Build List

-

Active Filters:

cnc

Build Author

Lasersc

Views

5454

Build Author

Lasersc

Views

5454

The D & R TigerPaw Trilogy

Hopefully this will be a quick guide to one way that you can add a laser to an existing CNC router.

CNC Router Machine

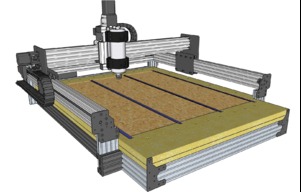

CNC Router with working area 550*550*200

Build Author

roadss

Views

26043

Build Author

roadss

Views

26043

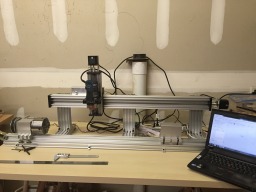

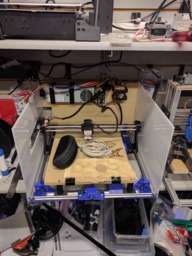

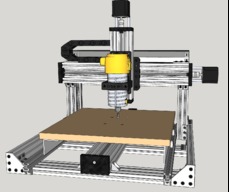

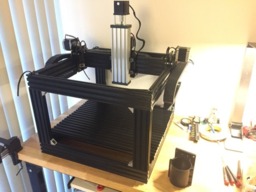

Rawcnc 1.5 Desktop Edition

This will showcase the build of my Rawcnc 1.5. A rigid cnc router from the Swedish company Rawcnc, featuring a rather cool linear motion system, rack & pinion and steel reinforced X-axis capable of milling aluminum.

Build Author

msdosfx

Views

6173

Build Author

msdosfx

Views

6173

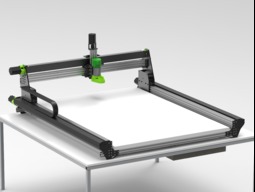

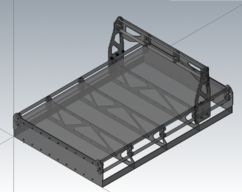

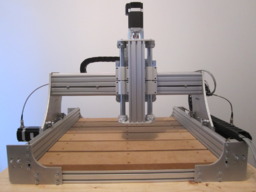

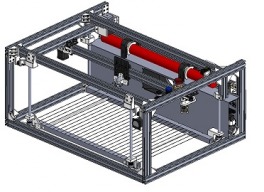

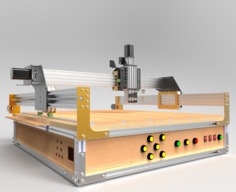

Workbee 1510 Screw Driven

Workbee 1510 screw driven build by MsDosFX.

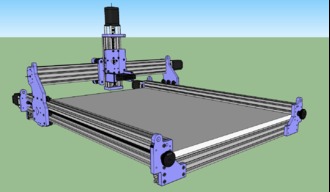

EOX v2

Upgrading my CNC router to run on ball screws. Me and the belts where not getting along.

Build Author

KronBjorn

Views

4480

Build Author

KronBjorn

Views

4480

WorkBee Lead 1010, Reduced Footprint, Nema17

This is a WorkBee 1000x1000mm with lead screws and Nema17's. It has a reduced footprint, with the geared Nema's inside the frame.

Build Author

RobFromLDMS

Views

5270

Build Author

RobFromLDMS

Views

5270

Lithgow Mens Shed CNC build

The tale of how we put together our CNC Router, and some of the difficulties encountered. It is now ready for final testing and commissioning.

Rotary CNC

I'm building a machine specifically for doing 4th axis work on woodwind instruments.

Phlux Core XY Laser Etcher

A 750mm x 1000mm Core XY Laser Etcher/Cutter. To cut down on cost I tried to have as many parts as possible be printed.

Build Author

John J Talavera

Views

18713

Build Author

John J Talavera

Views

18713

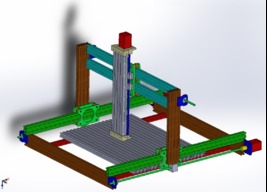

CNC FOR EVERYONE!

This build was very complex due to the fact I wanted to create a low cost larger than normal CNC. I did not want a MDF or plastic body. I wanted it to be able to do more than most CNC routers this size on the market.

Cnc mill, Plasma cutting and weld table

A functional table for plasma cutting, welding, tooling........

Build Author

Mark Carew

Views

36630

Build Author

Mark Carew

Views

36630

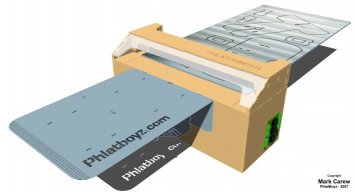

PhlatPrinter MK 3

The Phlatprinter 3 was designed to be used in a small shop with the ability to cut large sheets of foam for RC airplane projects. The idea was that you could save all of your aircraft as models and tweak to perfection after every flight.

Build Author

Mark Carew

Views

75555

Build Author

Mark Carew

Views

75555

Original PhlatPrinter

Phlatprinter foam cutting CNC machines are awesome space saving mills that use a rotary axis as a sheet feed.

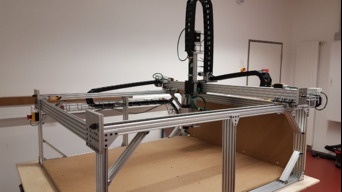

Open source large format CNC-machine and 3D printer

For a schoolproject we decided to build this large format CNC-machine. The greatest part of the mechanics were sourced from OpenBuilds.

CNC Hot Wire Cutter 4 Axis for Cutting Foam Wings

My build is to allow me to cut foam wings using CNC Hot Wire Cutter.

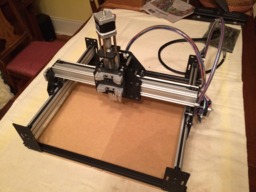

Shapeoko 2 - my first CNC

This was my first foray into CNC. I chose to go with a reliable kit build since my knowledge of GCode, controllers, and steppers was pretty rudimentary.

Build Author

Spark Concepts

Views

5458

Build Author

Spark Concepts

Views

5458

MPG Jog Controller for CNC xPRO

Been playing around with an MPG Jogwheel

Large format plasma ox

I will update this as I go, cad files upon request. My x beam is basically a belt driven r7

Build Author

Bikes and Beer

Views

4876

Build Author

Bikes and Beer

Views

4876

The Forever Project

Workbee 1010 Lead Screw with water cooled spindle and enclosure

Lead CNC build, Mansfield, Texas - BUILD COMPLETED WITH REVIEW OF THE KIT

The machine is a stock Lead CNC, with the Black Box controller and StepperOnline 269oz NEMA 23 motors. I'll be using the DeWalt 611 from Openbuilds, as well.

LimpyCNC

Inpired by the OpenBuilds OX and PrintrBot Crawlbot. This is the LimpyCNC. It's still a work-in-progress. But it provides a 120x120cm work space without using up 150x150cm of garage space.

Build Author

CharlieShimota

Views

16242

Build Author

CharlieShimota

Views

16242

Vox Solid State

I never thought owning a CNC machine was possible until I stumbled upon the Openbuilds site. After viewing numerous builds I was drawn to the Ox by Mark Carew but ultimately decided on a build of similar design, Halloumi by Savvas. It's a C-beam design driven by Nema 23 steppers with Acme lead screws. Like Savvas I will be fabricating temporary plates to get up and running then use the machine to mill the final plates. The material I'm using for the temp plates is solid surface (Avonite).

C-Beam Machine Build

This is my first CNC router build. I want to gain basic CNC building experience so I can go on to build other items such as a frosting or pancake printer.

Starting my build 2.8mx1.4m

Starting my cnc router, laser and plasma using aluminium 80x80

OoozNest WorkBee

A Journey on the WorkBee Build...

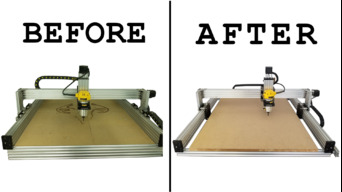

CNC Router Overhaul

This will be a complete overhaul of this router with some cool modifications.

Build Author

Christian James

Views

10004

Build Author

Christian James

Views

10004

Workbee "style" 1010 cnc

This build is based on the Workbee 1010 CNC. It is not a kit build and is much the same as the original but with some significant changes made here and there as the build progresses.

Ballmasters 1605 1500x1000 ox cnc

Upgraded 1500x1000 Ox cnc to 1605 Ballscrews on the Y axis. along with the J-tech laser to do most things.

Build Author

Joe Young

Views

5924

Build Author

Joe Young

Views

5924

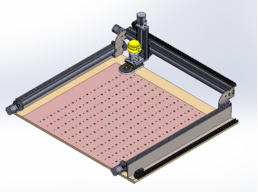

Goliath - CNC + 3D printer Hybrid

Mostly for Mill work, and FDM 3D printing (mostly Nylonx). I'm currently in the process of adding some hardware for a project requiring lathe work. I've included a solidworks 2014 pack and go for those of you interested in the build. if you need another file type, just let me know and i can try to accommodate. This is a scratch build (electronics and hardware)... see photos. Everything is pretty close to industrial quality... Electronics too. I got sick of other COTS designs breaking down

Build Author

TurfnSurf

Views

7155

Build Author

TurfnSurf

Views

7155

DIY C-Beam CNC

Theoretical Working Area: 360x360x75mm Actual Working Area: 300x300x75mm Will Update Later

Build Author

Doug Rowley

Views

4351

Build Author

Doug Rowley

Views

4351

My Workbee 1010

This is a workbee 1010 build using the mechanical parts from Open Builds. The electrical and electronic parts were from a prior build of a Root 3 CNC by Sailor Pete.

Build Author

Jacob Lotter

Views

6022

Build Author

Jacob Lotter

Views

6022

CNC ESS Controls System

My Controls box to run my Workbee 1510 That was retrofitted with Lead Screws as well as Lineal Bearings. The stock electrical configuration was not enough, so here are the Measures that I took to not only make this machine Run again, but to have fun with it, and make this system be able to run any CNC I run in the future with the installed microcontroller.

Build Author

joetemus

Views

6859

Build Author

joetemus

Views

6859

Shapeoko 2 Z-Axis Upgrade

This is a major redesign to the Z-axis of an otherwise stock Shapeoko 2.

Build Author

Rob Taylor

Views

20274

Build Author

Rob Taylor

Views

20274

Portable Diode Laser Cutter

Integrating custom machined components and off-the-shelf CNC components to create a portable diode laser etcher with air assist and reasonably substantial z-axis travel.

Build Author

Lumberjack Engineering

Views

20207

Build Author

Lumberjack Engineering

Views

20207

SOLAC: Space Optimized LAser Cutter

The Space Optimized LAser Cutter is a 40 watt CO2 laser cutter that supports a maximum part volume of 24" x 16" x 6.25". It consists of a V-slot frame + brackets/mounts designed to be 3D printed on a consumer desktop printer. Total cost of the machine is ~ $1,400 USD.

Sphinx 7575

Sphinx CNC modified to 750mm x 750mm c-beams. Parts not readily available in South Africa, so i have to make some modifications...

Build Author

Savvas

Views

18770

Build Author

Savvas

Views

18770

CNC Control Box with VFD etc etc

I'm currently working on the CNC control box, before doing any future work on the CNC Mountain Machine. I want the controller to be future proof and as professional as I can manage. I am planning to use stepper drivers, PSU's, a motor contactor unit to turn everything on, as well as a VFD and proximity limits switches. Each video will document the process and steps involved in researching, designing, planning and assembling a controller. I am not a natural electrician so learning as I go.

Build Author

Eric Jacobsson

Views

15440

Build Author

Eric Jacobsson

Views

15440

The Floating Dust Shoe

I wanted a dust shoe that have a easy access to tool change and something that kind of float on the surface. And I have seen shoes with long brush that sucked in by the vacuum. I think I have the solution too all that here.

Sphinx 1050

Openbuilds 1050 Sphinx. Thank you to Mark Carew for trading me a set of plates for a spindle and PSU I was not using. Mark is a champ!

Desktop CNC

Approximately 910mm x 955mm x 82mm. There is 250mm available in the Z, but the gantry is only 82mm from the bed surface.

OXmill

Small Mill type CNC machine, using C-Beams and V-Slot rail, bundle packs as a starter point. I needed a smallish desktop machine to fit a pretty narrow use case for my business, but the machine itself has larger applications to the OB community. Currently I will run the Dewalt 611 router on the Z axis, but have plans to add in a brushless RC style motor. So this design does have room to go either way easily.

Mostly Printed Cartesian CNC

This is a build that is just getting started. Not all of the parts are ordered or printed as of 5/27/2018. Hopefully in the next few weeks all parts will be printed and most parts ordered.

WorkBee 1510 - First CNC Build

This build will go through the construction of a WorkBee 1510 kit from the OpenBuilds Part Store, all mechanical and electrical components were purchased from the store in late October 2018.

Portable Sphinx 1050

Sphinx 1050 kit mounted to a Husky 46" x 24.5" mobile workbench.

Build Author

Lindsey Lewis

Views

8208

Build Author

Lindsey Lewis

Views

8208

CNC Mini Mill Build

CNC Mini Mill build with some mods after following standard build on Youtube video.

Brice's CNC Router Build

I'm building a CNC router for a long time. Here's the result on this long journee. I tried to do my best with the basic tools I have. Don't hesitate to ask if you have questions.

ECNCML (budget mashup)

This build summarizes my CNC milling and laser engraving machine conversion from a dimensional lumber frame and electrical mess to an all aluminum frame with a safe and well constructed (IMHO) control system with the resources I had available.

Non OX CNC Router

This CNC Router is to 95% made of standard parts and almost all of them from the http://openbuildspartstore.com/.

Another OX CNC Router

An OX CNC router using Blue OX Solutions gantry plates, a Bosch Colt router, and most of the remaining parts coming from Openbuilds parts store. Table has about 22"x55" cutting capacity and I am planning on a combination T-Slot and vacuum hold down system.

LaserShark300

300x300 belt drive laser etching/cutting platform. The design was borrowed from another's blog and customized to fit materials on-hand. Was a very fun project to assemble.

Flexible Axis Revolving Tool-holder

Drag knife and pen holder which mounts in spindle collet.

Workbee CNC 1500

Trying to build a machine of atleast 4x4ft working area. Work is in progress, hope to finish it soon

1075 Sphinx

My first attempt at building a CNC. I chose the Sphinx due to ease of build and extensive documentation provided by Kyo.

Ultimo

Ultimo is the ultimate multi tool for the person who's serious about prototyping new ideas. A Delta Robot frame supports 3d printing up to 450mm in diameter, a powerful CNC Mill, and 50 amp plasma cutter for processing steel plate. And that's just a start.....wait till you see some of the other attachments we are currently working on incorporating.

Build Author

Michael.M

Views

9694

Build Author

Michael.M

Views

9694

Sphinx Evolution

Let me explain: About a year ago I was planning to build a CNC router of my own design. I started gathering components including the THK linear rails. I soon found out you pretty much need a CNC to build a CNC and this is when I decided to build my Sphinx machine. I've had these rails and some other parts sitting around so it's time I used them! I'm planning to incorporate linear rails and 1605 ballscrews into the Sphinx design. I really like the overall appearance of the Sphinx.

Build Author

MikieLikesIt

Views

8269

Build Author

MikieLikesIt

Views

8269

Cousin CNC OX Router

A lower profiled machine. Built all out of aluminum. Removable control panel/PC unit. Option for vacuum table and cooling pump for a spindle.

Build Author

Kevr102

Views

5848

Build Author

Kevr102

Views

5848

Ooznest Ox CNC 1000 x 750

A few mods on my Ooznest supplied Ox cnc Encountered a few minor issues along the way but now all sorted.

Build Author

signzonepr

Views

13043

Build Author

signzonepr

Views

13043

HD c Beam CNC Router

24x32 Cnc Router, I used vSlot c Beam Extrusion and Wheels!

Build Author

Savvas

Views

14431

Build Author

Savvas

Views

14431

Halloumi CNC Machine - Acetal Plates

I built the original machine using plywood plates, and always intended to upgrade those parts to more durable ones. I decided to go with acetal as it's a lot easier to cut than aluminium. I used fusion 360 to model and rebuild the original machine. Once I have assembled everything and feel confident it all works I will release the plate designs here.

Build Author

Jones

Views

4011

Build Author

Jones

Views

4011

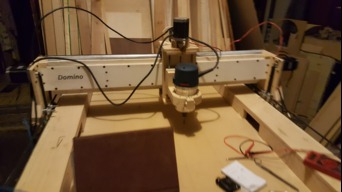

The Domino - 1.5m x 1m

DIY scratch build consisting of gas pipe, skate bearings, 12mm birch, 3/4 maple v-core ply, Nema 23's, and arduino and CNC shield with DRV8825's.

Build Author

Nicademus

Views

9584

Build Author

Nicademus

Views

9584

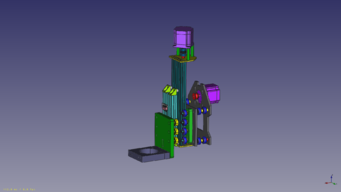

CNC/3DPrint/Laser/Mill (formerly CNC-inator3000)

Ultimately - the design is based on the highly successful Ultimaker concept, for which a regular size costs in the thousands, and one of this size would be edging into the 10's of thousands. Expected Build cost - <$800 It is a X/Y Cartesian printer with Raising/Lowering Z axis (Hotbed.) - Overall size is 610mm x 610mm x 750mm - with build volume of around 450mmx450mmx450mm - and will also have the ability to change work tools - such as for CNC Routing, Lazer etching, 3d Scanning, etc.

Build Author

Carl Siren

Views

7666

Build Author

Carl Siren

Views

7666

CNC-machine 650by700

A home-made CNC-machine with a 1.5 kW air cooled spindle motor suitable for milling materials such as wood, plastic and soft metals. The work table is 650 mm wide by 700 mm deep and the maximum movement is set to 560 mm for the x-axis, 480 mm for the y-axis and 105 mm for the z-axis.

HandCrafted WorkBee - HCWB

This will be a slow build as I collect parts and materials as funds permit for 1000mm x 1000mm Workbee. I call it the "Hand Crafted WorkBee" because I will be hand making the plates and as much of the build as possible using a drill press and hand tools.

Build Author

pedrofernandez

Views

12187

Build Author

pedrofernandez

Views

12187

Another Sphinx 7550 Made by an Openbuilds Cbeam

feel free to ask anything about this builds, but im a airline pilot and sometimes responding maybe will take me. while!!

Build Author

Glenn Weston

Views

18310

Build Author

Glenn Weston

Views

18310

"The Moagie Mill" My C-Beam XLarge

My Experiences building the C-Beam X Large. Maybe you can pick up a few pointers from my ramblings and experiences if you are considering building this machine.

Build Author

Colin Russon

Views

9443

Build Author

Colin Russon

Views

9443

OX / X3 CNC / Similar Z axis / 1605 Linear Actuator

Z axes 1605 ballscrew, a comparative design proposal.

Inspired by the Crawlbot

Building a couple of CNC's based on the Crawlbot

Build Author

Julius

Views

25498

Build Author

Julius

Views

25498

OX Balls - 1605 Ballscrew Powered 1000mmx1000mmm OX derivative

1000x1000mm Ballscrew driven OX Derivative. Dewalt 611 spindle and TB6600 Drivers.

Build Author

Sprags

Views

2749

Build Author

Sprags

Views

2749

C-Beam Kyo Sphinx 10060

More stuff here.

WorkBee 750x750 build

This CNC build is to help with some areas of my guitar builds - mainly inlays but some body work as well where appropriate. I expect it will be used for lots of other things once I get to know what it's capable of (sorry - what I'm capable of!).

Build Author

jpjoshua

Views

13456

Build Author

jpjoshua

Views

13456

Arduino Grbl Laser CNC

Arduino powered Laser CNC using GRBl firmware.

Plasma CNC, 4'6" × 8'8" v0318

A plasma table able to cut 4'6" x 8'8" sheet. Low cost as possible.

Solid basics CNC router

This build focuses on the basics to provide a good foundation to further enhance the ability to achieve tight tolerances

Build Author

TurfnSurf

Views

6221

Build Author

TurfnSurf

Views

6221

3-Axis Plywood CNC

Theoretical Working area: 38" x 24" x 6" Actual Working Area: 31" x 23.6" x 4" Positioning Accuracy: about 0.01mm

OX, of the house Steel

OOZNEST Style OX machine with 3D printed panels

Build Author

Brandon Satterfield

Views

7719

Build Author

Brandon Satterfield

Views

7719

SMW3D OX

The SMW3D OX, original other than a lot of learning!

Build Author

Hussein Dermay

Views

6527

Build Author

Hussein Dermay

Views

6527

Ooznest WorkBee 1000mm x 1000mm Screw Driven

I have decided to buy and build the ooznest workbee screw driven cnc (1000x1000) and also decided to use some plates and extrusions from the ox cnc. I will never use two machines anyway and hoping to build a strong base for the workbee.

Repurposed Steel Table 4 x 8 Build

Repurposed Steel Table for CNC Router Build.

C-Beam Machine XL

C-Beam XL upgraded with end-stops, E-stop, and cable chain. Running GRBL on Arduino Mega.

Workbee 1000x1000 mm screw driven Full Kit From Ooznest

A short summary of my Workbee CNC Build. I try to update it where I can

Build Author

Janis93

Views

15727

Build Author

Janis93

Views

15727

1000x1000 Two version of router Belt and Screw

Cheap sheet metal gantry solutions, for diy belt driven cnc and screw driven cnc.

Build Author

pedrofernandez

Views

7935

Build Author

pedrofernandez

Views

7935

ACRO 20x20

The Acro Laser Machine Build

C-Beam Machine - MyFirstCNC

This is my first foray into CNC machines, after much review I decided on the C-Beam machine as it seemed easy to work with and will enabled me to build more and larger machines as I gain knowledge. I am planning on building the machine largely unmodified from the reference design. I will be building the machine an axis at a time as I need to spread out costs over time.

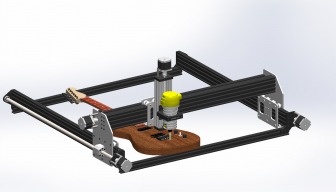

Something a Tad different

Future CNC router kit design

Build Author

Limine3D

Views

4573

Build Author

Limine3D

Views

4573

Shapeoko 1 upgrades

Replaced the original Z-axis for a shapeoko with a c-beam upgrade. This upgrade required a nema 17 mount and a quiet spindle mount I printed with a 3D printer.

Build Author

Andre Cooke

Views

17625

Build Author

Andre Cooke

Views

17625

CNC Greenland Paddle Carver build

CNC mill for carving / milling Greenland Paddles

Build Author

Gooshpoo

Views

9351

Build Author

Gooshpoo

Views

9351

Gooshpoo's H style cnc machine

A cool project about my cnc machines unique style.

Generic 6 Axis Controller

Generic 6 Axis (Stepper) Controller

Build Author

Weldsmith

Views

7732

Build Author

Weldsmith

Views

7732

CUT SMITH

I am building a multi tool CNC. I plan to have a quick change tooling system that will accept Routers, oxy acetylene torch, Plasma torch. etc. there will be a water bed under the convertible router table / work bench. The inspiration to build this machine is from having a small garage and not a shop.

EOX

Open builds style wood CNC router. Usable work aria 1000mm x 1250mm x 150MM (X x Y x Z). 80x40 C bleam for the Y axis , two 60x20 beams for X axis and a 60x20 fo Z. Interlocking GT3 belts for X and Y. Looking to change over to a rack and pinion system in the future. 8x8Tr Lead screw for the Z. Leadshine HBS507 close loop drivers and 3-phase servo motor 573HBM20-EC-1000 motors driving the Y and X axis. Would recommend them to anyone looking for servo like performance at a affordable price.

Hybrid shapeoko Xcarve cnc router

My scratch build using shapeoko, xcarve, and custom parts.

Big CNC plasma cutter

more later

Build Author

Bucky Wootmaster

Views

3005

Build Author

Bucky Wootmaster

Views

3005

Bucky CNC

CNC machine using extrusions with linear rails and ball screws on all axes - no plates

Build Author

OffAxis

Views

7752

Build Author

OffAxis

Views

7752

OffAxis CNC 1000x1500

Cut Area: 825 x 1340. Max Cutting depth: 2 inches. Arduino based control with Nema 23 and Nema 17 drive. 8mm leadscrew and 2GT belt drive. 400W 48V quite cut spindle.

Build Author

JAC_101

Views

6092

Build Author

JAC_101

Views

6092

Small PCB, Engraving and Delrin CNC Mill

This is my first attempt at building a spindle based CNC machine. The intention is to mill PCB boards and mill delrin blocks. The device was built with an Emergency Stop that actually cuts power to the spindle and motors. This is a post build write-up and consists of finished photo compilation and CAD renderings.

Build Author

jz321

Views

4576

Build Author

jz321

Views

4576

OTiS 500mm

OTiS (Off The Shelf) is 500mm cartesian CNC that can be built with all off the shelf parts from OpenBuildsStore. It features C-Beam actuators and a V-Slot frame.

Beefed-up and customized OX build

My Machine is based on the OX CNC designed by Mark Carew as well as the ooznest kit, and it incorporates a bunch of my own details and revisions to increase performance and robustness. It has become way more beastly than I originally planned!

Build Author

spark2

Views

5702

Build Author

spark2

Views

5702

C-Beam - Sphinx 1000x1000mm inspired by Kyo

A stable CNC Router that allows me to cut and carve bigger Parts. The Machine is an original Build from Kyo's Sphinx CNC Machine. Thanks for the great Work and the Effort Kyo. Your Files and Lists helped me a lot to build that Sphinx 1x1m.

Bedroom Builds (BrB) DIY CNC

So I am employed in the automotive industry and I walk by thousands of dollars of CNC products daily that are no use to me due to being a Technologist and not a machinist. So therefore with some research I found openbuilds and their great selection of products to build my own CNC. This CNC will consist of 4 axis one removable 360 degree axis for turning alongside a x axis table Y axis stationary gantry and a Z axis attracted to the Y axis linear actuator.

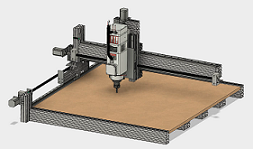

CNC design (parts named)

This design is previously posted in this area. I downloaded the file in order to customize as I needed. I found that the parts were not identified. I went through the design in an attempt to name the parts and identify them by location.