Build List

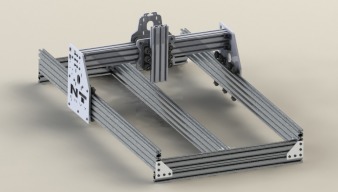

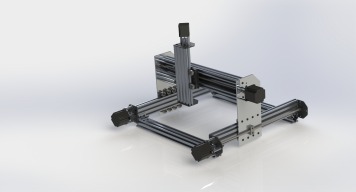

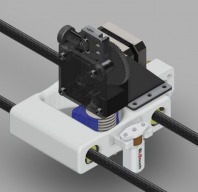

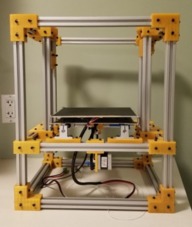

V-rex , Low cost CoreXY

Easy to build,low-cost, CoreXY

K-Cup Sealer

This is a K-Cup sealer i constructed does a fine job

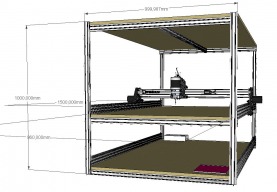

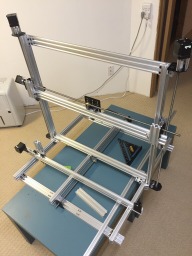

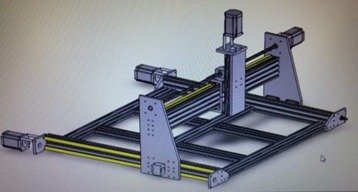

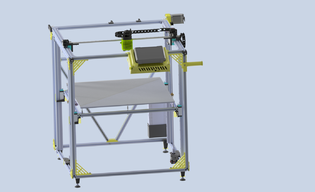

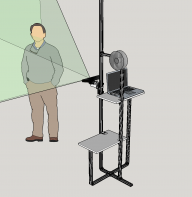

Custom push cart for CNC machines

I’m custom building a push table / cart for my cnc machines mostly out things I already had in my garage. Using a gray push utility cart as the main body and building around that.

Build Author

Genetoys

Views

3347

Build Author

Genetoys

Views

3347

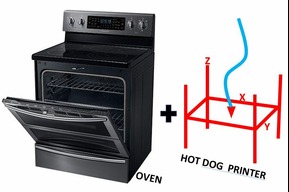

Oven Dog

Building a printer that can fit inside and operate at ~200 C oven temperatures

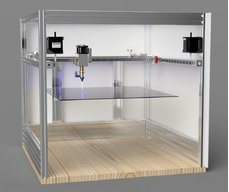

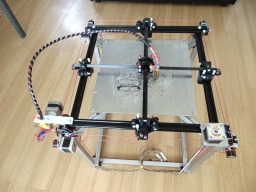

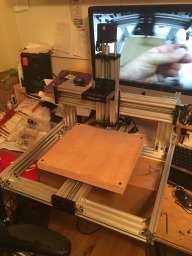

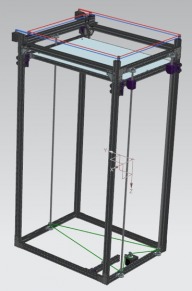

Corexy laser

I have tested my Opt Lasers laser module on a "open" frame for some time. Decided that I want to test a corexy setup and combine it with a boxed/enclosed design - my goal is to get high precision + a safe setup with protection from the laser light + a fan to extract the smoke/exhaust..

Build Author

Johnny Reich

Views

2072

Build Author

Johnny Reich

Views

2072

ProLight 1000 Mill Retrofit

Update a 20-year old bench top milling machine with OpenBuild Ecosystem electronics.

Build Author

Paul Amelang

Views

5731

Build Author

Paul Amelang

Views

5731

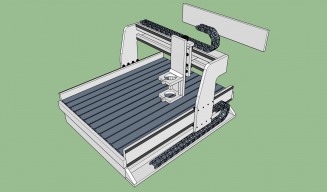

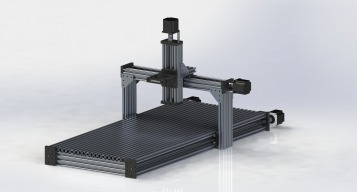

4x8 CNC Router for Composites

Router for making plugs for composite part production, and for cutting CFRP.

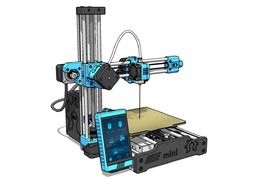

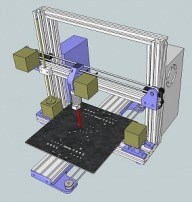

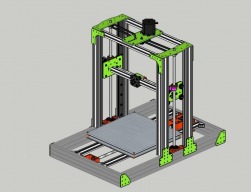

ME-Mini 3D Printer

Prusa mini inspired 3d printer

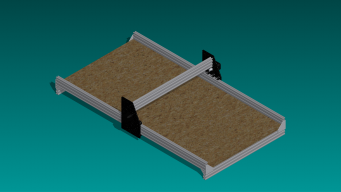

Home made CNC Plasma Cutter

Not completed yet but it does work, I will be changing small things as I finish the build and I have learned a lot from this build I am looking forward to finishing this one and Building another maybe larger table.

Build Author

Gary Caruso

Views

3092

Build Author

Gary Caruso

Views

3092

OpenPull From CNC Kitchen.. attempt

This project is a Pull tester for material testing or structural testing with stress (force) data logging, I don't have plans for strain logging but that might be down the road.

New Workbee Z Axis

Hopefully an upgrade of the Z axis of the Workbee.

Travel Printer

Build using standard parts as much as possible, Open Builds etc. To keep printer usable for more materials will be trying a heated bed with rotary elec union for the thermistor and power.

Build Author

Elias Ramburger

Views

6132

Build Author

Elias Ramburger

Views

6132

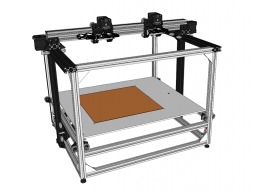

600 volume 3D-Printer "ABEA"

Hello. I build this 600 by 600 printer and hope to share it. I plan to sell custom builds with my website in the middle of this yeahr while making all parts accesibble online for replacements and own builds. My plan was to build a better and more accessible big volume 3d-printer as cheap as possible. I got some inspiration of the ender creality 3, the crazy-Print xyz 300 and the veho 600 tronxy which was simply not relaible and satisfying overal.

Build Author

nicklogan

Views

17037

Build Author

nicklogan

Views

17037

MDF Delta

A Rostock style delta bot with the parts which are typically 3D printed made from medium density fiberboard (MDF). It uses a home made hot end.

Build Author

John J Talavera

Views

12186

Build Author

John J Talavera

Views

12186

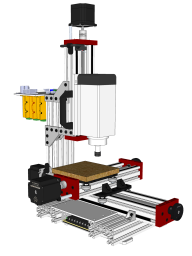

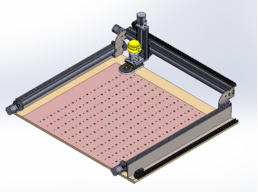

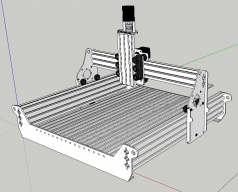

CNC FOR EVERYONE TITAN CNC ROUTER

www.cncforeveryone.com TITAN CNC ROUTER is the perfect PCB milling machine or for smaller projects. Don't be fooled by its small size it is capable of routing with the big boys...!

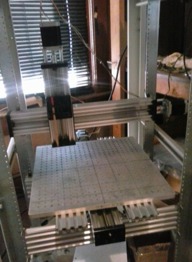

Router / Plasma Prototype Build

this is my first attempt at a CNC Table

TABLE OX Router/3D-Printer

OX MultiMachine

PS2 Keyboard And SD Card G code sender For GRBL

Now test ready

ROUX - A Routy-OX Hybrid

ROUX is a 2'x4' CNC that can be easily handbuilt without an existing mill and removes the need to buy generic plates for the Routy. A simpler, more refined machine.

Build Author

Bear

Views

11066

Build Author

Bear

Views

11066

OXBear

ANOTHER OX!~ Huge Thanks to Marc Carew and Open Builds. The primary reason I am building this CNC mill is to aid in my homemade snowboard creation. I am going to try and document as much of everything as I can and post it here to help others going a similar route. I know from past projects that taking the time to document each step can be tedious when you want to charge ahead but I will try! I hoping to get feedback on my design choices and set up as I am a complete newbie to CNC.

Build Author

UltiBots

Views

21275

Build Author

UltiBots

Views

21275

Kossel 250 V-Slot

This build is very straight forward. The design is simple. There is a great support community for Delta 3D printers.

OneUpSolid

This is the adult version of the QU-BD juvenile known as their OneUp. It not only uses extrusion framing instead of press board MDF, it is a full sized 8x8 build area w/ABS-Nylon capability. Only the OneUp's single Z axis driver concept is similar. I'm tempted to call it OneUpAdult for marketing.

Panther Printer - Lautr3k

My version of the popular Lautr3k 3D printer. UNI Panther colors of Purple and Yellow on black V-slot rails. 300x300 bed.

Open Rail Build

This will be a chronicle. It's my first CNC build so, I will be making many changes as I learn from my mistakes. I will pass on any tips or tricks i learn along the way. This build is an OX Hybrid. I decided to use the open rail with the V wheels and not to go with the V Slot. (I'll let you know how it works out.)

Sketchup Design of a PVC CNC I Intend to build.

Build Start to begin Feb 1st.

MaxBox

Simple cartesian style CNC. Uses ACME screws for all 3 axes, 20x40 v-slots and should have 50cm x 50cm x 50cm work volume.

CNC NT

This is our first CNC project is based on OX CNC. We show you some pictures about our progress. We finished assembly design, software test and drivers test, now we are building the machine.

Black Panther QR

The QuadRap 3D printer version based on OpenBuilds wheels. Born in https://plus.google.com/u/0/communities/103539262895202172380

cnc plasma table

ive got most of the wire harness made up too im using Chinese electronics for now I will upgrade later when this thing makes me some cash lol im using a ibm think center to case to hold my electronics ive got a 25' parallel cable to put some distance between the table and the computer

Build Author

Mohammed Iskandarani

Views

21420

Build Author

Mohammed Iskandarani

Views

21420

CO2 60 -130 WATT LASER ENGRAVING/CUTTING CNC WITH DSP AWC608 CONTROLLER

LASER ENGRAVING DIY 60 WATT

3 Axis MultiTool - 3D printer, CNC Mill and Plasma Cutter

So in short this build is a work in progress; it aims to make a large 3d printer, medium size CNC mill and a small plasma cutter all in one CNC unit.

Custom Ski and Snowboard CNC for a High School Woodwhop

A Custom size CNC to make custom skis and snowboards

Easy to build and robust 3D printer framework

Lord willing I will be showing you how build a robust and easy to build 3D printer framework using V-Slot rails and rollers. It's a little bulky, but it has all spring tensioned rollers on all axes, and can be built entirely without custom machining on any parts. You will need digital calipers, a drill press, a carbide toothed miter saw for cutting aluminum extrusions, and lots of little screws!

Build Author

Bruno Rivard

Views

6917

Build Author

Bruno Rivard

Views

6917

OB Heavy duty Prusa i3 "Lunar Injection"

Hell Yeah

Build Author

openhardwarecoza

Views

7140

Build Author

openhardwarecoza

Views

7140

Pocket Ox (Sheetmetal)

Small CNC - made with some custom lasercut+bent sheetmetal parts + Openbuilds V Slot

Vic Aussie Ox

Dove in and ordered the kit from Makerstore in Melbourne. While awaiting for the order watched videos and sourced steppers and controllers from China. Had some fun with the 4 axis TB6600 controller board. Ran into a few problems with the build, but after stripping and restarting looks like I am on track.

LYNX - Huge 3D printer

I'm basically building a larger version of my crappy wanhao 3d printer. My work was recycling some aluminium extrusion and it broke my heart to see such nice pieces of aluminium engineering being sent to a furnace. Mega 3d printer was born!

V Rail 3D printer

My version a Cartesian style 3d printer, an attempt to eliminate frame vibration and movement and to use up materials left over from other projects.

Build Author

Skoobs

Views

4958

Build Author

Skoobs

Views

4958

Pretty Standard + Slave X Axis

Planning my build, just looking for design input at the moment. I definitely want a slave X axis. I am potentially going to go with one of the 1500W Chinese water cooled spindles.

Build Author

Kaarbble

Views

10407

Build Author

Kaarbble

Views

10407

Kaarbble Nylon Bot

We plan experiment on nylon 3 D printing;

Zebu ( OX clone with Brasil materials)

An OX clone with alternative parts.

Square OX

Square shaped OX for doing general purpose engraving and cutting into wood, acrylic, and aluminum.

XYZ Factory Bot

Very large format build platform designed really for printing multiple items in one session ether all the same or different. Longer term I would like to have multiple X axis on the Y axis rail. bit of a slicer challenge though.

Polar Bot

Polar Bot which used to depress buttons

Large 3D printer

Hello ! This is my very first OpenBuilds build. It's based on the Maximus 3D Printer, published by mytechno3d : good source of inspiration !

The MULE (an OX inspired 3-axis CNC)

The Mule is a 3-axis CNC inspired by the OX CNC by Mark Carew. This machine borrows the OX's sturdy frame and upgrades the X and Y linear actuators through the use of three 500mm lead screws (as opposed to the belt system of the OX). The result is an inexpensive, sturdy, and powerful design built for cutting tough materials such as aluminum.

Build Author

David Arroyo

Views

14682

Build Author

David Arroyo

Views

14682

PiDuinoCNC Controller

Using a Raspberry Pi, Arduino and a Protoneer CNC Shield to create an Open Source CNC router controller. It will be equipped with a touch screen to control the on board processor. The touch screen will run a user interface that has buttons for added functionality. There will be a camera for monitoring progress from inside my office. The control box will also feature a way to power the vacuum and spindle/router . I will also be able to monitor room temp as well as Pi CPU temps and averages.

Arctic Ox CNC Router

This is a cartesian CNC Router build that is based off the OX CNC build by Mark Carew. I am using Spark Concepts CNC xPro controller board and their 400w spindle kit.

Build Author

evil2002usna

Views

11579

Build Author

evil2002usna

Views

11579

Evil Ox

Cheap Ballscrew Ox CNC Router.

Build Author

Paruk

Views

23174

Build Author

Paruk

Views

23174

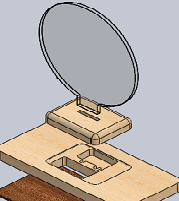

Buffal-O-Tron

A 3D Scanning Station

Build Author

Dave420

Views

6163

Build Author

Dave420

Views

6163

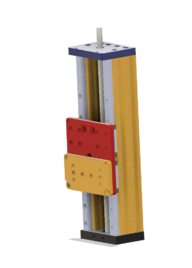

Dave's Z axis and powder coated.

I just did my first Powder coat paint job on a Z Axis with 9inchs of travel for the DIY CNC Plasma Cutter, Mill Head, Router, Engraver, Laser Head, Water Jet Cutter Machine. 2 different Z Axis ride plates and a 80mm Router/Mill Head/Spindle clamp. Baked on finish in a old oven i had.

Powder coated multi CNC Z Axis plasma adapter with Prox.

Powder coated multi CNC Z Axis plasma adapter with Proximity sensor. . It can also hold a 80mm Router head/Spindle as seen in my router build.

PCBman CNC

This is a design for a desktop CNC machine. It may be a router or laser. I am undecided as to the final design.

Core XY My-BOT 500 x 500 x 1000

My first construction after many years buys ready devices.

Build Author

eddyg

Views

5005

Build Author

eddyg

Views

5005

OX with a Custom Electronics Case

Embarking on my first build and trying to start with a clean setup by creating an enclosure box for my controllers and power supply.

Build Author

William Niedermeyer

Views

19675

Build Author

William Niedermeyer

Views

19675

Structured Light Turntable Scanner

3d Structured Light Scanner with Arduino Controlled Turntable

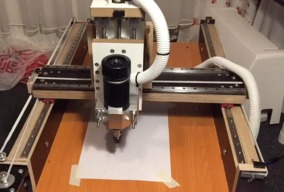

My 1st C-Beam Router

Pretty happy with the build, had some difficulty with the software loading up the settings due to me using the wrong com.

Reborn as the Soccer Pitch for our Robot Spider Soccer game - Robotics/Maker Club Teaching Cart

The Soccer Pitch for our Robot Spider Soccer game

Build Author

Dave420

Views

14532

Build Author

Dave420

Views

14532

10 x 5 ft plazma table build

Attaching V Slot or mutable V Slot end on end to a larger steel frame table.

Cheap linear rail set up for z-axis

A easy to do cheap upgrade for the z axis

Openbuilds D-Bot

A humble first time attempt at building a 3d printer from scratch

Build Author

dodgenet

Views

6613

Build Author

dodgenet

Views

6613

Budget 1500mm OpenBuilds V-Slot Deltabot Build

This 1500mm tall Delta is a work in progress. The triangle corners are water jetted from 1" 6061 Aluminum, and are welded to 1" square tubing. The 1500mm OpenBuilds 20x20 V-Slot extrusions are held into the corner brackets by two stainless steel set screws per bracket. This printer will need to be reinforced with wall brackets due to the combination of height/materials.

Build Author

COMsulting

Views

10107

Build Author

COMsulting

Views

10107

1x1 Meter Laser Engraver

Building of a big open frame laser engraver.

Epoxy dispenser, to apply non-conductive epoxy to electronic board.

Epoxy dispenser, 2nd one, first one works great. Uses HMI to allow for operator to pull up files for different jobs. 9 prox sensors, Eot and home on all 3 axis. High quality nema23 motors with intergrated drives from applied motion. Uses programmable router for drives.

My 2nd cnc build

My new build to upgrade from my worn out shapeoko

Build Author

Dmknerr

Views

5229

Build Author

Dmknerr

Views

5229

Server Rack Printer

My first project build. Concept build to use an existing 7.5 ft tall server rack as the frame. This ptoject may never be completed.

Double trolley X and Z belt training

Total belt drive GT2

The Artist Formerly Known as Prints

Work in progress large volume CoreXY printer

DIY LED acrylic lamp

This is a simple lamp using only 2 LEDs & 2 AAA batteries.

InDoreXY

A Large CoreXY build that can just barely get in through a doorway, aiming for under $1000. Build Volume approximately 18in x 24in x 26in.

MiniMill - A must have machine :)

The new MiniMill from Mark and Sonny is a great little machine.

OBlathe

A simple wood turning lathe.

Norm Inverted - Cartesian

As a tinkerer and hobbyist I need a reliable quality printer on a budget... Meaning I'm not looking to buy a: Prusa, Zortrax or LulzBot because of the added cost their marketing adds. I can definitely build a machine of hopefully equal quality at a lower cost that is not impacted by the marked-up priced from a large reputable manufacturer. I will need to dedicate time and more time for design shakedowns to ensure I produce a quality machine. Bare with me on this build... Thanks!

Stock CNC Router

This is my first CNC router, so be kind on the criticism. I'm still learning. Not an engineer, and not a machinist so I am having to research and learn aspect from both of those areas of study!

Linear Rail derivative with ball screw

basic start to design of cnc machine

Build Author

Jason Harding

Views

4100

Build Author

Jason Harding

Views

4100

Mobile bed cnc machine, first build

Currently i am reworking the frame still with current available parts just going to buy material to make the y and the z axis from openbuilds. The x axis is now going to be mobile similar to a 3d printer style.

OB Minimill with bottom frame PSU+Drivers

All-in-one OB Minimill

Build Author

Jeremiah Guinn

Views

5841

Build Author

Jeremiah Guinn

Views

5841

OX CNC SMW3d 1500x1500

A small business idea led us here, lets see where it will go.

Screen Mesh Stretching

The intention of this project is so that the mesh is on the well stretched frame, and thus there is a better production of frames.

Ancient Roland Table top Mill

The parts are now very reasonable.

C Beam Served

C Beam Machine built in a server cab. Hopefully this keeps every thing enclosed , clean and quite ?

My 80w Laser build (1000x1000 cutting area)

This is a 80w laser which I am building (picture of the case) the frame is constructed with normal square tubing with plastic corners. this laser needs to live outside

Ooznest workbee

This is my first build so I will let you know how I get on

Build Author

Bill325

Views

2356

Build Author

Bill325

Views

2356

One more life for a cube

Modify a Gen1 Cube printer into a small cnc router to cut pcbs and light (VERY light) milling work. Also easy to swap out the rotary head and mount a laser head for engraving.

Build Author

Liam Dahler

Views

6554

Build Author

Liam Dahler

Views

6554

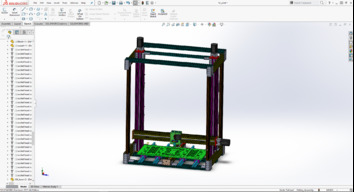

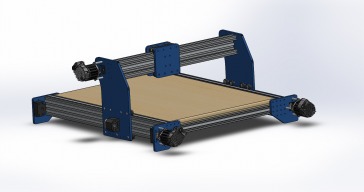

Affordable Cartesian Printer (Initial Design)

This specific build page is a collection of screenshots sampling some of my initial SolidWorks design and pictures showing physical construction of the initial design. I will be creating individual build articles as I redesign, test, and implement new aspects of the printer.

Silverchris's Laser Cutter

Work in Progress of a laser cutter design. Based on the CoreXY build from https://makerstore.com.au

Desktop CNC

Approximately 910mm x 955mm x 82mm. There is 250mm available in the Z, but the gantry is only 82mm from the bed surface.

Repurposed Steel Table 4 x 8 Build

Repurposed Steel Table for CNC Router Build.

Big-X Minimill

Minimill bundle, but with an extended X Axis

V5- 2in1 ( 3dPrint+laser Engraving )

2in1 ( 3dPrint+laser Engraving )

Galvos

3d printable galvos

Design and Performance Evaluation of A Large FDM 3D Printer

This build includes the design of a large FDM 3D printer. This machine has a 796mm by 796mm by 900mm (LxWxH) build volume. Motion is controlled by servo motors and the printer runs on python-based marlin firmware.

Build Author

SCYBUCK

Views

5140

Build Author

SCYBUCK

Views

5140

KYO SPHINX a la' SCYBUCK

KYO SPHINX, CENTROID ACORN, GECKO 540, HALL EFFECT LIMIT SWITCHES, 2.2 KW, 24,000 RPM SPINDLE, WATER COOLED, 600 oz-in STEPPERS, INTENDED TO CUT ALUMINUM.

Build Author

RobFromLDMS

Views

5272

Build Author

RobFromLDMS

Views

5272

Lithgow Mens Shed CNC build

The tale of how we put together our CNC Router, and some of the difficulties encountered. It is now ready for final testing and commissioning.

My new wood mill

First and foremost, I want to create accurate parts for my model aircraft. In second line I am interested in the control and electronics of the milling machine. If you are interested in drawings and the parts list, feel free to contact me.

John's Sphinx

1000mm x 750mm C-Beam Sphinx, running on Grbl

Pick and place

Pick and place based on the Openbuilds ACRO 20x20

OoozNest WorkBee

A Journey on the WorkBee Build...

My Workbee build

Workbee, 1000mmX750mm , from China