Build List

-

Active Filters:

cnc

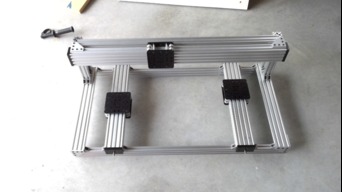

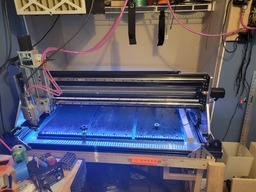

Expanded Routy using 290 build instructions

Using the Routy290 build and an awful lot of help from puntoMX, this machine has been expanded in the X and Y axis. My first build, I'm learning a lot about all of this. I've had to disassemble parts of this thing many times due to forgetfulness, but that's ok. Also, I've forgotten to take constant pictures throughout the build.

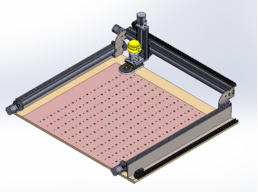

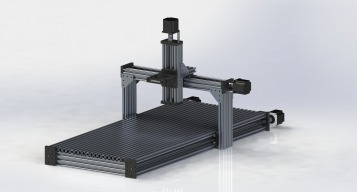

BD's C-Beam Machine CNC Router (WIP)

CNC router table based on OpenBuilds C-Beam Machine bundle.

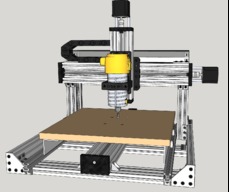

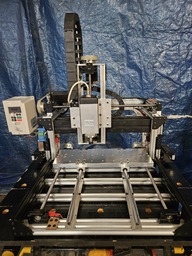

Small Desktop CNC Router/Mill

I designed and made this from scratch. The frame is welded steel filled with sand, and most of the other parts are aluminium. It's controlled with a DIY ESP32 controller running GRBL_ESP32

Build Author

Charles Roseberry

Views

5089

Build Author

Charles Roseberry

Views

5089

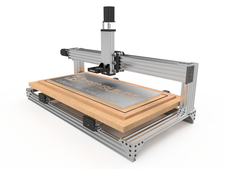

C-Beam 1000mmx1000mm

C-Beam basic package doubled in size.

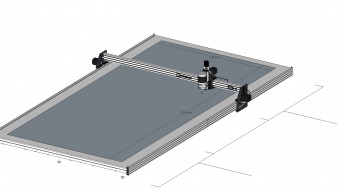

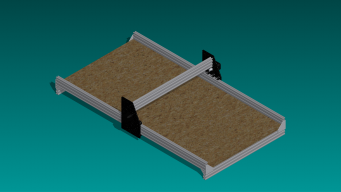

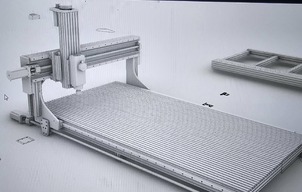

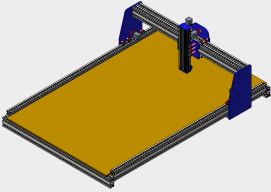

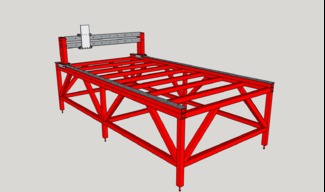

1200 x 2700 CNC based on OX

Preliminary design for cnc based on OX for cutting wood sheet products (ply, MDF etc.) for a sheet size of 1200mm x 2700mm

ROUX - A Routy-OX Hybrid

ROUX is a 2'x4' CNC that can be easily handbuilt without an existing mill and removes the need to buy generic plates for the Routy. A simpler, more refined machine.

EOX

Open builds style wood CNC router. Usable work aria 1000mm x 1250mm x 150MM (X x Y x Z). 80x40 C bleam for the Y axis , two 60x20 beams for X axis and a 60x20 fo Z. Interlocking GT3 belts for X and Y. Looking to change over to a rack and pinion system in the future. 8x8Tr Lead screw for the Z. Leadshine HBS507 close loop drivers and 3-phase servo motor 573HBM20-EC-1000 motors driving the Y and X axis. Would recommend them to anyone looking for servo like performance at a affordable price.

LimpyCNC

Inpired by the OpenBuilds OX and PrintrBot Crawlbot. This is the LimpyCNC. It's still a work-in-progress. But it provides a 120x120cm work space without using up 150x150cm of garage space.

CNC design (parts named)

This design is previously posted in this area. I downloaded the file in order to customize as I needed. I found that the parts were not identified. I went through the design in an attempt to name the parts and identify them by location.

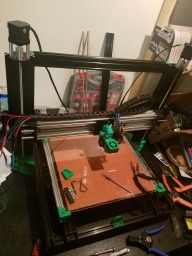

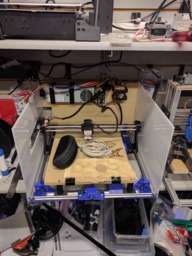

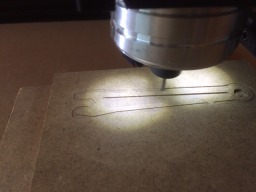

First CNC Build

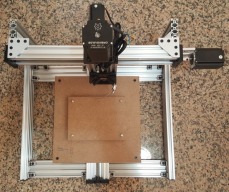

Building my First CNC for PCB milling. Some modification done to the original build from OpenBuild Bundle.

Build Author

EvanH

Views

4980

Build Author

EvanH

Views

4980

"Hawk" Heavy-duty dual-Z pseudo C-Beam

A compact, strong machine with very high Z clearance, yet can still mill aluminium easily.

Build Author

Skoobs

Views

4977

Build Author

Skoobs

Views

4977

Pretty Standard + Slave X Axis

Planning my build, just looking for design input at the moment. I definitely want a slave X axis. I am potentially going to go with one of the 1500W Chinese water cooled spindles.

Hybrid shapeoko Xcarve cnc router

My scratch build using shapeoko, xcarve, and custom parts.

Leveling Gantry

Large leveling platform to hold a 3hp router

Build Author

Craig Hollabaugh

Views

4944

Build Author

Craig Hollabaugh

Views

4944

Hyatt and My Journey to Tonehenge

I'm conducing guitar loudspeaker cabinet fabrication technique research (material type/thickness, mechanical joints, adhesives, etc) and how these relate to cabinet/speaker coupling and enclosure resonance with respect to psycho-acoustics. Basically, does one speaker cab sound better than another and why?

Build Author

RSch

Views

4933

Build Author

RSch

Views

4933

Scroll-saw Spiral Cutter

Attached to a scroll saw you can cut nested wooden spirals with this jig. Make two, three, four ... interlocking spirals that unwind/unscrew. Fascinating toys or art objects!

Build Author

Bikes and Beer

Views

4913

Build Author

Bikes and Beer

Views

4913

The Forever Project

Workbee 1010 Lead Screw with water cooled spindle and enclosure

Sphinx 7575

Sphinx CNC modified to 750mm x 750mm c-beams. Parts not readily available in South Africa, so i have to make some modifications...

Starting my build 2.8mx1.4m

Starting my cnc router, laser and plasma using aluminium 80x80

The FOX

This will be an OX based machine which I've designed to make the best use of my materials, be as precise as the design allows and operate as quietly as possible. I live in an apartment complex so space and noise are two important factors for me. Therefore the machine needs to do as much as possible while using little space and not annoy the neighbours.

Voxel Evolution

This is a remix of Marshal Peck's Voxel OX, with some design tweaks inspired by Makerparts and jjcolletta. It has a build area of 300mm X 300mm X 480mm, but is easily configured for just about any build area up to 500mm X 500mm X 750mm. I have used some laser cut acrylic plates and a couple of 3D printed parts in its construction, however it can be assembled using nothing but OpenBuilds parts with the exception of the heated bed and the Y axis carrier for the heated bed.

My 2nd cnc build

My new build to upgrade from my worn out shapeoko

Sandy3D wall mounted 1000 mm x 1000 mm C Beam Mill

I am attempting to mount The C-Beam Machine XLarge on the wall and have it look like a piece of art and be totally functional as this will be in our livingroom.

Build Author

cory stafford

Views

4803

Build Author

cory stafford

Views

4803

Home built laser cutter

This is a laser cutter built with intent to use arduino as controller for a co2 cutting laser.

Sphinx 1050

Openbuilds 1050 Sphinx. Thank you to Mark Carew for trading me a set of plates for a spindle and PSU I was not using. Mark is a champ!

32 Button Hand Pendant for the PlanetCNC Control Board

This project is for building a remote hand pendant for the Planet-CNC control board but could be adapted for many other projects. The pendant allows for machine control without being at the computer keyboard and the button functions on the pendant are defined by the user.

Heavy Metal

CNC Mill built for cutting metal.

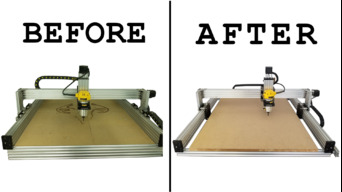

CNC Router Overhaul

This will be a complete overhaul of this router with some cool modifications.

WorkBee 1510 - First CNC Build

This build will go through the construction of a WorkBee 1510 kit from the OpenBuilds Part Store, all mechanical and electrical components were purchased from the store in late October 2018.

Build Author

Leon Style

Views

4698

Build Author

Leon Style

Views

4698

AluVault MINIMAX

Easy build cnc router with t slot profile and nylon machined part

MY NEW CNC

This build is not based on the ox, but got my ideas and inspiration from my first build,

Build Author

Limine3D

Views

4632

Build Author

Limine3D

Views

4632

Shapeoko 1 upgrades

Replaced the original Z-axis for a shapeoko with a c-beam upgrade. This upgrade required a nema 17 mount and a quiet spindle mount I printed with a 3D printer.

My CnC Router, custom DIY not open builds parts

Most of the way through the build, hopefully soon I will have it running

1075 Sphinx

My first attempt at building a CNC. I chose the Sphinx due to ease of build and extensive documentation provided by Kyo.

Build Author

Denis Lapratte

Views

4615

Build Author

Denis Lapratte

Views

4615

All metal Ox hybrid CNC Router Table

This is my second CNC build, but the first one that I design from the ground up. The base is all metal because I want to add Plasma facility later on. I used the Ox model for the gantry plates and made a few changes to adapt to my design. Since I wanted to use parts from my first CNC to save as much as possible, I kept the 5/8 Hi-Lead Screw I had from Roton for the Y and Z axis. I will also add a downdraft table to keep all parts tight on the table for cutting.

Build Author

jz321

Views

4605

Build Author

jz321

Views

4605

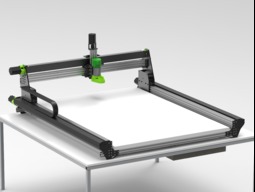

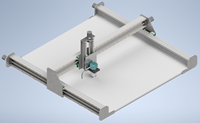

OTiS 500mm

OTiS (Off The Shelf) is 500mm cartesian CNC that can be built with all off the shelf parts from OpenBuildsStore. It features C-Beam actuators and a V-Slot frame.

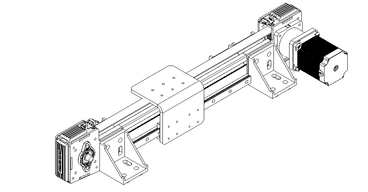

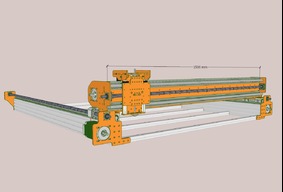

CNC Linear Slide for DIY project

Low cost cnc linear drive for making any xyz cnc structure

Build Author

Dave Pyatt

Views

4553

Build Author

Dave Pyatt

Views

4553

DaveP's Homemade CNC Project

Somewhere along the line sometime around February 2017 I got the bug in my head that I needed to build a CNC router. This is where I am today...

Build Author

cnc-trucker

Views

4535

Build Author

cnc-trucker

Views

4535

Arduino Mega to EMC2 (LinuxCNC) Plasma Table Conversion

This is a story about a guy who started with a $25 set of plans, and through 4 iterations/ rebuilds, ended up with a professional quality CNC plasma table capable of cutting anything steel up to 2 inches thick.

Build Author

ShockingTops

Views

4528

Build Author

ShockingTops

Views

4528

Opening into doors

Construction of a CNC table for a specific project that could cut an area larger than a door (>8'x4'). Much thought went into how to avoid the weight of the gantry bending the (long) Y axis, whilst still keeping down the complexity and cost.

Build Author

DaleShaw

Views

4515

Build Author

DaleShaw

Views

4515

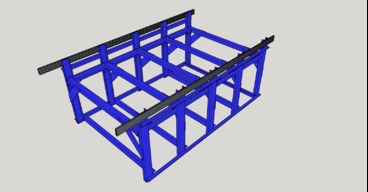

Senior Project CNC table

So for my senior project I decided to build a CNC router. I kind of need to get this done before May so we'll see what all goes down. It's going to be a 3 axis machine (for now) and will be able to handle 4x8 sheets of wood. This is my first build. It's going to be intresting..

Build Author

Darren Dickson

Views

4504

Build Author

Darren Dickson

Views

4504

3D printed CNC Machine

So I thought I would make the Leon van den Beukel version three 3D printed CNC Machine, it is the third incarnation so you would expect a relatively bug-free CNC Machine with a strong foundation.

Build Author

KronBjorn

Views

4494

Build Author

KronBjorn

Views

4494

WorkBee Lead 1010, Reduced Footprint, Nema17

This is a WorkBee 1000x1000mm with lead screws and Nema17's. It has a reduced footprint, with the geared Nema's inside the frame.

Build Author

islahcnc

Views

4477

Build Author

islahcnc

Views

4477

islahcnc&design

I will post soon some more details.

Build Author

ckgottabuild

Views

4386

Build Author

ckgottabuild

Views

4386

Lead CNC 1010 Platform and Rotating Laptop Mount

Moveable Lead CNC1010 build with handles on four corners. Everything fits on one sheet of cut out 4x8 plywood

big_recnc v2.0

cnc made with a 6mm metal body .

Build Author

Jasont

Views

4375

Build Author

Jasont

Views

4375

MY first CNC build

my first cnc build using the lead 1010 to build bigger and better!!

Build Author

Doug Rowley

Views

4367

Build Author

Doug Rowley

Views

4367

My Workbee 1010

This is a workbee 1010 build using the mechanical parts from Open Builds. The electrical and electronic parts were from a prior build of a Root 3 CNC by Sailor Pete.

Brice's CNC Router Build

I'm building a CNC router for a long time. Here's the result on this long journee. I tried to do my best with the basic tools I have. Don't hesitate to ask if you have questions.

Build Author

Tristen Poliseno

Views

4351

Build Author

Tristen Poliseno

Views

4351

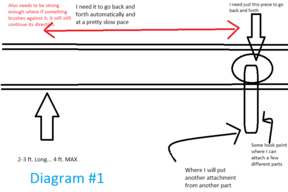

Back and forth rail mechanism

I have the whole description and all the details in the "Body" section!

Build Author

Suhmanda

Views

4345

Build Author

Suhmanda

Views

4345

DIY CNC SPINDLE

CNC SPINDLE FOR DIY ROUTERS AND MILLING MACHINES ITSRS-985 MOTOR HAS MUCH BEFINITS THAN ANY OTHER DC MOTOR IN MARKET

Old Faithful...FDM/CNC machine

I've owned some pretty unreliable printers, and I'll leave it at that... This design comes from the need to have a 3D printer that is reliable, period. I didn't have the money for a several thousand dollar 3d printer with an equivalent build area so that was out of the question. Plus as a fledgling Engineer, I really wanted to blood myself on a project. And that's how Old Faithful came to be. A simple, reliable, rigid, durable machine. Made by me :) Also, it'll be tough enough for light CNC.

OXO

an 8x4 CNC Router based on the OX

EOX v2

Upgrading my CNC router to run on ball screws. Me and the belts where not getting along.

Generic 6 Axis Controller

Generic 6 Axis (Stepper) Controller

Fastmill CNC

Very cheap CNC made from laser fired and bent parts.

Build Author

Steve Hall

Views

4209

Build Author

Steve Hall

Views

4209

Cartesian Style Build UK

Another Cartesian style build with parts from the UK, US & China.

Vertical Mill

This will be a CNC milling machine. My goal is to make this mill for the minimum cost I can while not sacrificing quality. In hope of staring an educational YouTube channel on CNC milling and 3D Printing. Along with when to use both.

Build Author

Edgar Robles

Views

4121

Build Author

Edgar Robles

Views

4121

Sheethexapod

Sheethexapod works with basic mechanims as direct metal-metal links and joints, all movements can be done by a rc servomotor in this case towerpro model.

Build Author

Jason Harding

Views

4119

Build Author

Jason Harding

Views

4119

Mobile bed cnc machine, first build

Currently i am reworking the frame still with current available parts just going to buy material to make the y and the z axis from openbuilds. The x axis is now going to be mobile similar to a 3d printer style.

MiniMill - A must have machine :)

The new MiniMill from Mark and Sonny is a great little machine.

Build Author

Sigifredo Cruz Rojas

Views

4106

Build Author

Sigifredo Cruz Rojas

Views

4106

ALl included interface

I have not too much space and need a portable solution, and tired of cleaning the electronics I decide to put everything inside a box and this is the result.

no xp cnc

This is my first cnc build, never used one before and don't know too much besides what i've read a little bit about them online. It's probably going to be about 31" y axis with hopefully around 4ft x axis, z height is still to be determined.

Build Author

Srđan Marković

Views

4062

Build Author

Srđan Marković

Views

4062

Second machine

Machine with 12,5Nm closed loop steppers or servo steppers

Build Author

theracermark

Views

4056

Build Author

theracermark

Views

4056

Reviving the Origonal PhlatPrinter with BlackBox

Reworked PhlatPrinter Gen1 Adding dual nema 17s to all 3 axis Supprot for carriage to insure even dept cuts Lighting for view of cutting area

Build Author

Jones

Views

4038

Build Author

Jones

Views

4038

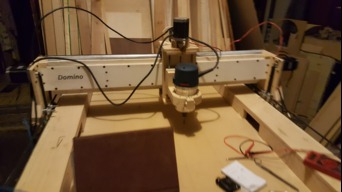

The Domino - 1.5m x 1m

DIY scratch build consisting of gas pipe, skate bearings, 12mm birch, 3/4 maple v-core ply, Nema 23's, and arduino and CNC shield with DRV8825's.

CNC China Router Conversion to Open Builds System

China Router frame with linear bolts, Nema23 and the icing on the cake “open build parts“

Kruk 0.1

This is a stool, designed in 18mm wood for a cnc router, it's easily scaleable to different wood-thicknesses, in 18mm wood it takes up 1200*1200mm. It can be assembled without screws, nails or glue and can therefore also be easily disassembled.

BKE Lead 1010 - First CNC Router

LEAD CNC

My Ooznest Workbee V2.0 build

I'm new to this whole process, so this is a build by a newbie for newbies.

Build Author

Rich Bowen

Views

3867

Build Author

Rich Bowen

Views

3867

WannaBe CNC - First time design and build

Design Change - Version 2.0 has a smaller foot print, custom gantry supports, and front and back covers. I will use standard V-Slot for gantry supports leaving me enough travel to manufacture the customer supports with this machine when completed. then update to final build. I also plan to install the controller into the front cover and power supply into the back cover. Should be nice and tidy.

Mostly Printed Cartesian CNC

This is a build that is just getting started. Not all of the parts are ordered or printed as of 5/27/2018. Hopefully in the next few weeks all parts will be printed and most parts ordered.

Norwegian OX

This build is based of Ooznest 's OX CNC Mechanical kit (500x750) with a few mods if all goes as planned.

Desktop CNC

Approximately 910mm x 955mm x 82mm. There is 250mm available in the Z, but the gantry is only 82mm from the bed surface.

Build Author

Builder+Bob

Views

3779

Build Author

Builder+Bob

Views

3779

Portable C-Beam

C-Beam Plate maker for My OX!

Build Author

Ken376

Views

3778

Build Author

Ken376

Views

3778

Welded project cnc first try

Kind of hard to see in this pic now lining up drive s and finishing framework

Denford CNC Resurrection

Denford CNC Mill Update

Retractable WorkBee1510 with Marlin+MarlinPanel high level build

WorkBee1510 with retractable space saving stand and customize build Marlin firmware and MarlinPanel (GCode Sender/UI)

Build Author

Braden Masse

Views

3687

Build Author

Braden Masse

Views

3687

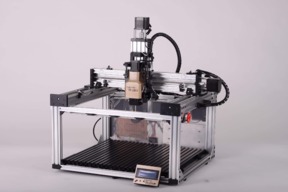

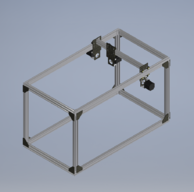

Microwave Filter Tuner

The Microwave Filter Tuner (MFT) combined with the University of Regina’s tuning algorithm automatically tunes microwave filters by using a custom CNC machine with a computer vision system for identifying, mapping, and tuning each filter element, providing improved consistency, flexibility, and accuracy compared to traditional methods. The MFT is low cost and is capable of tuning multiple filter configurations with minimal preparation.

A work in progress

One of my first projects might be cutting proper plates.

Build Author

bpatterson42

Views

3599

Build Author

bpatterson42

Views

3599

Inverted Y C-Beam Machine

Similar to C-Beam Machine build, but with inverted Y-axis assembly to shield drive screw. Integrated XZ gantry can be fixed to any solid surface. Build dimensions are 36" x 36" x 6".

Large C-Beam Sphinx style CNC Build

Started my build of a large Sphinx style cnc Router. I wanted one to handle the Dollar Tree Foam Board (DTFB) so I am making this to handle 2' X 3'. This is my first endeavor for a CNC so I am learning as I go but there is one thing for sure.

Cartesian CNC router

This project has been a steep learning curve in an unfamiliar area for me. It has been a very rewarding experience and has opened up so many more possibilities to pursue in the future.

CNC machine 700x1200mm

I love to build things. I want a large cnc machine can do with little money. use Aduino .

my version of xl

A table top version of the open build xl router kit set build. This use of c - beam and xl kit set was coupled with Mach 3 controller running on Dell opti -plex 755 and win 7 pro licence. A Dell opti-plex 755 empty case was used to house the controls and wiring , including the limit switch and emergency stop safety circuits

LaserShark300

300x300 belt drive laser etching/cutting platform. The design was borrowed from another's blog and customized to fit materials on-hand. Was a very fun project to assemble.

Bedroom Builds (BrB) DIY CNC

So I am employed in the automotive industry and I walk by thousands of dollars of CNC products daily that are no use to me due to being a Technologist and not a machinist. So therefore with some research I found openbuilds and their great selection of products to build my own CNC. This CNC will consist of 4 axis one removable 360 degree axis for turning alongside a x axis table Y axis stationary gantry and a Z axis attracted to the Y axis linear actuator.

Dust Shoe for Kyo's Sphinx

Dust Shoe design for a CNC router. Attaches to Chris Laidlaw's Mount design, with the DeWalt D26200 (which I think is the DWP 611 in the US).

Just Starting

My attempt at planning out my own CNC router

TFE2 CNC Build

My TFE2 CNC Build. The TFE was much smaller and all of the gantry plates were 3D printed. Despite this it will happily machine aluminium without issue. So I decided to use that to make the TFE2 which will be all aluminium plates and much larger (1200x800mm machining area with roughly 140mm in Z so I can later add a rotary axis.)

Build Author

Neil Scott

Views

3310

Build Author

Neil Scott

Views

3310

Barcelona Build

This will be my second CNC build but this time a proper CNC not a small desktop model that I played with for a while to learn Gcode, It was great but now its time to start playing with the big boys and girls.

Just Another CNC

I wanted to make my own unit. I enjoy building and was looking for a challenge.

HandCrafted WorkBee - HCWB

This will be a slow build as I collect parts and materials as funds permit for 1000mm x 1000mm Workbee. I call it the "Hand Crafted WorkBee" because I will be hand making the plates and as much of the build as possible using a drill press and hand tools.

Cnc Router 3000 x 1000 mm

In progress

Homemade CNC Router (Under $400)

So Instead of buying a CNC Router which can cost thousands of dollars I ventured on the quest to design and build my own. I have multiple parts to this series. Hopefully all of my information I share helps!

Build Author

Linkreincarnate

Views

3163

Build Author

Linkreincarnate

Views

3163

Amazon Special

I have parts that are apparently not suited to a cnc router or a 3d printer. I am still trying to figure out what to make out of what I have,

Build Author

Sir Bagels

Views

3148

Build Author

Sir Bagels

Views

3148

CNC Auto-pipette

Senior Design Project Bennett Robertson, Megan England University of Iowa College of Engineering

Build Author

Gary Caruso

Views

3128

Build Author

Gary Caruso

Views

3128

OpenPull From CNC Kitchen.. attempt

This project is a Pull tester for material testing or structural testing with stress (force) data logging, I don't have plans for strain logging but that might be down the road.

Workbee with less irritations

My workbee build with some add ons