Build List

-

Active Filters:

20

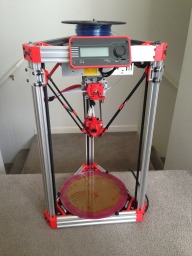

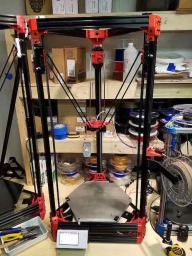

Delta-Six

Super rigid Delta printer, using 20X40 V-Slot

Build Author

HPB

Views

48301

Build Author

HPB

Views

48301

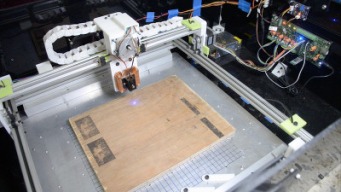

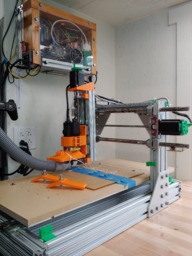

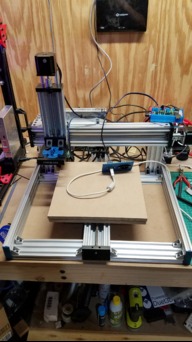

A simple XY laser engraver/cutter

A simple low-cost XY plane laser engraver/cutter inspired by the Much 4 laser build, with minimal parts and assembly time. Uses standard off the shelf components in almost 90% of the build with the exception of the axes motor and wheel mounts which need to be 3D printed.

Build Author

roadss

Views

26252

Build Author

roadss

Views

26252

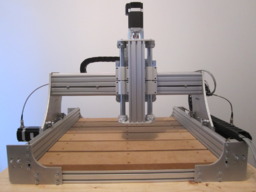

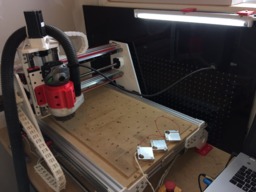

Rawcnc 1.5 Desktop Edition

This will showcase the build of my Rawcnc 1.5. A rigid cnc router from the Swedish company Rawcnc, featuring a rather cool linear motion system, rack & pinion and steel reinforced X-axis capable of milling aluminum.

Build Author

SecretSpy711

Views

22877

Build Author

SecretSpy711

Views

22877

RigidOko

Heavily upgrading my 1200x500 Shapeoko 2... ...er, wait, scratch that... Building an all new machine, roughly the same size, that should be more rigid than a Shapeoko 3!

Build Author

BeTrue3D

Views

22673

Build Author

BeTrue3D

Views

22673

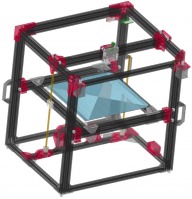

BeTrue3D Printer

High Quality CoreXY with focus on quality and optimized printarea versus physical size of the printer.

Build Author

ymilord

Views

22394

Build Author

ymilord

Views

22394

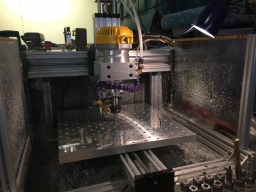

C-Beam Rigid - 'The Hog'

C-Beam Machine baseline build. DW618 Spindle. SuperPID. Gcode Controlled Mist Coolant. Rigid Work Surface. NEMA 23 (425oz-in) Leadshine 4 Axis Stepper Driver. LinuxCNC (MachineKit) Tool Touch Off Probe.

Build Author

inhan

Views

21623

Build Author

inhan

Views

21623

Openbuilds rovo laser mini(오픈빌드)

laser mini 20 * 40 OPENBUILDS base frame.(크기 412x455mm) laser mini 20*40 기본프레임입니다. 기존 여러부품을 사용한 제품보다 부품수를 줄이면서 최소한의 단가를 뽑을려고 디자인했습니다.. 기존대비 부품수 절반에 단가도 절반을 줄이면서 최적의성능을 내려합니다.

Build Author

MattR

Views

21119

Build Author

MattR

Views

21119

Fixed Gantry CNC Router with Old Industrial Supplies

I got lucky enough to purchase aluminum extrusions and linear motion components (and nuts/bolts/etc) at scrap metal prices when a bunch of industrial automation equipment was decommissioned. The only problem is that the aluminum extrusions are not metric sizes... they are the 1.5"x3" 80/20 series. It has presented a few challenges but nothing too bad.

Build Author

Rob Taylor

Views

19300

Build Author

Rob Taylor

Views

19300

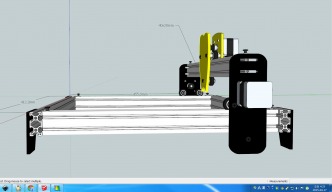

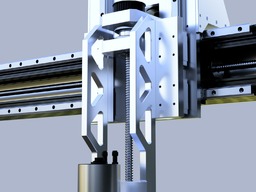

M4: 1510SS Heavy Mk.I

A 1500x1200mm, 20mm rail and 1610 ballscrew, heavy-duty, four-axis gantry machine. As high speed as spindle power MRR will allow for. Approx 4 x 3 x 1ft travels, intermediate size between benchtop and floor-scale units. Aiming at $10-15k machine in the $3k region.

Build Author

Sonny Lowe

Views

17435

Build Author

Sonny Lowe

Views

17435

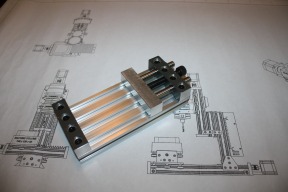

MakerSL MSL-8 OB Vise

Small Machining Vise designed around 20x80 Openbuilds Rail System

Build Author

David Bunch

Views

15086

Build Author

David Bunch

Views

15086

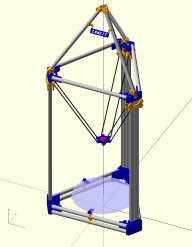

Emmett-Delta

Delta 3d Printer using 3/4" Electrical Metal Tubing (EMT) for Horizontals & 2060 V-Slot for the Verticals and adding a tetrahedron at the top.

Build Author

GinoTheCop

Views

14739

Build Author

GinoTheCop

Views

14739

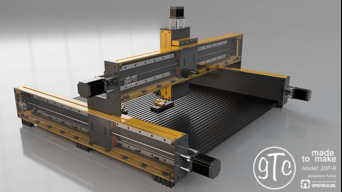

GTC2020

A 1000 by 1000 CNC Router with linear rails and a control box.

Build Author

JWhitten

Views

14299

Build Author

JWhitten

Views

14299

Build #2 - Bigger & Stronger

Large format CNC router with a 1500mm x 3000mm cutting envelope (5 x 10 ft) strong enough to cut wood and aluminum constructed from 20-series and 40-series aluminum extrusions. Complete Project Log w/ Pictures: https://goo.gl/photos/Co81AvGwVijE2zow9

Build Author

Kyo

Views

12682

Build Author

Kyo

Views

12682

V-Slot Cutting System

A System of 3d printed parts to use along with your projects aluminum extrusion to cut your pieces of v-slot to length manually.

Build Author

obmilllivebuild

Views

12523

Build Author

obmilllivebuild

Views

12523

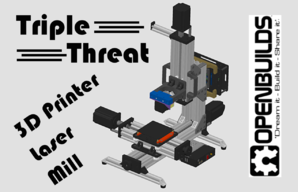

Live OpenBuilds MiniMill -> MiniPrint/Laser Conversion Demo @ MRRF2019

Transformation of an OpenBuilds Mini Mill into a convertible 3D printer / CNC mill with interchangeable tooling. Maybe a bonus conversion TBD.

Build Author

Martin Bogomolni

Views

12450

Build Author

Martin Bogomolni

Views

12450

Delta-Six ( Jerry426 variant )

Building a Delta-6 variant, using recycled parts from a WolfStock Delta printer.

Build Author

Sonny Lowe

Views

10963

Build Author

Sonny Lowe

Views

10963

Folger-Tech Y-Carriage

This a redesign of the Folger-Tech Y-Carriage using the Solid V-Wheels, Ball Bearings, the V-Slot Rail System.

Build Author

Darren Ditto

Views

10845

Build Author

Darren Ditto

Views

10845

V 1.4 - Bright Box Cartesian Printer - *BUILD PROGRESS PICTURES

Cartesian Printer, 200mm x 200mm x 380mm build area, enclosed, belt and pinion movement, heated bed, Raspberry Pi, Pi Cam, OctoPrint

Build Author

mathom713

Views

9759

Build Author

mathom713

Views

9759

27" by 40" CNC

DIY design and build of a roughing 2' by 3.5' CNC router

Build Author

recoush

Views

9521

Build Author

recoush

Views

9521

CoreXY 3D build one

an 8020 build with 1010 extrusion (1") Square tubing Rough size is 24x24x36 (600x600x900) The expected usable print area 21.5x21.5X32"roughly (510x510x760) An XY 3D printer with 3 extruders and 3 Z-axis 0.9 degree motors the table (Z-AXIS) will lift up to the XY Carriage on 3 12mm linear rod and 3 8mm Lead screw's Corexy designs complete and Z-axis build is started don’t have a 3D cad system yet so building my prototypes on a pcb layout tool

Build Author

HuguesP

Views

9386

Build Author

HuguesP

Views

9386

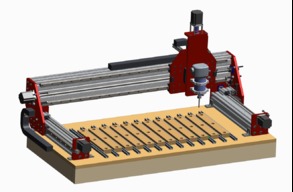

YACLR CNC

Yet Another Chinese Linear Rail CNC, my first one, doing this mainly for the fun of building it more than using it.

Live D-bot build at MRRF 2017 (Mar 25-26)

I will be attending the 2017 Midwest RepRap Festival (MRRF) with a small team of printer enthusiasts with a goal to fully assemble a Core-XY D-bot onsite during the event. This is our first attempt at building a D-bot and we will be learning things as we go. Our hope is to have the entire machine assembled, wired, and functional (at least to the setup and testing phase) before the end of the show. Please attend and watch us in person or visit our feed channel during/after the event.

Build Author

Marco964

Views

9138

Build Author

Marco964

Views

9138

Lead CNC 1510 modified

This is an Openbuilds LEAD 1510, modified to supports a liquid cooled 1.5Kw spindle. The movements are made with lead screw on all three axes.

OXilla - a 3ft x 3ft CNC Router/Mill - Goals are strength, power and speed

This will be an ongoing log as I build this machine. Name change by popular demand - at least a couple of us. :)

Build Author

Limine3D

Views

8711

Build Author

Limine3D

Views

8711

M3D Squared

A cartesian build with a build dimension of 200x200x750mm. I will be using a dual extruder, heated build plate, and a screw drive for the z axis.

Build Author

Corey Corbin

Views

7989

Build Author

Corey Corbin

Views

7989

Ball Screw Carrier.

Create a ball screw carrier with out BF BK bearing blocks.

Butterfly 3DP V 1.0

tronxy x3 like

Build Author

evgeny156

Views

7429

Build Author

evgeny156

Views

7429

3D Printer on Prusa architecture with best parts available

Wanna quet an nice looking device done by my hands

Build Author

joetemus

Views

7047

Build Author

joetemus

Views

7047

Shapeoko 2 Z-Axis Upgrade

This is a major redesign to the Z-axis of an otherwise stock Shapeoko 2.

V-Slot 2020 EggBot

To build a simple EggBot

Bored in the garage enclosure build

2 days to build Up and running some EMI issues but I think I have them resolved Big shoutout to the community

Build Author

obmilllivebuild

Views

5740

Build Author

obmilllivebuild

Views

5740

Live C-Beam Build @ MRRF2018

Contained within are links to our OpenBuilds sponsored C-beam Machine live build taking place at MRRF 2018 (Midwest Reprap Festival) on March 24 and 25, 2018. There will also be some build images and a few 3D printed STL items that were added.

Build Author

JerryD

Views

5421

Build Author

JerryD

Views

5421

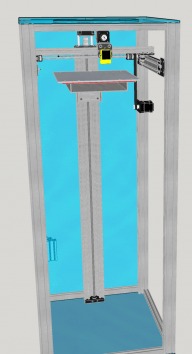

1500x1000mm Adjustable Height

I have the demand to cut/etch tall pieces of material. For this reason, I have designed a machine with 500mm uprights with adjustable gantry height. This way I can raise/lower the sled and z-axis as needed. I've also chosen to use a linear C-channel assembly for the Z axis with the plate mounted to the gantry instead of the other way around. This will allow for maximum range of the z-axis. The parts list/BOM does not include motors/belts/pulleys or electronics.

McRouter 3 Axis CNC

I wanted to put together a medium size router using PTFE slides from McMaster-Carr. I've had great experience with these slides in long term continuous motion operations in industrial environments.

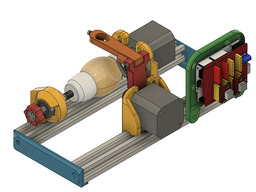

delta 3d printer kit

HE3D K200 kit build

Build Author

THE LINK

Views

5167

Build Author

THE LINK

Views

5167

2020 First build.

Probably cheapest DIY build youl see.

Build Author

David E. Flores E.

Views

3773

Build Author

David E. Flores E.

Views

3773

F-Ender-Plus 3D Printer

F-Ender-Plus its based on the Ender 3 Pro, but improved: CR-10 hotend, double gear extruder, double z-axis motor, bltouch incorporated, hotbed leveling improved strings kit. Most made using local vendor parts, and still I'm increasing my knowledge of how get better 3D printings by calibrating motors steps, leveling the hotbed and z-axis; using a 3mm thick glass...

Build Author

Axnfell

Views

3210

Build Author

Axnfell

Views

3210

WorkBee 1000x2000 ACME Screw Version

Hoping to build a WorkBee 1000 x 1000 (2000) from parts and not a kit, cannot afford the kit in full so going the long way round...