Build List

-

Active Filters:

be

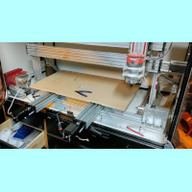

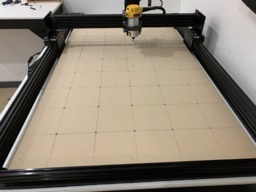

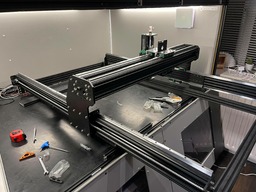

Workbee CNC 1500

Trying to build a machine of atleast 4x4ft working area. Work is in progress, hope to finish it soon

Build Author

James Evanko

Views

4758

Build Author

James Evanko

Views

4758

Ball Trajectory Machine

Need to build a machine that accurately positions objects for processing by a computer vision algorithm? Here is an example of a machine that does that for a ball trajectory application. The black anodized V-rails work well for applications in optics and imaging where the machine needs to stay out of the limelight.

Black out Edition Workbee 1010

Thanks to all the Open Build elves that meticulously package and wrap all the little tiny parts and pieces. I have put in a request to get you people a raise..

Build Author

Craig Hollabaugh

Views

4812

Build Author

Craig Hollabaugh

Views

4812

Hyatt and My Journey to Tonehenge

I'm conducing guitar loudspeaker cabinet fabrication technique research (material type/thickness, mechanical joints, adhesives, etc) and how these relate to cabinet/speaker coupling and enclosure resonance with respect to psycho-acoustics. Basically, does one speaker cab sound better than another and why?

Build Author

Vin1027

Views

7281

Build Author

Vin1027

Views

7281

C-Beam Sphinx

This is the original C-Beam Sphinx with the 16 wheel X gantry plates. I'm using the Ethernet Smoothstepper, Gecko G540 stepper driver and Mach 4 for motion control.

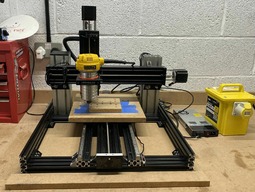

Phil's Workbee

Wanted a nice project to work and learn on... now have a big CNC to play with A 1500x1000mm Workbee

Build Author

Bikes and Beer

Views

4800

Build Author

Bikes and Beer

Views

4800

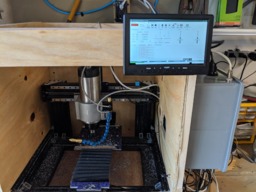

The Forever Project

Workbee 1010 Lead Screw with water cooled spindle and enclosure

John's Sphinx

1000mm x 750mm C-Beam Sphinx, running on Grbl

Build Author

Troy Proffitt

Views

28817

Build Author

Troy Proffitt

Views

28817

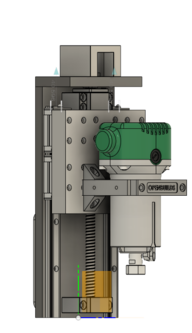

Sphinx Upgraded plates / ballscrews and linear rail

Upgraded Sphinx Cbeam using 3/8 aluminum plates and linear rails / ballscrews

Build Author

Christian James

Views

9819

Build Author

Christian James

Views

9819

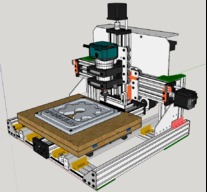

Workbee "style" 1010 cnc

This build is based on the Workbee 1010 CNC. It is not a kit build and is much the same as the original but with some significant changes made here and there as the build progresses.

Build Author

Jay Almers

Views

7927

Build Author

Jay Almers

Views

7927

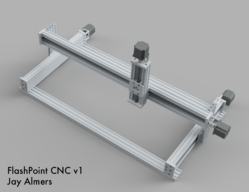

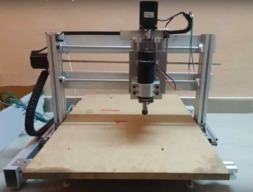

FlashPoint CNC v1: 500mm x 1000mm 3-Axis CNC Router

My build is based on many different builds but pieced together into a unit specifically to suit my needs. The footprint, without motors, is around 500mm x 1000mm with a gantry height of around 250mm. I used a combination of C-Beam, for the linear transmission, and V-Slot for the base and gantry supports. Forged angle connectors were used for attachment and I utilized the C-Beam gantry cart kits with anti-backlash blocks for both Y axes, the X axis, and Z axis.

"Stung by the Bee" OB Workbee 1010 Build

This will be a build Log for my Open Builds Workbee 1010 Build. I will keep a full descriptive log of the build and make any notes in the hope that it will help other builders that decide they would like to build this machine.

Build Author

Doug Rowley

Views

4303

Build Author

Doug Rowley

Views

4303

My Workbee 1010

This is a workbee 1010 build using the mechanical parts from Open Builds. The electrical and electronic parts were from a prior build of a Root 3 CNC by Sailor Pete.

Build Author

patnap71

Views

6830

Build Author

patnap71

Views

6830

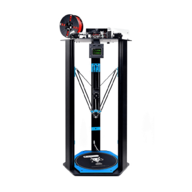

MEGADELTA, TLM CLONE with 500MM bed

All metal frame 500mm bed Delta 3D printer

Build Author

msdosfx

Views

6116

Build Author

msdosfx

Views

6116

Workbee 1510 Screw Driven

Workbee 1510 screw driven build by MsDosFX.

OoozNest WorkBee

A Journey on the WorkBee Build...

Build Author

Stan Howe

Views

3282

Build Author

Stan Howe

Views

3282

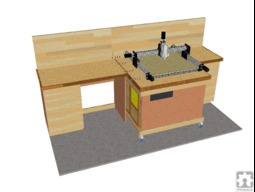

Bee the Boss

The frame of the CNC is going to to Bee a basic Work Bee with maybe 1 modification to the spoil board attachment. This will be located on a custom bench housing the electronics and vacuum. I plan to install Stepper online steppers, drivers, power supplies, and break out board. I will add a 1.5 KW water cooled spindle, with a radiator. The fans from the radiator will pull air from a filtered enclosure for all the electronics.

My Workbee build

Workbee, 1000mmX750mm , from China

Build Author

RV6APilot

Views

4186

Build Author

RV6APilot

Views

4186

South Carolina Workbee 1000X1000

This is about my build of a Workbee 1000X1000 being built here in Trenton, SC. My goal is to use it to help cut the new panel for my RV6A airplane.

Build Author

KronBjorn

Views

4437

Build Author

KronBjorn

Views

4437

WorkBee Lead 1010, Reduced Footprint, Nema17

This is a WorkBee 1000x1000mm with lead screws and Nema17's. It has a reduced footprint, with the geared Nema's inside the frame.

CBeam Sphinx Upgrade

Simple upgrade of the Y axis on a Cbeam sphinx from 500mm to 1000mm.

A More Rigid C-Beam

I added the steel to create a less flexible milling surface to make heavier cuts in aluminum. I can also do light steel cutting now as well. I wish OpenBuilds made a steel and rail version of these kits.

Rise of the Sphoenix

I am building a Sphinx 55 from the bones of my old C-Beam machine. Rising from the ashes so to speak.

Filament winder ( carbon fiber )

Carbon fiber filament winder

Build Author

tmadrms

Views

7635

Build Author

tmadrms

Views

7635

C-Beam Mods

C-beam machine mods.

Build Author

Joe F

Views

8406

Build Author

Joe F

Views

8406

Rack and Pinion Cartesian Mill

This is a rework of a previous build I did on here, a mostly printed cartesian CNC. Initially intended to just be an update to that, but so many things changed including the linear motion and every single part has been modified significantly that I felt as though it deserved a whole new build.

Workbee 1010

Hey all looking forward to sharing this build, I’ve learned a lot reviewing many of these great builds.

Build Author

Darren Dickson

Views

4372

Build Author

Darren Dickson

Views

4372

3D printed CNC Machine

So I thought I would make the Leon van den Beukel version three 3D printed CNC Machine, it is the third incarnation so you would expect a relatively bug-free CNC Machine with a strong foundation.

YAWBM - Yet another Workbee Modification

Increase Z axis travel by 20-25mm with minimal modifications

My C-Beam machine...

A C-Beam machine design, strengthened with extra brackets and plates. GRBL controlled, opto-isolated inputs, jogging box.

My C-Beam machine...from 500 to 1000mm base

C-Beam machine - 1000mm base.

Build Author

jeff johnson

Views

5716

Build Author

jeff johnson

Views

5716

workbee 1510

Getting more height out of the !510

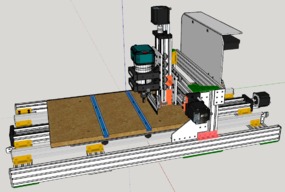

1515 Deluxe

Build features include a double c-beam gantry (bonded & mechanically fastened), linear x rails, custom gantry end plates, a custom linear rail & ballscrew Z axis, and custom lead screw tensioning plates. The primary goal was to remove twist from the 1500mm gantry & stiffen the Z axis.

Build Author

txcomp

Views

6785

Build Author

txcomp

Views

6785

WorkBee 1010 "Get Rid of the Slop" Build

My goals for this build were to eliminate slop and flex while also allowing easy serviceability.

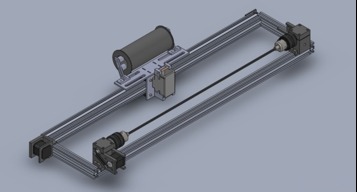

Model train lift - scale HO

This build is about a model train lift in a secure and dust free storage. It is a roll on/roll off concept for a model train layout.

Build Author

SandeepsCNC

Views

12081

Build Author

SandeepsCNC

Views

12081

Raspberry Pi CNC Software

The main objective is to build a software which can completely run on a single board computer, Rasbperry Pi, to reduce the complete cost of building a cnc machine. The software is extensively tested and can be run on any raspberry pi 2/3 boards. With no G-Code dependency, you can do complex 3D relief carving to simple tasks with simple GUI based project development environment. Please go through the YouTube channel for more details https://youtu.be/8KOXqLpvscg

WorkBee Saving Lives

Using the WorkBee to protect doctors against Corona virus.

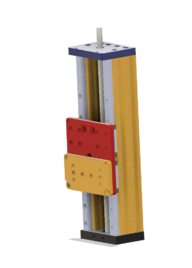

Workbee Z-axis Upgrade

Z-Axis upgrade with linear rails, SFU1204 Ball Screw and full aluminium construction.

Build Author

shanehooper

Views

15683

Build Author

shanehooper

Views

15683

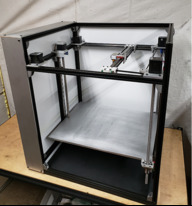

SolidCore CoreXY 3D Printer

Modular and Scalable CoreXY Printer with all metal parts.

ApiNui - CNC Router ( an oversized workbee )

Based on the WorkBee CNC, this is an oversized router built with a specific use-case in mind, for manufacutring beehives, and beehive components

Build Author

Leboeuf

Views

4919

Build Author

Leboeuf

Views

4919

Cartesian 3d printer

This is the build of a cartesian 3d printer made of an old Anet and Geeeteck, some 2020 alu profil and linear rail. Powered by a Rumba with a Nextion screen. It should be modular and accept dual Extrusion and laser engraving.

Another C-Beam machine

This is basically a Sphinx variant with few changes of my own...hope it'll work.

Retractable WorkBee1510 with Marlin+MarlinPanel high level build

WorkBee1510 with retractable space saving stand and customize build Marlin firmware and MarlinPanel (GCode Sender/UI)

Rotary axis for Workbee

Adding a rotary axis to the Workbee 1010. Including height modifications to the Workbee.

Build Author

Frank Gore

Views

9775

Build Author

Frank Gore

Views

9775

Kossel Extreme

A custom Delta printer for large projects with any filament that still retains speed and accuracy, all within a 15 amp/110VAC power budget. Based on Johann's Mini Kossel design.

Custom push cart for CNC machines

I’m custom building a push table / cart for my cnc machines mostly out things I already had in my garage. Using a gray push utility cart as the main body and building around that.

Build Author

CNCGear

Views

10511

Build Author

CNCGear

Views

10511

The BlackBee CNC

Ball screw drive, linear rail CNC Kit

Workbee with less irritations

My workbee build with some add ons

Build Author

Steve Hall

Views

4127

Build Author

Steve Hall

Views

4127

Cartesian Style Build UK

Another Cartesian style build with parts from the UK, US & China.

KillerBee 1515 customized

Killerbee 1515 with modifications.

My C-Beam build and modifications

Modified C-Beam which I plan to add a laser module and eventually convert to C-Beam XL size.

New Workbee Z Axis

Hopefully an upgrade of the Z axis of the Workbee.

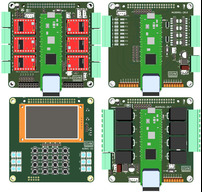

M10CUBE PICO CNC. A Universal Controller

An attempt is to be a Unified Modular Controller based on M10CUBE platform. For GRBLHAL and MARLINHAL applications. HAL porting is under way 1 - WIZnet Pico Clone W5100S-EVB-Pico 2 v- 6 X StepStick. Not sure about the sixth driver, (Pico pins limitation) . External connectors for larger drivers 3 - Opto - isolated spindle PWM. 4 - HMI 5 - I/O on diferent modules and Ethernet 10MBPS communication. Patches will be written to GRBLHAL for Ethernet I/Os (Interrupted).

Build Author

Shaun Weitzel

Views

7321

Build Author

Shaun Weitzel

Views

7321

OpenBuilds Lead 1515

First build of a Lead 1515!

C-beam charmer

Double C-beam Y axis 500mm., Double 2080 X axis 600mm. , C-beam Z axis 250mm, TB-6600 drivers, MKS-DLC32v2 GRBL w/wi-fi and blue tooth

Travel Printer

Build using standard parts as much as possible, Open Builds etc. To keep printer usable for more materials will be trying a heated bed with rotary elec union for the thermistor and power.

2 Axis Lathe cutter

Rubber company use as a lathe cutter for accurate cuts compared to hand cutting.

Y table for LEAD Lathe - essentially a High Z Cbeam XL

I built the lathe as a dedicated rotary axis, but I soon realized I could have a back up CNC for very little expense.

Build Author

Cam Garrett

Views

3955

Build Author

Cam Garrett

Views

3955

Sturdy Motorized Photographic Copy Stand

i would like to build a sturdy motorized photographic copy stand. i have hobbled together a hand crank version using a used umbrella pole but it is not suitable as it is awkward and wobbly.

Gerber 404 Retrofit

Not sure if the Blackbox X32 is the right option here, just looking for guidance.

Edge Carve MK1

I have created a video showing the Edger Carve features https://www.youtube.com/watch?v=v5mV_6vyxAA&t=3s