CNC ROUTER BUILDS

Build Author

JWhitten

Views

14140

Build Author

JWhitten

Views

14140

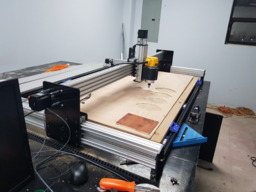

Build #2 - Bigger & Stronger

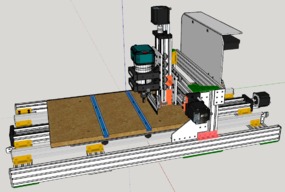

Large format CNC router with a 1500mm x 3000mm cutting envelope (5 x 10 ft) strong enough to cut wood and aluminum constructed from 20-series and 40-series aluminum extrusions. Complete Project Log w/ Pictures: https://goo.gl/photos/Co81AvGwVijE2zow9

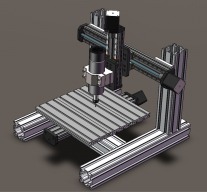

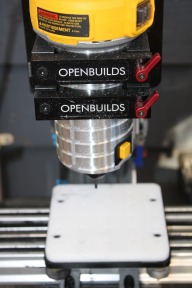

Improved CBM

Yet another build of an improved C-Beam Machine, improving stiffness, size, versatility, and strength without increasing costs much.

Build Author

viktop

Views

18587

Build Author

viktop

Views

18587

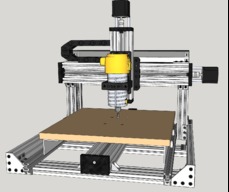

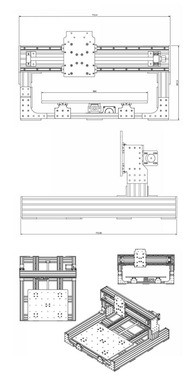

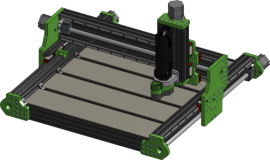

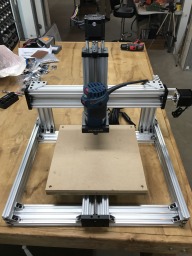

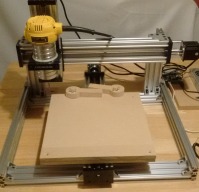

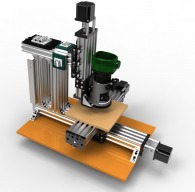

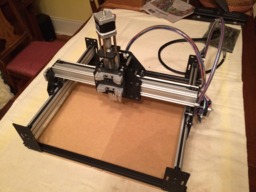

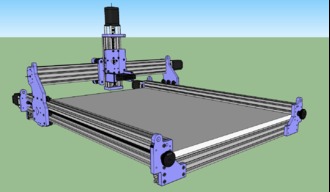

Simple CNC Router (Nema17, V-slot 2040, Arduino, GRBL)

An OX-inspired mini desktop mill.

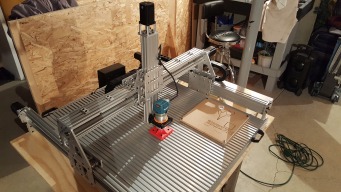

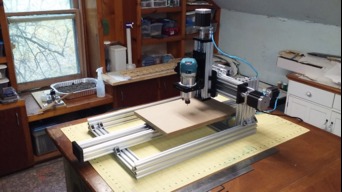

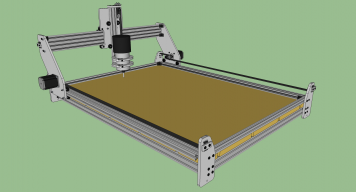

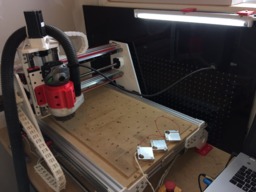

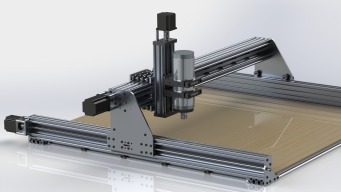

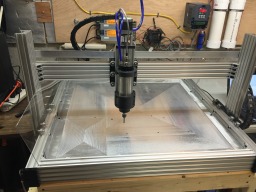

Fixed Gantry CNC Router

A fixed gantry router using OpenBuilds control and electronics.

Build Author

Frank Del Favero

Views

9737

Build Author

Frank Del Favero

Views

9737

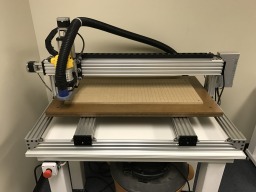

Portable self-contained Lead 1010 table

I have a two car garage NOT devoted to 3d printing or CNC. I have set aside a space for my 3d printer and a place to store my portable CNC table. The reason it’s portable is so that I wheel and can use my Lead 1010 outside where it won’t make a mess in the garage. The table is self contained. It houses a vac system as well as my CNC tools and supplies.

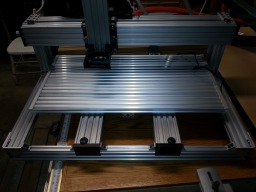

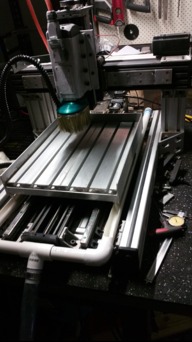

C-Beam XL with Aluminum Bed

C-Beam XL with v-slot aluminum bed for fixturing.

Behemoth cnc router with linear rails

Behemoth cnc router build in progress using hiwil rails and closedloop servos.

Horizontal MiniMill (x5)

The search for an affordable hobby 5 axis machine.

Custom 4x4 CNC

I started designing and ordering parts for this build back in Oct 2021. Unfortunately life got in the way and I had to sideline the project to deal with more important projects. I am now back working on this project full time. I originally was building a MPCNC on this torsion box platform I built but quickly realized how difficult it would be to produce anything with good accuracy. So I decided to design my own CNC that would be more robust and accurate.

The RAT. A form ply and aluminium hybrid.

A hybrid of form ply and aluminium. 835x1260x100mm working envelope.

Build Author

Peter Oakes

Views

44295

Build Author

Peter Oakes

Views

44295

The Bull Dog, A RoverCNC OX based 1500mm x 1500mm CNC - Tutorial build

I have based this build on the OX build so I will not be going into too much detail of specefic assembly modules as they asre so well covered by Mark Carew already, but will go through the complete build on video. I will be addig additional tutorials on steppers and the other electronic parts as needed though as this project is sponsored by RS Components in the form of most of the Electronics and this is also the key focus of my YouTube channel www.youtube.com/c/thebreadboardca.

Schematix OX metal build

OX metal build from an noob

C-Beam Machine XL

Overview of my experience building the C-Beam Machine XL from OpenBuilds, along with updates as I move along and get it going. My application is for creating plates needed for lab functions, 19 rack bay covers, and whatever else arises.

Build Author

Mark Carew

Views

36616

Build Author

Mark Carew

Views

36616

PhlatPrinter MK 3

The Phlatprinter 3 was designed to be used in a small shop with the ability to cut large sheets of foam for RC airplane projects. The idea was that you could save all of your aircraft as models and tweak to perfection after every flight.

OX, of the house Steel

OOZNEST Style OX machine with 3D printed panels

Build Author

pedrofernandez

Views

12183

Build Author

pedrofernandez

Views

12183

Another Sphinx 7550 Made by an Openbuilds Cbeam

feel free to ask anything about this builds, but im a airline pilot and sometimes responding maybe will take me. while!!

Build Author

HuguesP

Views

9264

Build Author

HuguesP

Views

9264

YACLR CNC

Yet Another Chinese Linear Rail CNC, my first one, doing this mainly for the fun of building it more than using it.

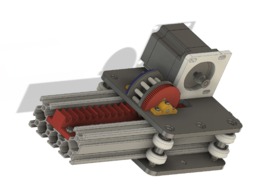

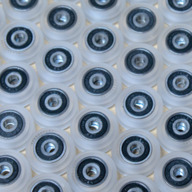

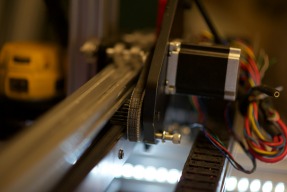

RRP - Roller Rack Pinion System

Current progress uses existing openbuilds bearings, but also uses 8mm shafts (custom)

LR/BS CNC Router

An easy to source/easy to build, yet quite robust CNC router. This design has not yet be implemented.

Build Author

that-jim

Views

11931

Build Author

that-jim

Views

11931

Z-Axis Upgrade For My Sphinx

Z-Axis Upgrade For My Sphinx

Build Author

alex_b

Views

17230

Build Author

alex_b

Views

17230

RONIN OX | The G10/Carbon Fiber Hogger

The Ronin OX is a dedicated fiber composite milling machine. I give a complete in-depth article on how to take a nearly stock OX build and easily turn it into something that can mill carbon fiber and G10 plate effectively and quickly.

OX Super "C" - Cpmpleted 11/02/16

This CNC utilizes the C-BEAM extruded aluminum for the "X", "Y", and "Z" axis. The gantry will move similar to the OX along with the "Z" except I am incorporating the C-BEAM instead of the 20x60 V-RAIL. To make the system as strong as possible I am using two C-BEAM rails back to back. The "Y" axis will encompass two sets of roller on both side of the C-BEAM extruded rails for added strength. All of the plates for this were created using the C-BEAM machine I completed several month ago.

Nox 1500mm x 1500mm C-Beam

C-Beam build using a double C-Beam for the X axis. 1500mm x 1500mm

Build Author

AK-Creation

Views

14961

Build Author

AK-Creation

Views

14961

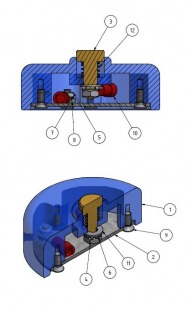

Reference sensor for CNC Tools

For the x and y Axis you set the zero point with a limit switch, but how can you get the zero position for the z Axis? You have different thickness of material to mill and when you change the tool, you have also a other z Axis positon. With the Sensor, you can define the zero position of the piece automaticly.

C-Beam to C-Beam XL Upgrade

This is my first public build. Please be kind. We upgraded our C-Beam to the C-Cbeam X-Large. I want to give special thanks to Moag and the OpenBuilds team for making this happen.

Arctic_Stingray CNC

This build is based on the C-Beam build by Mark Carew. I have added axis limit switches and a remote mounted control cabinet. This build also uses a custom moveable table.

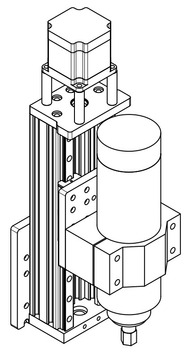

MiniMill Z Axis Upgrade with Offset Motor

Upgrade your Minimill with an off-set Z Axis Motor

MMXL - A MiniMill Conversion

Using most of the parts of the MiniMill, and adding a few other parts (cost < $200), transforms the MiniMill into a very capable machine. Final build area as shown is 10.25" x 16". With a custom Y-plate, I will take it to 10.25" x 20-24".

Build Author

jtaggard

Views

37187

Build Author

jtaggard

Views

37187

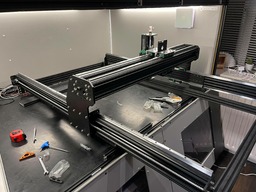

Modular DIY CNC Machine

This modular CNC machine is based on the OpenBuilds ACRO System, however I wanted something that did more than just laser engrave. So I designed my machine using the same style as the ACRO but with some upgrades such as an actual Z-axis and the ability for multiple tool attachments.

Build Author

Weldsmith

Views

7728

Build Author

Weldsmith

Views

7728

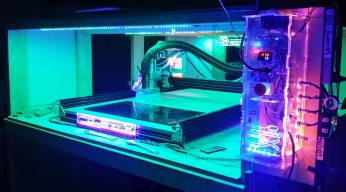

CUT SMITH

I am building a multi tool CNC. I plan to have a quick change tooling system that will accept Routers, oxy acetylene torch, Plasma torch. etc. there will be a water bed under the convertible router table / work bench. The inspiration to build this machine is from having a small garage and not a shop.

WorkBee 750x750 build

This CNC build is to help with some areas of my guitar builds - mainly inlays but some body work as well where appropriate. I expect it will be used for lots of other things once I get to know what it's capable of (sorry - what I'm capable of!).

Build Author

jz321

Views

4574

Build Author

jz321

Views

4574

OTiS 500mm

OTiS (Off The Shelf) is 500mm cartesian CNC that can be built with all off the shelf parts from OpenBuildsStore. It features C-Beam actuators and a V-Slot frame.

Build Author

Scott Martinez

Views

12196

Build Author

Scott Martinez

Views

12196

The Growler

This machine is a heavy duty, moving gantry style CNC router. It uses Teknic ClearPath servo motors driving ballscrews and linear rails. The machine has 36" x 48" x 19" of travel with about 7" of clearance below the gantry.

Build Author

Kyo

Views

28671

Build Author

Kyo

Views

28671

Sphinx 55

A Sphinx build to inspire and encourage all those who want to get started with cnc to check out Opensbuilds line of machine bundles and hardware.

Tall OX

After completing a standard OX build, I found I didn't have enough Z-clearance and designed a set of taller gantry plates

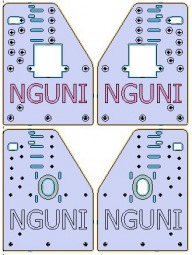

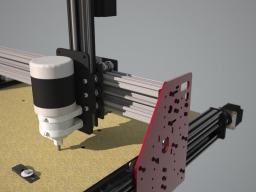

The Nguni - an OX variant

A modified OX with more X clearance, MDF plates, vacuum table

openbuilds rovo c-beam (700*1000)(1000*1000)한국오픈빌드.

Open the build will create open and sharing. 오픈빌드는 만들고 오픈하고 공유합니다.

CNC Rotary Table Rotational Axis, A Axis B Axis 4th 5th Axis CNC Dividing Head

This is my first major project.

Build Author

Ronald van Arkel

Views

16635

Build Author

Ronald van Arkel

Views

16635

Upgrading the C-Beam machine

So we have new plates, stronger motors, belt drive reduction, but what should we do with them? In this article you might find the answer you were looking for as we took an “old” C-Beam machine and started to upgrade the X/Z body and added more torque and precision to the Z-axis.

Custom Ox

Custom black and red Big Ox

RSW's C-Beam Build

I built a CNC Router using 3/4 MDF, 1/8 aluminum angle for bearing races and various other odds and ends. I learned a lot about how not to build a CNC router. I found Openbuilds.com and decided to build a C-Beam for my first build. The long term idea is to use this machine to build custom plates for and OX type machine and a 3d printer.

C-Beam "2" XLarge CNC Router

C-Beam 2XL CNC Router

Stargeezer Vertimill

Next up will be the electronics package. My parts bins are overflowing with boards so this may be the hardest decision to make of the entire build.

Build Author

dmasters

Views

8245

Build Author

dmasters

Views

8245

DM C-Beam XXL Tank

1000mm x 1000mm C-Beam XXL CNC with external drivers and high torque Nema 23 motors, 2.2KW Spindle with VFD.

Starting my build 2.8mx1.4m

Starting my cnc router, laser and plasma using aluminium 80x80

Workbee with Duet controller

Workbee 1010 with Duet controller from Ooznest

Another C-Beam machine

This is basically a Sphinx variant with few changes of my own...hope it'll work.

Build Author

Ryan155

Views

14033

Build Author

Ryan155

Views

14033

RIGCNC

I made a mill from first principles because I didn't like any of the ones that were out there, More info can be found on the website RigCNC.com

Build Author

Mark Carew

Views

14815

Build Author

Mark Carew

Views

14815

Phlatprinter MKII

Phlatprinter MKII Foam Cutting Machine

Build Author

SlyClockWerkz

Views

16917

Build Author

SlyClockWerkz

Views

16917

1000mm X 1500mm OX CNC -- Fiber/Garolite

Building the full size OX.

Build Author

Steve B

Views

15714

Build Author

Steve B

Views

15714

OX PPR - Portable Plasma/Router

PPR = Portable Plasma/Router. A ~30x30"work area with leadscrews. Work surface is below support members. Can be placed ONTO cutting surface.

Another (Mostly) Stock OX

For my first Openbuilds project, I decided to put together an OX CNC Router.

Build Author

ymilord

Views

22292

Build Author

ymilord

Views

22292

C-Beam Rigid - 'The Hog'

C-Beam Machine baseline build. DW618 Spindle. SuperPID. Gcode Controlled Mist Coolant. Rigid Work Surface. NEMA 23 (425oz-in) Leadshine 4 Axis Stepper Driver. LinuxCNC (MachineKit) Tool Touch Off Probe.

Build Author

ymilord

Views

12733

Build Author

ymilord

Views

12733

Kyoujin Mk1 (C-Beam /w Rack & Pinion)

C-Beam based CNC with Rack & Pinion (for the X Axis) and lead screws (for the Y Axis)

Jim's C-Beam Machine Build

This machine is fantastic. Teamed up with Fusion 360, Inkscape, and GrblPanel, I'm well on my way towards making at least one Christmas gift this year. I had some frustrating times during the build, mainly with getting everything to go together square, but overall it was fun. I can see that I'm going to need to be a bit creative in order to max out the work area for this machine so that I can produce the product I bought it for, but it will be able to do so much more for me as well.

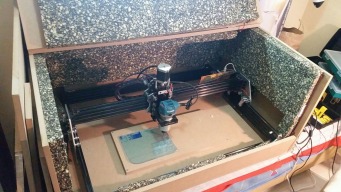

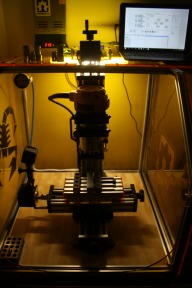

Soundproof case for Ox

Not much to say... Soundproofing box for noisy works... Build in MDF and 20 mm plexiglas. Very effective!!!

Build Author

Apothus

Views

22506

Build Author

Apothus

Views

22506

Sphinx rigid XL

Rigid variant of the C-Beam sphinx platform

Extendable Mini Mill

Another MiniMill, different to the OpenBuilds version and potentially more flexible because of the design.

Build Author

CharlieShimota

Views

16235

Build Author

CharlieShimota

Views

16235

Vox Solid State

I never thought owning a CNC machine was possible until I stumbled upon the Openbuilds site. After viewing numerous builds I was drawn to the Ox by Mark Carew but ultimately decided on a build of similar design, Halloumi by Savvas. It's a C-beam design driven by Nema 23 steppers with Acme lead screws. Like Savvas I will be fabricating temporary plates to get up and running then use the machine to mill the final plates. The material I'm using for the temp plates is solid surface (Avonite).

C_Beam Hammerhead 5x

setup for learning 5x

YAPCNC (Yet Another Poor's Man CNC)

Yet Another Poor's Man CNC (YAPCNC) is my first attempt to build a CNC. The idea is for the build to be as inexpensive as posible while being usable for my goals.

Build Author

Andreas Bockert

Views

12010

Build Author

Andreas Bockert

Views

12010

Sphinx Z-axis upgrade

Upgraded Z-axis for Sphinx-style CNC using ball screws and linear rails.

Workbee 1015 (50" wide by 30")

A Workbee able to cut 48"x24" material, built to continuously feed material so one can cut full sheets of ply.

Gary's Mod Plates for OX Heavy Duty X and Z

Gary's take on the OX HD X and Z plates, making it stiffer, adding mini wheels to the C-beam and Quick removable Z axis.

Gigantesque CNC

This is a upgrade to make a little deeper and a little bigger foot print for cutting. This is a copy of design off Rob Taylor idea for Dbl C Beam setup. The goal though is to design it around a new build with minimal tools for some one with no cnc access. Drillpress and drill bits and tap set. A 10in Non ferrous metal cutting blade for my table saw. Paper printer for printing DXF files.

5 x 10 CNC - Sub $3000 - Wall Mountable

I wanted a 5 x 10, Wall mounted CNC, that cost less than $3000. I think Im pretty close.

Tool position setting Part I

The method used for tool position setting is a matter of personal choice but this is what I do.

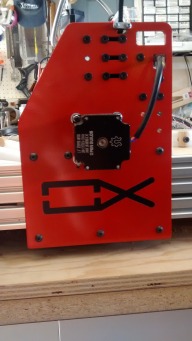

Small Red OX

A small router for thin plate stock

Build Author

M^3

Views

22036

Build Author

M^3

Views

22036

M Cubed CNC Mill

A no-nonsense CNC mini mill to get the job done.

CNC Jr.

A small, quiet and clean desktop CNC designed for fine cutting.

Build Author

Sonny Lowe

Views

7008

Build Author

Sonny Lowe

Views

7008

The MakerSL Customized OB Minimill

This is my interpretation of the OB Minimill, what I've changed so far, and what may continue to change as my requirements change.

Schematix Ox-Metal Build

A build of Schematix's Ox-Metal design, with a 0.8kw watercooled spindle.

Desktop PCB Maker

With the focus always on larger builds I wanted to focus on a desktop PCB milling machine that fulfills the average users desktop needs at an entry level cost. Design considerations will allow expandable capabilities to include 3D printing and any other functions a small form Cartesian robot can perform. The current iteration has a desktop footprint of approximately 15.5" X 14.5".

Build Author

chenderson

Views

12865

Build Author

chenderson

Views

12865

CRH C-BEAM Router, steel capable

C-beam based CNC router using mostly openbuilds parts.

Build Author

Joerharris

Views

6571

Build Author

Joerharris

Views

6571

Joe Harris's all metal CNC Router build

I'm building a CNC router in my garage (almost finished!) and I'm keeping a video build log of the process in the hope it may be useful to others wanting to do the same. I don't have much in the way of fancy tools so expect a bit of innovation on the way!

Build Author

Rob Mahan

Views

13779

Build Author

Rob Mahan

Views

13779

Rob's C-Beam Machine XLarge

This is my first CNC router build, so I started with the OpenBuilds C-Beam Machine XLarge mechanical bundle, including four high torque stepper motors. I took my time with the mechanical build, sought and found some great help for my control system, and designed and built a custom cabinet to house everything.

The BEE and ME

I have always wanted to work with CNC machinery...a few years back I got my chance to learn some basics at the Double Glazing Company where I was employed (very basic I might add) before the firm folded and I was made redundant...I wanted to continue learning and when I came across this site which push affordable machines I thought I'd give it a go. So I purchased a !000mmx750mm Screw Driven Workbee from Ooznest and I'm about to embark on my quest as many have done before me...Wish me Luck!

My giant "WORKBEE" 1750mm X 1750mm by ooznest

CNC MACHINE WORKBEE'S table making

Tool position setting Part III.

In this, the final part, I would like to introduce Machine Vision and show how it can be used, not only for tool position setting but also for resolving the triangle to calculate the G68 (local system rotated) for jobs which are not squarely placed on the work table.

Cheetah 1.1 CNC Router

I hope to have a working prototype built soon.

Routy GT2 300 BSX CNC Router

This is the first project that I would like to share with you. I know the build looks familiar and it is; it’s based on kram242´s Routy. Work area is 300*500*55 mm and is NEMA17/GT2 belt driven.

DTG OX

From where Mark left off from the Ox build I am going to film the whole process of customizing the Ox.

Build Author

Rakmup

Views

41394

Build Author

Rakmup

Views

41394

CNC Router Lathe

Steel square tube frame with dual feed gantry and indexing lathe section. Will have 36" x 30" x 6" travel. Has a Harmonic Drive on the 4th Axis.

My first OX build

This is the story of my experience building a 1000 x 750mm OOZNest OX CNC router

Desktop CNC machine

Stable solid, hope can cooperate with coolant in the future.

MakerSL MSL-21 OB Minimill Enclosure

Simple enclosure for the OB Minimill

Robo Morten

A horizontal-router CNC using openbuilds parts geared toward routing out mortise and tenon joinery; or any other end grain work on wood.

C-Beam Sphinx Vacuum

A modified 1000x1000 Sphinx, with a built in vaccum table.

SkyKae sphinx - c beam xl hybrid

I took what I thought were the best parts of the sphinx and the c beam xl to build a bigger and faster machine.

Yamm (Yet another MiniMill)

First time CNC user having a good time with a MiniMill

Build Author

GDanger117

Views

12360

Build Author

GDanger117

Views

12360

Gantry CNC - Decisions made only to change over and over.

This is my first CNC build. As per the norm, I went in with months of research, planning, and resource gathering tied neatly together with a solid plan. As the path went on, the plan continued to change to accommodate issues I hadn't counted on. But, at the end of the road, the project reached completion, and I learned a ton along the way!

EOX

Open builds style wood CNC router. Usable work aria 1000mm x 1250mm x 150MM (X x Y x Z). 80x40 C bleam for the Y axis , two 60x20 beams for X axis and a 60x20 fo Z. Interlocking GT3 belts for X and Y. Looking to change over to a rack and pinion system in the future. 8x8Tr Lead screw for the Z. Leadshine HBS507 close loop drivers and 3-phase servo motor 573HBM20-EC-1000 motors driving the Y and X axis. Would recommend them to anyone looking for servo like performance at a affordable price.

HandCrafted WorkBee - HCWB

This will be a slow build as I collect parts and materials as funds permit for 1000mm x 1000mm Workbee. I call it the "Hand Crafted WorkBee" because I will be hand making the plates and as much of the build as possible using a drill press and hand tools.

Shapeoko 2 - my first CNC

This was my first foray into CNC. I chose to go with a reliable kit build since my knowledge of GCode, controllers, and steppers was pretty rudimentary.

MiniMill build

A table top OpenBuilds MiniMill build. 48V 52mm spindle with ER11 collets.

Reworked Routkit SD

I could not "tram" the spindle to the table. I found that the V Rails could not accurately be adjusted so the Gantry was equal distance from the spoilboard in multiple places.

Build Author

GinoTheCop

Views

14632

Build Author

GinoTheCop

Views

14632

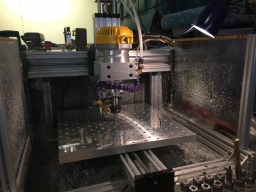

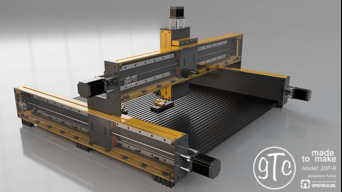

GTC2020

A 1000 by 1000 CNC Router with linear rails and a control box.

My C-Beam machine...from 500 to 1000mm base

C-Beam machine - 1000mm base.

Build Author

Corey Corbin

Views

7604

Build Author

Corey Corbin

Views

7604

Ball Screw Carrier.

Create a ball screw carrier with out BF BK bearing blocks.

Build Author

CNCGear

Views

10654

Build Author

CNCGear

Views

10654

The BlackBee CNC

Ball screw drive, linear rail CNC Kit