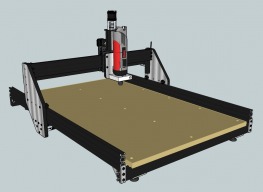

Cartesian Style CNC

Build Author

Kyo

Views

143137

Build Author

Kyo

Views

143137

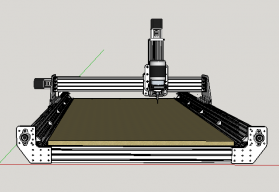

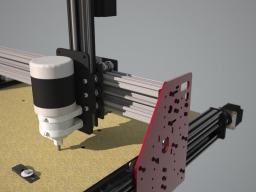

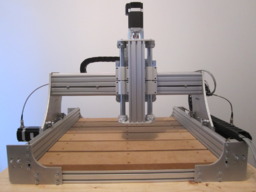

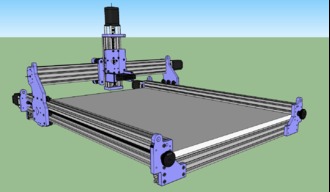

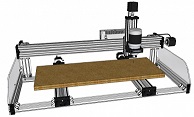

C-beam Sphinx

A strong desktop cnc router that will enable you to make larger aluminium plates without taking up to much room. Simple, strong and opensource ! Build one today..

Build Author

Michael.M

Views

66664

Build Author

Michael.M

Views

66664

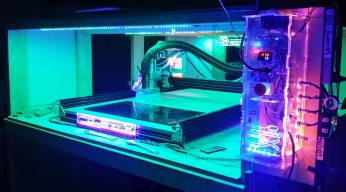

GRANITE 1.0

This machine has been in the works for quite a while. Most of the plates were cut with my Shpinx machine. I have a lot more photos and information to share soon.

Build Author

blterry1

Views

18152

Build Author

blterry1

Views

18152

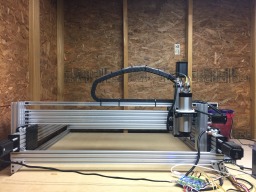

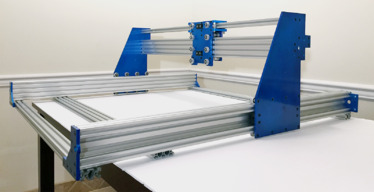

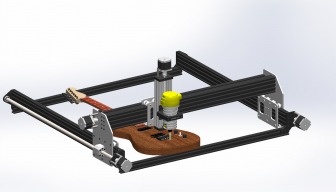

The Beeline CNC

Here are the instructions to build the Beeline custom CNC router table.

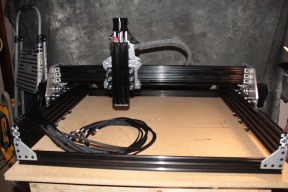

OX AI

This will be an Aluminum OX build. Plates and all design credit goes to Mark from open builds. I may add my own touches but mainly this is to see how Aluminum plates perform

Build Author

sebf34

Views

31478

Build Author

sebf34

Views

31478

OX Based cnc 3000 x 1500 Double belt

OX Based CNC

Build Author

roadss

Views

25105

Build Author

roadss

Views

25105

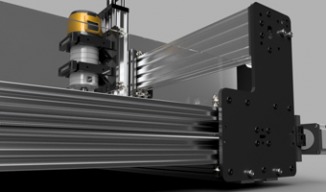

Rawcnc 1.5 Desktop Edition

This will showcase the build of my Rawcnc 1.5. A rigid cnc router from the Swedish company Rawcnc, featuring a rather cool linear motion system, rack & pinion and steel reinforced X-axis capable of milling aluminum.

ACME OX (A Lead Screw Driven Ox Derivative (850x1500))

Another build based on the original OX design with a cutting area will be about 26" (680mm) x 50" (1300mm) and driven by lead screws.

C-Beam XXLarge "Tank"

This is a modified build C-Beam XLarge. 1000mm C-Beam used for X and Y axis, and the Y Axis moves the X bridge, not the material being worked.

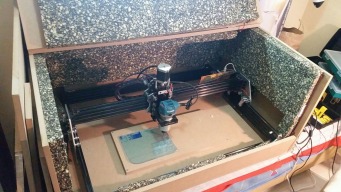

CubeFoot CNC

This small desktop machine is built inside a 300mm cube of 20mm extrusion. Work area is 14cm by 14cm. I used 400 step nema17 motors all around.

Build Author

ahayden

Views

26697

Build Author

ahayden

Views

26697

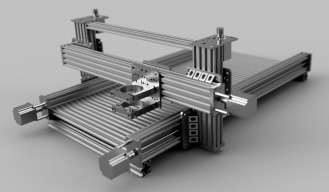

C-Beam Prefab Untitled

The C-Beam Prefab Untitled is designed as the cartesian compliment to the C-Beam XL. With the exception of requiring a couple more 1000mm C-Beams and lead screws, the build requires a minimum of additional parts. The primary intention of the build is to maximize the cutting envelope while still staying within the sweet spot for C-beam rigidity. This design can easily be modified and allows for further custom structural components to be cut with the initial build platform.

Build Author

Michael.M

Views

43017

Build Author

Michael.M

Views

43017

7050 Sphinx

This is a Kyo Sphinx CNC Router build. Working Area: 350mm X 500mm Link to original design: https://openbuilds.com/builds/c-beam-sphinx.3605/

Build Author

Sword66

Views

13401

Build Author

Sword66

Views

13401

The Archon R2

The Archon "In the style of Cartesian movement." A brief overview, guide and summary of my highly experimental build. and some insight into the challenges of building such a large format/belted machine.

The Frog: CNC Router

Frog CNC Router. Inspired by OX and "Routy". 24"x36" active working area, approx. 3" usable Z motion.

Build Author

Robert Hummel

Views

25122

Build Author

Robert Hummel

Views

25122

Stinger V Micro Mill

While building my OX AI I found myself with left over v slot and thought to myself, what do I need that I can build using them? Well since I make a lot of my own PCB boards for projects I figured a micro PCB mill would fit the bill ;) With inspiration from the OX and OX AI I give you the Stinger V :)

The RAT. A form ply and aluminium hybrid.

A hybrid of form ply and aluminium. 835x1260x100mm working envelope.

Build Author

Robert Bailey

Views

28976

Build Author

Robert Bailey

Views

28976

FRANKINATOR -- My CNC Router Built Around The C-Beam Rail

I started this build about 2 weeks after the c-beam hit the store. I purchased a single bundle and ordered a TinyG to run it. where I work I have Hardware, Software and Mechanical engineers and they all got sucked into my project. they want one to do prototyping at the office, once they see mine...

Build Author

alex_b

Views

16198

Build Author

alex_b

Views

16198

RONIN OX | The G10/Carbon Fiber Hogger

The Ronin OX is a dedicated fiber composite milling machine. I give a complete in-depth article on how to take a nearly stock OX build and easily turn it into something that can mill carbon fiber and G10 plate effectively and quickly.

Salmon Sphinx 1.0

A tribute build based on Kyo's wonderful CBeam Sphinx. My hope is to improve on that build slightly, but to be honest, I'll probably just screw it up. I'll use this build to publicly document my failures.

spunks.cam

Design of a multifunctional CNC machine.

Another (Mostly) Stock OX

For my first Openbuilds project, I decided to put together an OX CNC Router.

Build Author

CharlieShimota

Views

15829

Build Author

CharlieShimota

Views

15829

Vox Solid State

I never thought owning a CNC machine was possible until I stumbled upon the Openbuilds site. After viewing numerous builds I was drawn to the Ox by Mark Carew but ultimately decided on a build of similar design, Halloumi by Savvas. It's a C-beam design driven by Nema 23 steppers with Acme lead screws. Like Savvas I will be fabricating temporary plates to get up and running then use the machine to mill the final plates. The material I'm using for the temp plates is solid surface (Avonite).

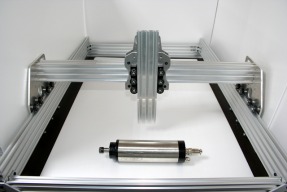

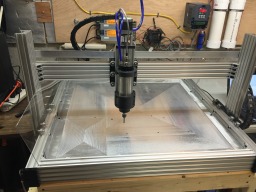

HD CNC

Heavy Duty build with 1605 Ballscrew and Linear Rail

Build Author

MarkM_NJ

Views

19521

Build Author

MarkM_NJ

Views

19521

Spartacus Inspire

My very first openbuilds cnc machine. Followed along DaztheGas's Spartacus build.

Sphinx 55 on MGN12 linear rails

My machine is a combination of the Openbuilds Sphinx 55, MGN12 linear rails knockoffs and custom made plates made by Chris Laidlaw

Build Author

Mike Campbell

Views

10563

Build Author

Mike Campbell

Views

10563

bor 454-D

A large format, modular, rack and pinion build designed around OpenBuilds components.

Custom 4x4 CNC

I started designing and ordering parts for this build back in Oct 2021. Unfortunately life got in the way and I had to sideline the project to deal with more important projects. I am now back working on this project full time. I originally was building a MPCNC on this torsion box platform I built but quickly realized how difficult it would be to produce anything with good accuracy. So I decided to design my own CNC that would be more robust and accurate.

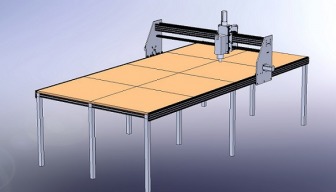

3000x1500 CNC

Here is my Project A CNC 3000 mm by 1500 mm, with a 2.2kW spindle collet ER25 and 4 stepper motor nema 23 425oz-in. The purpose being to have a large work surface for a minimum cost.

Build Author

winand

Views

17578

Build Author

winand

Views

17578

YAOR (Yet Another Openbuilds Router)

Yet Another Openbuilds Router, my version :-)

Build Author

Rural

Views

25568

Build Author

Rural

Views

25568

OS OX

Mechanically, a scaled up OX build (1500x1500). Electronically, GRBL on an Arduino and a gShield. From a software perspective, the focus is on useable open source software tool chains.

Small Red OX

A small router for thin plate stock

C-BEAM-GTC

Building a larger C-BEAM CNC Machine with no previous experience.

Build Author

Julius

Views

24834

Build Author

Julius

Views

24834

OX Balls - 1605 Ballscrew Powered 1000mmx1000mmm OX derivative

1000x1000mm Ballscrew driven OX Derivative. Dewalt 611 spindle and TB6600 Drivers.

Build Author

Savvas

Views

19156

Build Author

Savvas

Views

19156

C-Beam Lead Screw CNC Mountain

I’m making a desktop CNC machine based on the C-Beam platform. It will be driven by Tr8 Lead Screws, and initially made from 12mm birch ply plates.

Build Author

Gary Caruso

Views

24167

Build Author

Gary Caruso

Views

24167

OX Heavy Duty Build

OX Heavy Duty, using Chrisclub plates, for 2080 X-Y and C-beam Z

Ballmasters 1605 1500x1000 ox cnc

Upgraded 1500x1000 Ox cnc to 1605 Ballscrews on the Y axis. along with the J-tech laser to do most things.

Build Author

Jacob Lotter

Views

25585

Build Author

Jacob Lotter

Views

25585

1510 Workbee Modified

Some of the things that I have done to my 1510 Workbee Installed Linear rails and bearing blocks with drawings. Installed Ops console Made conversion plates for extruded aluminum to casters Extended z axis travel by a couple inches with steel plates. As of now in the process of installing Lead screws across the 1500mm length.

The BEE and ME

I have always wanted to work with CNC machinery...a few years back I got my chance to learn some basics at the Double Glazing Company where I was employed (very basic I might add) before the firm folded and I was made redundant...I wanted to continue learning and when I came across this site which push affordable machines I thought I'd give it a go. So I purchased a !000mmx750mm Screw Driven Workbee from Ooznest and I'm about to embark on my quest as many have done before me...Wish me Luck!

Build Author

mytechno3d

Views

26778

Build Author

mytechno3d

Views

26778

Router / plasma cutting table ( Rack and pinion )

Heavy DIY plasma cutting table

Build Author

Ryan155

Views

12707

Build Author

Ryan155

Views

12707

RIGCNC

I made a mill from first principles because I didn't like any of the ones that were out there, More info can be found on the website RigCNC.com

Build Author

Frank Del Favero

Views

8566

Build Author

Frank Del Favero

Views

8566

Portable self-contained Lead 1010 table

I have a two car garage NOT devoted to 3d printing or CNC. I have set aside a space for my 3d printer and a place to store my portable CNC table. The reason it’s portable is so that I wheel and can use my Lead 1010 outside where it won’t make a mess in the garage. The table is self contained. It houses a vac system as well as my CNC tools and supplies.

Build Author

richthorn

Views

8007

Build Author

richthorn

Views

8007

Aluminum Ox

I have been looking for a good solid kit to build off of for some time and when I saw the Ox buildlog I knew I had to have one. Ordered most of the pieces from Open Builds and started planning. Had a nice gentleman named Chris cut the required plates from 6061 aluminum for me (he sells them on eBay now if you're interested) and got to work.

Build Author

Serge E.

Views

60240

Build Author

Serge E.

Views

60240

myOX : a 4' x 2' OX CNC with potential

This is the story of me building myOX - my version of the "ideal" OX. I want a machine which can route/mill at least 4' wide and as long as I can feed through (don't be shy, think "infinity") as well as going deep on multiple faces - manual 4th axis. I have loads of ideas to take myOX towards that goal and way beyond. Time will tell. Just follow along through this build and possibly a few others along the way ... Check out my OXCalculator : let your computer figure out your BoM

Florida Ox 2x4 Area 51 CNC Parts Original Build

2x4 Ox with Vac table

OX Fixed Dust Shoe

A simple fixed dust shoe for your OX.

OX Tale

1000mm x 750mm OX with some planned enhancements. My first venture into CNC.

Cebu

Another build based on the venerable OX. xPRO CNC controller, and a few extras.

GrOX (OX based router)

1000mm x 1500mm OX router using Openbuilds parts and plates by Chris Laidlaw

Black Rabbit 1500

This is a router that I designed that is loosely based on the Openbuilds Ox, but designed to be heavy duty, rigid, and yet quick and agile.

Build Author

Maxime Favre

Views

9165

Build Author

Maxime Favre

Views

9165

SmoothiebrainZ CBeam Machine

Modded Plate maker with: Smoothiebrainz board and DQ542MA SN04 Endstops Modded Z axis Aluminium build plate and renforced Y axis Dust shoe

Build Author

Savvas

Views

14054

Build Author

Savvas

Views

14054

Halloumi CNC Machine - Acetal Plates

I built the original machine using plywood plates, and always intended to upgrade those parts to more durable ones. I decided to go with acetal as it's a lot easier to cut than aluminium. I used fusion 360 to model and rebuild the original machine. Once I have assembled everything and feel confident it all works I will release the plate designs here.

Build Author

dmasters

Views

7945

Build Author

dmasters

Views

7945

DM C-Beam XXL Tank

1000mm x 1000mm C-Beam XXL CNC with external drivers and high torque Nema 23 motors, 2.2KW Spindle with VFD.

Build Author

Joerharris

Views

6300

Build Author

Joerharris

Views

6300

Joe Harris's all metal CNC Router build

I'm building a CNC router in my garage (almost finished!) and I'm keeping a video build log of the process in the hope it may be useful to others wanting to do the same. I don't have much in the way of fancy tools so expect a bit of innovation on the way!

Build Author

Andre Cooke

Views

16840

Build Author

Andre Cooke

Views

16840

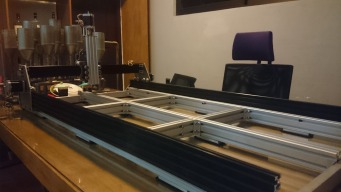

CNC Greenland Paddle Carver build

CNC mill for carving / milling Greenland Paddles

Build Author

Michael.M

Views

9192

Build Author

Michael.M

Views

9192

Sphinx Evolution

Let me explain: About a year ago I was planning to build a CNC router of my own design. I started gathering components including the THK linear rails. I soon found out you pretty much need a CNC to build a CNC and this is when I decided to build my Sphinx machine. I've had these rails and some other parts sitting around so it's time I used them! I'm planning to incorporate linear rails and 1605 ballscrews into the Sphinx design. I really like the overall appearance of the Sphinx.

Gary's Mod Plates for OX Heavy Duty X and Z

Gary's take on the OX HD X and Z plates, making it stiffer, adding mini wheels to the C-beam and Quick removable Z axis.

Build Author

that-jim

Views

46331

Build Author

that-jim

Views

46331

LINEAR RAIL SPHINX 55 (Blue OX plates)

Machine based on Sphinx 55 built with linear rails.

Build Author

Scott Drake

Views

23650

Build Author

Scott Drake

Views

23650

1500x1000 CNC Router

1500x1000, additional frame stiffening from laser cut Stainless steel bracing plates, Nema 34 motor upgrade and Hiwin 16mm ballscrew additions on the way. Ethernet Smooth stepper control, 2.2kw Water cooled spindle. Schneider atv320 variable speed drive. SICK inductive limit switches, Leadshine Em882S stepper drivers ,1kw 62V supply for Stepper drives

Build Author

BCulbertson

Views

2047

Build Author

BCulbertson

Views

2047

Lead 1515 with Upgrades

My upgraded OpenBuilds Lead 1515

Cheetah 1.1 CNC Router

I hope to have a working prototype built soon.

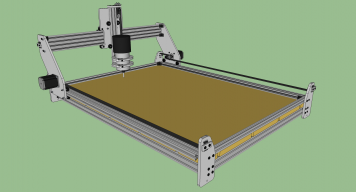

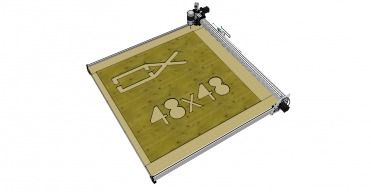

OpenBuilds OX 48x48 Aluminum

Variant on the OpenBuilds OX CNC Router, enlarged with 1500mm length beams for a cutting area of 48" x 48". Based on the original model, the larger of the two, with the addition of a third 20x60 beam on the gantry for strength. Estimated cost is around $1100, minus the router.

Router / Plasma Prototype Build

this is my first attempt at a CNC Table

Long Ox with drop in table

This build is a modified Ox build. The long rails are 1000mm. My build includes a solid clamping table.

Ox with Gecko Controller and CNC Linux

This build is the documentation of someone with no experience building the OX cnc machine with a Gecko G540 controller and CNClinux

Build Author

Pendragon

Views

10011

Build Author

Pendragon

Views

10011

bOX

A bigger OX. As this build is nothing new I will detail my build process, I am not an experienced builder, this will maybe help someone else. The size of the bOX will be 100cmx75cm. I will use aluminium plates, a tinyG, and most probably only open source / free software.

Build Author

Bear

Views

10593

Build Author

Bear

Views

10593

OXBear

ANOTHER OX!~ Huge Thanks to Marc Carew and Open Builds. The primary reason I am building this CNC mill is to aid in my homemade snowboard creation. I am going to try and document as much of everything as I can and post it here to help others going a similar route. I know from past projects that taking the time to document each step can be tedious when you want to charge ahead but I will try! I hoping to get feedback on my design choices and set up as I am a complete newbie to CNC.

OX-LX-3D

An OX build - little large than specs and plates 3D printed

Build Author

DiggerJ

Views

8370

Build Author

DiggerJ

Views

8370

Babe - The Big Blue (Laser) OX Build

A 1000 x 1500 OX build with the ability to router cut dovetails as well as laser engraving and light cutting.

Build Author

d0rk1e

Views

7408

Build Author

d0rk1e

Views

7408

OXford (OX fortified)

150x75 cm OX with additional Y axis supports and hopefully a working double belt system

OX Build

Standard OX Build

The Buffalo

OX 1500 x 1000 mm

Build Author

SlyClockWerkz

Views

16463

Build Author

SlyClockWerkz

Views

16463

1000mm X 1500mm OX CNC -- Fiber/Garolite

Building the full size OX.

Build Author

inhan

Views

12295

Build Author

inhan

Views

12295

OPENBUILDS Korea (ROVO 1000)

I am very grateful to Mark Carew with passion and imagination. Therefore, the machine is good, but making the website there too daedanhaeseo The end of the same either way to invisible homework. Thank you for allowing openbuilds team submitted to the challenge once again for those with a passion that I feel like in Korea, I want to be a great help.

CNC Jr.

A small, quiet and clean desktop CNC designed for fine cutting.

Build Author

andrew Adsit

Views

13515

Build Author

andrew Adsit

Views

13515

OX Cable Management, Electronics Case, E-Stops

750mm x 750mm OX build, xPro V2 controller, 400W Spindle with PWM controller.

My Ox

What I want to build is a unit to: rout wood, plastic and occasional aluminium . to be able to swap cutters. i.e. drragknife, laser, router, drill

Mini-OX

An OX-inspired mini desktop mill. Designed in OpenSCAD, these parts are fully parametric and can be customized to your liking.

Routy GT2 300 BSX CNC Router

This is the first project that I would like to share with you. I know the build looks familiar and it is; it’s based on kram242´s Routy. Work area is 300*500*55 mm and is NEMA17/GT2 belt driven.

DTG OX

From where Mark left off from the Ox build I am going to film the whole process of customizing the Ox.

Sea-OX

This is my first CNC build. The Sea-OX is a machine built out of three 1000mm C-Beams. I plan to have a Y length of 1000mm and a X length of 650mm. The Z should have the ability to move approximately 100mm.

Build Author

Laurence Carroll

Views

10713

Build Author

Laurence Carroll

Views

10713

C-Beam Double X

Per the special notes its a variant of the C-Beam, Machine.... I have noticed that alot of people build a CNC router to cut parts for other larger CNC machines.. eg Delta Printers etc....plus this will enable me to cut parts for model RC plans UAV's etc...

Beaver's OX 1500

OX 1500mm x 1500mm w/1.5Kw Water Cooled Spindle & VFD ran by a Gecko G540 & Mach3

OX

My build of the OX kit from SMW3D.com

Build Author

Jesse Jenkins

Views

9218

Build Author

Jesse Jenkins

Views

9218

Hedron's build with Ooznest kit and Xylotex motors

A 3-axis flying gantry (4'x4') mechanical kit is assembled. A 3D printer is used to make cable chain for tidy and cheap wire management. A BeagleBone Black development platform with Machinekit software (LinuxCNC) is configured to control a Xylotex motor driver box connected to an Openbuilds Ox direct-drive pulley and belt motion system. A vacuum dust-collection system is designed, CNC-routed and installed. A steel table is made to mount the table onto.

openbuilds rovo c-beam (700*1000)(1000*1000)한국오픈빌드.

Open the build will create open and sharing. 오픈빌드는 만들고 오픈하고 공유합니다.

Build Author

yakecadi

Views

5171

Build Author

yakecadi

Views

5171

All directions to innovate

all directions to innovate

Arctic Ox CNC Router

This is a cartesian CNC Router build that is based off the OX CNC build by Mark Carew. I am using Spark Concepts CNC xPro controller board and their 400w spindle kit.

Contrariwise -- A C-Beam Router

A C-Beam router made almost entirely of standard parts. Electronics include an xPro v2 board and NEMA 23 motors. Cuts are made with a small 300W DC spindle. A pressure foot is used to minimize the need for workholding.

Build Author

UltiBots

Views

36995

Build Author

UltiBots

Views

36995

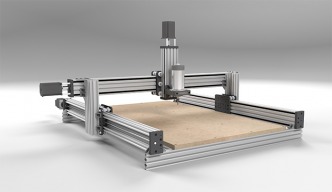

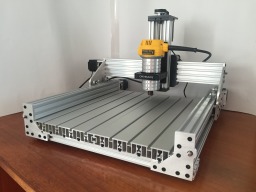

UltiBots CB3030 CNC Router

The UltiBots CB3030 CNC uses C-Beam, V-Slot and an extruded aluminum T-Slot work table. This allows 6mm T-Nuts, step clamps and blocks to secure materials to the work surface. The all metal design makes the use of a mister possible.

My first OX build

This is the story of my experience building a 1000 x 750mm OOZNest OX CNC router

C-Beam 1M

Basing this build on the C-Beam machine XL on the parts store, but added a few things to make it more like the C-Beam XXLarge "Tank" by Dollarz81. Going with the Dewalt 611 instead of a water cooled spindle at first. May change down the road. Using a Panucat Gradus M1 controller with BigFoot drivers.

OX CNC Router

Ca fait 2 ans que je rêve d'une Fraiseuse CNC. Ni trop grande ni trop petite, sans avoir le budget pour en acheter une toute faite. Je suis artisan menuisier ébéniste et j'ai finalement décidé de la construire. Le projet OX m'a séduit, alors je me lance.

OnyX-13

This is my OX. There are many like it, but this one is mine. My OX is my best friend. It is my life. I must master it as I must master my life.....

Build Author

chenderson

Views

12397

Build Author

chenderson

Views

12397

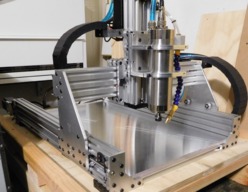

CRH C-BEAM Router, steel capable

C-beam based CNC router using mostly openbuilds parts.

Soundproof case for Ox

Not much to say... Soundproofing box for noisy works... Build in MDF and 20 mm plexiglas. Very effective!!!

ZANTRY CNC

CNC Based on CBeam, with No custom Plates, and Z GANTRY

MakerSL MSL-21 OB Minimill Enclosure

Simple enclosure for the OB Minimill

Build Author

Hisha

Views

8535

Build Author

Hisha

Views

8535

Sphinx XL/R7

A 1000mm x 1000mm Sphinx/R7 build.

C-Beam Sphinx Vacuum

A modified 1000x1000 Sphinx, with a built in vaccum table.

Build Author

Ryan Lock

Views

138287

Build Author

Ryan Lock

Views

138287

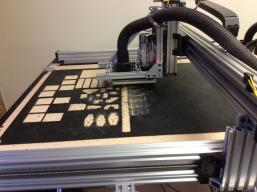

WorkBee CNC Machine

The WorkBee is our latest CNC Machine and is a culmination of all our experience, feedback, and suggestions from selling the OX CNC Machine over the past 2 years. The WorkBee is capable of accurately cutting foams, woods, plastics or aluminum at depths greater than 25mm to 0.2mm accuracy or greater.

SkyKae sphinx - c beam xl hybrid

I took what I thought were the best parts of the sphinx and the c beam xl to build a bigger and faster machine.