Build List

-

Active Filters:

nc

Build Author

Johnny Reich

Views

2051

Build Author

Johnny Reich

Views

2051

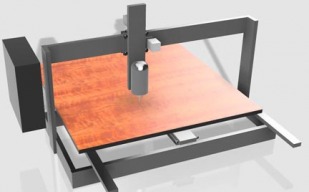

ProLight 1000 Mill Retrofit

Update a 20-year old bench top milling machine with OpenBuild Ecosystem electronics.

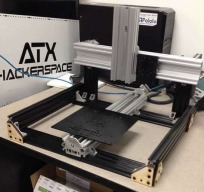

Home made CNC Plasma Cutter

Not completed yet but it does work, I will be changing small things as I finish the build and I have learned a lot from this build I am looking forward to finishing this one and Building another maybe larger table.

Build Author

Gary Caruso

Views

3068

Build Author

Gary Caruso

Views

3068

OpenPull From CNC Kitchen.. attempt

This project is a Pull tester for material testing or structural testing with stress (force) data logging, I don't have plans for strain logging but that might be down the road.

Build Author

OpenBuilds

Views

31833

Build Author

OpenBuilds

Views

31833

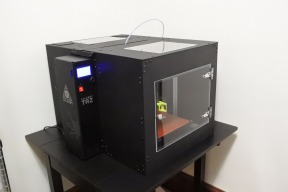

BlackBox X32

The next level of CNC motion control solutions. Packed with advanced new features and built on the reliability of the proven BlackBox system

Build Author

BCulbertson

Views

5016

Build Author

BCulbertson

Views

5016

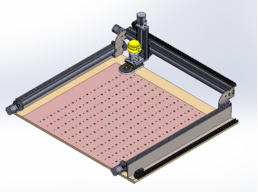

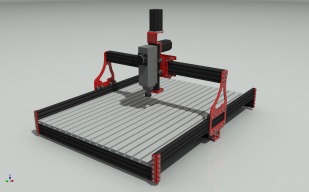

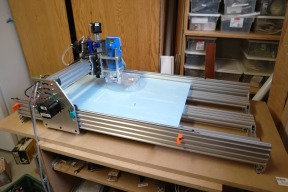

Lead 1515 with Upgrades

My upgraded OpenBuilds Lead 1515

Build Author

John J Talavera

Views

12169

Build Author

John J Talavera

Views

12169

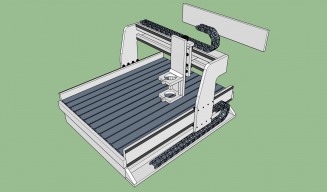

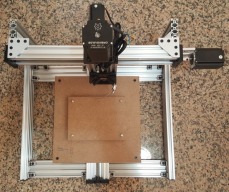

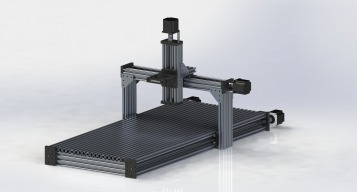

CNC FOR EVERYONE TITAN CNC ROUTER

www.cncforeveryone.com TITAN CNC ROUTER is the perfect PCB milling machine or for smaller projects. Don't be fooled by its small size it is capable of routing with the big boys...!

Build Author

Pendragon

Views

10309

Build Author

Pendragon

Views

10309

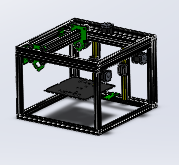

bOX

A bigger OX. As this build is nothing new I will detail my build process, I am not an experienced builder, this will maybe help someone else. The size of the bOX will be 100cmx75cm. I will use aluminium plates, a tinyG, and most probably only open source / free software.

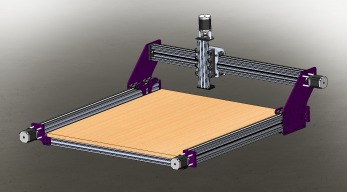

ROUX - A Routy-OX Hybrid

ROUX is a 2'x4' CNC that can be easily handbuilt without an existing mill and removes the need to buy generic plates for the Routy. A simpler, more refined machine.

Build Author

Bear

Views

11047

Build Author

Bear

Views

11047

OXBear

ANOTHER OX!~ Huge Thanks to Marc Carew and Open Builds. The primary reason I am building this CNC mill is to aid in my homemade snowboard creation. I am going to try and document as much of everything as I can and post it here to help others going a similar route. I know from past projects that taking the time to document each step can be tedious when you want to charge ahead but I will try! I hoping to get feedback on my design choices and set up as I am a complete newbie to CNC.

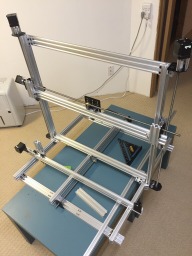

Open Rail Build

This will be a chronicle. It's my first CNC build so, I will be making many changes as I learn from my mistakes. I will pass on any tips or tricks i learn along the way. This build is an OX Hybrid. I decided to use the open rail with the V wheels and not to go with the V Slot. (I'll let you know how it works out.)

1500x1000 (4x2) Router - OX derivative

OX build with 1.5m gantry the 1m deep table.

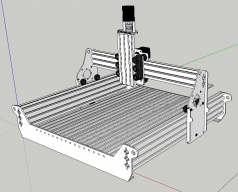

Sketchup Design of a PVC CNC I Intend to build.

Build Start to begin Feb 1st.

MaxBox

Simple cartesian style CNC. Uses ACME screws for all 3 axes, 20x40 v-slots and should have 50cm x 50cm x 50cm work volume.

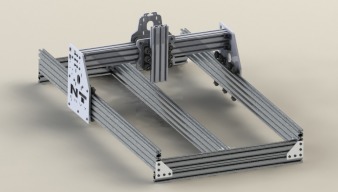

CNC NT

This is our first CNC project is based on OX CNC. We show you some pictures about our progress. We finished assembly design, software test and drivers test, now we are building the machine.

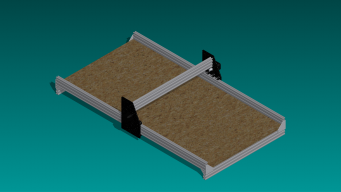

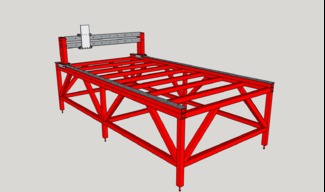

cnc plasma table

ive got most of the wire harness made up too im using Chinese electronics for now I will upgrade later when this thing makes me some cash lol im using a ibm think center to case to hold my electronics ive got a 25' parallel cable to put some distance between the table and the computer

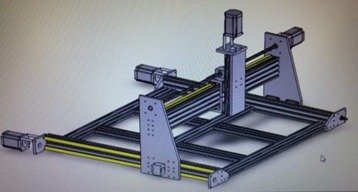

3 Axis MultiTool - 3D printer, CNC Mill and Plasma Cutter

So in short this build is a work in progress; it aims to make a large 3d printer, medium size CNC mill and a small plasma cutter all in one CNC unit.

Build Author

openhardwarecoza

Views

7129

Build Author

openhardwarecoza

Views

7129

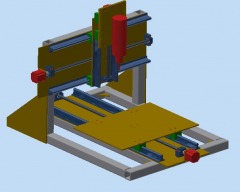

Pocket Ox (Sheetmetal)

Small CNC - made with some custom lasercut+bent sheetmetal parts + Openbuilds V Slot

Build Author

Skoobs

Views

4942

Build Author

Skoobs

Views

4942

Pretty Standard + Slave X Axis

Planning my build, just looking for design input at the moment. I definitely want a slave X axis. I am potentially going to go with one of the 1500W Chinese water cooled spindles.

Square OX

Square shaped OX for doing general purpose engraving and cutting into wood, acrylic, and aluminum.

Ooznest OX CNC Build

Ooznest OX CNC build

Build Author

David Arroyo

Views

14648

Build Author

David Arroyo

Views

14648

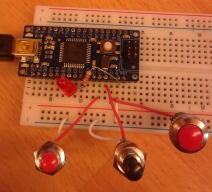

PiDuinoCNC Controller

Using a Raspberry Pi, Arduino and a Protoneer CNC Shield to create an Open Source CNC router controller. It will be equipped with a touch screen to control the on board processor. The touch screen will run a user interface that has buttons for added functionality. There will be a camera for monitoring progress from inside my office. The control box will also feature a way to power the vacuum and spindle/router . I will also be able to monitor room temp as well as Pi CPU temps and averages.

C-Beam Plate Machine

My first openbuilds submission, plain old c-beam machine. Seems like I've spent more time fighting the forum here redirecting in circles than actually building the machine. I'll try to add more pics if I ever find a path out of this corn maze...

Arctic Ox CNC Router

This is a cartesian CNC Router build that is based off the OX CNC build by Mark Carew. I am using Spark Concepts CNC xPro controller board and their 400w spindle kit.

Build Author

evil2002usna

Views

11559

Build Author

evil2002usna

Views

11559

Evil Ox

Cheap Ballscrew Ox CNC Router.

Build Author

Dave420

Views

6147

Build Author

Dave420

Views

6147

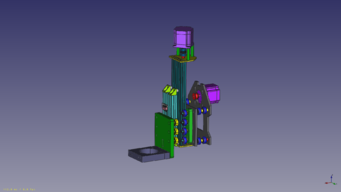

Dave's Z axis and powder coated.

I just did my first Powder coat paint job on a Z Axis with 9inchs of travel for the DIY CNC Plasma Cutter, Mill Head, Router, Engraver, Laser Head, Water Jet Cutter Machine. 2 different Z Axis ride plates and a 80mm Router/Mill Head/Spindle clamp. Baked on finish in a old oven i had.

Powder coated multi CNC Z Axis plasma adapter with Prox.

Powder coated multi CNC Z Axis plasma adapter with Proximity sensor. . It can also hold a 80mm Router head/Spindle as seen in my router build.

PCBman CNC

This is a design for a desktop CNC machine. It may be a router or laser. I am undecided as to the final design.

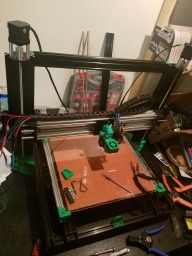

My 2nd cnc build

My new build to upgrade from my worn out shapeoko

Build Author

Jonathon Duerig

Views

7199

Build Author

Jonathon Duerig

Views

7199

Chrysalis: An Enclosure for TAZ 6 3d Printers

Aluminum-framed enclosure for TAZ 6 3d Printer made with Makerlink.

Build Author

Tomas F Uribe

Views

5337

Build Author

Tomas F Uribe

Views

5337

Atucnc

2 1/2 axis CNC chassis. Convertible to plasma, 3D printer and welder. Currently used as router. Plotting table dim: X axis 620 mm, Y 650 mm, Z 100 mm. Created for teaching purposes, open source license, currently used for engraving ukiyo-e wood plates and printmaking

MiniMill - A must have machine :)

The new MiniMill from Mark and Sonny is a great little machine.

First CNC Build

Building my First CNC for PCB milling. Some modification done to the original build from OpenBuild Bundle.

Build Author

Karan Singh Sisodia

Views

6300

Build Author

Karan Singh Sisodia

Views

6300

My Home made CNC

Home Made CNC Router from Scrape

Linear Rail derivative with ball screw

basic start to design of cnc machine

Build Author

Jason Harding

Views

4080

Build Author

Jason Harding

Views

4080

Mobile bed cnc machine, first build

Currently i am reworking the frame still with current available parts just going to buy material to make the y and the z axis from openbuilds. The x axis is now going to be mobile similar to a 3d printer style.

Build Author

Jeremiah Guinn

Views

5837

Build Author

Jeremiah Guinn

Views

5837

OX CNC SMW3d 1500x1500

A small business idea led us here, lets see where it will go.

Ancient Roland Table top Mill

The parts are now very reasonable.

Dust Shoe for Kyo's Sphinx

Dust Shoe design for a CNC router. Attaches to Chris Laidlaw's Mount design, with the DeWalt D26200 (which I think is the DWP 611 in the US).

Build Author

Terone Burgenheim

Views

2825

Build Author

Terone Burgenheim

Views

2825

My CNC

This build is my version of the CBeam machine. I opted to NOT use the Gussets, and instead went for the 40, and 60 mil angle brackets to cut the price back a little further. I started with the smoothieboard but decided it was still "too new" and very much experimental. This build took me a few (2-3) days to complete. The CBeams and Lead-Screws really make building things faster since you don't have to clamor over belts.

Build Author

Bill325

Views

2338

Build Author

Bill325

Views

2338

One more life for a cube

Modify a Gen1 Cube printer into a small cnc router to cut pcbs and light (VERY light) milling work. Also easy to swap out the rotary head and mount a laser head for engraving.

Build Author

JAC_101

Views

6071

Build Author

JAC_101

Views

6071

Small PCB, Engraving and Delrin CNC Mill

This is my first attempt at building a spindle based CNC machine. The intention is to mill PCB boards and mill delrin blocks. The device was built with an Emergency Stop that actually cuts power to the spindle and motors. This is a post build write-up and consists of finished photo compilation and CAD renderings.

Generic 6 Axis Controller

Generic 6 Axis (Stepper) Controller

Plasma CNC, 4'6" × 8'8" v0318

A plasma table able to cut 4'6" x 8'8" sheet. Low cost as possible.

Homemade CNC

This started as an attempt to learn to weld and quickly took on a life of its own.

Build Author

Limine3D

Views

4542

Build Author

Limine3D

Views

4542

Shapeoko 1 upgrades

Replaced the original Z-axis for a shapeoko with a c-beam upgrade. This upgrade required a nema 17 mount and a quiet spindle mount I printed with a 3D printer.

Desktop CNC

Approximately 910mm x 955mm x 82mm. There is 250mm available in the Z, but the gantry is only 82mm from the bed surface.

Voxel Evolution

This is a remix of Marshal Peck's Voxel OX, with some design tweaks inspired by Makerparts and jjcolletta. It has a build area of 300mm X 300mm X 480mm, but is easily configured for just about any build area up to 500mm X 500mm X 750mm. I have used some laser cut acrylic plates and a couple of 3D printed parts in its construction, however it can be assembled using nothing but OpenBuilds parts with the exception of the heated bed and the Y axis carrier for the heated bed.

Repurposed Steel Table 4 x 8 Build

Repurposed Steel Table for CNC Router Build.

Build Author

Jones

Views

3989

Build Author

Jones

Views

3989

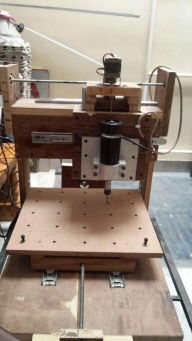

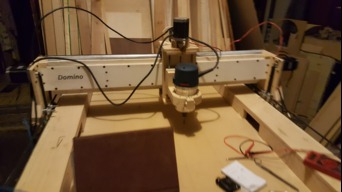

The Domino - 1.5m x 1m

DIY scratch build consisting of gas pipe, skate bearings, 12mm birch, 3/4 maple v-core ply, Nema 23's, and arduino and CNC shield with DRV8825's.

Build Author

Mark Carew

Views

6163

Build Author

Mark Carew

Views

6163

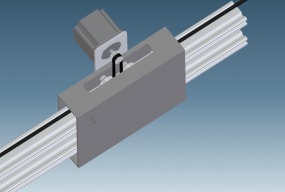

OpenCase Mounting Kit

The OpenCase Mounting Kit makes wire management quick and easy!

Build Author

Mark Carew

Views

27149

Build Author

Mark Carew

Views

27149

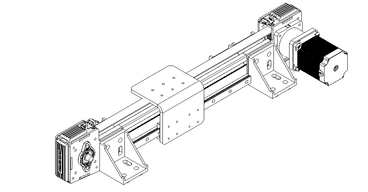

V-Slot™ Nema 23 Linear Actuator (Belt Driven)

This example build shows how easy it is to make a linear actuator using a few OpenBuilds Parts.

Build Author

RobFromLDMS

Views

5238

Build Author

RobFromLDMS

Views

5238

Lithgow Mens Shed CNC build

The tale of how we put together our CNC Router, and some of the difficulties encountered. It is now ready for final testing and commissioning.

Build Author

Vin1027

Views

7334

Build Author

Vin1027

Views

7334

C-Beam Sphinx

This is the original C-Beam Sphinx with the 16 wheel X gantry plates. I'm using the Ethernet Smoothstepper, Gecko G540 stepper driver and Mach 4 for motion control.

Build Author

Doug Rowley

Views

4338

Build Author

Doug Rowley

Views

4338

My Workbee 1010

This is a workbee 1010 build using the mechanical parts from Open Builds. The electrical and electronic parts were from a prior build of a Root 3 CNC by Sailor Pete.

OoozNest WorkBee

A Journey on the WorkBee Build...

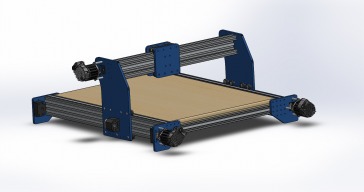

BKE Lead 1010 - First CNC Router

LEAD CNC

Build Author

DaleShaw

Views

4461

Build Author

DaleShaw

Views

4461

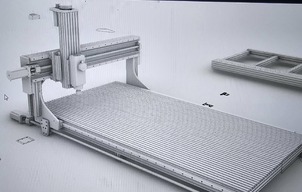

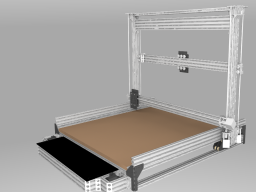

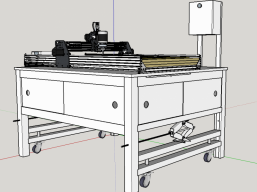

Senior Project CNC table

So for my senior project I decided to build a CNC router. I kind of need to get this done before May so we'll see what all goes down. It's going to be a 3 axis machine (for now) and will be able to handle 4x8 sheets of wood. This is my first build. It's going to be intresting..

SharkBits Holder

Get organized with the SharkBits Holder!

Ox cnc improvements chain driven

Just ox cnc experiment

Learning how to build

I made a 5x10 foot cnc out of the parts I bought on this site. It's been upgraded and tinkered with ever since. The end goal is to learn enough to learn to build a large 10x10 foot 3d printer.

Build Author

Frank Gore

Views

9846

Build Author

Frank Gore

Views

9846

Kossel Extreme

A custom Delta printer for large projects with any filament that still retains speed and accuracy, all within a 15 amp/110VAC power budget. Based on Johann's Mini Kossel design.

Build Author

ckgottabuild

Views

4299

Build Author

ckgottabuild

Views

4299

Lead CNC 1010 Platform and Rotating Laptop Mount

Moveable Lead CNC1010 build with handles on four corners. Everything fits on one sheet of cut out 4x8 plywood

OB Lead 1515 CNC Router 2021

Building the OB Lead 1515 was straight forward. The on-line OpenBuilds assembly videos were extremely clear and easy to follow. Initial build of this machine is with OpenBuilds BlackBox which simplified getting the electronics to work the first time. OpenBuilds staff are friendly and helpful.

C-beam charmer

Double C-beam Y axis 500mm., Double 2080 X axis 600mm. , C-beam Z axis 250mm, TB-6600 drivers, MKS-DLC32v2 GRBL w/wi-fi and blue tooth

Build Author

Jasont

Views

4276

Build Author

Jasont

Views

4276

MY first CNC build

my first cnc build using the lead 1010 to build bigger and better!!

Build Author

Sigifredo Cruz Rojas

Views

4063

Build Author

Sigifredo Cruz Rojas

Views

4063

ALl included interface

I have not too much space and need a portable solution, and tired of cleaning the electronics I decide to put everything inside a box and this is the result.

CNC Linear Slide for DIY project

Low cost cnc linear drive for making any xyz cnc structure

Build Author

David E. Flores E.

Views

7709

Build Author

David E. Flores E.

Views

7709

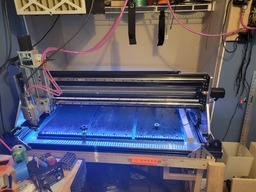

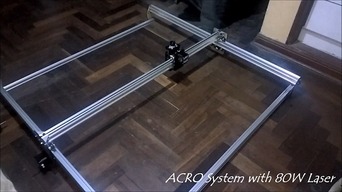

ACRO System w/Laser 80W

This is my version of the OpenBuilds ACRO System CNC, a 1010 version (1000mm x 1000mm). I need this machine to build PCB prototypes within 2-days at maximum. I will try to build PCBs using drill and laser methods...

Just Another CNC

I wanted to make my own unit. I enjoy building and was looking for a challenge.

TFE2 CNC Build

My TFE2 CNC Build. The TFE was much smaller and all of the gantry plates were 3D printed. Despite this it will happily machine aluminium without issue. So I decided to use that to make the TFE2 which will be all aluminium plates and much larger (1200x800mm machining area with roughly 140mm in Z so I can later add a rotary axis.)

Build Author

mirage335

Views

11986

Build Author

mirage335

Views

11986

FlexReplicator

Multi-tool 3D printer, laser cutter, and CNC mill.

Build Author

Bobnet

Views

13352

Build Author

Bobnet

Views

13352

Rackmount + OpenRail

OpenRail attached to a 19" rackmount 15U box.

Build Author

Christer Langley

Views

9449

Build Author

Christer Langley

Views

9449

CNC-Solutions Build

My first Build with V-slot

Build Author

John J Talavera

Views

8470

Build Author

John J Talavera

Views

8470

CNC FOR EVERYONE, THE DUCK!

www.cncforeveryone.com. the Duck is something that i think would be helpful in my shop since we already do cold casting.

CNC MILLING ROUTER

CNC MILLING ROUTER

Little Big OX

A complete CNC newbie is tackling a mighty challenge, Not only is he making a CNC router, He's going to try and upsize it.

USB Pendant

An USB Pendant for LinuxCNC / Mach3

DoubleX

This is a Dual X-axis platform.

Build Author

Richard Bugland

Views

8986

Build Author

Richard Bugland

Views

8986

Heavy Inexpensive CNC

Acquiring a CNC has been on my list for some time now. This concept is a bare bones, upgradeable machine that will not require a complete rebuild when new parts become available. With a cutting surface over 36" square, this beast should be capable of creating its own parts. Lowering the price to make upgrading and making this contraption beefier, faster, and more precise.

OXO

an 8x4 CNC Router based on the OX

CNC CARDBOARD BOX CUTTER

Just an easy build .... uncomplicated.... simple tools .... but hoping for a good result!

Build Author

Philippe Bergeron

Views

10101

Build Author

Philippe Bergeron

Views

10101

My first 3D printer: Absolute3Dr

You are about to read the evolution of my 3d Printer build.

Build Author

sw3Dp

Views

11810

Build Author

sw3Dp

Views

11810

stranger than fiction OX

OX hybrid all CAD open sourced non-commercial ip; .dwg, .dxf,.3dm, .iam, .ipt files jamming their pie

Build Author

Kyo

Views

10594

Build Author

Kyo

Views

10594

Fina

This is Fina; My Lautr3k inspired build.

Norwegian OX

This build is based of Ooznest 's OX CNC Mechanical kit (500x750) with a few mods if all goes as planned.

First Ooznest OX

The ooznest OX CNC Machine is based on the OX CNC Machine designed by Mark Carew of Openbuilds, and incorporates many upgrades from the Openbuilds community. Mark Carew based the OX on the Routy, which was in turn based on the Shapeoko

C beam cnc modified

C beam cnc modified

RoStockFAZZ

My large printer design. 400mm build plate, ~1000mm build height. Most of structure is 8020 but the sliders are V-Rail

Murphy OX-CNC Dreamin

I am in the design phase of my CNC. I would like to thank everyone who has placed resources on the site. I am using it to the up most! I will update as I continue the design and share my progress.

Idea for any axis support and Drive

Just an idea right now but will attempt a prototype in the near future. Not sure if this has been tried before or not.....

My first build: a other OX CNC

I love to build things. I decided to build a CNC machine to help me build more things! I had a lot of fun and I learn a lot of thing in the process of building this machine. p.s. my primary language is french not english. Forgive me if I made some mistake.

Build Author

Asaku

Views

9649

Build Author

Asaku

Views

9649

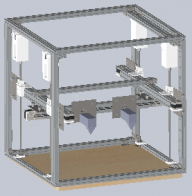

mBOX

Hi! This build is, or at least should be, a multipurpose box (mBOX). Due to limited space I want to build something that can serve multiple purposes such as 3d printing, 3d scan, plexiglass cutting and hopefully some milling too (both wood and metal). Switching between modes should involve switching heads and worksurface (change heatbed with a wood platform and viceversa). (for the scan part I'm thinking of integrating this opensource project into the frame: http://www.freelss.org/ )

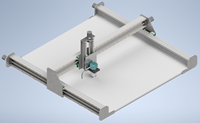

Cartesian CNC router

This project has been a steep learning curve in an unfamiliar area for me. It has been a very rewarding experience and has opened up so many more possibilities to pursue in the future.

C-Machine

MY experience as a first time introduction to the CNC world!

SUPER OX NEMA 34 1600 OZ Motors!!!

CNC OX 1500X3000

Old Faithful...FDM/CNC machine

I've owned some pretty unreliable printers, and I'll leave it at that... This design comes from the need to have a 3D printer that is reliable, period. I didn't have the money for a several thousand dollar 3d printer with an equivalent build area so that was out of the question. Plus as a fledgling Engineer, I really wanted to blood myself on a project. And that's how Old Faithful came to be. A simple, reliable, rigid, durable machine. Made by me :) Also, it'll be tough enough for light CNC.

C-Beam Machine Build

This is my first CNC router build. I want to gain basic CNC building experience so I can go on to build other items such as a frosting or pancake printer.

Build Author

Robert Huxford

Views

3978

Build Author

Robert Huxford

Views

3978

High Intensity Dive Light

Long duration , high intensity SCUBA dive light using Li-Po 18650 batteries and advanced circuitry.

Build Author

Matt Barile

Views

7496

Build Author

Matt Barile

Views

7496

Fixed Gantry Welded Steel Router

Fully welded, fixed gantry CNC router, with chinese linear motion parts, in progress