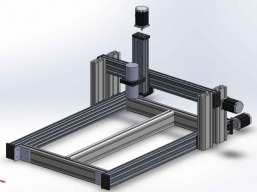

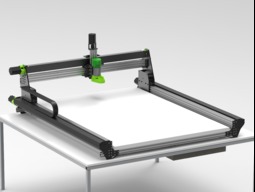

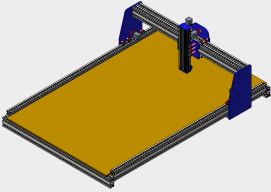

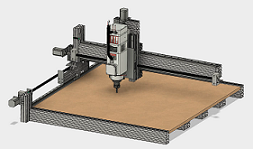

Cartesian Style CNC

Murphy OX-CNC Dreamin

I am in the design phase of my CNC. I would like to thank everyone who has placed resources on the site. I am using it to the up most! I will update as I continue the design and share my progress.

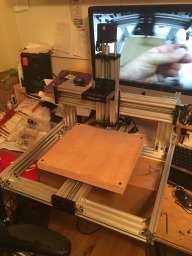

"Hirata scrap find" CNC

First CNC and first attempt at building one also, so yeah... good luck to me!

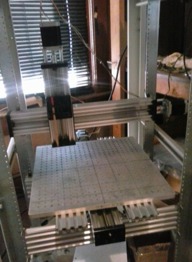

C-Beam CNC (1st cnc build!)

1st build CBeam Machine w/ raspberry pi-protoneer hat controller

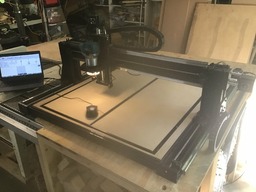

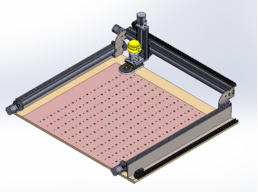

BD's C-Beam Machine CNC Router (WIP)

CNC router table based on OpenBuilds C-Beam Machine bundle.

Build Author

BCulbertson

Views

5144

Build Author

BCulbertson

Views

5144

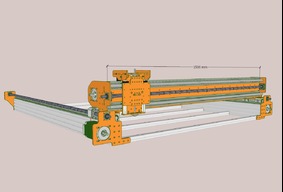

Lead 1515 with Upgrades

My upgraded OpenBuilds Lead 1515

1010 with linear rails

Has a 700 by 700 cutting area and is very stable

Build Author

SCYBUCK

Views

5140

Build Author

SCYBUCK

Views

5140

KYO SPHINX a la' SCYBUCK

KYO SPHINX, CENTROID ACORN, GECKO 540, HALL EFFECT LIMIT SWITCHES, 2.2 KW, 24,000 RPM SPINDLE, WATER COOLED, 600 oz-in STEPPERS, INTENDED TO CUT ALUMINUM.

Build Author

Corey Corbin

Views

5110

Build Author

Corey Corbin

Views

5110

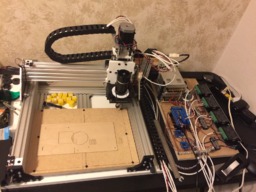

Sphinx Derived Router

I Like the Sphinx design thought I would attempt my first build. I wanted to build this and use Arduino controller with GRBL to be able to learn and understand my machine.

Small Desktop CNC Router/Mill

I designed and made this from scratch. The frame is welded steel filled with sand, and most of the other parts are aluminium. It's controlled with a DIY ESP32 controller running GRBL_ESP32

Build Author

Hisha

Views

5068

Build Author

Hisha

Views

5068

Routy based build

Routy based build using 1000mm Y axis beams and 500mm X axis beams. Using a 20x80 Z axis to use the OpenBuilds router mount.

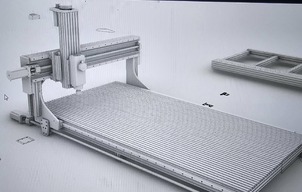

1200 x 2700 CNC based on OX

Preliminary design for cnc based on OX for cutting wood sheet products (ply, MDF etc.) for a sheet size of 1200mm x 2700mm

ROUX - A Routy-OX Hybrid

ROUX is a 2'x4' CNC that can be easily handbuilt without an existing mill and removes the need to buy generic plates for the Routy. A simpler, more refined machine.

EOX

Open builds style wood CNC router. Usable work aria 1000mm x 1250mm x 150MM (X x Y x Z). 80x40 C bleam for the Y axis , two 60x20 beams for X axis and a 60x20 fo Z. Interlocking GT3 belts for X and Y. Looking to change over to a rack and pinion system in the future. 8x8Tr Lead screw for the Z. Leadshine HBS507 close loop drivers and 3-phase servo motor 573HBM20-EC-1000 motors driving the Y and X axis. Would recommend them to anyone looking for servo like performance at a affordable price.

"Stung by the Bee" OB Workbee 1010 Build

This will be a build Log for my Open Builds Workbee 1010 Build. I will keep a full descriptive log of the build and make any notes in the hope that it will help other builders that decide they would like to build this machine.

Build Author

eddyg

Views

5006

Build Author

eddyg

Views

5006

OX with a Custom Electronics Case

Embarking on my first build and trying to start with a clean setup by creating an enclosure box for my controllers and power supply.

The Ox That Wood

This is my story about my need for a CNC router on a budget that wound up in the $5K range !!! but I have a good belt drive Ox

LimpyCNC

Inpired by the OpenBuilds OX and PrintrBot Crawlbot. This is the LimpyCNC. It's still a work-in-progress. But it provides a 120x120cm work space without using up 150x150cm of garage space.

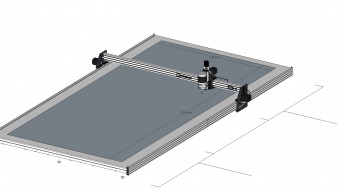

Leveling Gantry

Large leveling platform to hold a 3hp router

Build Author

Craig Hollabaugh

Views

4910

Build Author

Craig Hollabaugh

Views

4910

Hyatt and My Journey to Tonehenge

I'm conducing guitar loudspeaker cabinet fabrication technique research (material type/thickness, mechanical joints, adhesives, etc) and how these relate to cabinet/speaker coupling and enclosure resonance with respect to psycho-acoustics. Basically, does one speaker cab sound better than another and why?

Build Author

Bikes and Beer

Views

4885

Build Author

Bikes and Beer

Views

4885

The Forever Project

Workbee 1010 Lead Screw with water cooled spindle and enclosure

Sphinx 7575

Sphinx CNC modified to 750mm x 750mm c-beams. Parts not readily available in South Africa, so i have to make some modifications...

The FOX

This will be an OX based machine which I've designed to make the best use of my materials, be as precise as the design allows and operate as quietly as possible. I live in an apartment complex so space and noise are two important factors for me. Therefore the machine needs to do as much as possible while using little space and not annoy the neighbours.

My 2nd cnc build

My new build to upgrade from my worn out shapeoko

Techsoft Roland TS-30 rebuild

Replacing the Electronics and Spindle. Intending to rewire all the buttons and make it into a more modern and easy to use CNC.

Sphinx 1050

Openbuilds 1050 Sphinx. Thank you to Mark Carew for trading me a set of plates for a spindle and PSU I was not using. Mark is a champ!

Workbee 1500x1500 belt

Workbee CNC 1500x1500 with timing belt

WorkBee 1510 - First CNC Build

This build will go through the construction of a WorkBee 1510 kit from the OpenBuilds Part Store, all mechanical and electrical components were purchased from the store in late October 2018.

Build Author

Leon Style

Views

4682

Build Author

Leon Style

Views

4682

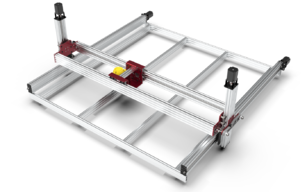

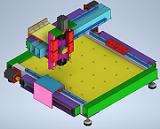

AluVault MINIMAX

Easy build cnc router with t slot profile and nylon machined part

C-Beam on X, Y and Z Attempting to use internal channel first go around

C-Beam build using the small C-Beam gantry plates only.

Sphinx 1000 x 500

Building a Sphinx based CNC based on Kyo's plans. Going with a 1000 x 500 table size.

1075 Sphinx

My first attempt at building a CNC. I chose the Sphinx due to ease of build and extensive documentation provided by Kyo.

Build Author

jz321

Views

4578

Build Author

jz321

Views

4578

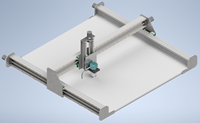

OTiS 500mm

OTiS (Off The Shelf) is 500mm cartesian CNC that can be built with all off the shelf parts from OpenBuildsStore. It features C-Beam actuators and a V-Slot frame.

Build Author

Limine3D

Views

4577

Build Author

Limine3D

Views

4577

Shapeoko 1 upgrades

Replaced the original Z-axis for a shapeoko with a c-beam upgrade. This upgrade required a nema 17 mount and a quiet spindle mount I printed with a 3D printer.

Cheap linear rail set up for z-axis

A easy to do cheap upgrade for the z axis

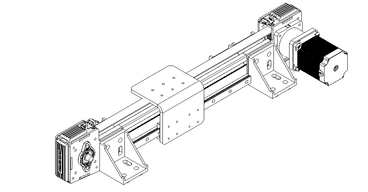

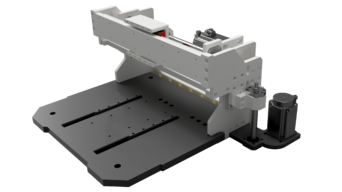

CNC Linear Slide for DIY project

Low cost cnc linear drive for making any xyz cnc structure

Build Author

Dave Pyatt

Views

4525

Build Author

Dave Pyatt

Views

4525

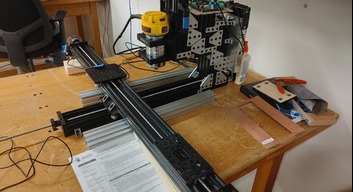

DaveP's Homemade CNC Project

Somewhere along the line sometime around February 2017 I got the bug in my head that I needed to build a CNC router. This is where I am today...

Build Author

DaleShaw

Views

4489

Build Author

DaleShaw

Views

4489

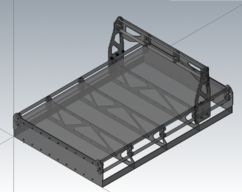

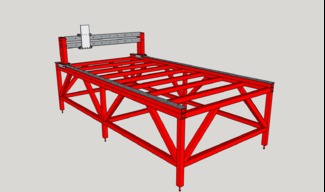

Senior Project CNC table

So for my senior project I decided to build a CNC router. I kind of need to get this done before May so we'll see what all goes down. It's going to be a 3 axis machine (for now) and will be able to handle 4x8 sheets of wood. This is my first build. It's going to be intresting..

Build Author

KronBjorn

Views

4480

Build Author

KronBjorn

Views

4480

WorkBee Lead 1010, Reduced Footprint, Nema17

This is a WorkBee 1000x1000mm with lead screws and Nema17's. It has a reduced footprint, with the geared Nema's inside the frame.

big_recnc v2.0

cnc made with a 6mm metal body .

Build Author

ckgottabuild

Views

4335

Build Author

ckgottabuild

Views

4335

Lead CNC 1010 Platform and Rotating Laptop Mount

Moveable Lead CNC1010 build with handles on four corners. Everything fits on one sheet of cut out 4x8 plywood

Monster-not-so-mini-mill

My Minimill hit the gym, and isn't so mini anymore

Brice's CNC Router Build

I'm building a CNC router for a long time. Here's the result on this long journee. I tried to do my best with the basic tools I have. Don't hesitate to ask if you have questions.

Build Author

Suhmanda

Views

4309

Build Author

Suhmanda

Views

4309

DIY CNC SPINDLE

CNC SPINDLE FOR DIY ROUTERS AND MILLING MACHINES ITSRS-985 MOTOR HAS MUCH BEFINITS THAN ANY OTHER DC MOTOR IN MARKET

EOX v2

Upgrading my CNC router to run on ball screws. Me and the belts where not getting along.

Build Author

crnrstndes

Views

4253

Build Author

crnrstndes

Views

4253

C-Beam Upgrade to Larger C-Beam

My goal was to be able to enlarge my C-Beam with as many original parts as possible. I was able to recycle almost all of them with a only the two 500 mm rails left over. I used 1000 mm rails for the X Axis and I added another complete Y Axis assembly. I chose to keep it simple and I am very happy with the result!

75x75

Simple cnc with 5mm steel plates.

Build Author

RV6APilot

Views

4244

Build Author

RV6APilot

Views

4244

South Carolina Workbee 1000X1000

This is about my build of a Workbee 1000X1000 being built here in Trenton, SC. My goal is to use it to help cut the new panel for my RV6A airplane.

Fastmill CNC

Very cheap CNC made from laser fired and bent parts.

Build Author

Steve Hall

Views

4188

Build Author

Steve Hall

Views

4188

Cartesian Style Build UK

Another Cartesian style build with parts from the UK, US & China.

John's Sphinx

1000mm x 750mm C-Beam Sphinx, running on Grbl

YAPCNC (Yet Another Poor's Man CNC)

Yet Another Poor's Man CNC (YAPCNC) is my first attempt to build a CNC. The idea is for the build to be as inexpensive as posible while being usable for my goals.

no xp cnc

This is my first cnc build, never used one before and don't know too much besides what i've read a little bit about them online. It's probably going to be about 31" y axis with hopefully around 4ft x axis, z height is still to be determined.

Build Author

rob4cnc

Views

4036

Build Author

rob4cnc

Views

4036

Rock n Roll

The Rock n Roll is built on granite, is solid as a rock, and gathers no moss. This build provides a high degree of accuracy and repeatability. Built to be strong, use redundancy, and use long lever arms to average out imperfections in the equipment. Built to go fast and light. We will use a high speed spindle, large high voltage stepper motors and small cutting heads to overwhelm the forces produced at the cutting head.

Build Author

Jones

Views

4017

Build Author

Jones

Views

4017

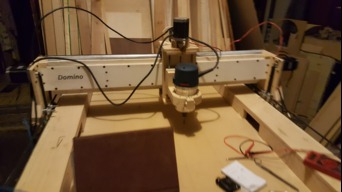

The Domino - 1.5m x 1m

DIY scratch build consisting of gas pipe, skate bearings, 12mm birch, 3/4 maple v-core ply, Nema 23's, and arduino and CNC shield with DRV8825's.

Black out Edition Workbee 1010

Thanks to all the Open Build elves that meticulously package and wrap all the little tiny parts and pieces. I have put in a request to get you people a raise..

Build Author

Colin Russon

Views

3944

Build Author

Colin Russon

Views

3944

TITAN GAMBIT

Anti-Twist Design, larger lead screws, enhanced M8 wheel sets.

Kruk 0.1

This is a stool, designed in 18mm wood for a cnc router, it's easily scaleable to different wood-thicknesses, in 18mm wood it takes up 1200*1200mm. It can be assembled without screws, nails or glue and can therefore also be easily disassembled.

Norwegian OX

This build is based of Ooznest 's OX CNC Mechanical kit (500x750) with a few mods if all goes as planned.

Mostly Printed Cartesian CNC

This is a build that is just getting started. Not all of the parts are ordered or printed as of 5/27/2018. Hopefully in the next few weeks all parts will be printed and most parts ordered.

Build Author

Chetan PM

Views

3828

Build Author

Chetan PM

Views

3828

Composer

Gantry style rigid build

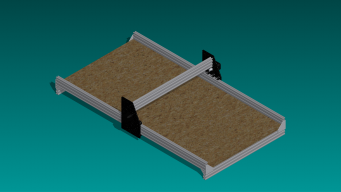

Custom Ski and Snowboard CNC for a High School Woodwhop

A Custom size CNC to make custom skis and snowboards

My 1st C-Beam Router

Pretty happy with the build, had some difficulty with the software loading up the settings due to me using the wrong com.

Desktop CNC

Approximately 910mm x 955mm x 82mm. There is 250mm available in the Z, but the gantry is only 82mm from the bed surface.

Build Author

McAdam

Views

3752

Build Author

McAdam

Views

3752

Need a catchy name - enlarging CNC

The aim of this build is to have a CNC that can cut a FULL sheet of wood when I need it to, but also shrink down and cut smaller sheets the rest of the time. The prototype is based on an OX cnc but soon it will be completely custom using Openbuilds Parts

Retractable WorkBee1510 with Marlin+MarlinPanel high level build

WorkBee1510 with retractable space saving stand and customize build Marlin firmware and MarlinPanel (GCode Sender/UI)

Gerber 404 Retrofit

Not sure if the Blackbox X32 is the right option here, just looking for guidance.

C-Beam unit with 400W Spindle

Standard (If there is one) C-Beam with plnth

Large C-Beam Sphinx style CNC Build

Started my build of a large Sphinx style cnc Router. I wanted one to handle the Dollar Tree Foam Board (DTFB) so I am making this to handle 2' X 3'. This is my first endeavor for a CNC so I am learning as I go but there is one thing for sure.

Stock CNC Router

This is my first CNC router, so be kind on the criticism. I'm still learning. Not an engineer, and not a machinist so I am having to research and learn aspect from both of those areas of study!

CNC machine 700x1200mm

I love to build things. I want a large cnc machine can do with little money. use Aduino .

Plate 'o CBEAM

I'm starting with the c-beam bundle, and I hope to end up with a pretty useful little platemaker/shallow relief carver. I'm hoping to discover how accurate and efficient it can be.

C Beam CNC+Laser

You will be following the assembly of the mechanical kit and how i integrate the electronics into the final build.

Build Author

Stan Howe

Views

3361

Build Author

Stan Howe

Views

3361

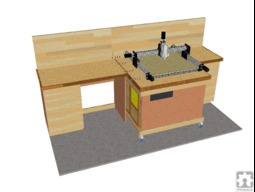

Bee the Boss

The frame of the CNC is going to to Bee a basic Work Bee with maybe 1 modification to the spoil board attachment. This will be located on a custom bench housing the electronics and vacuum. I plan to install Stepper online steppers, drivers, power supplies, and break out board. I will add a 1.5 KW water cooled spindle, with a radiator. The fans from the radiator will pull air from a filtered enclosure for all the electronics.

Just Starting

My attempt at planning out my own CNC router

Dust Shoe for Kyo's Sphinx

Dust Shoe design for a CNC router. Attaches to Chris Laidlaw's Mount design, with the DeWalt D26200 (which I think is the DWP 611 in the US).

Build Author

Neil Scott

Views

3283

Build Author

Neil Scott

Views

3283

Barcelona Build

This will be my second CNC build but this time a proper CNC not a small desktop model that I played with for a while to learn Gcode, It was great but now its time to start playing with the big boys and girls.

Another Kyo inspired Sphinx

A 1000mm x 1000mm copy of Kyo's Sphinx

HandCrafted WorkBee - HCWB

This will be a slow build as I collect parts and materials as funds permit for 1000mm x 1000mm Workbee. I call it the "Hand Crafted WorkBee" because I will be hand making the plates and as much of the build as possible using a drill press and hand tools.

Just Another CNC

I wanted to make my own unit. I enjoy building and was looking for a challenge.

Cnc Router 3000 x 1000 mm

In progress

Build Author

Axnfell

Views

3115

Build Author

Axnfell

Views

3115

WorkBee 1000x2000 ACME Screw Version

Hoping to build a WorkBee 1000 x 1000 (2000) from parts and not a kit, cannot afford the kit in full so going the long way round...

TFE2 CNC Build

My TFE2 CNC Build. The TFE was much smaller and all of the gantry plates were 3D printed. Despite this it will happily machine aluminium without issue. So I decided to use that to make the TFE2 which will be all aluminium plates and much larger (1200x800mm machining area with roughly 140mm in Z so I can later add a rotary axis.)

C Beam Served

C Beam Machine built in a server cab. Hopefully this keeps every thing enclosed , clean and quite ?

Workbee with less irritations

My workbee build with some add ons

Repurposed Steel Table 4 x 8 Build

Repurposed Steel Table for CNC Router Build.

Build Author

Bucky Wootmaster

Views

3007

Build Author

Bucky Wootmaster

Views

3007

Bucky CNC

CNC machine using extrusions with linear rails and ball screws on all axes - no plates

Something a Tad different

Future CNC router kit design

Build Author

Terone Burgenheim

Views

2836

Build Author

Terone Burgenheim

Views

2836

My CNC

This build is my version of the CBeam machine. I opted to NOT use the Gussets, and instead went for the 40, and 60 mil angle brackets to cut the price back a little further. I started with the smoothieboard but decided it was still "too new" and very much experimental. This build took me a few (2-3) days to complete. The CBeams and Lead-Screws really make building things faster since you don't have to clamor over belts.

Mark 1

My first attempt at building a CNC style machine. Overall my plan is to use the PlanetCNC breakout board and software to run the machine from a dedicated laptop/tablet.

NotAnOx

From plywood and linear rail to c-beam. I probably should have bought a kit.

Build Author

Sprags

Views

2752

Build Author

Sprags

Views

2752

C-Beam Kyo Sphinx 10060

More stuff here.

ECNCML (budget mashup)

This build summarizes my CNC milling and laser engraving machine conversion from a dimensional lumber frame and electrical mess to an all aluminum frame with a safe and well constructed (IMHO) control system with the resources I had available.

C-Beam Machine XL

C-Beam XL upgraded with end-stops, E-stop, and cable chain. Running GRBL on Arduino Mega.

CBeam Sphinx Upgrade

Simple upgrade of the Y axis on a Cbeam sphinx from 500mm to 1000mm.

Build Author

Yosmany325

Views

2440

Build Author

Yosmany325

Views

2440

OrionPlus

Cartesian style CNC with a working area of around 360mm x 360mm x 120 mm (X, Y, Z) using Linear rails and ball screws. The linear rails are (Hiwin?) HGR 20mm x 520mm and the ball screws are SFU1204 (12mm lead 4mm) of around +/- 430 mm. The base structure is made from rectangular aluminum profiles of 70mm x 45mm x 3mm (thickness of walls).

frugal-ist workbee

a 1000x1000 acme screw workbee built as frugally as possible. thanks so much to ooznest and openbuilds :)

C beam Larger and Stronger

My first build based on the original C beam Sphinx. I’m not sure at this point what the final size will be. I have the parts from the c beam Sphinx and extra beams and lead screws to build up to 1000mm x 1000mm.

Lead 1510

Customised Lead 1010 making it a 1510. T-Track work area with dual Y limit switches for auto-squaring. Powered by xPro v5 & CNC.js