Build List

-

Active Filters:

plasma

Build Author

Retsaj

Views

74227

Build Author

Retsaj

Views

74227

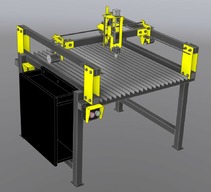

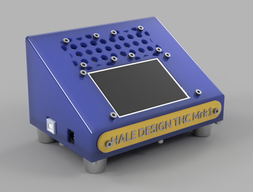

Standalone Torch Height Controller for CNC Plasma Cutting

A Torch Height Controller helps improve plasma cut quality and can save a CNC Machine from crashing. This design doesn't require you to know electronics or need any custom circuits... Its plug and play! This is a COMPLETELY standalone controller with a built-in Driver powerful enough to run just about any stepper motor. (maybe a little to powerful for a NEMA17)

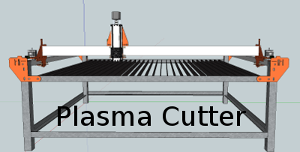

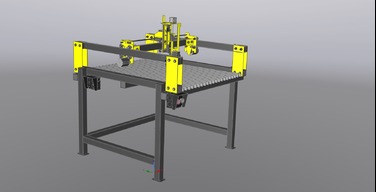

5 X 5 Plasma SIMPLE Build

5 X 5 Plasma table...Hypertherm 45 XP....CandCNC....Openbuilds

Plasma cutter - 608 on steel tube version

CNC Plasma cutter: 608ZZ on steel square tube linear rollers Welded frame HDT2-15 Belt Drive Tradeweld Cut-40 Plasma cutter with converted hand torch Virtual Torch Height Control through inductive probing - open source electronics project

Build Author

mytechno3d

Views

37028

Build Author

mytechno3d

Views

37028

Plasma cutting table

This is our plasma cutting table , based on the famous OX CNC . Can cut up to 15 mm ( steel , stainless , aluminium ) with a really good accuracy and at a really high speed .

Build Author

OpenBuilds

Views

32221

Build Author

OpenBuilds

Views

32221

BlackBox X32

The next level of CNC motion control solutions. Packed with advanced new features and built on the reliability of the proven BlackBox system

Dragon Plasma cutter

Inspired by MetalGuru's idea : The plasma too cutter . If you have to cut small to medium sheet of steel with a plasma , this build may be for you

Ultimo

Ultimo is the ultimate multi tool for the person who's serious about prototyping new ideas. A Delta Robot frame supports 3d printing up to 450mm in diameter, a powerful CNC Mill, and 50 amp plasma cutter for processing steel plate. And that's just a start.....wait till you see some of the other attachments we are currently working on incorporating.

Build Author

mytechno3d

Views

28272

Build Author

mytechno3d

Views

28272

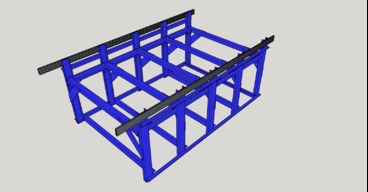

Router / plasma cutting table ( Rack and pinion )

Heavy DIY plasma cutting table

plasma cnc

Homemade plasma cnc

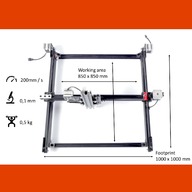

Dragon Portable CNC Plasma Cutter

A small portable CNC Plasma Cutter with some unique features

Build Author

brw_racing

Views

16321

Build Author

brw_racing

Views

16321

3d printed 2.5' X 2.5' cnc plasma cutting machine

Improvements to a cnc plasma cutter i designed a while back. Not that it really needs it to work but i think it could be an improvement.

Build Author

Steve B

Views

15734

Build Author

Steve B

Views

15734

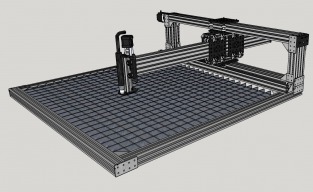

OX PPR - Portable Plasma/Router

PPR = Portable Plasma/Router. A ~30x30"work area with leadscrews. Work surface is below support members. Can be placed ONTO cutting surface.

Build Author

mytechno3d

Views

15549

Build Author

mytechno3d

Views

15549

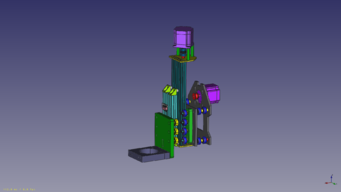

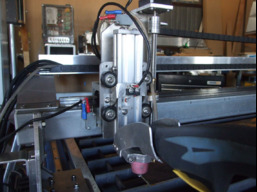

Z FLoating head for Plasma cutting (OX CNC compatible)

How to convert your OX CNC to a plasma cutter at low cost

Dragon Too Plasma Cutter

A Benchtop Plasma Cutter Concept

Build Author

Jason Moore

Views

13150

Build Author

Jason Moore

Views

13150

Lead1500 Plasma Table w/THC

lead machine plasma table with Black Box, and Torch Height Control

Plasma Table 006

Fast, inexpensive, near-zero maintenance, and 2+ years of near-daily use.

Big CNC plasma cutter

more later

W|W plasma/drag knife 1500x1500 (floating head & z-axis)

Step by step designing and implementing of my plasma approach

Large format plasma ox

I will update this as I go, cad files upon request. My x beam is basically a belt driven r7

cnc plasma table

ive got most of the wire harness made up too im using Chinese electronics for now I will upgrade later when this thing makes me some cash lol im using a ibm think center to case to hold my electronics ive got a 25' parallel cable to put some distance between the table and the computer

3 Axis MultiTool - 3D printer, CNC Mill and Plasma Cutter

So in short this build is a work in progress; it aims to make a large 3d printer, medium size CNC mill and a small plasma cutter all in one CNC unit.

Powder coated multi CNC Z Axis plasma adapter with Prox.

Powder coated multi CNC Z Axis plasma adapter with Proximity sensor. . It can also hold a 80mm Router head/Spindle as seen in my router build.

CNC Plasma Table 006

Inexpensive plasma table. Accurate, fast, and low maintenance.

Build Author

Weldsmith

Views

7749

Build Author

Weldsmith

Views

7749

CUT SMITH

I am building a multi tool CNC. I plan to have a quick change tooling system that will accept Routers, oxy acetylene torch, Plasma torch. etc. there will be a water bed under the convertible router table / work bench. The inspiration to build this machine is from having a small garage and not a shop.

Plasma CNC, 4'6" × 8'8" v0318

A plasma table able to cut 4'6" x 8'8" sheet. Low cost as possible.

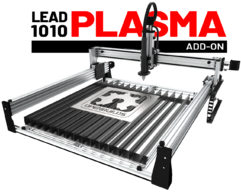

LEAD 1010 PLASMA Add-On

LEAD 1010 PLASMA Add-On is a great modification you can do for your LEAD 1010 to convert it into a metal cutting monster machine!

Based on 608 tube Plasma Cutter

Simple steel tube design Plasma water table

5'x10' CNC Plasma/Mill Table

Plasma Mill CNC

Home made CNC Plasma Cutter

Not completed yet but it does work, I will be changing small things as I finish the build and I have learned a lot from this build I am looking forward to finishing this one and Building another maybe larger table.

Build Author

CONUCON

Views

6882

Build Author

CONUCON

Views

6882

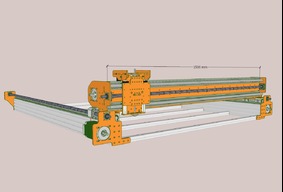

3DTwinX Gantry CNC System

Belt driven 3-axis linear system for high precision and low costs. > Threading and linear real cutting needed

Vacuum laser table

Large 10’x6’ vacuum table made from steel tubing and 1/4 inch steel plate

Router / Plasma Prototype Build

this is my first attempt at a CNC Table

Cnc mill, Plasma cutting and weld table

A functional table for plasma cutting, welding, tooling........

Learning how to build

I made a 5x10 foot cnc out of the parts I bought on this site. It's been upgraded and tinkered with ever since. The end goal is to learn enough to learn to build a large 10x10 foot 3d printer.

Plasma CNC machine

The plasma CNC that I have built has a water table that measures 1350mm x 650mm. The water is flooded onto the cut area while cutting and recycled around with a pump. This is to reduce smoke, cool the metal being cut to reduce distortion and also to keep sparks to a minimum. Most of the machine has been made from aluminium , the frame and table from steel, the water table, stainless steel.

Z Floating Head

It's a Z floating head idea. Works well. Recommend cleaning the inside of your holes well with Q tips, and polishing the 1/4-20 bolts with car wax and you won't need oil as it slides perfectly. Hope this helps

Starting my build 2.8mx1.4m

Starting my cnc router, laser and plasma using aluminium 80x80

Build Author

Denis Lapratte

Views

4599

Build Author

Denis Lapratte

Views

4599

All metal Ox hybrid CNC Router Table

This is my second CNC build, but the first one that I design from the ground up. The base is all metal because I want to add Plasma facility later on. I used the Ox model for the gantry plates and made a few changes to adapt to my design. Since I wanted to use parts from my first CNC to save as much as possible, I kept the 5/8 Hi-Lead Screw I had from Roton for the Y and Z axis. I will also add a downdraft table to keep all parts tight on the table for cutting.

Build Author

cnc-trucker

Views

4487

Build Author

cnc-trucker

Views

4487

Arduino Mega to EMC2 (LinuxCNC) Plasma Table Conversion

This is a story about a guy who started with a $25 set of plans, and through 4 iterations/ rebuilds, ended up with a professional quality CNC plasma table capable of cutting anything steel up to 2 inches thick.

big_recnc v2.0

cnc made with a 6mm metal body .

Build Author

Ken376

Views

3768

Build Author

Ken376

Views

3768

Welded project cnc first try

Kind of hard to see in this pic now lining up drive s and finishing framework

Build Author

mjenkins5720

Views

2971

Build Author

mjenkins5720

Views

2971

Modified LEAD machine

At the moment this build is in progress, I will be updating the files as I finish the remainder of the machine. This machine is intended to be a multipurpose CNC, but a bit bigger than a desktop unit. The machine is scalable in the X and Y axis.

Build Author

robert christensen

Views

1534

Build Author

robert christensen

Views

1534

Tool holder

I saw a video of some one pouring resin in a mold,so i did a little research, i bought some resin,and some molds and magnets all from Amazon, it took me several tries and a big mess but it finally finished. The first pour i poured a small batch to make a templet,i marked all the holes that needed drilling then i marked the underside of the mold where i wanted the magnets, next was making the pcs i needed