Build List

-

Active Filters:

8

Build Author

roadss

Views

26183

Build Author

roadss

Views

26183

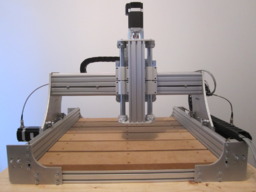

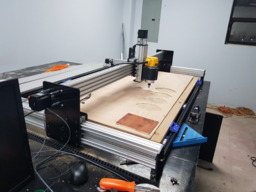

Rawcnc 1.5 Desktop Edition

This will showcase the build of my Rawcnc 1.5. A rigid cnc router from the Swedish company Rawcnc, featuring a rather cool linear motion system, rack & pinion and steel reinforced X-axis capable of milling aluminum.

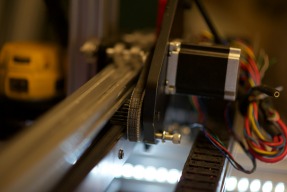

Custom build 80w Co2 Laser Cutter

Building a custom made 80W Co2 Laser cutter. Making it from scratch and it's a work in progress but I've learned a lot and I'll be sharing a bit of that knowledge with you guys since I've learned a lot from here.

Build Author

Mark Carew

Views

65408

Build Author

Mark Carew

Views

65408

V-Slot NEMA 23 Linear Actuator (Lead Screw)

Learn to build a super strong nema 23 lead driven linear actuator

Build Author

ymilord

Views

22364

Build Author

ymilord

Views

22364

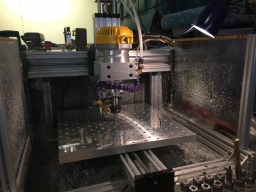

C-Beam Rigid - 'The Hog'

C-Beam Machine baseline build. DW618 Spindle. SuperPID. Gcode Controlled Mist Coolant. Rigid Work Surface. NEMA 23 (425oz-in) Leadshine 4 Axis Stepper Driver. LinuxCNC (MachineKit) Tool Touch Off Probe.

Build Author

dddman

Views

13724

Build Author

dddman

Views

13724

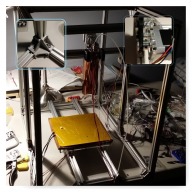

Prusa i3 (Acrylic frame with OB rods)

The Prusa i3 (iteration 3) is the newest and most current 3D Printer design by RepRap Core Developer Prusajr (source: http://reprap.org/wiki/Prusa_i3)

Build Author

Darren Ditto

Views

10784

Build Author

Darren Ditto

Views

10784

V 1.4 - Bright Box Cartesian Printer - *BUILD PROGRESS PICTURES

Cartesian Printer, 200mm x 200mm x 380mm build area, enclosed, belt and pinion movement, heated bed, Raspberry Pi, Pi Cam, OctoPrint

Build Author

JWhitten

Views

14247

Build Author

JWhitten

Views

14247

Build #2 - Bigger & Stronger

Large format CNC router with a 1500mm x 3000mm cutting envelope (5 x 10 ft) strong enough to cut wood and aluminum constructed from 20-series and 40-series aluminum extrusions. Complete Project Log w/ Pictures: https://goo.gl/photos/Co81AvGwVijE2zow9

Build Author

DiggerJ

Views

8857

Build Author

DiggerJ

Views

8857

Babe - The Big Blue (Laser) OX Build

A 1000 x 1500 OX build with the ability to router cut dovetails as well as laser engraving and light cutting.

Build Author

Paul Amelang

Views

5900

Build Author

Paul Amelang

Views

5900

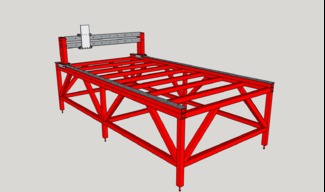

4x8 CNC Router for Composites

Router for making plugs for composite part production, and for cutting CFRP.

Build Author

nickchnv

Views

12729

Build Author

nickchnv

Views

12729

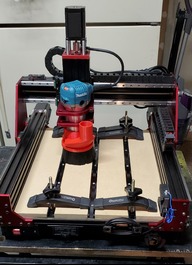

Rigid Compact Desktop C-BEAM

This modified C-Beam, is a compact, powerful and affordable desktop CNC.

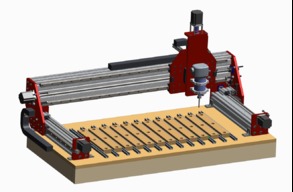

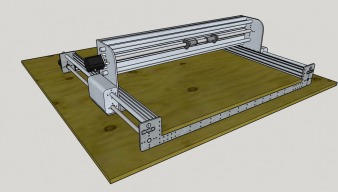

Prototype Rack-n-Pinion 4'x8'

This is a custom gear rack drive machine with a 4'x8' cut capacity.

Based on 608 tube Plasma Cutter

Simple steel tube design Plasma water table

Build Author

Andrew Helsel

Views

12281

Build Author

Andrew Helsel

Views

12281

MiniMill Smoothie

MiniMill with DW611 and SmoothieBoard 4x v1.1

Build Author

Venturebit

Views

13992

Build Author

Venturebit

Views

13992

SHRED-Buddy3D UPcycler - Open Source Multi Material Cutter&Pelletizer

The whole system is powered by 12V / DC power. Process it into Pellets or Granules to use it with your 3D Printer or Filament Extruder. Our self-developed steppermotor Controls allows you to optimally adjust Feedrate for your Situation. Forward, Backward and Stop is integrated for easy operation. The Speed can be continuously regulated via rotary switch.

Build Author

Sonny Lowe

Views

17329

Build Author

Sonny Lowe

Views

17329

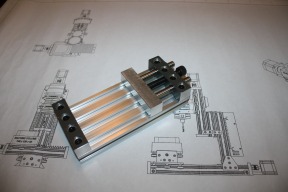

MakerSL MSL-8 OB Vise

Small Machining Vise designed around 20x80 Openbuilds Rail System

Build Author

Gerrald

Views

6447

Build Author

Gerrald

Views

6447

Pong CNC

This build is to show what's possible as well with openBuilds! I use a single ArduinoMega and 5 separate stepper drivers (A4988). The LEDs are all NeoPixels. Collision 'detection' is all done within the code, so the endstops are only sensors I use in this build. I'm a self-employed video-artist and this is my first installation which just needs power and it runs (where I'm quite proud of). Normally my interactive installations take a long setup time, so this installation is a relief :)

OpenBuilds OX 48x48 Aluminum

Variant on the OpenBuilds OX CNC Router, enlarged with 1500mm length beams for a cutting area of 48" x 48". Based on the original model, the larger of the two, with the addition of a third 20x60 beam on the gantry for strength. Estimated cost is around $1100, minus the router.

Build Author

Sonny Lowe

Views

10927

Build Author

Sonny Lowe

Views

10927

Folger-Tech Y-Carriage

This a redesign of the Folger-Tech Y-Carriage using the Solid V-Wheels, Ball Bearings, the V-Slot Rail System.

Openbuilds Co2 80w Laser Cutter

Co2 80 watt openbuilds laser cutter, 1200mm laser tube, 1500x1000x500mm dimensions. Build frame first and then panels to be added.

INDY-TR12 CNC (12mm Diameter Lead Screws)

TR12x3 screws, M8 wheel sets, a draw built into the design, an electronics set built onto the kit, back brace to stop C-Beam twist.

Build Author

Dave420

Views

6217

Build Author

Dave420

Views

6217

Dave's Z axis and powder coated.

I just did my first Powder coat paint job on a Z Axis with 9inchs of travel for the DIY CNC Plasma Cutter, Mill Head, Router, Engraver, Laser Head, Water Jet Cutter Machine. 2 different Z Axis ride plates and a 80mm Router/Mill Head/Spindle clamp. Baked on finish in a old oven i had.

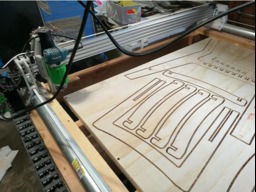

Openbuilds 4x8 cnc

I built this cnc using 2 z axis actuators thinking it would minimize deflection and it seems to be very sturdy. I used 2 1500mm c channels for my x axis, 1 1500mm c channel for my y axis, nema 23 stepper motors, dm556 drivers, 2 24v power supplies, smc5-5-n-n controller, 9mm wide belts, and the Hitachi m12vc router. So far it's working very well with a few hiccups. Programming the controller was a learning experience but I'm very happy with it.

Build Author

ymilord

Views

12800

Build Author

ymilord

Views

12800

Kyoujin Mk1 (C-Beam /w Rack & Pinion)

C-Beam based CNC with Rack & Pinion (for the X Axis) and lead screws (for the Y Axis)

Build Author

Wes Dwight

Views

7876

Build Author

Wes Dwight

Views

7876

Modified Sphinx 55 with MGN12 linear rails

Inspired by previous Sphinx builds by Sorin (w/ MGN Rails) and Kenneth's witthuhnCNC XKLBR-1S. I wanted to create a desktop unit that kept a minimal profile and neatly contained the PS, Controller, and all wiring, making it a singular unit that could be easily transportable (as it will be doing double duty at my home and at work)

Plastic Monstrosity

Large inexpensive build that can cut a 4x8 ft sheet with room to spare. Can be built using only a 3D printer and standard parts -- no special CNC'd plates required.

X Axis Upgrade for AM8 (ANET All Metal)

My goal is to upgrade the acrylic ANET A8 to all metal.

Build Author

Rob Taylor

Views

11113

Build Author

Rob Taylor

Views

11113

Grizzly G0758 Benchtop Mill Conversion

A proper CNC mill conversion. But quite small, with my trademark idiosyncracies.

Build Author

TurfnSurf

Views

6276

Build Author

TurfnSurf

Views

6276

3-Axis Plywood CNC

Theoretical Working area: 38" x 24" x 6" Actual Working Area: 31" x 23.6" x 4" Positioning Accuracy: about 0.01mm

Workbee 1015 (50" wide by 30")

A Workbee able to cut 48"x24" material, built to continuously feed material so one can cut full sheets of ply.

Rigidbot Big with glass bed

Started with a Rigidbot Big Added a single flat glass bed Used a Smoothieboard clone driving DRV8825

Build Author

Steven Sampson

Views

11013

Build Author

Steven Sampson

Views

11013

RiNo Route

A CNC router designed to handle a 4'x8' sheet, for as close to $2000 as possible. The price barrier resulted in my choice to use timing belts rather than leadscrews or rack&pinion. Build List still being updated

Build Author

DaleShaw

Views

4559

Build Author

DaleShaw

Views

4559

Senior Project CNC table

So for my senior project I decided to build a CNC router. I kind of need to get this done before May so we'll see what all goes down. It's going to be a 3 axis machine (for now) and will be able to handle 4x8 sheets of wood. This is my first build. It's going to be intresting..

1250x1000 Build

A new design of my based on a couple different machines I have seen both on openbuilds and youtube. In the end will have a and X/Y workspace of 1250mm x 1000mm and a Z axis range of about 200mm.

McRouter 3 Axis CNC

I wanted to put together a medium size router using PTFE slides from McMaster-Carr. I've had great experience with these slides in long term continuous motion operations in industrial environments.

Bored in the garage enclosure build

2 days to build Up and running some EMI issues but I think I have them resolved Big shoutout to the community

OXilla - a 3ft x 3ft CNC Router/Mill - Goals are strength, power and speed

This will be an ongoing log as I build this machine. Name change by popular demand - at least a couple of us. :)

Hybrid OX (Ball Screw, Linear Guides, Ect.)

Planning my first build. Hope to achieve a larger format yet rigid design.

Build Author

Steve Hall

Views

4233

Build Author

Steve Hall

Views

4233

Cartesian Style Build UK

Another Cartesian style build with parts from the UK, US & China.

Build Author

Suhmanda

Views

4391

Build Author

Suhmanda

Views

4391

DIY CNC SPINDLE

CNC SPINDLE FOR DIY ROUTERS AND MILLING MACHINES ITSRS-985 MOTOR HAS MUCH BEFINITS THAN ANY OTHER DC MOTOR IN MARKET

5 x 10 CNC - Sub $3000 - Wall Mountable

I wanted a 5 x 10, Wall mounted CNC, that cost less than $3000. I think Im pretty close.

Build Author

SecretSpy711

Views

22800

Build Author

SecretSpy711

Views

22800

RigidOko

Heavily upgrading my 1200x500 Shapeoko 2... ...er, wait, scratch that... Building an all new machine, roughly the same size, that should be more rigid than a Shapeoko 3!

Gargoile reproduction C-Beam™ Machine - Plate Maker

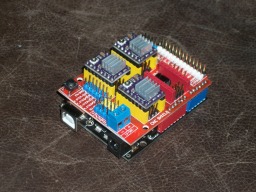

A stock C-Beam with a CNC shield with DRV8825's

Textile machine bearing structures CNC engraving machine

With the textile machine bearing feel better strength, better durability 用纺织机轴承感觉强度要好一些,耐用性更好

Build Author

Gary Bonard

Views

6240

Build Author

Gary Bonard

Views

6240

OxZilla

This is my second Ox with a working area of 14" x 14" x 5" I wanted to build a small sturdy potable CNC router and this OxZilla has the nice upgrades !

Build Author

mikev

Views

8678

Build Author

mikev

Views

8678

C-Beam Evolution MkII

The C-Beam Evolution is an evolving machine. The MkII is inspired by Kyo's C-Beam Spinx but currently uses my own design of plates made of 8mm acrylic (X-axis ends) and 6mm polycarbonate (Y axis ends). The plates were made on the MkI but I hope to be able to make 6mm aluminium plates on the MkII for the MkIII.

Build Author

recoush

Views

9453

Build Author

recoush

Views

9453

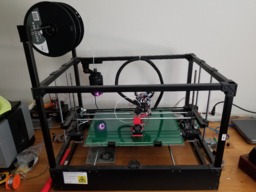

CoreXY 3D build one

an 8020 build with 1010 extrusion (1") Square tubing Rough size is 24x24x36 (600x600x900) The expected usable print area 21.5x21.5X32"roughly (510x510x760) An XY 3D printer with 3 extruders and 3 Z-axis 0.9 degree motors the table (Z-AXIS) will lift up to the XY Carriage on 3 12mm linear rod and 3 8mm Lead screw's Corexy designs complete and Z-axis build is started don’t have a 3D cad system yet so building my prototypes on a pcb layout tool

Build Author

Jens Grabner

Views

4184

Build Author

Jens Grabner

Views

4184

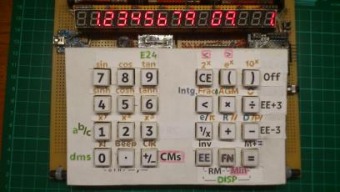

snc98_Slash-Number-Calculator

This calculator work inside with a spezail count format - Fraction as Mantisse + Dezimal exponent .. in summ 9 Byte.

Build Author

JerryD

Views

5390

Build Author

JerryD

Views

5390

1500x1000mm Adjustable Height

I have the demand to cut/etch tall pieces of material. For this reason, I have designed a machine with 500mm uprights with adjustable gantry height. This way I can raise/lower the sled and z-axis as needed. I've also chosen to use a linear C-channel assembly for the Z axis with the plate mounted to the gantry instead of the other way around. This will allow for maximum range of the z-axis. The parts list/BOM does not include motors/belts/pulleys or electronics.

Build Author

Neptunes Guitars

Views

8587

Build Author

Neptunes Guitars

Views

8587

Neptunes Ox

First build of CNC OX for the purpose of using it for Guitar building to take a lot of the muscle work out so I can concentrate on the finer details.

Build Author

obmilllivebuild

Views

5706

Build Author

obmilllivebuild

Views

5706

Live C-Beam Build @ MRRF2018

Contained within are links to our OpenBuilds sponsored C-beam Machine live build taking place at MRRF 2018 (Midwest Reprap Festival) on March 24 and 25, 2018. There will also be some build images and a few 3D printed STL items that were added.

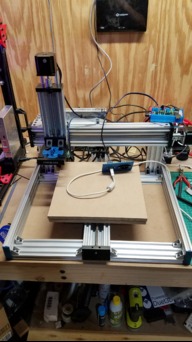

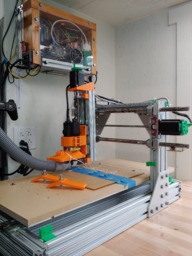

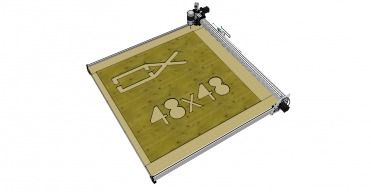

C-Beam Router, 48"x48"

C-Beam Router using 1500mm lengths, 48x48" build area, and rack and pinion movement.

Build Author

Tucstrlly

Views

9161

Build Author

Tucstrlly

Views

9161

Stainless OX Kit Build "Diamondback CNC"

A copy of the Stainless Ox by Martin Barfoed. Similar design, construction and control.

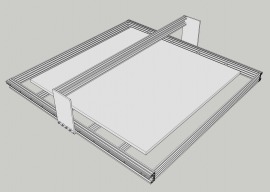

80watt Lasercutter, workingarea 105x52[cm], steel frame

I will write a short buildlog here with mostly pictures. I designed this lasercutter in solidworks(not totally finished) for a good overview and such that the steel tubes could be lasercut by a company, the metal frame is based on the lasercutter the KÄSER, which you can find on cnczone.nl. The mechical parts are designed by myself because I had no mill to my use, so the mechnical parts are lasercut(same company as tube) steelplates welded together.

My 80w Laser build (1000x1000 cutting area)

This is a 80w laser which I am building (picture of the case) the frame is constructed with normal square tubing with plastic corners. this laser needs to live outside

Build Author

GDanger117

Views

12501

Build Author

GDanger117

Views

12501

Gantry CNC - Decisions made only to change over and over.

This is my first CNC build. As per the norm, I went in with months of research, planning, and resource gathering tied neatly together with a solid plan. As the path went on, the plan continued to change to accommodate issues I hadn't counted on. But, at the end of the road, the project reached completion, and I learned a ton along the way!

Build Author

MattR

Views

20891

Build Author

MattR

Views

20891

Fixed Gantry CNC Router with Old Industrial Supplies

I got lucky enough to purchase aluminum extrusions and linear motion components (and nuts/bolts/etc) at scrap metal prices when a bunch of industrial automation equipment was decommissioned. The only problem is that the aluminum extrusions are not metric sizes... they are the 1.5"x3" 80/20 series. It has presented a few challenges but nothing too bad.

Build Author

Sprags

Views

2792

Build Author

Sprags

Views

2792

C-Beam Kyo Sphinx 10060

More stuff here.

![80watt Lasercutter, workingarea 105x52[cm], steel frame](https://builds.openbuilds.com/data/article_images/l/6/6014.jpg?t=1513166610)