Build List

-

Active Filters:

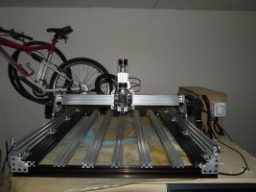

ox

Build Author

tmadrms

Views

7580

Build Author

tmadrms

Views

7580

C-Beam Mods

C-beam machine mods.

Build Author

Bruce Walker

Views

6974

Build Author

Bruce Walker

Views

6974

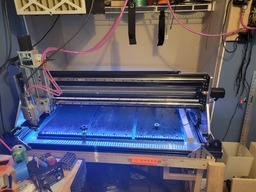

BD's Burn Box - ACRO Laser Engraver System

Two plus years in the making, I finally have a working ACRO 510 laser engraver system complete with enclosure and air filtration.

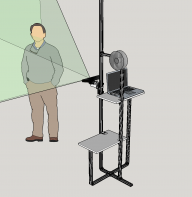

CNC accessory box Made 100 % from recovery materials

Quick construction. A few pieces of wood recovered in the trash can, two hooks one hinge, a few screws and a little glue. [Edit] Added the SVG file for sharing (I forgot it)

Build Author

richthorn

Views

8188

Build Author

richthorn

Views

8188

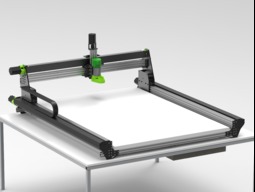

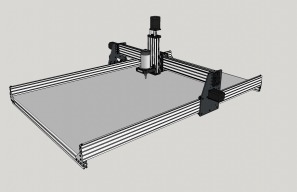

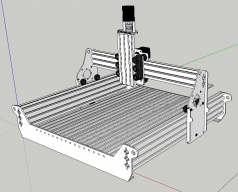

Aluminum Ox

I have been looking for a good solid kit to build off of for some time and when I saw the Ox buildlog I knew I had to have one. Ordered most of the pieces from Open Builds and started planning. Had a nice gentleman named Chris cut the required plates from 6061 aluminum for me (he sells them on eBay now if you're interested) and got to work.

Build Author

DiggerJ

Views

8688

Build Author

DiggerJ

Views

8688

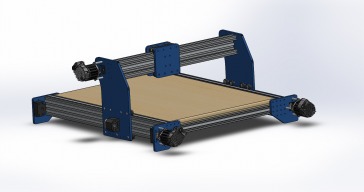

Babe - The Big Blue (Laser) OX Build

A 1000 x 1500 OX build with the ability to router cut dovetails as well as laser engraving and light cutting.

Build Author

d0rk1e

Views

7641

Build Author

d0rk1e

Views

7641

OXford (OX fortified)

150x75 cm OX with additional Y axis supports and hopefully a working double belt system

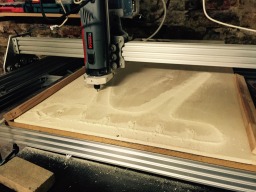

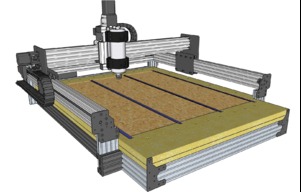

Another OX CNC Router

An OX CNC router using Blue OX Solutions gantry plates, a Bosch Colt router, and most of the remaining parts coming from Openbuilds parts store. Table has about 22"x55" cutting capacity and I am planning on a combination T-Slot and vacuum hold down system.

Modified OX CNC Router (1000x750 mm)

An OX Router I'd like to modify to improve the frame rigidity and resolve some alignment problems

Build Author

Larry_AK

Views

10206

Build Author

Larry_AK

Views

10206

MUSK-OX

Pretty much a straight OPENBUILDS OX that slowly getting some modifications.

Viking OX

My OX cnc upgrade.

OX 1000mm Y Axis Upgrade

Expands y-axis to 1000mm. 1/2 day build.

Builder Bob's CNC

Here is the consolidation of my woodworking shop, a CNC Router!

Build Author

Tim Pierce

Views

14262

Build Author

Tim Pierce

Views

14262

Openbuilds V slot Rail extrusion retrofits for Lulzbot 4/5 Taz Printers (X, Y and Z axis)

This project shows how to use Openbuilds Vv slot extrusions and wheels to retrofit a Lulzbot Taz 4 or 5 printer. These modifications improve layer consistency, eliminate nozzle and bed sag, and allow for larger toolhead mounting. Project updates and newer accessory files may be located at http://www.thingiverse.com/piercet/designs

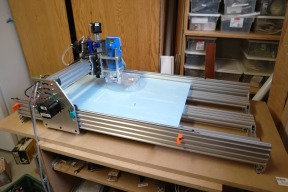

OX CNC Build

OX CNC built using the kit from SMW3D with a Smoothieboard 5 and external motor drivers.

Wifi'not

A simple made hideaway for ugly electronics

Build Author

James Evanko

Views

4714

Build Author

James Evanko

Views

4714

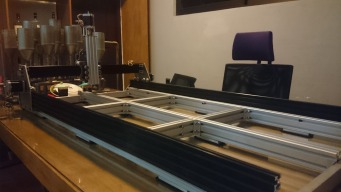

Ball Trajectory Machine

Need to build a machine that accurately positions objects for processing by a computer vision algorithm? Here is an example of a machine that does that for a ball trajectory application. The black anodized V-rails work well for applications in optics and imaging where the machine needs to stay out of the limelight.

My C-Beam machine...

A C-Beam machine design, strengthened with extra brackets and plates. GRBL controlled, opto-isolated inputs, jogging box.

Build Author

Damian V-SLOT Poland

Views

3613

Build Author

Damian V-SLOT Poland

Views

3613

LEGO BOX

Discover our unique DIY project that blends creativity, utility, and sustainability. This guide will take you through the construction of a LEGO display box, ingeniously crafted using offcuts of V-SLOT aluminium profiles and OpenBuilds accessories. Not only is this an eco-friendly approach to reusing surplus materials, but it also results in a stylish, functional display for your prized LEGO models. Whether you're a LEGO enthusiast or have little LEGO fans at home, this innovative project offers

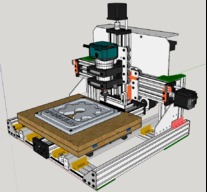

OX 1500x1500 Dual Drive

Ox inspired 1500 x 1500 CNC with belt and pinion drive and lead screw drive options.

Aluminium OX - Canada

Document my OX build process. I will also be sharing SolidWorks parts files & assemblies.

Aluminium Router From Dubai

Another modification on the OX

Build Author

Hytech2k

Views

6882

Build Author

Hytech2k

Views

6882

Micro Ox 2 x 2

Micro Ox Build

The FOX

This will be an OX based machine which I've designed to make the best use of my materials, be as precise as the design allows and operate as quietly as possible. I live in an apartment complex so space and noise are two important factors for me. Therefore the machine needs to do as much as possible while using little space and not annoy the neighbours.

Build Author

Steve Marsh

Views

5681

Build Author

Steve Marsh

Views

5681

Dust Shoe for Colt router and OxCarve

A simple 3D printed dust shoe for the cnc router. 2 parts held together with magnets for easy bit changes.

Build Author

Edgar Robles

Views

4030

Build Author

Edgar Robles

Views

4030

Sheethexapod

Sheethexapod works with basic mechanims as direct metal-metal links and joints, all movements can be done by a rc servomotor in this case towerpro model.

Build Author

Denis Lapratte

Views

4472

Build Author

Denis Lapratte

Views

4472

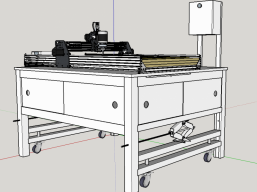

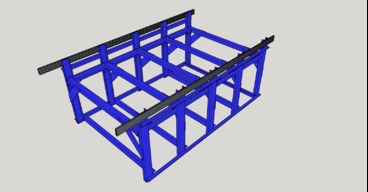

All metal Ox hybrid CNC Router Table

This is my second CNC build, but the first one that I design from the ground up. The base is all metal because I want to add Plasma facility later on. I used the Ox model for the gantry plates and made a few changes to adapt to my design. Since I wanted to use parts from my first CNC to save as much as possible, I kept the 5/8 Hi-Lead Screw I had from Roton for the Y and Z axis. I will also add a downdraft table to keep all parts tight on the table for cutting.

Build Author

Hussein Dermay

Views

6397

Build Author

Hussein Dermay

Views

6397

Ooznest WorkBee 1000mm x 1000mm Screw Driven

I have decided to buy and build the ooznest workbee screw driven cnc (1000x1000) and also decided to use some plates and extrusions from the ox cnc. I will never use two machines anyway and hoping to build a strong base for the workbee.

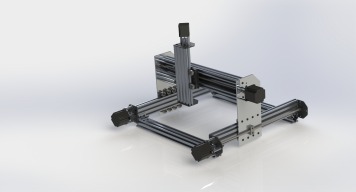

EOX v2

Upgrading my CNC router to run on ball screws. Me and the belts where not getting along.

Build Author

Fábio Pires

Views

6961

Build Author

Fábio Pires

Views

6961

Frezar - Desktop CNC

This is a small desktop CNC inspired by the Mini OX project. It's designed with the nema 17 motors in mind. It's a 650mm x 500mm machine that it will be used to mill cast acrlic.

An other Ox Metal Build AZ

Had left over parts from cnc plasma build.

Build Author

Johnny Reich

Views

1956

Build Author

Johnny Reich

Views

1956

ProLight 1000 Mill Retrofit

Update a 20-year old bench top milling machine with OpenBuild Ecosystem electronics.

Build Author

OpenBuilds

Views

30902

Build Author

OpenBuilds

Views

30902

BlackBox X32

The next level of CNC motion control solutions. Packed with advanced new features and built on the reliability of the proven BlackBox system

Build Author

BCulbertson

Views

4275

Build Author

BCulbertson

Views

4275

Lead 1515 with Upgrades

My upgraded OpenBuilds Lead 1515

Build Author

Bear

Views

10928

Build Author

Bear

Views

10928

OXBear

ANOTHER OX!~ Huge Thanks to Marc Carew and Open Builds. The primary reason I am building this CNC mill is to aid in my homemade snowboard creation. I am going to try and document as much of everything as I can and post it here to help others going a similar route. I know from past projects that taking the time to document each step can be tedious when you want to charge ahead but I will try! I hoping to get feedback on my design choices and set up as I am a complete newbie to CNC.

Yet Another Ox Build

This build log will chronicle the construction of my oversize (1000mm X 1500mm) OX router.

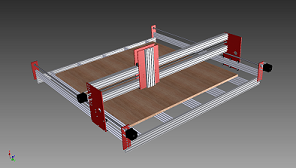

1500x1000 (4x2) Router - OX derivative

OX build with 1.5m gantry the 1m deep table.

Build Author

openhardwarecoza

Views

7077

Build Author

openhardwarecoza

Views

7077

Pocket Ox (Sheetmetal)

Small CNC - made with some custom lasercut+bent sheetmetal parts + Openbuilds V Slot

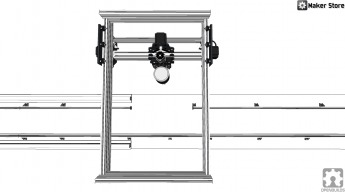

Vic Aussie Ox

Dove in and ordered the kit from Makerstore in Melbourne. While awaiting for the order watched videos and sourced steppers and controllers from China. Had some fun with the 4 axis TB6600 controller board. Ran into a few problems with the build, but after stripping and restarting looks like I am on track.

Zebu ( OX clone with Brasil materials)

An OX clone with alternative parts.

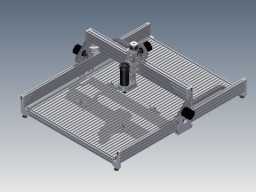

Square OX

Square shaped OX for doing general purpose engraving and cutting into wood, acrylic, and aluminum.

The MULE (an OX inspired 3-axis CNC)

The Mule is a 3-axis CNC inspired by the OX CNC by Mark Carew. This machine borrows the OX's sturdy frame and upgrades the X and Y linear actuators through the use of three 500mm lead screws (as opposed to the belt system of the OX). The result is an inexpensive, sturdy, and powerful design built for cutting tough materials such as aluminum.

Ooznest OX CNC Build

Ooznest OX CNC build

Arctic Ox CNC Router

This is a cartesian CNC Router build that is based off the OX CNC build by Mark Carew. I am using Spark Concepts CNC xPro controller board and their 400w spindle kit.

Build Author

evil2002usna

Views

11477

Build Author

evil2002usna

Views

11477

Evil Ox

Cheap Ballscrew Ox CNC Router.

Build Author

Paruk

Views

22941

Build Author

Paruk

Views

22941

Buffal-O-Tron

A 3D Scanning Station

Build Author

eddyg

Views

4939

Build Author

eddyg

Views

4939

OX with a Custom Electronics Case

Embarking on my first build and trying to start with a clean setup by creating an enclosure box for my controllers and power supply.

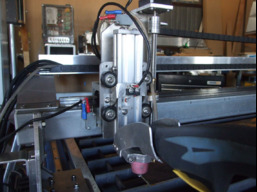

Epoxy dispenser, to apply non-conductive epoxy to electronic board.

Epoxy dispenser, 2nd one, first one works great. Uses HMI to allow for operator to pull up files for different jobs. 9 prox sensors, Eot and home on all 3 axis. High quality nema23 motors with intergrated drives from applied motion. Uses programmable router for drives.

My 2nd cnc build

My new build to upgrade from my worn out shapeoko

Sphinx 1000 x 500

Building a Sphinx based CNC based on Kyo's plans. Going with a 1000 x 500 table size.

Build Author

RobFromLDMS

Views

5123

Build Author

RobFromLDMS

Views

5123

Lithgow Mens Shed CNC build

The tale of how we put together our CNC Router, and some of the difficulties encountered. It is now ready for final testing and commissioning.

OX (Large) CNC

Building a Large OX CNC Open Build on a fold down table.

Ox cnc improvements chain driven

Just ox cnc experiment

Build Author

Jasont

Views

4146

Build Author

Jasont

Views

4146

MY first CNC build

my first cnc build using the lead 1010 to build bigger and better!!

Build Author

Sigifredo Cruz Rojas

Views

3994

Build Author

Sigifredo Cruz Rojas

Views

3994

ALl included interface

I have not too much space and need a portable solution, and tired of cleaning the electronics I decide to put everything inside a box and this is the result.

Little Big OX

A complete CNC newbie is tackling a mighty challenge, Not only is he making a CNC router, He's going to try and upsize it.

Norwegian OX

This build is based of Ooznest 's OX CNC Mechanical kit (500x750) with a few mods if all goes as planned.

First Ooznest OX

The ooznest OX CNC Machine is based on the OX CNC Machine designed by Mark Carew of Openbuilds, and incorporates many upgrades from the Openbuilds community. Mark Carew based the OX on the Routy, which was in turn based on the Shapeoko

Cancelled - Modified OX CNC for Mitre Cutting (Picture Framing)

Creating a CNC mitre (45°) cutter, for picture frame cutting. Starting with an OX, but inverting various parts and adding a material table, with a stepper-controlled measuring guide.

The Ox That Wood

This is my story about my need for a CNC router on a budget that wound up in the $5K range !!! but I have a good belt drive Ox

My first build: a other OX CNC

I love to build things. I decided to build a CNC machine to help me build more things! I had a lot of fun and I learn a lot of thing in the process of building this machine. p.s. my primary language is french not english. Forgive me if I made some mistake.

Build Author

Asaku

Views

9567

Build Author

Asaku

Views

9567

mBOX

Hi! This build is, or at least should be, a multipurpose box (mBOX). Due to limited space I want to build something that can serve multiple purposes such as 3d printing, 3d scan, plexiglass cutting and hopefully some milling too (both wood and metal). Switching between modes should involve switching heads and worksurface (change heatbed with a wood platform and viceversa). (for the scan part I'm thinking of integrating this opensource project into the frame: http://www.freelss.org/ )

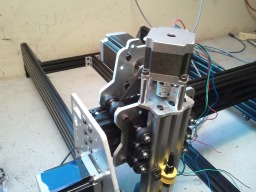

CBeam OX

i wanted to use both the ox and the C beam C beam for the gantry because its stronger i also made the gantry 20 mm higher so i can cut thinker material i will maybe later go to rack& pinion on the 1500 mm Y axes also instead of the V wheels i will maybe go to hiwin in the furture

SUPER OX NEMA 34 1600 OZ Motors!!!

CNC OX 1500X3000

Build Author

McAdam

Views

3686

Build Author

McAdam

Views

3686

Need a catchy name - enlarging CNC

The aim of this build is to have a CNC that can cut a FULL sheet of wood when I need it to, but also shrink down and cut smaller sheets the rest of the time. The prototype is based on an OX cnc but soon it will be completely custom using Openbuilds Parts

Build Author

Matt Barile

Views

7358

Build Author

Matt Barile

Views

7358

Fixed Gantry Welded Steel Router

Fully welded, fixed gantry CNC router, with chinese linear motion parts, in progress

Build Author

Lasersc

Views

5295

Build Author

Lasersc

Views

5295

The D & R TigerPaw Trilogy

Hopefully this will be a quick guide to one way that you can add a laser to an existing CNC router.

Denford CNC Resurrection

Denford CNC Mill Update

Build Author

Zootalaws

Views

6414

Build Author

Zootalaws

Views

6414

OXENlarged

This is a 1500 x 1500 Ox build

HardKnot OX 4x4

I've been working on commercial woodworking CNC's for year's under shop owner's that didn't want me to progress any further at a certain point. This is a project I've wanting to build for about 10 years now. I can't wait for the freedom to build what I know is possible without any negative input.

ChadRat's ox

This is my first cnc router. I like the open builds concept. I bought parts when I had the money. It seems everytime i think i have all the parts, i find something I am missing. My controller won't be ready until the end of the month so I am in no hurry. I will add things that i find. Eager to make some saw dust.

KerryH's OX

My adventure in CNC routing.

Meister-CNC

This is a cnc router with 3 axis and a kress 1050 motor. Its 140x120cm and a homebuild with your help!

Build Author

dcarlisle

Views

10659

Build Author

dcarlisle

Views

10659

pain in my ox

build is in process the machine went together perfectly no issues at all but the software is another issue I have been trying to get the thing dialed in it is driving me nuts I'm still in the process will update if I ever get it figured out

Build Author

CWidt

Views

8625

Build Author

CWidt

Views

8625

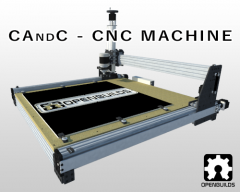

OpenBuilds CAndC - CNC Machine

A new derivative of the famous OX CNC, with increases strength, rigidity, and accuracy.

Ooznest Moded CNC

Modded OX with full nema23 4 point support

OX

My build of the OX kit from SMW3D.com

Build Author

zann68

Views

9103

Build Author

zann68

Views

9103

OX CNC 4'x4'

Out with the Old in with the New. Trying to build a nice clean setup that myself and my sons can use and enjoy.

Build Author

Gary Bonard

Views

6096

Build Author

Gary Bonard

Views

6096

OxZilla

This is my second Ox with a working area of 14" x 14" x 5" I wanted to build a small sturdy potable CNC router and this OxZilla has the nice upgrades !

Ooznest build - 1500mm x 1000mm

Its the first build for me so its just the story of me attempting to build the kit and hopefully end up with something I can use. Hopefully without destroying anything or anyone.

Ooznest OX CNC for Architecture Modell

While i achieved the desired taler Z axis this was very notable of the cost of the stiffness of the Y axis - the Y axis is now quite wobbly. i do not recommend such a big Z axis on a OX CNC machine where the requirement is a good precision.

OnyX-13

This is my OX. There are many like it, but this one is mine. My OX is my best friend. It is my life. I must master it as I must master my life.....

Plasma CNC machine

The plasma CNC that I have built has a water table that measures 1350mm x 650mm. The water is flooded onto the cut area while cutting and recycled around with a pump. This is to reduce smoke, cool the metal being cut to reduce distortion and also to keep sparks to a minimum. Most of the machine has been made from aluminium , the frame and table from steel, the water table, stainless steel.

Build Author

theracermark

Views

3936

Build Author

theracermark

Views

3936

Reviving the Origonal PhlatPrinter with BlackBox

Reworked PhlatPrinter Gen1 Adding dual nema 17s to all 3 axis Supprot for carriage to insure even dept cuts Lighting for view of cutting area