Build List

-

Active Filters:

3

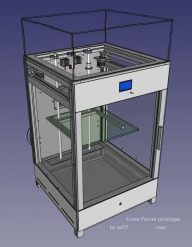

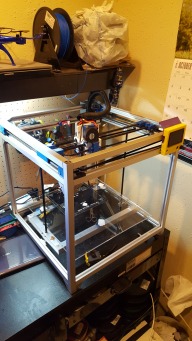

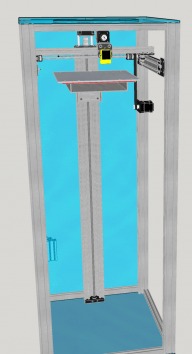

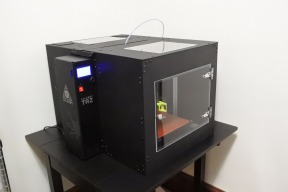

Tower Printer

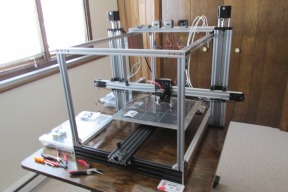

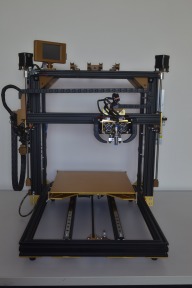

Tower Printer H-Belt type printer Prototype

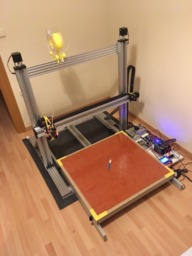

Large 3D printer

Hello ! This is my very first OpenBuilds build. It's based on the Maximus 3D Printer, published by mytechno3d : good source of inspiration !

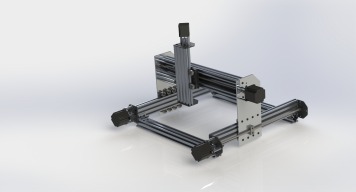

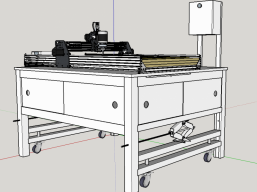

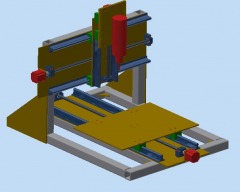

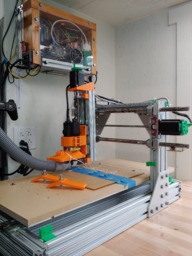

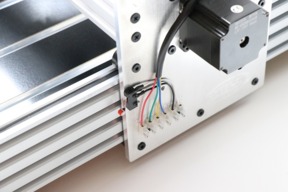

The MULE (an OX inspired 3-axis CNC)

The Mule is a 3-axis CNC inspired by the OX CNC by Mark Carew. This machine borrows the OX's sturdy frame and upgrades the X and Y linear actuators through the use of three 500mm lead screws (as opposed to the belt system of the OX). The result is an inexpensive, sturdy, and powerful design built for cutting tough materials such as aluminum.

Build Author

Nwrgordon

Views

15831

Build Author

Nwrgordon

Views

15831

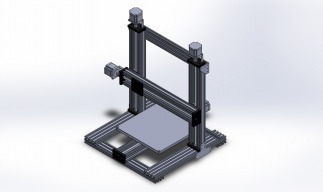

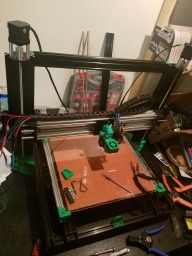

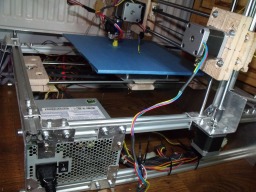

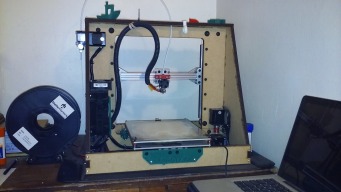

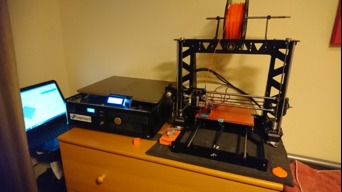

RepRap Intro

An easy Epic Win for novice engineers new to the RepRap project www.3distributed.com

Build Author

Julius

Views

8158

Build Author

Julius

Views

8158

The "Hand" CNC (or OXCarve)

more to come, please follow along the journey!

Desktop CNC

This unit is made with openbuild v-rail and c-beam. using direct drive with lead screws. Nema23 motors

bertha

This build will hopefully be 18x18x24 build space using RAMPS 1.4 with Marlin firmware. Using NEMA 17 motors and belts to drive the X and Y axis, lead screws for the Z axis. The build plate will be heated with a delrin Y carriage for the glass and heatbed. Z axis motors will be top mounted. Possibly and ATX power supply.

Build Author

Cbrown330

Views

5344

Build Author

Cbrown330

Views

5344

Big 3d Printer, Big Brown

This is a big 609 x 609 x 914 3d pritner with exchangable hot ends and extruders.

Build Author

Colin Russon

Views

9340

Build Author

Colin Russon

Views

9340

OX / X3 CNC / Similar Z axis / 1605 Linear Actuator

Z axes 1605 ballscrew, a comparative design proposal.

Build Author

Paruk

Views

23005

Build Author

Paruk

Views

23005

Buffal-O-Tron

A 3D Scanning Station

Build Author

Keteland

Views

10664

Build Author

Keteland

Views

10664

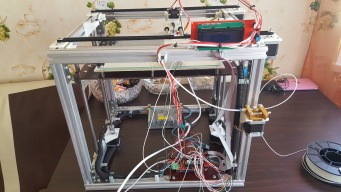

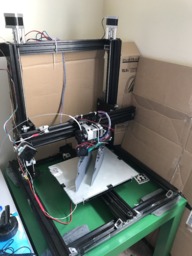

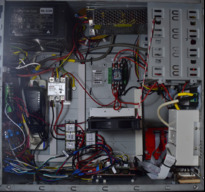

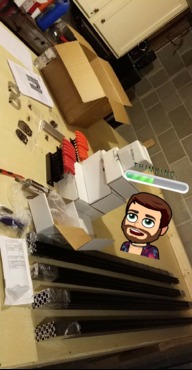

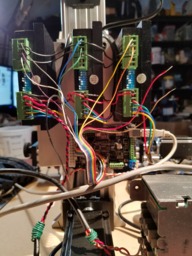

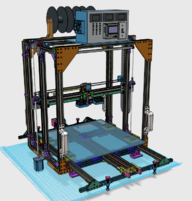

MULIMATERIAL 3D PRINTER (in progress)

ELECTRONICS - ARDUINO Mega 2560 + RAMPS 1.4 + power supply 12V - Leadshine DM 5042 external driver + Power supply 36V + NEMA 23 stepper motor SOFTWARE - Repetier Host to communicate with the Ramps - ARDUINO to upload the firmware (Marlin) MECANIC - V-Slots rails 40x40 + home-made plates - everything goes fine on the side of the build

Build Author

Anthony Bolgar

Views

11957

Build Author

Anthony Bolgar

Views

11957

L'FOX - Large Format OX deriviative. Designed and built by Revision 13 Prototypes

This build is for a testing rig to use while testing out different controller boards and CAM software for milling and routing. It is in the early stages, planning is complete, parts are ordered. Awaiting parts delivery to start build. Please not the BOM only covers parts from the OpenBuilds part store. I will be posting the other required items very shortly.

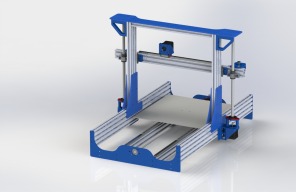

XDrive 3d Printer

XDrive 3d printer, high quality large build volume.

Build Author

UltiBots

Views

10504

Build Author

UltiBots

Views

10504

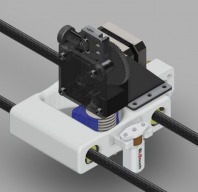

Machined Aluminum MagBall Carriages

Machined Aluminum MagBall Carriages

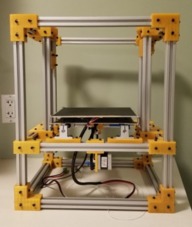

Core XY My-BOT 500 x 500 x 1000

My first construction after many years buys ready devices.

C-Beam Big Mouth

My first build was with the basic C-Beam Build. I soon found the z clearance a little constricting So I added 2 500 mm actuators to support the x axis rail . I also left off the front and back y axis support rails for easy cleaning. I mounted the base of the machine to 1/2" mdf with 10/32 screws and blind nuts.

Build Author

Rwetzler

Views

9295

Build Author

Rwetzler

Views

9295

C-Beam Prototype

This is a variant of a typical OX (Mark Carew inspiration) router using C-Beams/8mm Acme rods to drive all three axis. I went with a 1000mm x 1000mm frame size. Useable space is 28" (711mm) X 26" (660mm) with a Z axis work travel of approx. 3.25" (82.5mm). A TinyG is used as a controller along with Fusion 360/Chilipper as the software for generating and running gcode files.

Build Author

griso

Views

9188

Build Author

griso

Views

9188

3d nika

Over 840 parts. Of whom around 450 are screws and nuts, more than 100 parts are printed on a 3D printer, the frame consists of about 60 components. There is nearly 40 electrical components connected with tens of meters of wires, most of them sleeved.

Dream to practical

This is my journey from a dream machine to a practical (for me) machine. This is a Cartesian style frame that can change tool heads quickly. The first version will have milling and 3D printing tool heads. Later on I'll add a drag knife tool head.

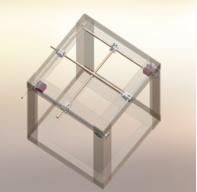

CoreXY Cubish

A dual extrusion CoreXY printer with a 290 X 290mm build volume built entirely out of 2020 aluminum extrusion and using openbuilds mini-carriages for motion.

My C-Beam 3D Printer

Larger format FDM printer using C-Beam linear stages

Build Author

William Niedermeyer

Views

19506

Build Author

William Niedermeyer

Views

19506

Structured Light Turntable Scanner

3d Structured Light Scanner with Arduino Controlled Turntable

Zen3D Atlantis 3D printer, H-Bot mechanics

H-Bot mechanics 3D printer. Build volume - 300x300x300mm dimensions: 560x500x500mm

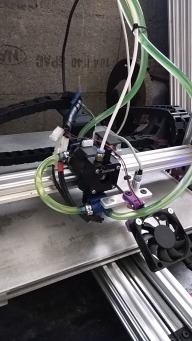

Watercooled 3D printer : Maximus Evo Rev 2

Watercooled 3D printer

Build Author

Simon Rafferty

Views

7516

Build Author

Simon Rafferty

Views

7516

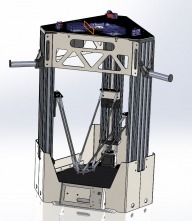

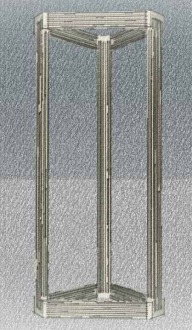

Rigid Delta

A Rigid Delta Printer using C-Beam screw actuators

MOJO 3D

Fast, Large build area, CoreXY design

Build Author

Edgar Robles

Views

4065

Build Author

Edgar Robles

Views

4065

Sheethexapod

Sheethexapod works with basic mechanims as direct metal-metal links and joints, all movements can be done by a rc servomotor in this case towerpro model.

Build Author

Power Playground

Views

4799

Build Author

Power Playground

Views

4799

PowerBot

This is my own modified version of the D-Bot printer. I wanted to spec this printer to be able to print exotic materials at high accuracy with little to no compromises and maximum reliability.

delta 3d printer kit

HE3D K200 kit build

Another 3D Printer using OpenBuilds Hardware only

A light 3D printer made of OpenBuilds hardware only

SUPER OX NEMA 34 1600 OZ Motors!!!

CNC OX 1500X3000

Build Author

sgspenceley

Views

8816

Build Author

sgspenceley

Views

8816

LinearRail - 3D Printer

I have re-purposed many of the parts from my Linear OX build. I'm using MGN 12 linear rails on all three axis, 5 start lead screws on the Z axis and I'm going to experiment with 5 start lead screw on the X axis. The frame plates are made from 1/8" laser cut mild steel, & open builds extrusion.

Build Author

Ken376

Views

3705

Build Author

Ken376

Views

3705

Welded project cnc first try

Kind of hard to see in this pic now lining up drive s and finishing framework

Build Author

dodgenet

Views

6528

Build Author

dodgenet

Views

6528

Budget 1500mm OpenBuilds V-Slot Deltabot Build

This 1500mm tall Delta is a work in progress. The triangle corners are water jetted from 1" 6061 Aluminum, and are welded to 1" square tubing. The 1500mm OpenBuilds 20x20 V-Slot extrusions are held into the corner brackets by two stainless steel set screws per bracket. This printer will need to be reinforced with wall brackets due to the combination of height/materials.

Build Author

TouchPadKing

Views

5068

Build Author

TouchPadKing

Views

5068

1500mmx500mm Kossel Delta

Please, look over my build and make any recommendations you can think of! I haven't figured out how long my arms need to be yet. Nor have I done any shopping around to find better prices...

Large Delta Printer made from scrap 80/20

This printer will leverage scrap pieces around the shop to fulfill a single print's needs. It will use a combination of 80/20, OpenBuilds, and 3D printed parts.

Old Faithful...FDM/CNC machine

I've owned some pretty unreliable printers, and I'll leave it at that... This design comes from the need to have a 3D printer that is reliable, period. I didn't have the money for a several thousand dollar 3d printer with an equivalent build area so that was out of the question. Plus as a fledgling Engineer, I really wanted to blood myself on a project. And that's how Old Faithful came to be. A simple, reliable, rigid, durable machine. Made by me :) Also, it'll be tough enough for light CNC.

Build Author

Linkreincarnate

Views

3095

Build Author

Linkreincarnate

Views

3095

Amazon Special

I have parts that are apparently not suited to a cnc router or a 3d printer. I am still trying to figure out what to make out of what I have,

Large 3D printer 12"x12"x12" with heated bed

I want to have a printer to support senior projects. Also working on supporting 3D printing needs in the local community.

My 3D Printer

A DIY 3D printer. At beginning made from aluminium profiles, aluminium sheet and wood :)

Build Author

Kyo

Views

6483

Build Author

Kyo

Views

6483

C-beam Delta Printer

Large scale delta robot using c-beam as the core frame component.

Build Author

taratata2016

Views

8479

Build Author

taratata2016

Views

8479

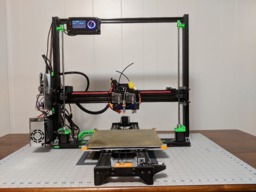

Panther 3D printer

After use of the i3 Prusa 200x200x180, the volume increases to 300x300x450 on the V-Slot and driven by a Megatronics V3

Build Author

Limine3D

Views

8507

Build Author

Limine3D

Views

8507

M3D Squared

A cartesian build with a build dimension of 200x200x750mm. I will be using a dual extruder, heated build plate, and a screw drive for the z axis.

Build Author

Makerparts

Views

7647

Build Author

Makerparts

Views

7647

DIY Multi Row Nodal Point Spherical Panorama Head

DIY Pano Head

Build Author

Tom Dirriwachter

Views

7310

Build Author

Tom Dirriwachter

Views

7310

3DS Cube 3 Modular Extruder

How to modularize the 3D Systems Cube 3 extruder nozzle.

Build Author

McAdam

Views

3704

Build Author

McAdam

Views

3704

Need a catchy name - enlarging CNC

The aim of this build is to have a CNC that can cut a FULL sheet of wood when I need it to, but also shrink down and cut smaller sheets the rest of the time. The prototype is based on an OX cnc but soon it will be completely custom using Openbuilds Parts

Build Author

Matt Barile

Views

7404

Build Author

Matt Barile

Views

7404

Fixed Gantry Welded Steel Router

Fully welded, fixed gantry CNC router, with chinese linear motion parts, in progress

VoS

3D Printer based upon 3d printed parts and open builds componets

Build Author

J-Wahl Dezign

Views

9098

Build Author

J-Wahl Dezign

Views

9098

1.4 meter tall build height, 300x410mm build plate cartesian

The original plan was to build a 3d printer with a 1200x1200 build platform with a 600mm build height. I was having issues getting ahold of a large enough borosilicate glass plate for the build so I decided to go for build height. I plan on using a smoothieboard for the controller. The build has currently slowed down. I was removing a broken drillbit from the linear rail mount, and it shattered and took out my eye. I am doing what I can when I can focus my eyes long enough for the build.

Build Author

3D Meister

Views

5436

Build Author

3D Meister

Views

5436

Camera slider with rotation prototype

I made a cam slider prototype with adjustable rotation to get experience for my CNC milled slider in planing.

Build Author

recoush

Views

9147

Build Author

recoush

Views

9147

CoreXY 3D build one

an 8020 build with 1010 extrusion (1") Square tubing Rough size is 24x24x36 (600x600x900) The expected usable print area 21.5x21.5X32"roughly (510x510x760) An XY 3D printer with 3 extruders and 3 Z-axis 0.9 degree motors the table (Z-AXIS) will lift up to the XY Carriage on 3 12mm linear rod and 3 8mm Lead screw's Corexy designs complete and Z-axis build is started don’t have a 3D cad system yet so building my prototypes on a pcb layout tool

Build Author

Jonathon Duerig

Views

7154

Build Author

Jonathon Duerig

Views

7154

Chrysalis: An Enclosure for TAZ 6 3d Printers

Aluminum-framed enclosure for TAZ 6 3d Printer made with Makerlink.

Build Author

nschreiber0813

Views

5438

Build Author

nschreiber0813

Views

5438

Schreibotics Fabricator MkII

It all started after my prusa i3 build inspired me to experiment with resin 3D printers because I want to learn if they are worth it and if I can design my own printer.

eTrueUp Glide

A TrueUp Glide modified to use 20x40 V-Slot with a 300x300 bed.

Build Author

Tomas F Uribe

Views

5298

Build Author

Tomas F Uribe

Views

5298

Atucnc

2 1/2 axis CNC chassis. Convertible to plasma, 3D printer and welder. Currently used as router. Plotting table dim: X axis 620 mm, Y 650 mm, Z 100 mm. Created for teaching purposes, open source license, currently used for engraving ukiyo-e wood plates and printmaking

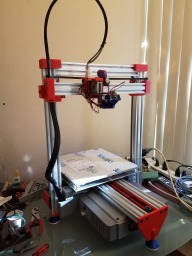

My first printer

My first printer! I went for a simple cartesian design, based on evilc66 one. It uses 1000 mm C-beam linear actuators. The build volume is 700x700x700 mm^3.

Build Author

islahcnc

Views

4415

Build Author

islahcnc

Views

4415

islahcnc&design

I will post soon some more details.

HUGE 3D printer build

just wanted to share my build of a huge 3d printer. It stands just over 2 meters tall and has a total print area of around 850mm x 850mm.

Skyggen 3D Printer

GT2 belt-driven Cartesian 3D Printer on an OpenBuilds Extrusion gantry, developed through Autodesk Fusion 360.

Norm Inverted - Cartesian

As a tinkerer and hobbyist I need a reliable quality printer on a budget... Meaning I'm not looking to buy a: Prusa, Zortrax or LulzBot because of the added cost their marketing adds. I can definitely build a machine of hopefully equal quality at a lower cost that is not impacted by the marked-up priced from a large reputable manufacturer. I will need to dedicate time and more time for design shakedowns to ensure I produce a quality machine. Bare with me on this build... Thanks!

OX, of the house Steel

OOZNEST Style OX machine with 3D printed panels

First CoreXY Build

First CoreXY. Simple Square build, hopes for faster movements.

Build Author

Scotty Orr

Views

11519

Build Author

Scotty Orr

Views

11519

QuorXZ: A String-driven, Core XZ Printer

The QuorXZ doesn't magically appear. It's gestation takes time, careful attention, and requires many parts. However, when it is ready, a magical, mechanical instrument is born....(and when you finally say its name, it sounds a little bit like "corks").

First Ever Build

This is my first attempt at building my own 3d printer.

Build Author

Jeremiah Guinn

Views

5805

Build Author

Jeremiah Guinn

Views

5805

OX CNC SMW3d 1500x1500

A small business idea led us here, lets see where it will go.

Build Author

Tucstrlly

Views

9001

Build Author

Tucstrlly

Views

9001

Stainless OX Kit Build "Diamondback CNC"

A copy of the Stainless Ox by Martin Barfoed. Similar design, construction and control.

ivern

Toying around a concept. Inputs are welcome on whether to use lead screw or belt drive. My lead screw will be single start 500 mm lenght, 2 mm pitch and 2 mm lead. Nema 17 motors will be used. All veterans, suggestions please.

Ancient Roland Table top Mill

The parts are now very reasonable.

Build Author

patdee

Views

5051

Build Author

patdee

Views

5051

777 CNC Build

To begin the "Build" I have ordered a few parts from OpenBuilds to get started. They are arriving today; according to "tracking". I cant wait! Praise Jesus! This 85 yr old man is getting a "New " life. Hallelujah and amen. Because I am building this on an existing machine, I have to be careful; so I will order some parts then see what I don't need (such as a base); along with parts that I may need to adapt it to the machine. It should be fun! "Caint wait!"

Core XY

Just now in the planning phase of my build. Waiting for some parts to come in to see what I am going to build off of. Print area going to be close to 300x300x350. Trying to decide if I want it enclosed. I do want to print ABS... so probably so.

Build Author

ZacharyB

Views

5697

Build Author

ZacharyB

Views

5697

Arizona OpenBuilds MiniMill CNC

I ordered the OpenBuilds MiniMill from the OpenBuilds Parts Store http://openbuildspartstore.com/ They were out of Motors and Electronics when I ordered so I had to source these items elsewhere. But it turned out well doing it this way.

Build Author

Terone Burgenheim

Views

2790

Build Author

Terone Burgenheim

Views

2790

My CNC

This build is my version of the CBeam machine. I opted to NOT use the Gussets, and instead went for the 40, and 60 mil angle brackets to cut the price back a little further. I started with the smoothieboard but decided it was still "too new" and very much experimental. This build took me a few (2-3) days to complete. The CBeams and Lead-Screws really make building things faster since you don't have to clamor over belts.

Build Author

GDanger117

Views

12245

Build Author

GDanger117

Views

12245

Gantry CNC - Decisions made only to change over and over.

This is my first CNC build. As per the norm, I went in with months of research, planning, and resource gathering tied neatly together with a solid plan. As the path went on, the plan continued to change to accommodate issues I hadn't counted on. But, at the end of the road, the project reached completion, and I learned a ton along the way!

Build Author

Lindsey Lewis

Views

8929

Build Author

Lindsey Lewis

Views

8929

Update Eleksmaker with Openbuild eccentrics for X-Carriage

A simple approach to making the Eleksmaker A3 Laser build have a better functioning X-Carriage! Of course this assumes you bought an Eleksmaker A3 or plan to.

Build Author

Bill325

Views

2306

Build Author

Bill325

Views

2306

One more life for a cube

Modify a Gen1 Cube printer into a small cnc router to cut pcbs and light (VERY light) milling work. Also easy to swap out the rotary head and mount a laser head for engraving.

Build Author

Nicademus

Views

9468

Build Author

Nicademus

Views

9468

CNC/3DPrint/Laser/Mill (formerly CNC-inator3000)

Ultimately - the design is based on the highly successful Ultimaker concept, for which a regular size costs in the thousands, and one of this size would be edging into the 10's of thousands. Expected Build cost - <$800 It is a X/Y Cartesian printer with Raising/Lowering Z axis (Hotbed.) - Overall size is 610mm x 610mm x 750mm - with build volume of around 450mmx450mmx450mm - and will also have the ability to change work tools - such as for CNC Routing, Lazer etching, 3d Scanning, etc.

Build Author

Rob Withoff

Views

5008

Build Author

Rob Withoff

Views

5008

Mini-Mill Enhanced

Some enhancements of the basic mini-mill

Build Author

TurfnSurf

Views

6174

Build Author

TurfnSurf

Views

6174

3-Axis Plywood CNC

Theoretical Working area: 38" x 24" x 6" Actual Working Area: 31" x 23.6" x 4" Positioning Accuracy: about 0.01mm

Build Author

MattR

Views

19889

Build Author

MattR

Views

19889

Fixed Gantry CNC Router with Old Industrial Supplies

I got lucky enough to purchase aluminum extrusions and linear motion components (and nuts/bolts/etc) at scrap metal prices when a bunch of industrial automation equipment was decommissioned. The only problem is that the aluminum extrusions are not metric sizes... they are the 1.5"x3" 80/20 series. It has presented a few challenges but nothing too bad.

Build Author

Connor Mckeown

Views

6330

Build Author

Connor Mckeown

Views

6330

My Prusa Build

The process from my bought printer, to a custom home built machine

Build Author

Liam Dahler

Views

6459

Build Author

Liam Dahler

Views

6459

Affordable Cartesian Printer (Initial Design)

This specific build page is a collection of screenshots sampling some of my initial SolidWorks design and pictures showing physical construction of the initial design. I will be creating individual build articles as I redesign, test, and implement new aspects of the printer.

Build Author

BinaryConstruct

Views

10146

Build Author

BinaryConstruct

Views

10146

BinaryConstruct V3

This printer is a design that has evolved over three years. The original goals of this project were to design a rigid printer that had a large print volume, 300mm^3, with easily sources parts and a minimum of complicated printed parts.

Build Author

h3rb

Views

3698

Build Author

h3rb

Views

3698

TEVO Little Monster Marine Vinyl Removable Enclosure

Make a vinyl burrito ENCLOSURE for your TEVO LITTLE MONSTER for < $30 (<$20 if you don't have your vinyl shipped!)

Build Author

h3rb

Views

5638

Build Author

h3rb

Views

5638

TEVO Little Monster Direct Mount Extruder

Cheap, experimental Modification to Tevo Little Monster's bowden system for the extruder

Voxel Evolution

This is a remix of Marshal Peck's Voxel OX, with some design tweaks inspired by Makerparts and jjcolletta. It has a build area of 300mm X 300mm X 480mm, but is easily configured for just about any build area up to 500mm X 500mm X 750mm. I have used some laser cut acrylic plates and a couple of 3D printed parts in its construction, however it can be assembled using nothing but OpenBuilds parts with the exception of the heated bed and the Y axis carrier for the heated bed.

Build Author

Kevr102

Views

5754

Build Author

Kevr102

Views

5754

Ooznest Ox CNC 1000 x 750

A few mods on my Ooznest supplied Ox cnc Encountered a few minor issues along the way but now all sorted.

Build Author

Brandon Satterfield

Views

7655

Build Author

Brandon Satterfield

Views

7655

SMW3D OX

The SMW3D OX, original other than a lot of learning!

DPR-v2 full metal

pictures and mony doku see later

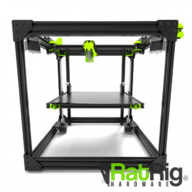

Build Author

Rat Rig

Views

31362

Build Author

Rat Rig

Views

31362

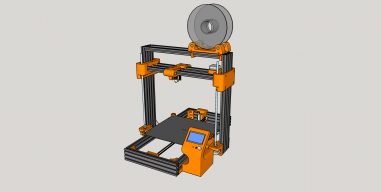

Rat Rig V-Core 3D Printer ( Core XY )

Fully OpenBuilds based Core XY printer design by Rat Rig. CAD files, build manual, build videos available!

V5- 2in1 ( 3dPrint+laser Engraving )

2in1 ( 3dPrint+laser Engraving )

Build Author

JerwanDavis

Views

6026

Build Author

JerwanDavis

Views

6026

Coined by my family as the: Davomatic

Build Notes: Here are all the parts necessary to re-produce this design. Please note, all of the parts are either sourced through openbuilds or have been selected and printed from thingiverse.

Build Author

Mark Carew

Views

16878

Build Author

Mark Carew

Views

16878

C-Beam XLarge X/Y Table

This OpenBuilds C-Beam XLarge X/Y Table is a great display of how easy it is to modify and create awesome configurations with the OpenBuilds system!

Build Author

Mark Carew

Views

18212

Build Author

Mark Carew

Views

18212

Nema 23 Belt and Pinion Actuator

This easy to build and effective system can take your builds to the next level! This design is strong and accurate and could be the solution/upgrade that you've been looking for!

Galvos

3d printable galvos

Design and Performance Evaluation of A Large FDM 3D Printer

This build includes the design of a large FDM 3D printer. This machine has a 796mm by 796mm by 900mm (LxWxH) build volume. Motion is controlled by servo motors and the printer runs on python-based marlin firmware.

CNC Lathe Upgrade

So, not much here, as I'm still building, but I'm putting in the work.

Build Author

Rob Taylor

Views

10793

Build Author

Rob Taylor

Views

10793

Grizzly G0758 Benchtop Mill Conversion

A proper CNC mill conversion. But quite small, with my trademark idiosyncracies.

26 x 26 x 45 3D Printer/Mill

Super tall 3D printer. All lead screw design.

Build Author

Bob Darrow

Views

9957

Build Author

Bob Darrow

Views

9957

BA3DP

A slightly more than one half cubic meter 3D Printer using V Rails, V Rollers, "C" Rail, mounting plates, and a bunch of 3D printed brackets to provide strength and stability to the frame. Rigidity was the goal and precision and accuracy the result. The software is a whole other topic, many weeks spent dialing that in to make the printer print.

Brice's CNC Router Build

I'm building a CNC router for a long time. Here's the result on this long journee. I tried to do my best with the basic tools I have. Don't hesitate to ask if you have questions.