Build List

-

Active Filters:

k

Horizontal MiniMill (x5)

The search for an affordable hobby 5 axis machine.

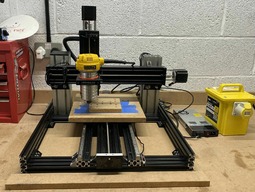

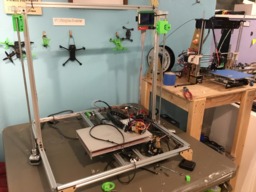

My C-Beam build and modifications

Modified C-Beam which I plan to add a laser module and eventually convert to C-Beam XL size.

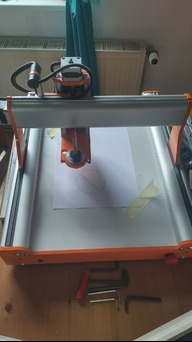

Shapeoko 2 - my first CNC

This was my first foray into CNC. I chose to go with a reliable kit build since my knowledge of GCode, controllers, and steppers was pretty rudimentary.

SkyKae sphinx - c beam xl hybrid

I took what I thought were the best parts of the sphinx and the c beam xl to build a bigger and faster machine.

Build Author

RobFromLDMS

Views

5176

Build Author

RobFromLDMS

Views

5176

Lithgow Mens Shed CNC build

The tale of how we put together our CNC Router, and some of the difficulties encountered. It is now ready for final testing and commissioning.

Build Author

Dmknerr

Views

5171

Build Author

Dmknerr

Views

5171

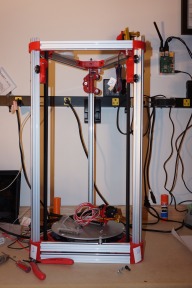

Server Rack Printer

My first project build. Concept build to use an existing 7.5 ft tall server rack as the frame. This ptoject may never be completed.

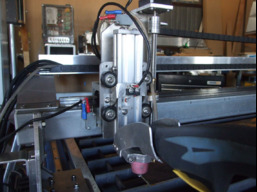

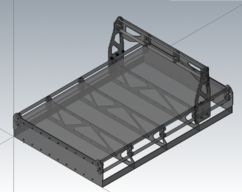

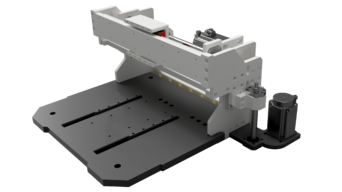

Plasma CNC machine

The plasma CNC that I have built has a water table that measures 1350mm x 650mm. The water is flooded onto the cut area while cutting and recycled around with a pump. This is to reduce smoke, cool the metal being cut to reduce distortion and also to keep sparks to a minimum. Most of the machine has been made from aluminium , the frame and table from steel, the water table, stainless steel.

delta 3d printer kit

HE3D K200 kit build

Reborn as the Soccer Pitch for our Robot Spider Soccer game - Robotics/Maker Club Teaching Cart

The Soccer Pitch for our Robot Spider Soccer game

WorkLead, no wait, LeadBee, naw... WoodWorker

Improvements on the Lead machine using some Workbee parts

Build Author

SCYBUCK

Views

5103

Build Author

SCYBUCK

Views

5103

KYO SPHINX a la' SCYBUCK

KYO SPHINX, CENTROID ACORN, GECKO 540, HALL EFFECT LIMIT SWITCHES, 2.2 KW, 24,000 RPM SPINDLE, WATER COOLED, 600 oz-in STEPPERS, INTENDED TO CUT ALUMINUM.

Build Author

TouchPadKing

Views

5072

Build Author

TouchPadKing

Views

5072

1500mmx500mm Kossel Delta

Please, look over my build and make any recommendations you can think of! I haven't figured out how long my arms need to be yet. Nor have I done any shopping around to find better prices...

Build Author

Rob Withoff

Views

5027

Build Author

Rob Withoff

Views

5027

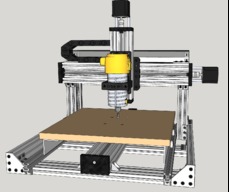

Mini-Mill Enhanced

Some enhancements of the basic mini-mill

Build Author

Skoobs

Views

4916

Build Author

Skoobs

Views

4916

Pretty Standard + Slave X Axis

Planning my build, just looking for design input at the moment. I definitely want a slave X axis. I am potentially going to go with one of the 1500W Chinese water cooled spindles.

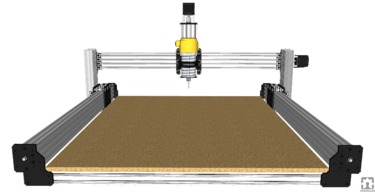

CNC design (parts named)

This design is previously posted in this area. I downloaded the file in order to customize as I needed. I found that the parts were not identified. I went through the design in an attempt to name the parts and identify them by location.

Hybrid shapeoko Xcarve cnc router

My scratch build using shapeoko, xcarve, and custom parts.

"Stung by the Bee" OB Workbee 1010 Build

This will be a build Log for my Open Builds Workbee 1010 Build. I will keep a full descriptive log of the build and make any notes in the hope that it will help other builders that decide they would like to build this machine.

Sphinx 7575

Sphinx CNC modified to 750mm x 750mm c-beams. Parts not readily available in South Africa, so i have to make some modifications...

20x24 inch Fixed Gantry Mill

I have shared many pictures of this project it is now complete I have had my first cuts on this machine and it is solid , still learning the new motion Controller. The Acorn is more like you would find on a commercial built CNC or CNC Lathe.But it does have all of the functionally one needs

Build Author

Craig Hollabaugh

Views

4812

Build Author

Craig Hollabaugh

Views

4812

Hyatt and My Journey to Tonehenge

I'm conducing guitar loudspeaker cabinet fabrication technique research (material type/thickness, mechanical joints, adhesives, etc) and how these relate to cabinet/speaker coupling and enclosure resonance with respect to psycho-acoustics. Basically, does one speaker cab sound better than another and why?

Build Author

Bikes and Beer

Views

4801

Build Author

Bikes and Beer

Views

4801

The Forever Project

Workbee 1010 Lead Screw with water cooled spindle and enclosure

Build Author

Robert J Rissell

Views

4763

Build Author

Robert J Rissell

Views

4763

Remix of Sage's Delta-Six

I'm looking to build a large build-volume, accurate, steady 3D printer with the eventual aim of swapping in a diode laser to allow for use as a cutter for printing/cutting parts out of balsa sheet for building model aircraft.

Build Author

James Evanko

Views

4759

Build Author

James Evanko

Views

4759

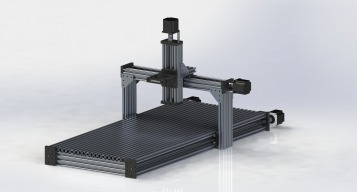

Ball Trajectory Machine

Need to build a machine that accurately positions objects for processing by a computer vision algorithm? Here is an example of a machine that does that for a ball trajectory application. The black anodized V-rails work well for applications in optics and imaging where the machine needs to stay out of the limelight.

Build Author

cory stafford

Views

4732

Build Author

cory stafford

Views

4732

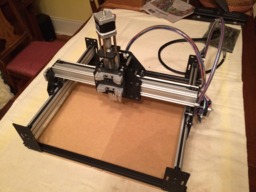

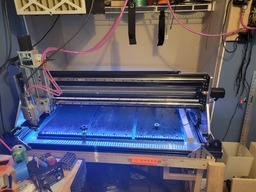

Home built laser cutter

This is a laser cutter built with intent to use arduino as controller for a co2 cutting laser.

Workbee 1500x1500 belt

Workbee CNC 1500x1500 with timing belt

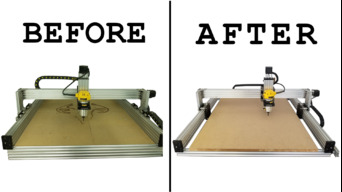

CNC Router Overhaul

This will be a complete overhaul of this router with some cool modifications.

WorkBee 1510 - First CNC Build

This build will go through the construction of a WorkBee 1510 kit from the OpenBuilds Part Store, all mechanical and electrical components were purchased from the store in late October 2018.

Build Author

BCulbertson

Views

4617

Build Author

BCulbertson

Views

4617

Lead 1515 with Upgrades

My upgraded OpenBuilds Lead 1515

Kossel Mini Delta

This is a Chinese kit I got on ebay from someone in CA.

32 Button Hand Pendant for the PlanetCNC Control Board

This project is for building a remote hand pendant for the Planet-CNC control board but could be adapted for many other projects. The pendant allows for machine control without being at the computer keyboard and the button functions on the pendant are defined by the user.

Build Author

Cosmosteel

Views

4516

Build Author

Cosmosteel

Views

4516

Clear Acrylic Dust Shoe

Attaches router with screw clamping. Clear Skirt is 2" long or can be made longer if requested. Works well keeping dust within the chamber. It can be made to fit shapeoko, ox cnc, workbee, xcarve, 6040, laguna,piranha, millright etc. with similar setup including Bosh, Makita , dewalt 611 routers or spindles.

Build Author

Denis Lapratte

Views

4512

Build Author

Denis Lapratte

Views

4512

All metal Ox hybrid CNC Router Table

This is my second CNC build, but the first one that I design from the ground up. The base is all metal because I want to add Plasma facility later on. I used the Ox model for the gantry plates and made a few changes to adapt to my design. Since I wanted to use parts from my first CNC to save as much as possible, I kept the 5/8 Hi-Lead Screw I had from Roton for the Y and Z axis. I will also add a downdraft table to keep all parts tight on the table for cutting.

Build Author

jz321

Views

4508

Build Author

jz321

Views

4508

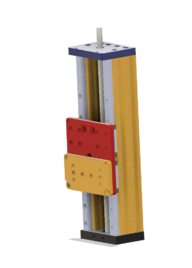

OTiS 500mm

OTiS (Off The Shelf) is 500mm cartesian CNC that can be built with all off the shelf parts from OpenBuildsStore. It features C-Beam actuators and a V-Slot frame.

Build Author

stepper

Views

4504

Build Author

stepper

Views

4504

Touch screen macro imaging

This is a brief overview of the build of my macro imaging slide.

Build Author

Dave Pyatt

Views

4478

Build Author

Dave Pyatt

Views

4478

DaveP's Homemade CNC Project

Somewhere along the line sometime around February 2017 I got the bug in my head that I needed to build a CNC router. This is where I am today...

Build Author

Limine3D

Views

4475

Build Author

Limine3D

Views

4475

Shapeoko 1 upgrades

Replaced the original Z-axis for a shapeoko with a c-beam upgrade. This upgrade required a nema 17 mount and a quiet spindle mount I printed with a 3D printer.

Build Author

Cortellini

Views

4462

Build Author

Cortellini

Views

4462

The FEEDBACK FRACTAL Build

The Feedback Fractal Project (Project) - building "A Monument For Our Time." As its intent is to build a monumental sculpture, the Project will produce an object d'art. Yet, once begun, the Project has evolved a life and character of its own. I continue to follow the thread woven by the materials, the processes, and the people that come to it and in the end the work will not only be a faithful rendition of an image and a concept, it will also be a tapestry of the story of its making.

Build Author

ShockingTops

Views

4459

Build Author

ShockingTops

Views

4459

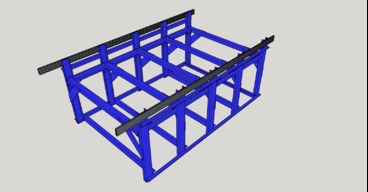

Opening into doors

Construction of a CNC table for a specific project that could cut an area larger than a door (>8'x4'). Much thought went into how to avoid the weight of the gantry bending the (long) Y axis, whilst still keeping down the complexity and cost.

Build Author

KronBjorn

Views

4437

Build Author

KronBjorn

Views

4437

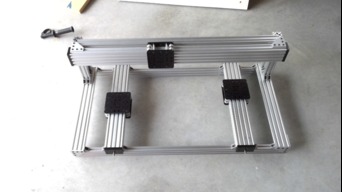

WorkBee Lead 1010, Reduced Footprint, Nema17

This is a WorkBee 1000x1000mm with lead screws and Nema17's. It has a reduced footprint, with the geared Nema's inside the frame.

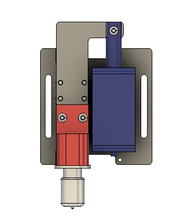

cnc back stop for brake press

back stop build

Build Author

Darren Dickson

Views

4372

Build Author

Darren Dickson

Views

4372

3D printed CNC Machine

So I thought I would make the Leon van den Beukel version three 3D printed CNC Machine, it is the third incarnation so you would expect a relatively bug-free CNC Machine with a strong foundation.

Build Author

Doug Rowley

Views

4303

Build Author

Doug Rowley

Views

4303

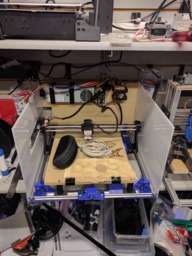

My Workbee 1010

This is a workbee 1010 build using the mechanical parts from Open Builds. The electrical and electronic parts were from a prior build of a Root 3 CNC by Sailor Pete.

big_recnc v2.0

cnc made with a 6mm metal body .

Dedicated Rotary Laser Made from Scrap and Spares

A clone of https://openbuilds.com/builds/dedicated-compact-rotary-axis-laser-engraver.10204/

Build Author

Jasont

Views

4207

Build Author

Jasont

Views

4207

MY first CNC build

my first cnc build using the lead 1010 to build bigger and better!!

Build Author

Tristen Poliseno

Views

4204

Build Author

Tristen Poliseno

Views

4204

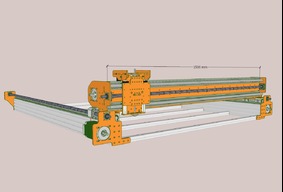

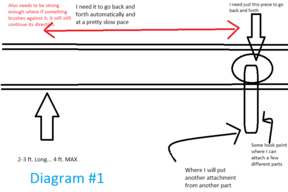

Back and forth rail mechanism

I have the whole description and all the details in the "Body" section!

Workbee 1010

Hey all looking forward to sharing this build, I’ve learned a lot reviewing many of these great builds.

Build Author

RV6APilot

Views

4186

Build Author

RV6APilot

Views

4186

South Carolina Workbee 1000X1000

This is about my build of a Workbee 1000X1000 being built here in Trenton, SC. My goal is to use it to help cut the new panel for my RV6A airplane.

D-Bot Version B

D-Bot with a Replicate controller.

Build Author

crnrstndes

Views

4166

Build Author

crnrstndes

Views

4166

C-Beam Upgrade to Larger C-Beam

My goal was to be able to enlarge my C-Beam with as many original parts as possible. I was able to recycle almost all of them with a only the two 500 mm rails left over. I used 1000 mm rails for the X Axis and I added another complete Y Axis assembly. I chose to keep it simple and I am very happy with the result!

Vertical Mill

This will be a CNC milling machine. My goal is to make this mill for the minimum cost I can while not sacrificing quality. In hope of staring an educational YouTube channel on CNC milling and 3D Printing. Along with when to use both.

KinectSkin

For all other builders and robotic technies!

Wifi'not

A simple made hideaway for ugly electronics

Edge Carve MK1

I have created a video showing the Edger Carve features https://www.youtube.com/watch?v=v5mV_6vyxAA&t=3s

Build Author

rob4cnc

Views

3988

Build Author

rob4cnc

Views

3988

Rock n Roll

The Rock n Roll is built on granite, is solid as a rock, and gathers no moss. This build provides a high degree of accuracy and repeatability. Built to be strong, use redundancy, and use long lever arms to average out imperfections in the equipment. Built to go fast and light. We will use a high speed spindle, large high voltage stepper motors and small cutting heads to overwhelm the forces produced at the cutting head.

Build Author

theracermark

Views

3971

Build Author

theracermark

Views

3971

Reviving the Origonal PhlatPrinter with BlackBox

Reworked PhlatPrinter Gen1 Adding dual nema 17s to all 3 axis Supprot for carriage to insure even dept cuts Lighting for view of cutting area

Black out Edition Workbee 1010

Thanks to all the Open Build elves that meticulously package and wrap all the little tiny parts and pieces. I have put in a request to get you people a raise..

Build Author

Jones

Views

3943

Build Author

Jones

Views

3943

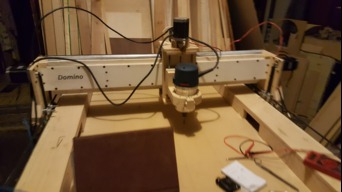

The Domino - 1.5m x 1m

DIY scratch build consisting of gas pipe, skate bearings, 12mm birch, 3/4 maple v-core ply, Nema 23's, and arduino and CNC shield with DRV8825's.

Build Author

MidnightQuads

Views

3870

Build Author

MidnightQuads

Views

3870

MQTitan printer

Components- RAMPS, running marlin, Nema 17, All metal extruder, 600mm lead screws, 600mm 2020 aluminum extrusions, 12v 30a power supply, 12v LED strip, Typical endstops, 600mm 8mm linear rods, Bearing block for 8mm bearings, Openbuilds plates, wheels, and bearings, 500x500mm borosilicate glass plate

New Workbee Z Axis

Hopefully an upgrade of the Z axis of the Workbee.

My Ooznest Workbee V2.0 build

I'm new to this whole process, so this is a build by a newbie for newbies.

Build Author

Chetan PM

Views

3772

Build Author

Chetan PM

Views

3772

Composer

Gantry style rigid build

Reworked Sepcraft 420 CK

Its alive !

Build Author

Thair.nl

Views

3759

Build Author

Thair.nl

Views

3759

Plate Maker Plus

C-Beam Plate Maker with a larger size of the work area and electronics added.

Build Author

George Motichka

Views

3747

Build Author

George Motichka

Views

3747

Transformer

I wanted a machine that could easily switch between 3D Printing and Laser Engraving

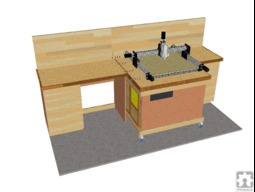

Custom Ski and Snowboard CNC for a High School Woodwhop

A Custom size CNC to make custom skis and snowboards

Build Author

Builder+Bob

Views

3717

Build Author

Builder+Bob

Views

3717

Portable C-Beam

C-Beam Plate maker for My OX!

Build Author

Hidro669

Views

3711

Build Author

Hidro669

Views

3711

My custom world of tanks gaming desk built by Ragged Edge Eaming Solutions

summary huh... If it doesnt fit MAKE IT!

Build Author

McAdam

Views

3708

Build Author

McAdam

Views

3708

Need a catchy name - enlarging CNC

The aim of this build is to have a CNC that can cut a FULL sheet of wood when I need it to, but also shrink down and cut smaller sheets the rest of the time. The prototype is based on an OX cnc but soon it will be completely custom using Openbuilds Parts

Build Author

Damian V-SLOT Poland

Views

3683

Build Author

Damian V-SLOT Poland

Views

3683

LEGO BOX

Discover our unique DIY project that blends creativity, utility, and sustainability. This guide will take you through the construction of a LEGO display box, ingeniously crafted using offcuts of V-SLOT aluminium profiles and OpenBuilds accessories. Not only is this an eco-friendly approach to reusing surplus materials, but it also results in a stylish, functional display for your prized LEGO models. Whether you're a LEGO enthusiast or have little LEGO fans at home, this innovative project offers

Retractable WorkBee1510 with Marlin+MarlinPanel high level build

WorkBee1510 with retractable space saving stand and customize build Marlin firmware and MarlinPanel (GCode Sender/UI)

Denford CNC Resurrection

Denford CNC Mill Update

Clock repair stand

Open source clock movement stand

Build Author

Rodrigo Gonzalez

Views

3570

Build Author

Rodrigo Gonzalez

Views

3570

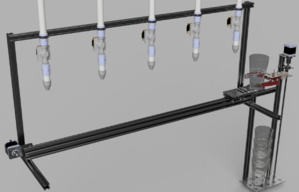

Nightfuel

The user will input a selection from a variety of pre-established drinks. The user will not need a glass, since it will be provided in the automation process. This completely eliminates the need for a bartender if an RFID purchase system is implemented.

My 5' by 5'

I have constructed frame out of 1 1/2" square tubing. Have my Y aces mounted. and awaiting parts.

Build Author

Calotype

Views

3563

Build Author

Calotype

Views

3563

My DIY panoramic rolling (&banding) Machine.

DO WHAT YOU IMAGINE !

Build Author

bpatterson42

Views

3523

Build Author

bpatterson42

Views

3523

Inverted Y C-Beam Machine

Similar to C-Beam Machine build, but with inverted Y-axis assembly to shield drive screw. Integrated XZ gantry can be fixed to any solid surface. Build dimensions are 36" x 36" x 6".

Rotary axis for Workbee

Adding a rotary axis to the Workbee 1010. Including height modifications to the Workbee.

My Workbee build

Workbee, 1000mmX750mm , from China

Stock CNC Router

This is my first CNC router, so be kind on the criticism. I'm still learning. Not an engineer, and not a machinist so I am having to research and learn aspect from both of those areas of study!

Build Author

Daniel.korneliussen

Views

3460

Build Author

Daniel.korneliussen

Views

3460

Reprap prusa mendel i2 Frankenstein 2018 build

Mad plumbers choice what Else can i say?

MOVABLE ART TO SCREEN WALL-MOUNTED TV

This project produced a movable framed canvas to cover a wall-mounted flat-screen TV when not being viewed, which at the touch of of a switch moves down below the TV and sound bar. The same switch is used afterwards to return the artwork up to cover the TV again. Photo shows mechanism without the canvas frame. See other photos.

C Beam CNC+Laser

You will be following the assembly of the mechanical kit and how i integrate the electronics into the final build.

my version of xl

A table top version of the open build xl router kit set build. This use of c - beam and xl kit set was coupled with Mach 3 controller running on Dell opti -plex 755 and win 7 pro licence. A Dell opti-plex 755 empty case was used to house the controls and wiring , including the limit switch and emergency stop safety circuits

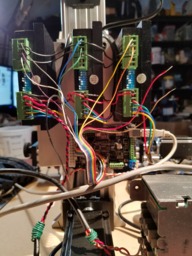

Bedroom Builds (BrB) DIY CNC

So I am employed in the automotive industry and I walk by thousands of dollars of CNC products daily that are no use to me due to being a Technologist and not a machinist. So therefore with some research I found openbuilds and their great selection of products to build my own CNC. This CNC will consist of 4 axis one removable 360 degree axis for turning alongside a x axis table Y axis stationary gantry and a Z axis attracted to the Y axis linear actuator.

LaserShark300

300x300 belt drive laser etching/cutting platform. The design was borrowed from another's blog and customized to fit materials on-hand. Was a very fun project to assemble.

Build Author

Stan Howe

Views

3283

Build Author

Stan Howe

Views

3283

Bee the Boss

The frame of the CNC is going to to Bee a basic Work Bee with maybe 1 modification to the spoil board attachment. This will be located on a custom bench housing the electronics and vacuum. I plan to install Stepper online steppers, drivers, power supplies, and break out board. I will add a 1.5 KW water cooled spindle, with a radiator. The fans from the radiator will pull air from a filtered enclosure for all the electronics.

Build Author

hbtousa

Views

3230

Build Author

hbtousa

Views

3230

Quack Ball

Quack Ball is a game in which the objective is to knock down moving ducks. The ducks are protected by a barricade that moves at a very fast speed. The game can be played individually or by two or more players. Each round consists of a total of ten targets to shoot and each player will have four balls to shoot. Prior to beginning play, a player selects how many ducks, maximum four, the player will knock down continuously. If player fails games is over for that player.

K-Cup Sealer

This is a K-Cup sealer i constructed does a fine job

Another Kyo inspired Sphinx

A 1000mm x 1000mm copy of Kyo's Sphinx

HandCrafted WorkBee - HCWB

This will be a slow build as I collect parts and materials as funds permit for 1000mm x 1000mm Workbee. I call it the "Hand Crafted WorkBee" because I will be hand making the plates and as much of the build as possible using a drill press and hand tools.

Noob 1000Sphinx

A complete noob stumbling thru his first cnc build in winter.. and trying to find the time with 2 toddlers..

Build Author

Axnfell

Views

3040

Build Author

Axnfell

Views

3040

WorkBee 1000x2000 ACME Screw Version

Hoping to build a WorkBee 1000 x 1000 (2000) from parts and not a kit, cannot afford the kit in full so going the long way round...

Workbee with less irritations

My workbee build with some add ons

SharkBits Holder

Get organized with the SharkBits Holder!

Build Author

Gary Caruso

Views

2990

Build Author

Gary Caruso

Views

2990

OpenPull From CNC Kitchen.. attempt

This project is a Pull tester for material testing or structural testing with stress (force) data logging, I don't have plans for strain logging but that might be down the road.

CNC Cutter Knife

CNC knife cutter with loline blades

Something a Tad different

Future CNC router kit design

C-Beam Elexa

This build will be based on the C-Beam Plate Maker, with additional changes based on other builds and ideas.