Build List

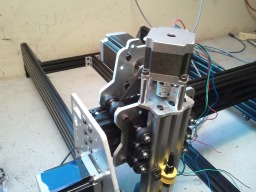

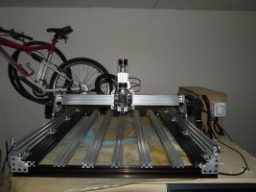

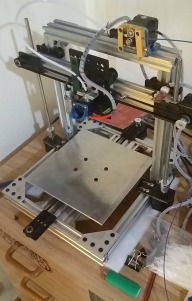

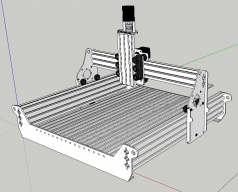

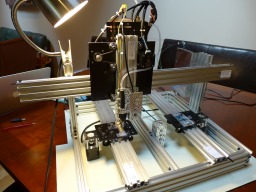

Ooznest Moded CNC

Modded OX with full nema23 4 point support

Build Author

zann68

Views

9333

Build Author

zann68

Views

9333

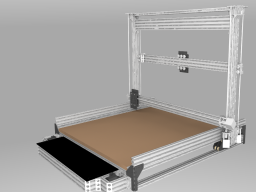

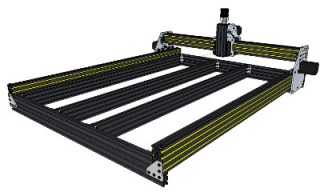

OX CNC 4'x4'

Out with the Old in with the New. Trying to build a nice clean setup that myself and my sons can use and enjoy.

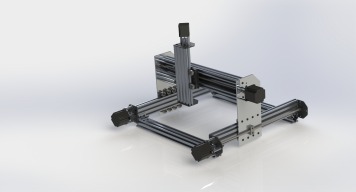

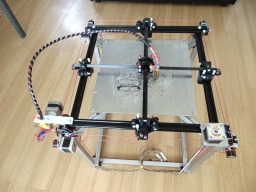

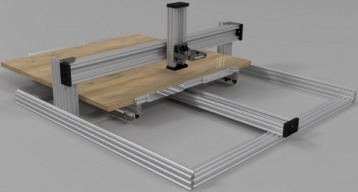

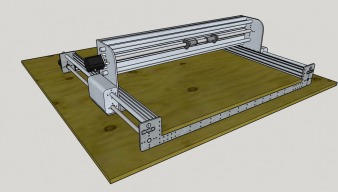

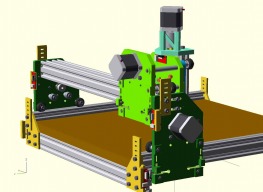

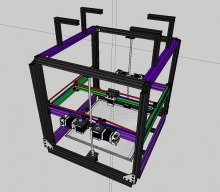

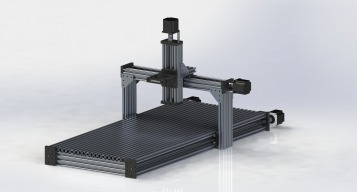

The MULE (an OX inspired 3-axis CNC)

The Mule is a 3-axis CNC inspired by the OX CNC by Mark Carew. This machine borrows the OX's sturdy frame and upgrades the X and Y linear actuators through the use of three 500mm lead screws (as opposed to the belt system of the OX). The result is an inexpensive, sturdy, and powerful design built for cutting tough materials such as aluminum.

Build Author

Kermareg

Views

17370

Build Author

Kermareg

Views

17370

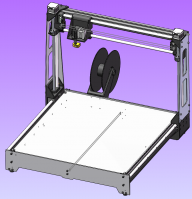

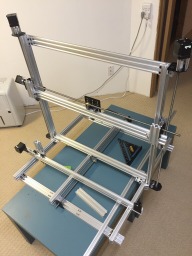

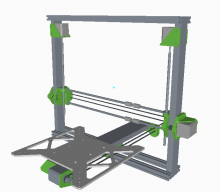

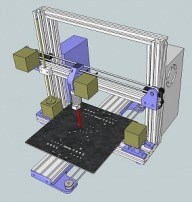

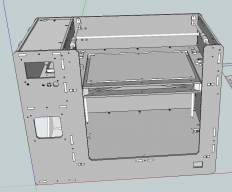

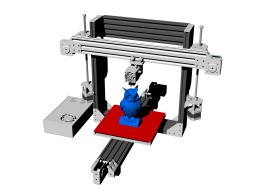

MOX CNC

[EN] Build of my Multiple OX CNC. It's goal is to run in 2 differents modes : router and 3D printer modes. The router mode will allows the use of a laser diode or a standard spindle. [FR] Construction d'une CNC basée sur l'OX pour des usages multiples. Deux modes principaux sont prévus : l'impression 3D et l'usinage via une defonceuses. Le mode usinage permettra à l'avenir de placerune tête laser pour effectuer quelques gravures simples. Une version française : http://kermareg.be/?page_id=103

Build Author

Steve Marsh

Views

5770

Build Author

Steve Marsh

Views

5770

Dust Shoe for Colt router and OxCarve

A simple 3D printed dust shoe for the cnc router. 2 parts held together with magnets for easy bit changes.

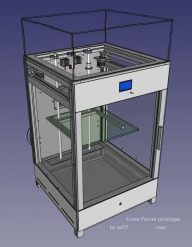

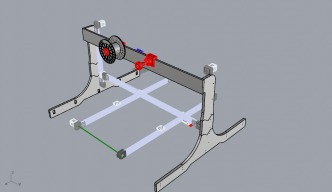

Tower Printer

Tower Printer H-Belt type printer Prototype

Zebu ( OX clone with Brasil materials)

An OX clone with alternative parts.

Build Author

evildean

Views

8916

Build Author

evildean

Views

8916

OX-SUMO, SUMO-OX, OXSUMO?

One meter square. Short and stout.... reminds me of a Sumo Wrestler. A temporary and adjustable configuration I have devised to cut my own plates. I have kicked around ideas for about a year and the C-Beam extrusion has made this attempt to realize my ideas irresistible. This is just one step towards bigger and better things!

Wakezor

I'm starting my first own build cnc machine which is inspired by routy and the ox. Were my goal was not to use the ox plates but use the standard plates available in the parts store for the design.

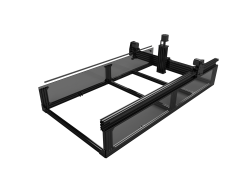

C-beam Router rack and pinion

I want build a frame that is as sturdy as possibility while at the same time keeping it as compact as possible. working area will be approx 1200mm x 600mm

Build Author

Gary Bonard

Views

6190

Build Author

Gary Bonard

Views

6190

OxZilla

This is my second Ox with a working area of 14" x 14" x 5" I wanted to build a small sturdy potable CNC router and this OxZilla has the nice upgrades !

Build Author

TomH

Views

16360

Build Author

TomH

Views

16360

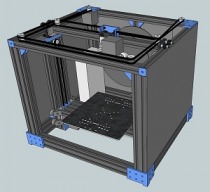

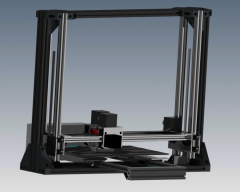

H-Bot CoreXY Cube with Fixed Build Plate

Use of V-Slot for frame and rails with option to use identical 500mm uncut lengths: 8 * 20x60 x 500mm 8 * 20x40 x 500mm 7 * 20x20 x 500mm (2 cut into four identical 125mm pieces for filament holders) Use of uncut 500mm rails obtained through use of 12 joining plates for use as spacers. Alternate approach is to trim two 20x40 and 1 20x20 rail by 6-8mm each. Build volume ~400mm cubed (with dual extruders). Use of only openbuilds components! Currently in design phase...

HAPP Printer

This 3D Printer is made to provide the most accurate results with the least amount of investment. This Printer is being designed to allow the common user to own a very accurate piece of machinery.

The Ox That Wood

This is my story about my need for a CNC router on a budget that wound up in the $5K range !!! but I have a good belt drive Ox

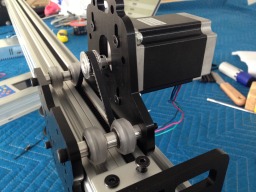

C-beam Camera slider

feel kind of bad calling this a build because of pretty much everything is off the shelf parts. I'm writing my own sketch right now for the motion but there is a version or 2 floating around on the net based of this design. I will post my code once it's done.

Build Author

Mogens Kusk

Views

5206

Build Author

Mogens Kusk

Views

5206

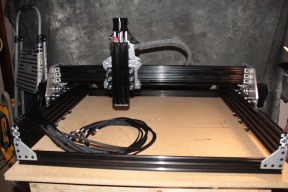

Belt driven 1200mm x 700mm x170mm axis

CNC router

OX-Based Self-Contaned HVLP Spray Booth

A CNC HVLP spray booth based on OX.

Build Author

motopreserve

Views

9104

Build Author

motopreserve

Views

9104

Persnickety Plate Maker

My very first attempt at a CNC build. Based on the OpenBuilds C-Beam Machine, small tweaks will be made to tailor it for my goals: machining G10, aluminum & some carbon fiber for use with multirotor and motorcycle parts. I am looking forward to the day when I am comfortable enough to bring the ideas in my head to the tip of the end mill in a smooth fashion...

Build Author

UltiBots

Views

21277

Build Author

UltiBots

Views

21277

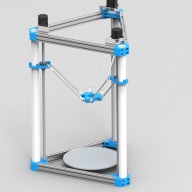

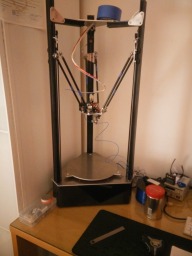

Kossel 250 V-Slot

This build is very straight forward. The design is simple. There is a great support community for Delta 3D printers.

Beaver's OX 1500

OX 1500mm x 1500mm w/1.5Kw Water Cooled Spindle & VFD ran by a Gecko G540 & Mach3

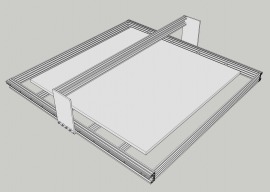

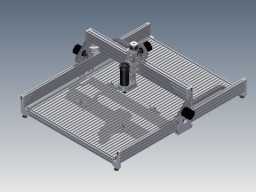

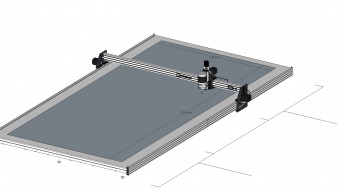

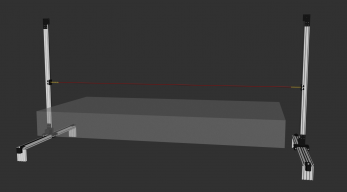

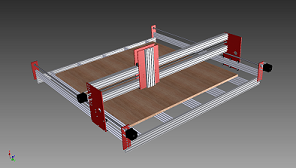

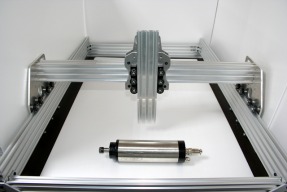

Laser cutter project by students

This build is made by students from Fontys Hogescholen Eindhoven, department Engineering. Every quarter a new group continues the work of the previous group. We have been working on the project since september 2015, and as it is a work in progress, a lot will be added later. The first months have mainly been about designing and building an XY-table on which later all the electronic components will be added and the laser.

Build Author

dcarlisle

Views

10770

Build Author

dcarlisle

Views

10770

pain in my ox

build is in process the machine went together perfectly no issues at all but the software is another issue I have been trying to get the thing dialed in it is driving me nuts I'm still in the process will update if I ever get it figured out

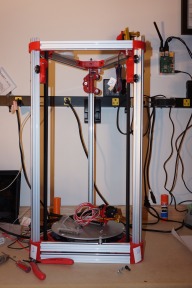

Delta 3d Printer

I am going to use this as a build log for my delta 3d printer build. I have access to a MakerBOT to print some of the parts. I am still finishing up a few of the design elements but the idea is to have a rigid unit to eliminate deflection in components and maintain accuracy.

Build Author

andrew Adsit

Views

14076

Build Author

andrew Adsit

Views

14076

OX Cable Management, Electronics Case, E-Stops

750mm x 750mm OX build, xPro V2 controller, 400W Spindle with PWM controller.

Kossel Mini Delta

This is a Chinese kit I got on ebay from someone in CA.

C-Beam on X, Y and Z Attempting to use internal channel first go around

C-Beam build using the small C-Beam gantry plates only.

DoubleX

This is a Dual X-axis platform.

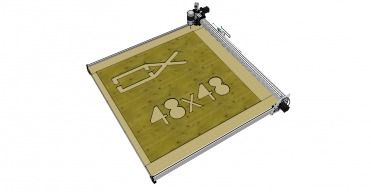

C-Beam Router, 48"x48"

C-Beam Router using 1500mm lengths, 48x48" build area, and rack and pinion movement.

Build Author

Fabio Bertuzz

Views

4255

Build Author

Fabio Bertuzz

Views

4255

DutziDelta RepStrap

Fascinated for some time by 3D Printing. Now, after studying countless forum posts, blogs and similiar stuff, i want to Start with my own build. Maybe a bit much but usually i thrive with the challenge.

Black Panther QR

The QuadRap 3D printer version based on OpenBuilds wheels. Born in https://plus.google.com/u/0/communities/103539262895202172380

My CnC Router, custom DIY not open builds parts

Most of the way through the build, hopefully soon I will have it running

STEAM crane printer

The STEAM Crane 3d printer uses the new C-Beam linear rail. It is being developed for an after school / summer camp program for kids. All of the electronics are housed in the base and the wiring is routed down the channels of the c-beam. This is done to contain as much of the loose wiring as possible, hopefully keeping it safer for kids.

Build Author

Sam Dobbie

Views

7820

Build Author

Sam Dobbie

Views

7820

the STD

A fully aluminium printer made from off the shelf components, no printed parts.

core xy smoothie

i had som left over parts and i dit like to test the corexy control so this is wat i came up with. sorry bad englich.

CoreXY Enclosed

A compact, enclosed Core XY design, based on off-the-shelf parts.

Build Author

openhardwarecoza

Views

9304

Build Author

openhardwarecoza

Views

9304

3D Printer 320x220x200

Someone donated a E3D Volcano to me (http://e3d-online.com/Volcano/V6-VOLCANO-POWER-PACK-175-UNIVERSAL-24V) and with a super hotend like that, it feels like a waste to stick it into a small 3D printer. So I decided I want a 320x220mm (XY) machine, 200mm Z is plenty for me

Build Author

Skoobs

Views

4958

Build Author

Skoobs

Views

4958

Pretty Standard + Slave X Axis

Planning my build, just looking for design input at the moment. I definitely want a slave X axis. I am potentially going to go with one of the 1500W Chinese water cooled spindles.

Longhorn OX (Under Construction and In Progress)

I ran across the OX and knew it was the one I wanted to build. Some of the things I wanted to include was make it bigger and a little more solid than what the original plans called for. So here is where I am at so far. It will have a cutting area of 48" x 48". The waste board support frame will have more support rails. The Y axis will have (3) 20mm x 60mm rails instead of the original (2) that is called for. 1/4" aluminum OX plates. And a few more odds and ends.

Aluminium Router From Dubai

Another modification on the OX

Build Author

CubeSpawn

Views

16110

Build Author

CubeSpawn

Views

16110

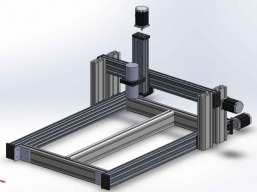

CubeSpawn 3 Axis Mill Module

Small Form factor based 3 axis Gantry style mill, Removeable mechanical module. Removable Electronics. with a removable machine pallet, for automation.

Build Author

Steve hope

Views

19229

Build Author

Steve hope

Views

19229

8x4 CNC build

Routy cnc upgrade.

Build Author

inhan

Views

12608

Build Author

inhan

Views

12608

OPENBUILDS Korea (ROVO 1000)

I am very grateful to Mark Carew with passion and imagination. Therefore, the machine is good, but making the website there too daedanhaeseo The end of the same either way to invisible homework. Thank you for allowing openbuilds team submitted to the challenge once again for those with a passion that I feel like in Korea, I want to be a great help.

Just Starting

My attempt at planning out my own CNC router

Build Author

Bear

Views

11067

Build Author

Bear

Views

11067

OXBear

ANOTHER OX!~ Huge Thanks to Marc Carew and Open Builds. The primary reason I am building this CNC mill is to aid in my homemade snowboard creation. I am going to try and document as much of everything as I can and post it here to help others going a similar route. I know from past projects that taking the time to document each step can be tedious when you want to charge ahead but I will try! I hoping to get feedback on my design choices and set up as I am a complete newbie to CNC.

My Little OX

This build has been an educational experience. Software and hardware alike.

Ez3D - Phoenix 3D Printer Build

This is my 1st submission to openbuilds.com and my 1st venture into building a 3D Printer. The Phoenix 3d Printer is a kit from Ez3D, a company based out of Colorado, started and backed by successful Kick-starter and IndieGogo campaigns. The Phoenix 3d Printer kit is currently backlogged 10 to 12 weeks which means quite a wait. I will be chronicling my experience with this kit as I get it done.

1200 x 2700 CNC based on OX

Preliminary design for cnc based on OX for cutting wood sheet products (ply, MDF etc.) for a sheet size of 1200mm x 2700mm

First Ooznest OX

The ooznest OX CNC Machine is based on the OX CNC Machine designed by Mark Carew of Openbuilds, and incorporates many upgrades from the Openbuilds community. Mark Carew based the OX on the Routy, which was in turn based on the Shapeoko

Build Author

openhardwarecoza

Views

7141

Build Author

openhardwarecoza

Views

7141

Pocket Ox (Sheetmetal)

Small CNC - made with some custom lasercut+bent sheetmetal parts + Openbuilds V Slot

Build Author

Mohammed Iskandarani

Views

21420

Build Author

Mohammed Iskandarani

Views

21420

CO2 60 -130 WATT LASER ENGRAVING/CUTTING CNC WITH DSP AWC608 CONTROLLER

LASER ENGRAVING DIY 60 WATT

C-BEAM 1K

The new C-Beam kit expanded to 1000mm . extra support built in for the extents of the travel.

Build Author

Mark Carew

Views

14824

Build Author

Mark Carew

Views

14824

Phlatprinter MKII

Phlatprinter MKII Foam Cutting Machine

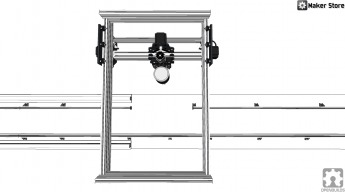

Vic Aussie Ox

Dove in and ordered the kit from Makerstore in Melbourne. While awaiting for the order watched videos and sourced steppers and controllers from China. Had some fun with the 4 axis TB6600 controller board. Ran into a few problems with the build, but after stripping and restarting looks like I am on track.

Cancelled - Modified OX CNC for Mitre Cutting (Picture Framing)

Creating a CNC mitre (45°) cutter, for picture frame cutting. Starting with an OX, but inverting various parts and adding a material table, with a stepper-controlled measuring guide.

OpenBuilds OX 48x48 Aluminum

Variant on the OpenBuilds OX CNC Router, enlarged with 1500mm length beams for a cutting area of 48" x 48". Based on the original model, the larger of the two, with the addition of a third 20x60 beam on the gantry for strength. Estimated cost is around $1100, minus the router.

Custom Ski and Snowboard CNC for a High School Woodwhop

A Custom size CNC to make custom skis and snowboards

Build Author

UltiBots

Views

32997

Build Author

UltiBots

Views

32997

Mini Kossel V-Slot 3D Printer

This build is very straight forward. The design is simple. There is a great support community for Delta 3D printers.

McRouter 3 Axis CNC

I wanted to put together a medium size router using PTFE slides from McMaster-Carr. I've had great experience with these slides in long term continuous motion operations in industrial environments.

Build Author

Bruno Rivard

Views

6917

Build Author

Bruno Rivard

Views

6917

OB Heavy duty Prusa i3 "Lunar Injection"

Hell Yeah

Large Manual 3d Printer

This is the largest printer I have found. It is also the cheapest. The reason is that it is run by hand, without computer or motors or electronics. Put an object on one side and move the 3d pen while tracing the object. Move the z dimension by turning the crank on the lab jack to move the printed copy down a notch. Be creative!

Build Author

inhan

Views

6215

Build Author

inhan

Views

6215

openbuilds rovo 1000mmx1000mm(rovo x)(korea)

Open build rovo 1000mm * 1000mm. (Rovo x ver) 20.06.2015 now in progress. rovo kit is the 10th product. 8th rovo 750,9 th rovo1000, 10th rovo x ver progress at the same time. 10th item is an aspect of 1000. It changes the size and z-axis has been up.

MaxBox

Simple cartesian style CNC. Uses ACME screws for all 3 axes, 20x40 v-slots and should have 50cm x 50cm x 50cm work volume.

3 Axis MultiTool - 3D printer, CNC Mill and Plasma Cutter

So in short this build is a work in progress; it aims to make a large 3d printer, medium size CNC mill and a small plasma cutter all in one CNC unit.

Hybrid OX (Ball Screw, Linear Guides, Ect.)

Planning my first build. Hope to achieve a larger format yet rigid design.

Build Author

Darren Ditto

Views

10702

Build Author

Darren Ditto

Views

10702

V 1.4 - Bright Box Cartesian Printer - *BUILD PROGRESS PICTURES

Cartesian Printer, 200mm x 200mm x 380mm build area, enclosed, belt and pinion movement, heated bed, Raspberry Pi, Pi Cam, OctoPrint

Norwegian OX

This build is based of Ooznest 's OX CNC Mechanical kit (500x750) with a few mods if all goes as planned.

3D Printer DELTA

Delta printer, Bed size 280 cm dimeter Print Height 300 cm not tested yet the speed

Build Author

CWidt

Views

8748

Build Author

CWidt

Views

8748

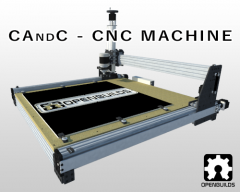

OpenBuilds CAndC - CNC Machine

A new derivative of the famous OX CNC, with increases strength, rigidity, and accuracy.

Bandicoot v1

My first custom build, using vslot rails for Z and Y and 8mm rails for X. Currently printing parts for this using my Prusa I3. The build volume will be roughly 300mm^3, X and Y are belt driven with 8mm acme lead screws for Z. Will be uploading more info shortly as i continue to build the printer.

Build Author

Donald D. Parker

Views

5671

Build Author

Donald D. Parker

Views

5671

BABE - CanUSA Blue OX, bigger than the average OX

This is a basic description of my OX-like build of Babe, Paul Bunyan's Blue Ox. It is a work in progress. The idea has been germinating for about 4 years, with several twists and turns and false starts along the way.

Build Author

JoeH

Views

7666

Build Author

JoeH

Views

7666

COTSPnP

The COTSPnP pick-and-place machine (PnP) is used to place surface-mount devices (SMDs) onto a printed circuit board and was designed and built exclusively from off-the-shelf (COTS) components, predominantly sourced from OpenBuilds and Actobotics. Its intended use is prototyping and not high rate, high volume production and is capable of precisely placing parts as small as 0402 capacitors and resistors but more importantly, can precisely place components with lead spacing as small a 0.4mm.

The FOX

This will be an OX based machine which I've designed to make the best use of my materials, be as precise as the design allows and operate as quietly as possible. I live in an apartment complex so space and noise are two important factors for me. Therefore the machine needs to do as much as possible while using little space and not annoy the neighbours.

Little Big OX

A complete CNC newbie is tackling a mighty challenge, Not only is he making a CNC router, He's going to try and upsize it.

Custom OX Build

Inspired by the original OX by Mark Carew, this is my Custom OX. Many small changes, additions, and upgrades. Build is in progress and this post will be updated regularly with photos. Enjoy!

CoreXZ

I am building a H bot style printer so this design will not be finished any more than it is.

CNC Hotwire Foam Cutter

Here is my first ever CNC build. A CNC Hotwire Foam Cutter. I will update about achievements. I would love to read from you guys - advices, ideas. Especially regarding the electronics. I feel confident with the hardware part which I can't say about the electronics part.

KerryH's OX

My adventure in CNC routing.

Build Author

Hytech2k

Views

6960

Build Author

Hytech2k

Views

6960

Micro Ox 2 x 2

Micro Ox Build

Panther Printer - Lautr3k

My version of the popular Lautr3k 3D printer. UNI Panther colors of Purple and Yellow on black V-slot rails. 300x300 bed.

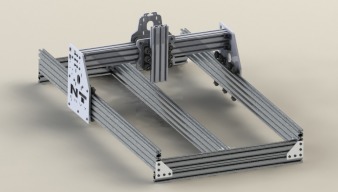

CNC NT

This is our first CNC project is based on OX CNC. We show you some pictures about our progress. We finished assembly design, software test and drivers test, now we are building the machine.

Modified OX CNC Router (1000x750 mm)

An OX Router I'd like to modify to improve the frame rigidity and resolve some alignment problems

Build Author

MechEng

Views

15888

Build Author

MechEng

Views

15888

Generic Rigid 3D Printer (Currently on 1st Revision!)

Rigid 3d printer with more than enough room for dual extruders. Easily expandable platform.

OX-LX-3D

An OX build - little large than specs and plates 3D printed

large format printer

I am hoping to post a detailed build of my printer it is a large format using the RepRap RAMPS 1.4 & Mega 2560 & DRV8825 Driver + optical end stop +LCD 12864 -C 0.4mm Far-end Distal Dual-Head Nozzle Extruder Double Nozzle

OX 1500x1500 Dual Drive

Ox inspired 1500 x 1500 CNC with belt and pinion drive and lead screw drive options.

Birdie CNC

OpenBuilds CNC 500x500

Build Author

Zootalaws

Views

6480

Build Author

Zootalaws

Views

6480

OXENlarged

This is a 1500 x 1500 Ox build

OneUpSolid

This is the adult version of the QU-BD juvenile known as their OneUp. It not only uses extrusion framing instead of press board MDF, it is a full sized 8x8 build area w/ABS-Nylon capability. Only the OneUp's single Z axis driver concept is similar. I'm tempted to call it OneUpAdult for marketing.

CreoBot

T-slot, v-slot, aluminum angle make up the majority of the structure.

Parthenon

Custom build, after building the prusa i3 and upgrading to i3v, I wanted to build something more sturdy that can print fast and more accurate. Model is built in Fusion 360

Small Red OX

A small router for thin plate stock

V-Slot Workbench

A Workbench idea built from V-slot and openbuilds parts.

PROTODERA 5-axis CNC machine

We are a team representing private industry and public university all concerned about community. In the place i'm from we face problems related to prototyping industry, there's no accesibility to it, not because there is not machines to work with but the costs are really high if i want to make a single piece of any idea in order to develop a concept, our students get their degree but never were able to try any of the Hass or 3d systems machines available as it seems they need a PhD.

ChadRat's ox

This is my first cnc router. I like the open builds concept. I bought parts when I had the money. It seems everytime i think i have all the parts, i find something I am missing. My controller won't be ready until the end of the month so I am in no hurry. I will add things that i find. Eager to make some saw dust.

Build Author

Joey Selzler

Views

13563

Build Author

Joey Selzler

Views

13563

My JGro CNC becomes an OpenBuild Project

This is the story of my progression from the JGRO cnc router design to using the OpenBuild system. In the process I think I have learned some things about cnc routers and the accuracy required to make a good build.

Build Author

Nugz

Views

13532

Build Author

Nugz

Views

13532

Angus : A Slightly "Beefier" OX

This is where I will share my attempt at building a slightly "beefier" OpenBuilds OX CNC Machine using commonly available parts in the spirit of OPENBUILDS and Open Source in general. I have a tendancy to over-build things so I will be balancing that tendacy against budget constraints and common sense as much as possible.

Build Author

Christer Langley

Views

9461

Build Author

Christer Langley

Views

9461

CNC-Solutions Build

My first Build with V-slot

CNC CARDBOARD BOX CUTTER

Just an easy build .... uncomplicated.... simple tools .... but hoping for a good result!