Build List

-

Active Filters:

x

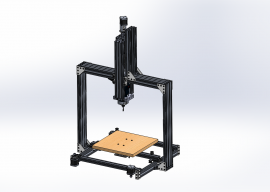

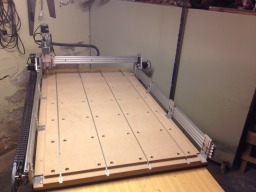

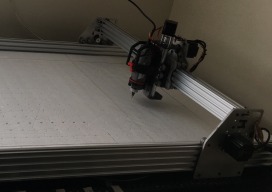

A work in progress

One of my first projects might be cutting proper plates.

Build Author

Dmknerr

Views

5238

Build Author

Dmknerr

Views

5238

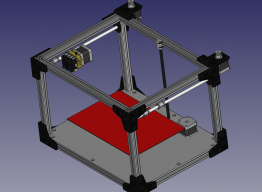

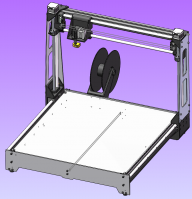

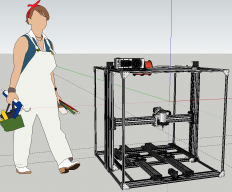

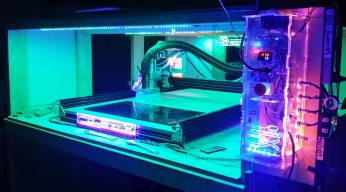

Server Rack Printer

My first project build. Concept build to use an existing 7.5 ft tall server rack as the frame. This ptoject may never be completed.

Build Author

Anthony Bolgar

Views

12097

Build Author

Anthony Bolgar

Views

12097

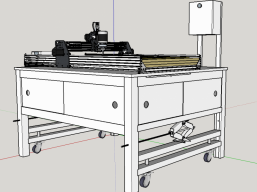

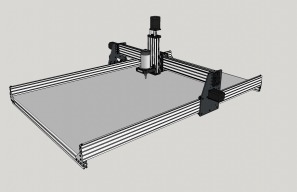

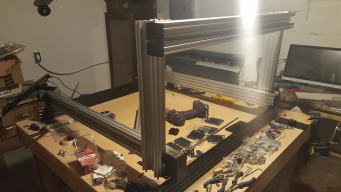

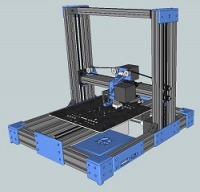

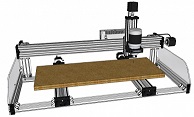

L'FOX - Large Format OX deriviative. Designed and built by Revision 13 Prototypes

This build is for a testing rig to use while testing out different controller boards and CAM software for milling and routing. It is in the early stages, planning is complete, parts are ordered. Awaiting parts delivery to start build. Please not the BOM only covers parts from the OpenBuilds part store. I will be posting the other required items very shortly.

OnyX-13

This is my OX. There are many like it, but this one is mine. My OX is my best friend. It is my life. I must master it as I must master my life.....

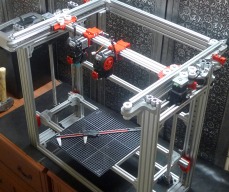

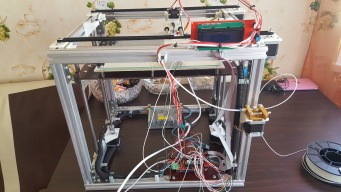

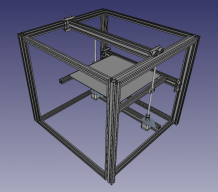

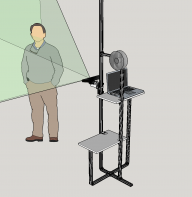

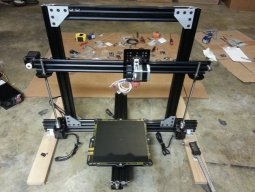

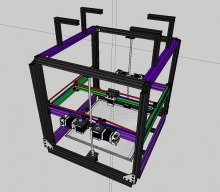

CoreXY Tower

CoreXY Table with Symmetric Lead Screw Z axis, Build volume: 293mm x 290.75mm x 223.83mm

Build Author

Ronald van Arkel

Views

33599

Build Author

Ronald van Arkel

Views

33599

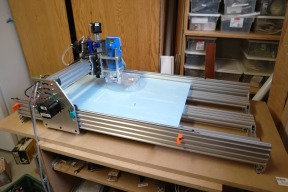

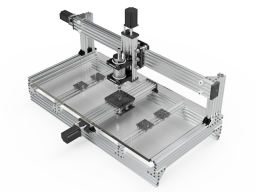

Routy GT2 290 BSX CNC Router, Low Cost and Good!

The Routy GT2 300 BSX CNC Router is a Low Cost CNC build. It performs the same as the larger Routy's from OpenBuilds but doesn't break the bank!

Build Author

Keteland

Views

10731

Build Author

Keteland

Views

10731

MULIMATERIAL 3D PRINTER (in progress)

ELECTRONICS - ARDUINO Mega 2560 + RAMPS 1.4 + power supply 12V - Leadshine DM 5042 external driver + Power supply 36V + NEMA 23 stepper motor SOFTWARE - Repetier Host to communicate with the Ramps - ARDUINO to upload the firmware (Marlin) MECANIC - V-Slots rails 40x40 + home-made plates - everything goes fine on the side of the build

Epoxy dispenser, to apply non-conductive epoxy to electronic board.

Epoxy dispenser, 2nd one, first one works great. Uses HMI to allow for operator to pull up files for different jobs. 9 prox sensors, Eot and home on all 3 axis. High quality nema23 motors with intergrated drives from applied motion. Uses programmable router for drives.

Wifi'not

A simple made hideaway for ugly electronics

Water Buffalo - Water jet cut OX+

A modified OX based on Aluminum plates cut on a waterjet. Some new ideas and additions from other builds are included.

3D printer inspired by the Bukito

I have been working on this project for something like 3 years on and off, sometimes leaving it for a few months. Now I really want to finish it. For me, the mechanical part was the easy (though long) part because I get to use about 17 CNC machines and MasterCAM and I am a machinist. The hard part is the electronics part. Had a few problems getting Windows to communicate to the X5 Mini via the USB cable but found something on the Smoothie forum and got the machine moving.

betterBot

This is going to be a more or less detailed how to build BetterBot. Pictures and more (decent) text are to be added.

Slightly larger sphinx

Another C-Beam Sphinx but a little larger,

Build Author

dodgenet

Views

6621

Build Author

dodgenet

Views

6621

Budget 1500mm OpenBuilds V-Slot Deltabot Build

This 1500mm tall Delta is a work in progress. The triangle corners are water jetted from 1" 6061 Aluminum, and are welded to 1" square tubing. The 1500mm OpenBuilds 20x20 V-Slot extrusions are held into the corner brackets by two stainless steel set screws per bracket. This printer will need to be reinforced with wall brackets due to the combination of height/materials.

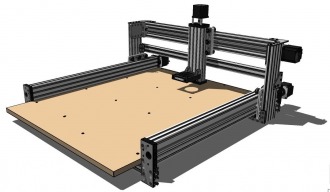

OX Tale

1000mm x 750mm OX with some planned enhancements. My first venture into CNC.

Stainless OX kit

This is a 1500 X 1500 Stainless OX kit build, by a cnc novice. It is the first cnc machine i have ovned and build I got this kit from http://makersupplies.dk/20-ox-cnc-kits

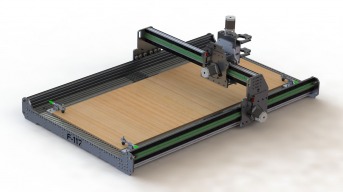

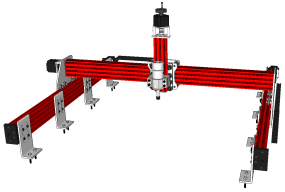

Area 51 CNC Parts F-117 CNC Gear Rack Drive System

This is my journey on building a rack and pinion Ox variant called the F-117 CNC.

Hlidskjalf, CoreXYU (dual X-carriage)

Dual X-Carriage CoreXY. Not impossible, but probably the only one. Use the link to Thingiverse "Hlidskjalf" for parts and downloads.

Build Author

Steve B

Views

15741

Build Author

Steve B

Views

15741

OX PPR - Portable Plasma/Router

PPR = Portable Plasma/Router. A ~30x30"work area with leadscrews. Work surface is below support members. Can be placed ONTO cutting surface.

Build Author

Larry_AK

Views

10294

Build Author

Larry_AK

Views

10294

MUSK-OX

Pretty much a straight OPENBUILDS OX that slowly getting some modifications.

MyCNC(1000mm x 1500mm)

My CNC project

Ooznest build - 1500mm x 1000mm

Its the first build for me so its just the story of me attempting to build the kit and hopefully end up with something I can use. Hopefully without destroying anything or anyone.

SUPER OX NEMA 34 1600 OZ Motors!!!

CNC OX 1500X3000

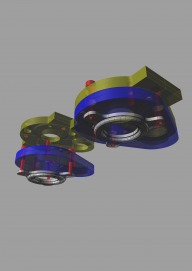

CNC Rotary Table Rotational Axis, A Axis B Axis 4th 5th Axis CNC Dividing Head

This is my first major project.

CBeam OX

i wanted to use both the ox and the C beam C beam for the gantry because its stronger i also made the gantry 20 mm higher so i can cut thinker material i will maybe later go to rack& pinion on the 1500 mm Y axes also instead of the V wheels i will maybe go to hiwin in the furture

Build Author

Joe Garritano

Views

11737

Build Author

Joe Garritano

Views

11737

X-carve upgrade

Using criticall OpenBuilds components to upgrade the rigidity and reliability of an X-Carve 1000mm build.

Pure Cbeam 900x1000

This is a pure cbeam build to maximize envelope and rigidity. All the parts used are available from open builds.

My first OX build

This is the story of my experience building a 1000 x 750mm OOZNest OX CNC router

Build Author

Power Playground

Views

4864

Build Author

Power Playground

Views

4864

PowerBot

This is my own modified version of the D-Bot printer. I wanted to spec this printer to be able to print exotic materials at high accuracy with little to no compromises and maximum reliability.

Build Author

Edgar Robles

Views

4118

Build Author

Edgar Robles

Views

4118

Sheethexapod

Sheethexapod works with basic mechanims as direct metal-metal links and joints, all movements can be done by a rc servomotor in this case towerpro model.

Build Author

Mark Carew

Views

74852

Build Author

Mark Carew

Views

74852

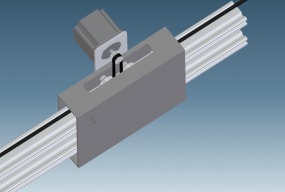

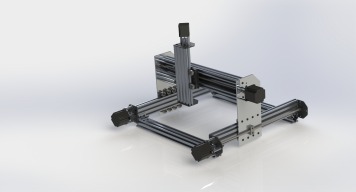

X Y Table OpenRail / V-Slot Build Examples

The X/Y table system is a great starting point for many CNC projects giving you the ability to move an object on the X and Y axis in a simple compact style.

CNC Glass Grinder

This is a 1-Axis CNC Glass Grinder. It uses a hobby grinder to miter a precise angle on the edge of a piece of glass.

Build Author

Tim Pierce

Views

14500

Build Author

Tim Pierce

Views

14500

Openbuilds V slot Rail extrusion retrofits for Lulzbot 4/5 Taz Printers (X, Y and Z axis)

This project shows how to use Openbuilds Vv slot extrusions and wheels to retrofit a Lulzbot Taz 4 or 5 printer. These modifications improve layer consistency, eliminate nozzle and bed sag, and allow for larger toolhead mounting. Project updates and newer accessory files may be located at http://www.thingiverse.com/piercet/designs

Controlbox for a CNC Router

A Controlbox for my CNC-Router, containing stepper-drivers, Planet-CNC MK3 Controller and a Controlpanel with joysticks.

Nox 1500mm x 1500mm C-Beam

C-Beam build using a double C-Beam for the X axis. 1500mm x 1500mm

Schematix OX metal build

OX metal build from an noob

Build Author

Krishnakumar

Views

8803

Build Author

Krishnakumar

Views

8803

Hobby OX CNC

This "hobby OX" CNC is built for multiple purposes such as cutting and engraving various materials, laser etching and cutting, etc... Its a great platform for hobby enthusiasts like me where this machine can be used for so many different purposes effectively and efficiently!

Cheap linear rail set up for z-axis

A easy to do cheap upgrade for the z axis

Build Author

Asaku

Views

9679

Build Author

Asaku

Views

9679

mBOX

Hi! This build is, or at least should be, a multipurpose box (mBOX). Due to limited space I want to build something that can serve multiple purposes such as 3d printing, 3d scan, plexiglass cutting and hopefully some milling too (both wood and metal). Switching between modes should involve switching heads and worksurface (change heatbed with a wood platform and viceversa). (for the scan part I'm thinking of integrating this opensource project into the frame: http://www.freelss.org/ )

Build Author

Anglesachse

Views

9074

Build Author

Anglesachse

Views

9074

Zorkbot

Corexy, with possible head change (3d, cnc, laser)

Build Author

Dave420

Views

14564

Build Author

Dave420

Views

14564

10 x 5 ft plazma table build

Attaching V Slot or mutable V Slot end on end to a larger steel frame table.

Build Author

dddman

Views

13674

Build Author

dddman

Views

13674

Prusa i3 (Acrylic frame with OB rods)

The Prusa i3 (iteration 3) is the newest and most current 3D Printer design by RepRap Core Developer Prusajr (source: http://reprap.org/wiki/Prusa_i3)

CrOX Carbon Reinforced OX

Modified OX with carbon fiber reinforced X and Z axes. 1500mm Y, 1000mm X and 120mm Z clearence

Zen3D Atlantis 3D printer, H-Bot mechanics

H-Bot mechanics 3D printer. Build volume - 300x300x300mm dimensions: 560x500x500mm

My first build: a other OX CNC

I love to build things. I decided to build a CNC machine to help me build more things! I had a lot of fun and I learn a lot of thing in the process of building this machine. p.s. my primary language is french not english. Forgive me if I made some mistake.

D-Bot CoreXY printer

A CoreXY D-Bot 3d printer using gantries as wheel-carriages.

Moag's CNC Mill

A design in progress, to 3D carve two-part Aluminium injection moulds for Soft Plastic Lures and Lead Jigs, so I can prototype some of the concepts rattling around in my head. All Openbuilds parts where possible, 1000x500mm footprint, 0.8kw Water-cooled Spindle?, High Torque Stepper?,Smoothieboard?, I still have no idea. As a newbie to the CNC world, any wisdom would be welcome to take this from just a idea into reality so I can start playing with all this awesome stuff. Thanks in advance

BrandoneOuX

I'm Brandoneous; hence, the BrandoneOuX, a cartesian CNC build. Large format (1000mm x 1000mm) but beefed-up to solidly augment the ability to cut Aluminum in addition to wood and other solid materials. As I am currently living in a rented apartment for an out-of-state job, my secondary challenge is to build a sound dampening enclosure that will function as a torsion box base, a sound dampening enclosure, and a dust containment system. Easy, right? Well, we'll see... Join my journey

C-Beam Big Mouth

My first build was with the basic C-Beam Build. I soon found the z clearance a little constricting So I added 2 500 mm actuators to support the x axis rail . I also left off the front and back y axis support rails for easy cleaning. I mounted the base of the machine to 1/2" mdf with 10/32 screws and blind nuts.

eeYZee Router

The first criteria was portability, the second was cutting out a sheet of ply, the third was the ability to shape a foam surfboard blank, but the main criteria was a small budget.

The Buffalo

OX 1500 x 1000 mm

Build Author

Matt Nelson

Views

12352

Build Author

Matt Nelson

Views

12352

Matt's Ox

I'm building an OX CNC router. It will be the larger size of 750x 1000mm. This should give me a working area of about 22"x30".

Metalguru's C-Beam 750

This is a C-Beam build, fairly heavy duty, and 750mm x 750mm. Should be a good, sturdy machine that's relatively easy to assemble.

Build Author

M^3

Views

17712

Build Author

M^3

Views

17712

M Cubed 3 Axis Bluetooth CNC Controller

Low cost, Bluetooth enabled, 3 axis CNC controller. GRBL 0.9 compatible.

Build Author

Peter Oakes

Views

44371

Build Author

Peter Oakes

Views

44371

The Bull Dog, A RoverCNC OX based 1500mm x 1500mm CNC - Tutorial build

I have based this build on the OX build so I will not be going into too much detail of specefic assembly modules as they asre so well covered by Mark Carew already, but will go through the complete build on video. I will be addig additional tutorials on steppers and the other electronic parts as needed though as this project is sponsored by RS Components in the form of most of the Electronics and this is also the key focus of my YouTube channel www.youtube.com/c/thebreadboardca.

![(R)OX CNC [FR/EN]](https://builds.openbuilds.com/data/article_images/l/1/1584.jpg?t=1423259127)

Build Author

AndersFaust

Views

12600

Build Author

AndersFaust

Views

12600

(R)OX CNC [FR/EN]

Another (R)OX CNC something like build, in French please ! Pics Heavy !

Build Author

Rwetzler

Views

9427

Build Author

Rwetzler

Views

9427

C-Beam Prototype

This is a variant of a typical OX (Mark Carew inspiration) router using C-Beams/8mm Acme rods to drive all three axis. I went with a 1000mm x 1000mm frame size. Useable space is 28" (711mm) X 26" (660mm) with a Z axis work travel of approx. 3.25" (82.5mm). A TinyG is used as a controller along with Fusion 360/Chilipper as the software for generating and running gcode files.

4-axis C-Beam Hot Wire Wing cutter

4-axis CNC Hot wire foam wing cutter

GrOX (OX based router)

1000mm x 1500mm OX router using Openbuilds parts and plates by Chris Laidlaw

Build Author

Dave420

Views

6176

Build Author

Dave420

Views

6176

Dave's Z axis and powder coated.

I just did my first Powder coat paint job on a Z Axis with 9inchs of travel for the DIY CNC Plasma Cutter, Mill Head, Router, Engraver, Laser Head, Water Jet Cutter Machine. 2 different Z Axis ride plates and a 80mm Router/Mill Head/Spindle clamp. Baked on finish in a old oven i had.

Arctic Ox CNC Router

This is a cartesian CNC Router build that is based off the OX CNC build by Mark Carew. I am using Spark Concepts CNC xPro controller board and their 400w spindle kit.

Build Author

Sheepdog

Views

26877

Build Author

Sheepdog

Views

26877

Griffin Delta Printer

Designed from the ground up as a low cost, highly scalable delta printer. This printer has been built as small as carry on luggage size, up to an 18in wide print surface and is capable of larger. Approximate cost is low to mid $500 range start to finish, including electronics for a basic model.

Dust Boot and Holddown in one

only 2 screws to hold down even bent sheet material and vaccum dust removal in one

Build Author

Jesse Jenkins

Views

9440

Build Author

Jesse Jenkins

Views

9440

Hedron's build with Ooznest kit and Xylotex motors

A 3-axis flying gantry (4'x4') mechanical kit is assembled. A 3D printer is used to make cable chain for tidy and cheap wire management. A BeagleBone Black development platform with Machinekit software (LinuxCNC) is configured to control a Xylotex motor driver box connected to an Openbuilds Ox direct-drive pulley and belt motion system. A vacuum dust-collection system is designed, CNC-routed and installed. A steel table is made to mount the table onto.

Ooznest OX CNC for Architecture Modell

While i achieved the desired taler Z axis this was very notable of the cost of the stiffness of the Y axis - the Y axis is now quite wobbly. i do not recommend such a big Z axis on a OX CNC machine where the requirement is a good precision.

XDrive 3d Printer

XDrive 3d printer, high quality large build volume.

My 5' by 5'

I have constructed frame out of 1 1/2" square tubing. Have my Y aces mounted. and awaiting parts.

Build Author

Gerrald

Views

6405

Build Author

Gerrald

Views

6405

Pong CNC

This build is to show what's possible as well with openBuilds! I use a single ArduinoMega and 5 separate stepper drivers (A4988). The LEDs are all NeoPixels. Collision 'detection' is all done within the code, so the endstops are only sensors I use in this build. I'm a self-employed video-artist and this is my first installation which just needs power and it runs (where I'm quite proud of). Normally my interactive installations take a long setup time, so this installation is a relief :)

Screaming Ox CNC Machine

Big brother of the Charging Ox CNC machine.

Large OX

A larger version of the OX.

Build Author

Laurence Carroll

Views

10985

Build Author

Laurence Carroll

Views

10985

C-Beam Double X

Per the special notes its a variant of the C-Beam, Machine.... I have noticed that alot of people build a CNC router to cut parts for other larger CNC machines.. eg Delta Printers etc....plus this will enable me to cut parts for model RC plans UAV's etc...

Idea for any axis support and Drive

Just an idea right now but will attempt a prototype in the near future. Not sure if this has been tried before or not.....

Build Author

Paruk

Views

23204

Build Author

Paruk

Views

23204

Buffal-O-Tron

A 3D Scanning Station

Build Author

Sonny Lowe

Views

10882

Build Author

Sonny Lowe

Views

10882

Folger-Tech Y-Carriage

This a redesign of the Folger-Tech Y-Carriage using the Solid V-Wheels, Ball Bearings, the V-Slot Rail System.

BldrBot Pro

A completely belt driven cartesian design with a center mounted X motor. This is a very compact, rugged design.

1500 x 1500 mm OpenBuild CNC

1500 x 1500 mm OpenBuild CNC

Build Author

Robert Hummel

Views

73425

Build Author

Robert Hummel

Views

73425

890KV OX RC spindle

This build is intended as a light alternative to the Dremel rotary tool.

Build Author

John J Talavera

Views

8504

Build Author

John J Talavera

Views

8504

CNC FOR EVERYONE, THE DUCK!

www.cncforeveryone.com. the Duck is something that i think would be helpful in my shop since we already do cold casting.

Cebu

Another build based on the venerable OX. xPRO CNC controller, and a few extras.

Aluminium OX - Canada

Document my OX build process. I will also be sharing SolidWorks parts files & assemblies.

CNC Router (Non OX)

My own Design (not an OX Derivative) using standard Parts.

Build Author

The Dude

Views

22070

Build Author

The Dude

Views

22070

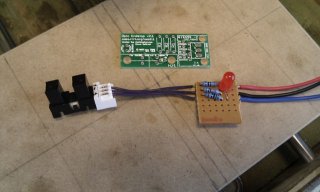

Optical Limit + Home Switches

Optical home and limit switches for cnc, 3D printers, laser cutters, etc.

Build Author

Cbrown330

Views

5417

Build Author

Cbrown330

Views

5417

Big 3d Printer, Big Brown

This is a big 609 x 609 x 914 3d pritner with exchangable hot ends and extruders.

Builder Bob's CNC

Here is the consolidation of my woodworking shop, a CNC Router!

My Ox

What I want to build is a unit to: rout wood, plastic and occasional aluminium . to be able to swap cutters. i.e. drragknife, laser, router, drill

Square OX

Square shaped OX for doing general purpose engraving and cutting into wood, acrylic, and aluminum.

Build Author

Nwrgordon

Views

15932

Build Author

Nwrgordon

Views

15932

RepRap Intro

An easy Epic Win for novice engineers new to the RepRap project www.3distributed.com

Build Author

Cuong Vu

Views

35691

Build Author

Cuong Vu

Views

35691

3D Printer

It took me 18 long nights to build it

Ooznest Moded CNC

Modded OX with full nema23 4 point support

Build Author

zann68

Views

9368

Build Author

zann68

Views

9368

OX CNC 4'x4'

Out with the Old in with the New. Trying to build a nice clean setup that myself and my sons can use and enjoy.

The MULE (an OX inspired 3-axis CNC)

The Mule is a 3-axis CNC inspired by the OX CNC by Mark Carew. This machine borrows the OX's sturdy frame and upgrades the X and Y linear actuators through the use of three 500mm lead screws (as opposed to the belt system of the OX). The result is an inexpensive, sturdy, and powerful design built for cutting tough materials such as aluminum.

Build Author

Kermareg

Views

17381

Build Author

Kermareg

Views

17381

MOX CNC

[EN] Build of my Multiple OX CNC. It's goal is to run in 2 differents modes : router and 3D printer modes. The router mode will allows the use of a laser diode or a standard spindle. [FR] Construction d'une CNC basée sur l'OX pour des usages multiples. Deux modes principaux sont prévus : l'impression 3D et l'usinage via une defonceuses. Le mode usinage permettra à l'avenir de placerune tête laser pour effectuer quelques gravures simples. Une version française : http://kermareg.be/?page_id=103

Build Author

Steve Marsh

Views

5784

Build Author

Steve Marsh

Views

5784

Dust Shoe for Colt router and OxCarve

A simple 3D printed dust shoe for the cnc router. 2 parts held together with magnets for easy bit changes.

Zebu ( OX clone with Brasil materials)

An OX clone with alternative parts.

Build Author

alex_b

Views

17287

Build Author

alex_b

Views

17287

RONIN OX | The G10/Carbon Fiber Hogger

The Ronin OX is a dedicated fiber composite milling machine. I give a complete in-depth article on how to take a nearly stock OX build and easily turn it into something that can mill carbon fiber and G10 plate effectively and quickly.

Build Author

evildean

Views

8929

Build Author

evildean

Views

8929

OX-SUMO, SUMO-OX, OXSUMO?

One meter square. Short and stout.... reminds me of a Sumo Wrestler. A temporary and adjustable configuration I have devised to cut my own plates. I have kicked around ideas for about a year and the C-Beam extrusion has made this attempt to realize my ideas irresistible. This is just one step towards bigger and better things!

Build Author

Gary Bonard

Views

6199

Build Author

Gary Bonard

Views

6199

OxZilla

This is my second Ox with a working area of 14" x 14" x 5" I wanted to build a small sturdy potable CNC router and this OxZilla has the nice upgrades !

Build Author

TomH

Views

16372

Build Author

TomH

Views

16372

H-Bot CoreXY Cube with Fixed Build Plate

Use of V-Slot for frame and rails with option to use identical 500mm uncut lengths: 8 * 20x60 x 500mm 8 * 20x40 x 500mm 7 * 20x20 x 500mm (2 cut into four identical 125mm pieces for filament holders) Use of uncut 500mm rails obtained through use of 12 joining plates for use as spacers. Alternate approach is to trim two 20x40 and 1 20x20 rail by 6-8mm each. Build volume ~400mm cubed (with dual extruders). Use of only openbuilds components! Currently in design phase...

HAPP Printer

This 3D Printer is made to provide the most accurate results with the least amount of investment. This Printer is being designed to allow the common user to own a very accurate piece of machinery.