Build List

-

Active Filters:

beam

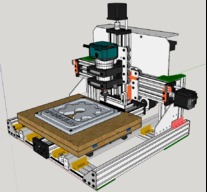

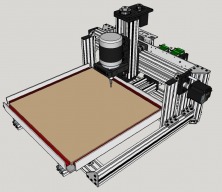

Gargoile reproduction C-Beam™ Machine - Plate Maker

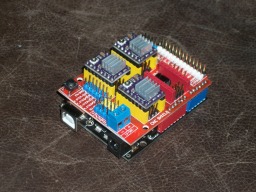

A stock C-Beam with a CNC shield with DRV8825's

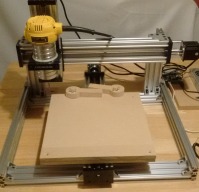

TAZ C-Beam CnC Router by RC-CnC

C-Beam inspired CnC Router (1000x750) Approx 90mm of Z travel

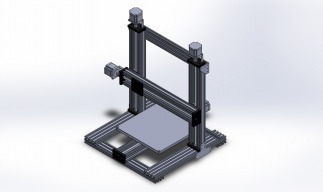

XDrive 3d Printer

XDrive 3d printer, high quality large build volume.

Build Author

UltiBots

Views

10577

Build Author

UltiBots

Views

10577

Machined Aluminum MagBall Carriages

Machined Aluminum MagBall Carriages

laser add-on for C-Beam machine

3.8 W laser add-on for C-Beam machine. Can easily be swapped with the router.

C-Beam Big Mouth

My first build was with the basic C-Beam Build. I soon found the z clearance a little constricting So I added 2 500 mm actuators to support the x axis rail . I also left off the front and back y axis support rails for easy cleaning. I mounted the base of the machine to 1/2" mdf with 10/32 screws and blind nuts.

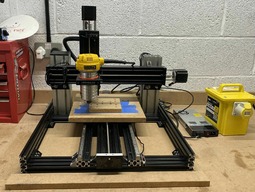

C-Beam CNC (1st cnc build!)

1st build CBeam Machine w/ raspberry pi-protoneer hat controller

Build Author

Metalguru

Views

14704

Build Author

Metalguru

Views

14704

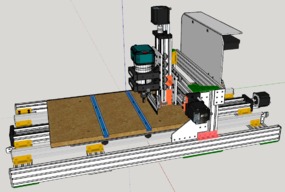

C-Beam Machine Too

C-Beam Machine upgrade using linear rails to increase machining size by 2.5 times and increase rigidity

Build Author

Rwetzler

Views

9393

Build Author

Rwetzler

Views

9393

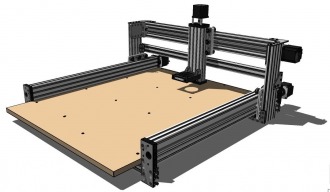

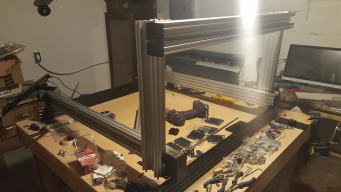

C-Beam Prototype

This is a variant of a typical OX (Mark Carew inspiration) router using C-Beams/8mm Acme rods to drive all three axis. I went with a 1000mm x 1000mm frame size. Useable space is 28" (711mm) X 26" (660mm) with a Z axis work travel of approx. 3.25" (82.5mm). A TinyG is used as a controller along with Fusion 360/Chilipper as the software for generating and running gcode files.

Metalguru's C-Beam 750

This is a C-Beam build, fairly heavy duty, and 750mm x 750mm. Should be a good, sturdy machine that's relatively easy to assemble.

My C-Beam 3D Printer

Larger format FDM printer using C-Beam linear stages

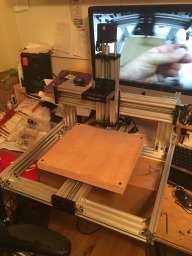

Jim's C-Beam Machine Build

This machine is fantastic. Teamed up with Fusion 360, Inkscape, and GrblPanel, I'm well on my way towards making at least one Christmas gift this year. I had some frustrating times during the build, mainly with getting everything to go together square, but overall it was fun. I can see that I'm going to need to be a bit creative in order to max out the work area for this machine so that I can produce the product I bought it for, but it will be able to do so much more for me as well.

My 1st C-Beam Router

Pretty happy with the build, had some difficulty with the software loading up the settings due to me using the wrong com.

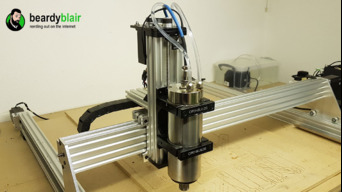

My first CNC - The C-Beam Basic

I am a newbie and this is my first build. After hours and hours of research I decided on the C-Beam. I will be changing one or two things but I will basically be building this as per Mark's video.

Build Author

beardyblair

Views

25312

Build Author

beardyblair

Views

25312

Sphinx XL

My build log of an adapted Sphinx design with additional height and a larger X and Y axis.

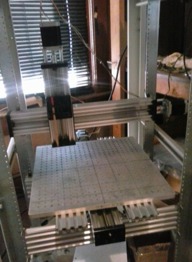

C-Beam Machine XL

Overview of my experience building the C-Beam Machine XL from OpenBuilds, along with updates as I move along and get it going. My application is for creating plates needed for lab functions, 19 rack bay covers, and whatever else arises.

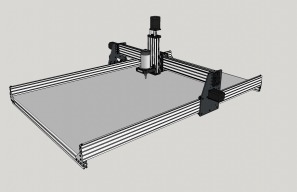

Pure Cbeam 900x1000

This is a pure cbeam build to maximize envelope and rigidity. All the parts used are available from open builds.

CBeam OX

i wanted to use both the ox and the C beam C beam for the gantry because its stronger i also made the gantry 20 mm higher so i can cut thinker material i will maybe later go to rack& pinion on the 1500 mm Y axes also instead of the V wheels i will maybe go to hiwin in the furture

Slightly larger sphinx

Another C-Beam Sphinx but a little larger,

Build Author

mikev

Views

8600

Build Author

mikev

Views

8600

C-Beam Evolution MkII

The C-Beam Evolution is an evolving machine. The MkII is inspired by Kyo's C-Beam Spinx but currently uses my own design of plates made of 8mm acrylic (X-axis ends) and 6mm polycarbonate (Y axis ends). The plates were made on the MkI but I hope to be able to make 6mm aluminium plates on the MkII for the MkIII.

c-beam hello world

My first ever build. Straight C-beam with tinyg controller a few do-dads and some make do choices. Non-metric length lead screws to save long lead time. Jog knobs to cover the extra length and also practical. My old Bosch Colt never had it so good. Build out work remains, wire dressing, drag chain, vacuum, permanent base, etc.

Build Author

signzonepr

Views

13044

Build Author

signzonepr

Views

13044

HD c Beam CNC Router

24x32 Cnc Router, I used vSlot c Beam Extrusion and Wheels!

Build Author

Kyo

Views

6539

Build Author

Kyo

Views

6539

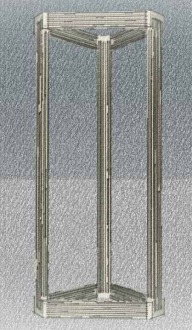

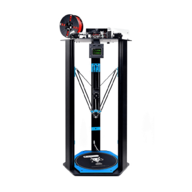

C-beam Delta Printer

Large scale delta robot using c-beam as the core frame component.

My 2nd cnc build

My new build to upgrade from my worn out shapeoko

Build Author

Greg Lampman

Views

9239

Build Author

Greg Lampman

Views

9239

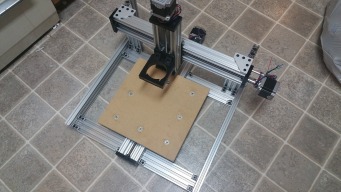

C-Beam Intro to CNC

Build log for my first CNC machine, a C-Beam Plate Maker

Triangular CNC Milling Machine

A wonky build to eliminate slop on a long Z axis

C-Beam Machine upgrade to 1000mm x 1000mm

This built is to convert an existing 500x500 C-Beam Machine into 1000x1000. Inspired by several builds including C-Beam Machine : (http://www.openbuilds.com/builds/c-beam%E2%84%A2-machine-plate-maker.2020/) and Gino's build : (http://www.openbuilds.com/builds/c-beam-gtc.3250/)

C-Beam XL build

So for a summary its a great kit that was easy to build, could not be more happy.

Dogmeat's Custom C-Beam XL

I love the C-Beam XL concept, this build is my custom version with the goal of increasing rigidity for metal milling.

C-Beam Desktop On Rails

My attempt at a Desktop CNC using C-Beam and Open-Rail with Steel Wheel bearings and LeadScrew Drive.

Build Author

Huub65

Views

9318

Build Author

Huub65

Views

9318

My C Beam - NEMA 17 - GRBL- Arduino project

Cbeam machine. Using small stepper motors (NEMA 17) and Arduino controller. Try to get this working in de upcoming month.

CNC Planning

Reusing parts to build a CNC - planning stage

Dixie C-Beam XL

Build log of the Dixie C-Beam XL CNC Router.

BD's C-Beam Machine CNC Router (WIP)

CNC router table based on OpenBuilds C-Beam Machine bundle.

C beam xl

I would recommend this challenge to any woodworker looking for something new.

C Beam CNC+Laser

You will be following the assembly of the mechanical kit and how i integrate the electronics into the final build.

C beam Larger and Stronger

My first build based on the original C beam Sphinx. I’m not sure at this point what the final size will be. I have the parts from the c beam Sphinx and extra beams and lead screws to build up to 1000mm x 1000mm.

C-Beam Elexa

This build will be based on the C-Beam Plate Maker, with additional changes based on other builds and ideas.

Heavy duty C Beam

a 1000mm x 1500mm CBeam build with hgr20 hiwin rails 600w er16 spindle

C beam machine (with larger T-slot platform)

Larger, more rigid build plate C beam machine

Brokkr CNC 2.0

1M C-beam xy variant

Build Author

Anthony Castelluci

Views

3247

Build Author

Anthony Castelluci

Views

3247

Simple Camera Lofted Camera Slider

Build a manual camera slider.

C-Beam XL ( 1 meter²)

A modified C-Beam Build with a few Addons

Build Author

Kyo

Views

10109

Build Author

Kyo

Views

10109

Plate Maker V-slot Table

C-beam Plate Maker V-slot Table System to aid in clamping and setup of jobs.

1200X600 SPHINX

Need cnc to make alumunium sign, brass stamp, etc

C Beam Served

C Beam Machine built in a server cab. Hopefully this keeps every thing enclosed , clean and quite ?

Build Author

Terone Burgenheim

Views

2836

Build Author

Terone Burgenheim

Views

2836

My CNC

This build is my version of the CBeam machine. I opted to NOT use the Gussets, and instead went for the 40, and 60 mil angle brackets to cut the price back a little further. I started with the smoothieboard but decided it was still "too new" and very much experimental. This build took me a few (2-3) days to complete. The CBeams and Lead-Screws really make building things faster since you don't have to clamor over belts.

Build Author

Carl van Heezik

Views

8461

Build Author

Carl van Heezik

Views

8461

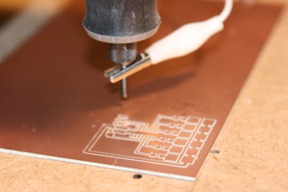

C-Beam™ Machine for PCB milling

C-Beam Machine for PCB milling

Build Author

OffAxis

Views

7753

Build Author

OffAxis

Views

7753

OffAxis CNC 1000x1500

Cut Area: 825 x 1340. Max Cutting depth: 2 inches. Arduino based control with Nema 23 and Nema 17 drive. 8mm leadscrew and 2GT belt drive. 400W 48V quite cut spindle.

Build Author

spark2

Views

5705

Build Author

spark2

Views

5705

C-Beam - Sphinx 1000x1000mm inspired by Kyo

A stable CNC Router that allows me to cut and carve bigger Parts. The Machine is an original Build from Kyo's Sphinx CNC Machine. Thanks for the great Work and the Effort Kyo. Your Files and Lists helped me a lot to build that Sphinx 1x1m.

Build Author

crnrstndes

Views

4248

Build Author

crnrstndes

Views

4248

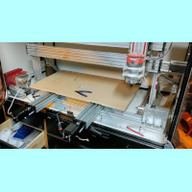

C-Beam Upgrade to Larger C-Beam

My goal was to be able to enlarge my C-Beam with as many original parts as possible. I was able to recycle almost all of them with a only the two 500 mm rails left over. I used 1000 mm rails for the X Axis and I added another complete Y Axis assembly. I chose to keep it simple and I am very happy with the result!

Build Author

obmilllivebuild

Views

5650

Build Author

obmilllivebuild

Views

5650

Live C-Beam Build @ MRRF2018

Contained within are links to our OpenBuilds sponsored C-beam Machine live build taking place at MRRF 2018 (Midwest Reprap Festival) on March 24 and 25, 2018. There will also be some build images and a few 3D printed STL items that were added.

Build Author

Limine3D

Views

4575

Build Author

Limine3D

Views

4575

Shapeoko 1 upgrades

Replaced the original Z-axis for a shapeoko with a c-beam upgrade. This upgrade required a nema 17 mount and a quiet spindle mount I printed with a 3D printer.

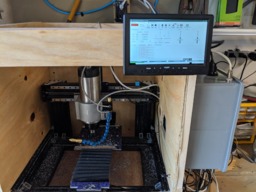

C-Beam Machine XL

C-Beam XL upgraded with end-stops, E-stop, and cable chain. Running GRBL on Arduino Mega.

1075 Sphinx

My first attempt at building a CNC. I chose the Sphinx due to ease of build and extensive documentation provided by Kyo.

Build Author

ChrisViral

Views

7181

Build Author

ChrisViral

Views

7181

OP C-Beam Machine XL by ChrisViral

Video diary C-Beam XL build with massive steppers and a 1.5kW Chinese spindle.

Build Author

Mark Carew

Views

25370

Build Author

Mark Carew

Views

25370

C-Beam® XLarge Linear Actuator

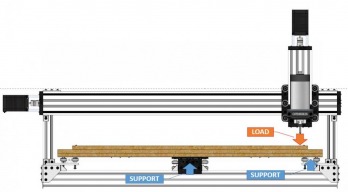

This OpenBuilds C-Beam XL actuator is the backbone of a lot of the awesome builds put together by the OpenBuilds community

Build Author

Mark Carew

Views

17089

Build Author

Mark Carew

Views

17089

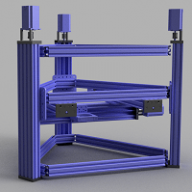

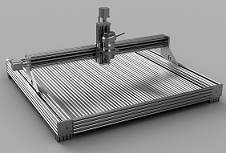

C-Beam XLarge X/Y Table

This OpenBuilds C-Beam XLarge X/Y Table is a great display of how easy it is to modify and create awesome configurations with the OpenBuilds system!

C-Beam unit with 400W Spindle

Standard (If there is one) C-Beam with plnth

NotAnOx

From plywood and linear rail to c-beam. I probably should have bought a kit.

Build Author

Vin1027

Views

7360

Build Author

Vin1027

Views

7360

C-Beam Sphinx

This is the original C-Beam Sphinx with the 16 wheel X gantry plates. I'm using the Ethernet Smoothstepper, Gecko G540 stepper driver and Mach 4 for motion control.

John's Sphinx

1000mm x 750mm C-Beam Sphinx, running on Grbl

Build Author

Troy Proffitt

Views

29061

Build Author

Troy Proffitt

Views

29061

Sphinx Upgraded plates / ballscrews and linear rail

Upgraded Sphinx Cbeam using 3/8 aluminum plates and linear rails / ballscrews

Build Author

Christian James

Views

10005

Build Author

Christian James

Views

10005

Workbee "style" 1010 cnc

This build is based on the Workbee 1010 CNC. It is not a kit build and is much the same as the original but with some significant changes made here and there as the build progresses.

Build Author

Jay Almers

Views

8054

Build Author

Jay Almers

Views

8054

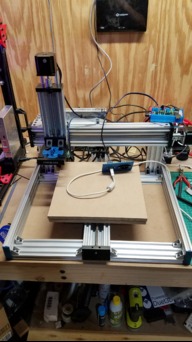

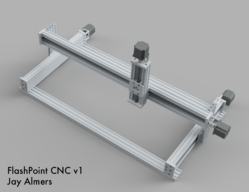

FlashPoint CNC v1: 500mm x 1000mm 3-Axis CNC Router

My build is based on many different builds but pieced together into a unit specifically to suit my needs. The footprint, without motors, is around 500mm x 1000mm with a gantry height of around 250mm. I used a combination of C-Beam, for the linear transmission, and V-Slot for the base and gantry supports. Forged angle connectors were used for attachment and I utilized the C-Beam gantry cart kits with anti-backlash blocks for both Y axes, the X axis, and Z axis.

Build Author

patnap71

Views

6920

Build Author

patnap71

Views

6920

MEGADELTA, TLM CLONE with 500MM bed

All metal frame 500mm bed Delta 3D printer

CBeam Sphinx Upgrade

Simple upgrade of the Y axis on a Cbeam sphinx from 500mm to 1000mm.

A More Rigid C-Beam

I added the steel to create a less flexible milling surface to make heavier cuts in aluminum. I can also do light steel cutting now as well. I wish OpenBuilds made a steel and rail version of these kits.

Rise of the Sphoenix

I am building a Sphinx 55 from the bones of my old C-Beam machine. Rising from the ashes so to speak.

Build Author

tmadrms

Views

7744

Build Author

tmadrms

Views

7744

C-Beam Mods

C-beam machine mods.

Build Author

Joe F

Views

8527

Build Author

Joe F

Views

8527

Rack and Pinion Cartesian Mill

This is a rework of a previous build I did on here, a mostly printed cartesian CNC. Initially intended to just be an update to that, but so many things changed including the linear motion and every single part has been modified significantly that I felt as though it deserved a whole new build.

My C-Beam machine...

A C-Beam machine design, strengthened with extra brackets and plates. GRBL controlled, opto-isolated inputs, jogging box.

My C-Beam machine...from 500 to 1000mm base

C-Beam machine - 1000mm base.

Model train lift - scale HO

This build is about a model train lift in a secure and dust free storage. It is a roll on/roll off concept for a model train layout.

Another C-Beam machine

This is basically a Sphinx variant with few changes of my own...hope it'll work.

Build Author

Steve Hall

Views

4186

Build Author

Steve Hall

Views

4186

Cartesian Style Build UK

Another Cartesian style build with parts from the UK, US & China.

My C-Beam build and modifications

Modified C-Beam which I plan to add a laser module and eventually convert to C-Beam XL size.

C-beam charmer

Double C-beam Y axis 500mm., Double 2080 X axis 600mm. , C-beam Z axis 250mm, TB-6600 drivers, MKS-DLC32v2 GRBL w/wi-fi and blue tooth

Y table for LEAD Lathe - essentially a High Z Cbeam XL

I built the lathe as a dedicated rotary axis, but I soon realized I could have a back up CNC for very little expense.

Build Author

Cam Garrett

Views

4082

Build Author

Cam Garrett

Views

4082

Sturdy Motorized Photographic Copy Stand

i would like to build a sturdy motorized photographic copy stand. i have hobbled together a hand crank version using a used umbrella pole but it is not suitable as it is awkward and wobbly.